Thermal management device, system and method of fuel cell stack

A fuel cell stack, fuel cell stack technology, applied in fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of system vibration, affecting the working performance of control elements and control elements, and large temperature fluctuations , to achieve the effect of easy filling and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

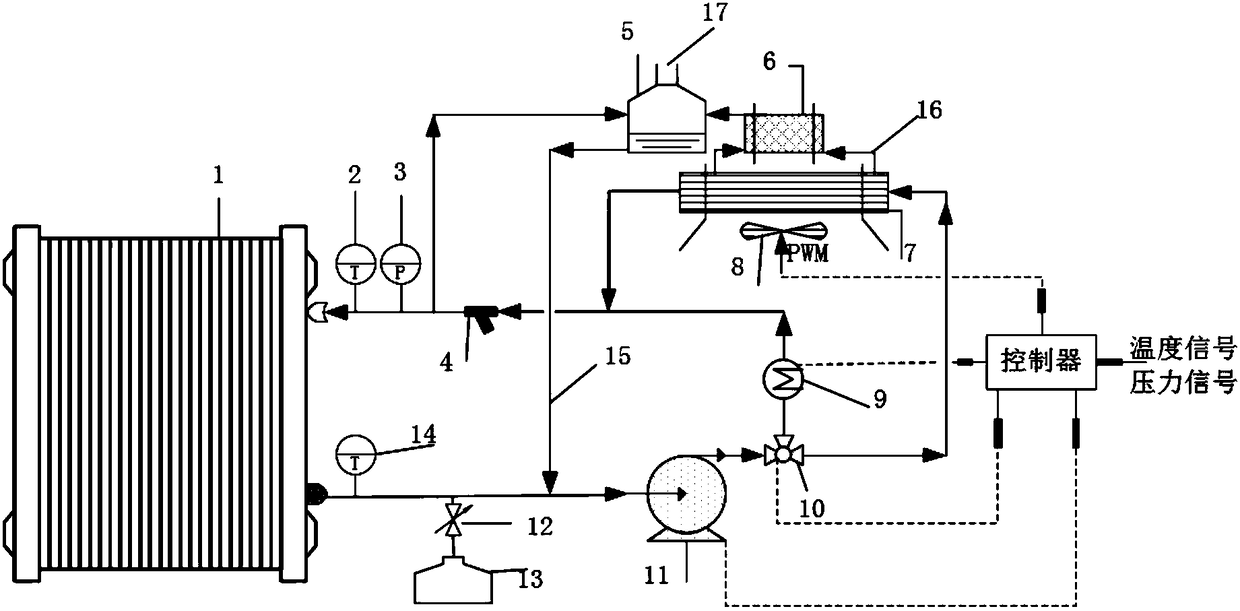

[0054] This embodiment combines image 3 , illustrating the working process of the cooling system for fuel cell stack thermal management:

[0055] In the embodiment of the present invention, when the temperature of the cooling liquid is lower than the preset temperature range, the cooling liquid is discharged from the cooling liquid outlet of the fuel cell stack, pressurized by the water pump, passes through the needle valve mechanism, and is discharged from the cooling liquid inlet of the fuel cell stack. Perform endothermic cooling of the fuel cell stack. If there are bubbles in the coolant, when the coolant circulates to the coolant inlet of the fuel cell stack, the bubbles will be discharged from the exhaust pipe to the water tank, and then discharged from the exhaust port at the upper end of the water tank. This process can be referred to as a small cycle.

[0056] When the temperature of the coolant is within the preset temperature range, the coolant is discharged from ...

Embodiment 2

[0060] to combine image 3 , this embodiment illustrates the composition of the fuel cell stack thermal management system: including: fuel cell stack 1, radiator 7, fan 8, water pump 11, electronic three-way valve 10, deionization tank 6, water supply tank 5, controller, filter Device 4, heating rod 9, temperature sensor 2 and pressure sensor 3. Using an electronic three-way valve 10 to adjust the large and small circulation of the cooling flow path can quickly change the opening of the three-way valve 10 according to the change of water temperature. Excessive temperature and pressure fluctuations effectively avoid damage to the interior of the stack caused by excessive water temperature. The replenishing water tank 5 can be used to remove the gas in the pipeline, and can also be filled with deionized water from the exhaust pipeline 16, which is convenient and quick to operate. A heating rod 9 is installed in the small circulation pipeline, which is used when starting the el...

Embodiment 3

[0062] This embodiment combines image 3 , Composition of fuel cell stack thermal management system: including:

[0063] Stack 1;

[0064] The exhaust pipeline, including two situations of small circulation and large circulation, is connected with the water tank.

[0065] The deionization tank 6 is connected in parallel with the radiator 7 and installed in the exhaust pipeline of the radiator 7 .

[0066] The water tank 5 is installed on the top of the radiator 7, and is used for filling deionized water and removing gas in the pipeline.

[0067] Electronic three-way valve 10 is used to control large and small circulation.

[0068] Heating rod 9 is installed in the small circulating water circuit and is used for cold start.

[0069] The fan 8 is controlled by a PMW (Pulse Width Modulation, Pulse Width Modulation) signal, and can be infinitely variable according to the temperature change of the water.

[0070] The controller is used to receive signals from the sensors and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com