Method for synthesizing and regenerating mercury-free catalyst for hydrochlorination of acetylene and application thereof

An acetylene hydrochlorination, mercury catalyst technology, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of catalyst deactivation, high catalyst cost, low strength of activated carbon, etc. The effect of high strength, good selectivity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

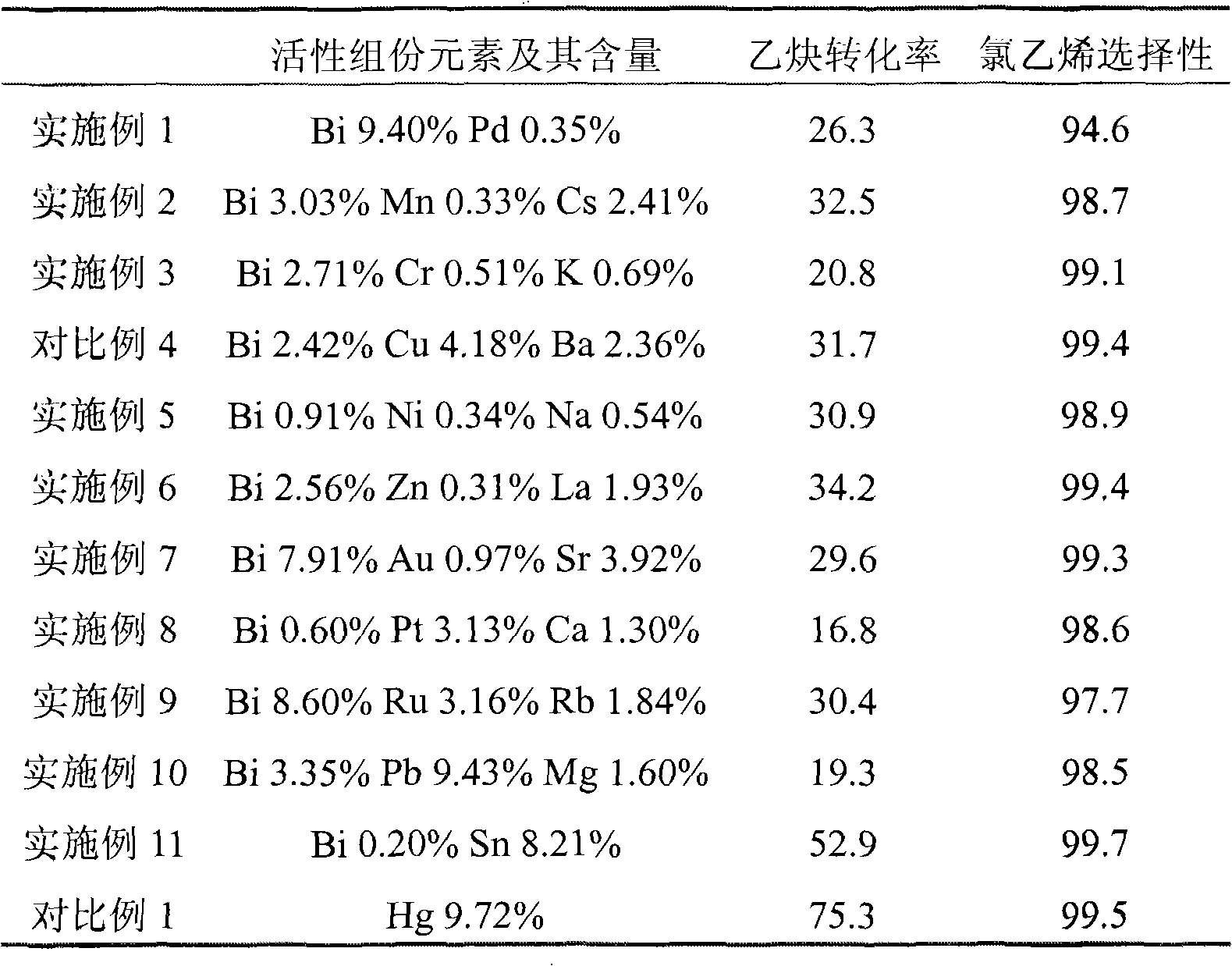

Embodiment 1

[0042] Dissolve 1 g of bismuth chloride and 0.05 g of palladium chloride in 10 g of 10% hydrochloric acid and 10% phosphoric acid aqueous solution, and stir evenly until all the solids are dissolved. The specific surface area of 6g is 350-400m 2 / g, 100-200 mesh SiO 2 Add it into the prepared solution, let it stand for 5 hours, dry it at 120°C for 5 hours, and then bake it at 450°C for 8 hours.

Embodiment 2

[0044] Dissolve 0.3g of bismuth chloride, 0.05g of manganese chloride and 0.2g of cesium chloride in 10g of 10% hydrochloric acid and 6% phosphoric acid aqueous solution, and stir evenly until all the solids are dissolved. The specific surface area of 6g is 350-400m 2 / g, 100-200 mesh SiO 2 Add it into the prepared solution, let it stand for 5 hours, dry it at 120°C for 5 hours, and then bake it at 400°C for 8 hours.

Embodiment 3

[0046] Dissolve 0.3g of bismuth phosphate, 0.2g of chromium chloride hexahydrate, and 0.1g of potassium chloride in 10g of 10% hydrochloric acid and 6% phosphoric acid aqueous solution, and stir evenly until all the solids are dissolved. The specific surface area of 7g is 150-200m 2 / g, 100~200 mesh α-Al 2 o 3 Add it into the prepared solution, let it stand for 5 hours, dry it at 120°C for 5 hours, and then bake it at 800°C for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com