Preparation method of non-nutritional table sugar

A nutritional and table technology, which is applied in the field of preparation of non-nutritive table sugar, can solve the problems of short shelf life, increased cost, and large loss of main sweeteners, so as to improve sweetness dispersibility, reduce production costs, and improve raw material formula reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

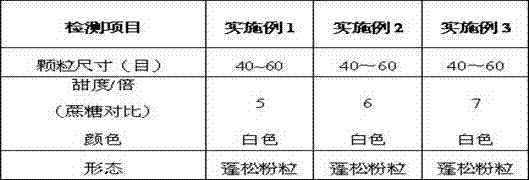

Examples

preparation example Construction

[0017] The preparation process of the non-nutritive table sugar: first put erythritol and maltitol accounting for 50-70% of the total amount into a multi-dimensional mixer, and mix for 20-40 minutes at a rate of 600-1000rpm, and control the volume of the mixed material. The particle size is 80~130 meshes to obtain a mixture of erythritol and maltitol; then dissolve sucralose, isomaltooligosaccharide and the remaining amount of maltitol in deionized water to obtain sucralose and isomaltooligosaccharide Mixed aqueous solution with maltitol; then put the mixed material into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerates from bottom to top, and the spray fluidized bed Apply negative pressure to the upper part and vibrate from top to bottom to make the mixed material boil up and down in the fluidized bed. The air inlet temperature of the fluidized bed is contro...

Embodiment 1

[0020] (1) Put 8.5 kg of erythritol and 58.35 kg of maltitol into a multidimensional mixer, control the number of stages of the multidimensional mixer to 800rpm, and mix for 30 minutes to obtain a mixture of erythritol and maltitol, with a particle size of 80 Between ~130 meshes;

[0021] (2) Mix 0.83 kg of sucralose, 0.4 kg of isomaltooligosaccharide, and 31.42 kg of remaining maltitol with deionized water, heat up and stir to dissolve, and obtain a mixed aqueous solution of sucralose, isomaltooligosaccharide and maltitol;

[0022] (3) Put the mixed material obtained in step (1) into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerates from bottom to top, and the sprayed fluidized bed Negative pressure is applied to the upper part of the fluidized bed to vibrate from top to bottom to make the mixed material boil up and down in the fluidized bed to form fine su...

Embodiment 2

[0025] (1) Put 10 kg of erythritol and 57.2 kg of maltitol into a multidimensional mixer, control the number of stages of the multidimensional mixer to 800 rpm, and mix for 30 minutes to obtain a mixture of erythritol and maltitol, with a particle size of 80 Between ~130 meshes;

[0026] (2) Mix 1 kg of sucralose, 0.6 kg of isomaltooligosaccharide, and 30.7 kg of remaining maltitol with deionized water, heat up and stir to dissolve, and obtain a mixed aqueous solution of sucralose, isomaltooligosaccharide and maltitol;

[0027] (3) Put the mixed material obtained in step (1) into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerates from bottom to top, and the sprayed fluidized bed Negative pressure is applied to the upper part of the fluidized bed to vibrate from top to bottom to make the mixed material boil up and down in the fluidized bed to form fine sugar a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com