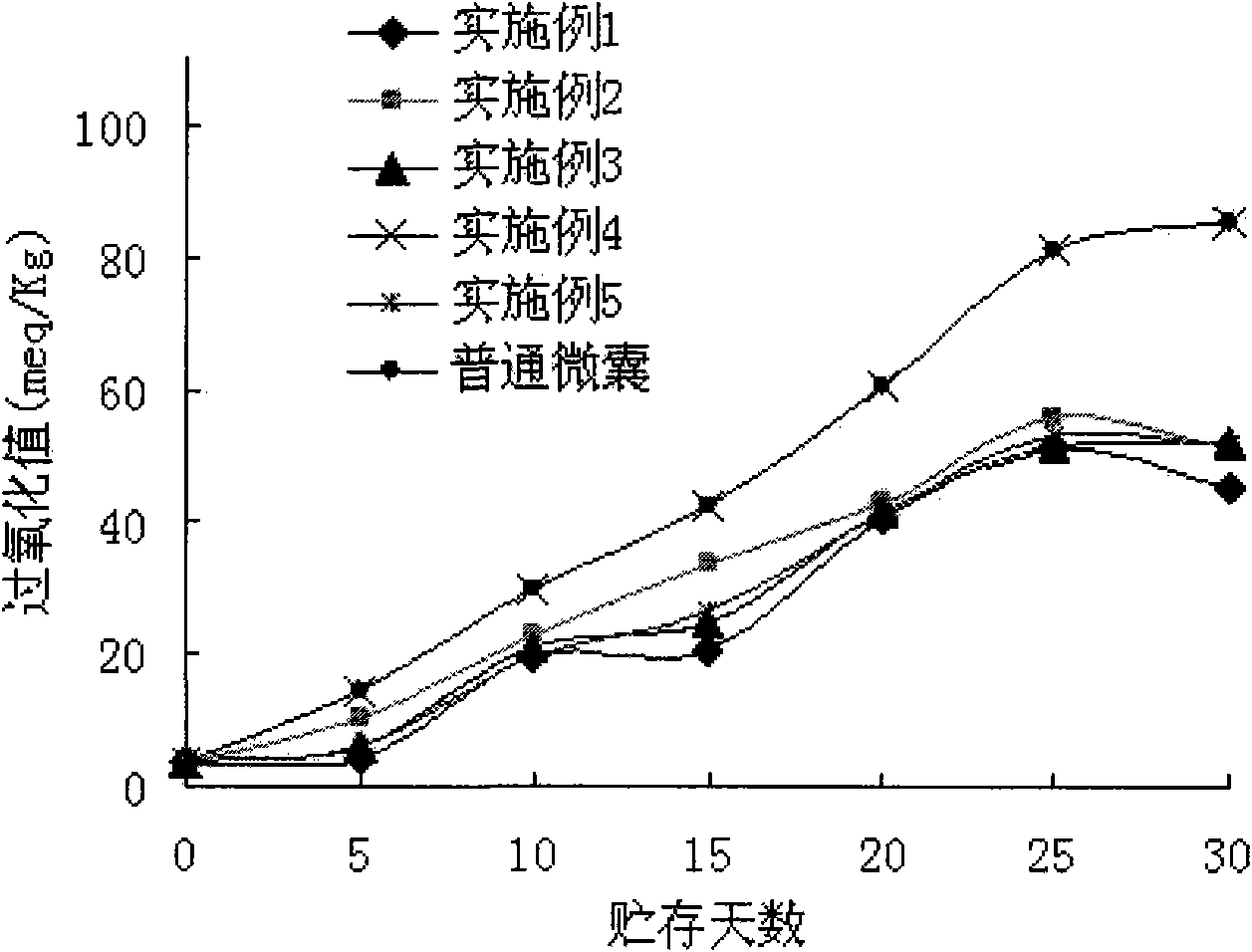

Strong anti-oxidation DHA microcapsule and preparation method thereof

An anti-oxidation and anti-oxidant technology, applied in the direction of microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problems of weak anti-oxidation, waste, and poor product stability, and achieve enhanced product anti-oxidation and product shelf life. The effect of prolonged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] DHA Fish Oil 15%

[0024] Gelatin 60%

[0025] Vitamin C 0.1%

[0026] Lecithin 0.1%

[0027] Dextrin 24.8%

[0028] Appropriate amount of purified water

[0029] Preparation

[0030] 1) Prepare the oil phase solution: mix DHA fish oil and vitamin C according to the ratio and stir evenly.

[0031] 2) Preparation of aqueous phase solution: mix gelatin, dextrin and lecithin in water according to the proportion, stir and disperse evenly.

[0032] 3) Preparation of emulsion: Slowly add the oil phase solution into the water phase solution and stir at high speed to emulsify for a certain period of time.

[0033] 4) High-pressure homogenization: the above-mentioned emulsion is homogenized under high pressure for more than 3 times under a pressure of 40-50 MPa.

[0034] 5) Spray granulation: Add the above homogenized emulsion into the centrifugal spray dryer, the air inlet temperature is 150-190°C, the outlet air temperature is 70-80°C, and the nozzle speed is 20,000-30,...

Embodiment 2

[0037] DHA Fish Oil 20%

[0038] Starch Octenylsuccinate 50%

[0039] Vitamin C 0.1%

[0040] Vitamin E 0.1%

[0041] Sodium Caseinate 29.8%

[0042] Appropriate amount of purified water

[0043] Preparation

[0044] 1) Prepare the oil phase solution: mix DHA fish oil and vitamin C according to the ratio and stir evenly.

[0045] 2) Preparation of water phase solution: mix octenyl succinate starch, sodium caseinate and vitamin E in water according to the proportion, stir and disperse evenly.

[0046] 3) Preparation of emulsion: Slowly add the oil phase solution into the water phase solution and stir at high speed to emulsify for a certain period of time.

[0047] 4) High-pressure homogenization: the above-mentioned emulsion is homogenized under high pressure for more than 3 times under a pressure of 40-50 MPa.

[0048] 5) Spray granulation: Add the above homogenized emulsion into a centrifugal spray dryer with an inlet air temperature of 150-190°C, an outlet air tempera...

Embodiment 3

[0051] DHA Fish Oil 25%

[0052] Starch Octenylsuccinate 45%

[0053] Tea polyphenols 0.05%

[0054] Lecithin 0.15%

[0055] Sodium Caseinate 29.8%

[0056] Appropriate amount of purified water

[0057] Preparation

[0058] 1) Preparation of oil phase solution: mix DHA fish oil and tea polyphenols according to the proportion and stir evenly.

[0059] 2) Preparation of aqueous phase solution: Mix octenyl succinate starch, sodium caseinate and lecithin in water according to the proportion, stir and disperse evenly.

[0060] 3) Preparation of emulsion: Slowly add the oil phase solution into the water phase solution and stir at high speed to emulsify for a certain period of time.

[0061] 4) High-pressure homogenization: the above-mentioned emulsion is homogenized under high pressure for more than 3 times under a pressure of 40-50 MPa.

[0062] 5) Spray granulation: Add the above homogenized emulsion into a centrifugal spray dryer with an inlet air temperature of 150-190°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com