Preparation method of tungsten carbide-cobalt or tungsten carbide-cobalt-chromium thermal spraying powder

A technology of thermal spraying powder and tungsten carbide powder, which is applied in coating, chemical industry, fusion spraying, etc., can solve the problems of low production efficiency, high energy consumption, long production cycle, etc., and achieve long production cycle and uniform heating , Reduce the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

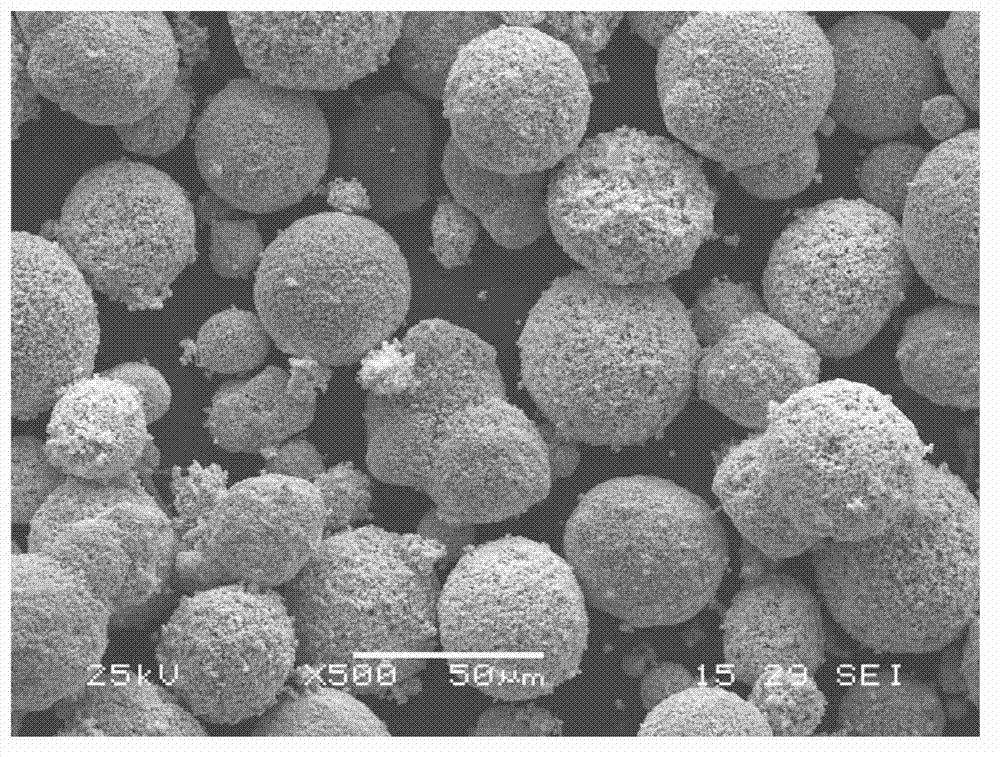

[0019] Embodiment 1: WC-17Co thermal spray powder

[0020] First, add 83wt% tungsten carbide powder and 17wt% cobalt powder into the ball mill, add deionized water at the same time, control the solid content to 70%, wet milling, wet milling time 12h; after wet milling, the average particle size of the mixed powder is 0.1 micron ~10 microns, add polyethylene glycol accounting for 3% of the mixed powder mass fraction, stir for 2 hours, and then granulate in a spray drying tower to obtain granulated powder; the inlet temperature is controlled at 260°C, and the outlet temperature is controlled at 110°C; Pass the granulated powder through 200-mesh and 900-mesh double-layer vibrating sieves to obtain powder in the sieve with a particle size of 15-75 microns, and return the powder on the 200-mesh sieve and the powder under the 900-mesh sieve to wet milling; Degreasing treatment is carried out in the furnace at a temperature of 800°C for 4 hours to fully remove the polyethylene glycol...

Embodiment 2

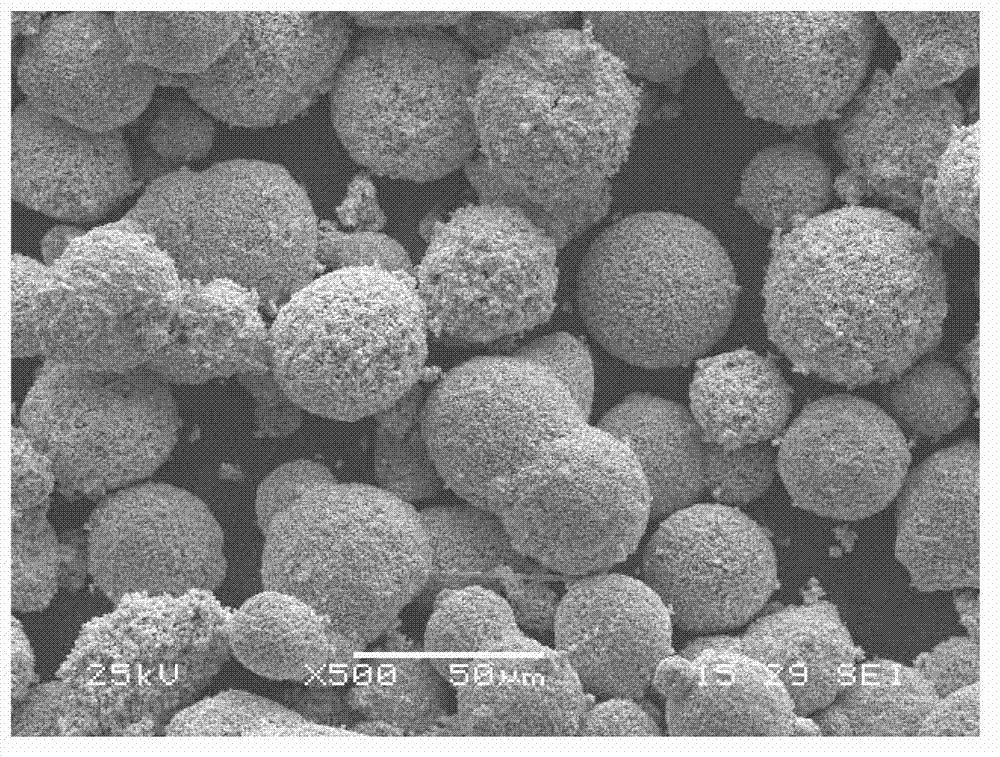

[0022] Embodiment 2: WC-10Co-4Cr thermal spray powder

[0023] First, add 86wt% tungsten carbide powder, 10wt% cobalt powder and 4wt% chromium powder into the ball mill, add deionized water at the same time, control the solid content to 75%, wet grinding, wet grinding time 12h; after wet grinding, mix The average particle size of the powder is 0.1 micron to 10 micron, add polyethylene glycol accounting for 2% of the mass fraction of the mixed powder, stir for 2 hours, and then granulate in a spray drying tower to obtain a granulated powder; the inlet temperature is controlled at 260°C, and the outlet The temperature is controlled at 110°C; the granulated powder is passed through a 200-mesh and 900-mesh double-layer vibrating sieve to obtain a powder in the sieve with a particle size of 15-75 microns, and the powder on the 200-mesh sieve and the powder under the 900-mesh sieve are returned to wet grinding; the obtained The powder in the sieve is degreased in a tube furnace at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com