Quick pre-buried optical fiber connection device

A technology of fast connection and pre-embedded optical fiber, which is applied in the coupling of optical waveguides, etc., can solve the problems of non-embedded optical fiber connection devices such as inconvenient operation, poor flexibility of use, and increased cost, so as to reduce the processing accuracy requirements and manufacturing costs of components. Low, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

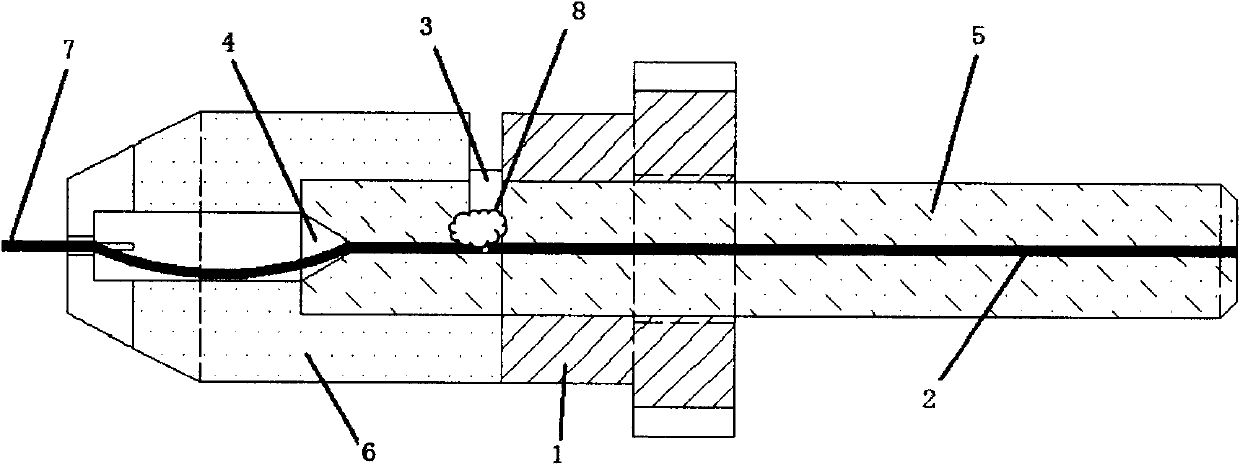

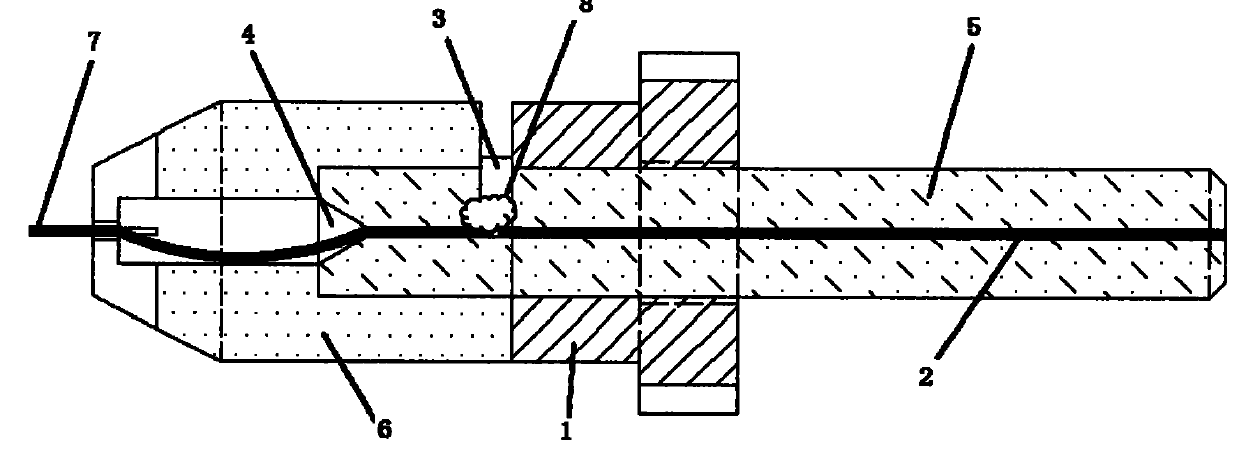

[0009] The pre-embedded optical fiber quick connection device of the present invention comprises a wheel handle and pre-embedded optical fiber. The wheel shank is mainly a ferrule with a nominal aperture. There is an opening on the ferrule, and a conical guide port is provided at one end to facilitate the insertion of the optical fiber to be connected. When it is practical, there is a matching liquid at the opening; the joint point between the optical fiber to be connected and the pre-embedded optical fiber is located at the opening of the wheel handle; the sleeve keeps the optical fiber in the tube slightly bent when locking the optical fiber to be connected, so as to ensure that the pre-embedded optical fiber and the pre-embedded optical fiber The fiber end faces remain in contact.

[0010] The device includes a wheel handle 1, pre-embedded optical fiber 2, nominal aperture ferrule 5 and sleeve 6. There is an opening 3 on the ferrule 5, which is convenient for the matching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com