Reconfigurable centrifuge-rotor micro-nano spinning formation device

A centrifugal rotor, micro-nano technology, applied in filament/thread forming, textile and papermaking, complete sets of equipment for the production of artificial threads, etc., can solve the problems of low spinning efficiency, inability to adjust parameters such as thickness and shape of micro-nano fibers , to achieve the effect of improving the spinning efficiency and shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

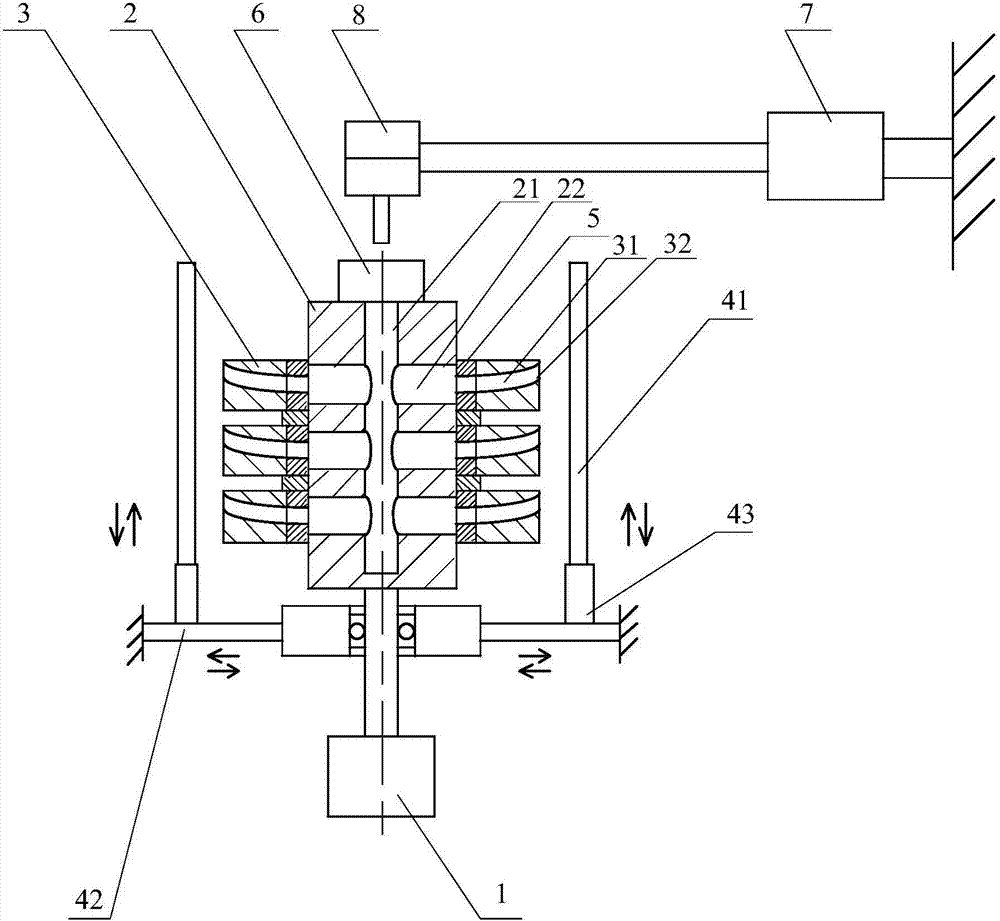

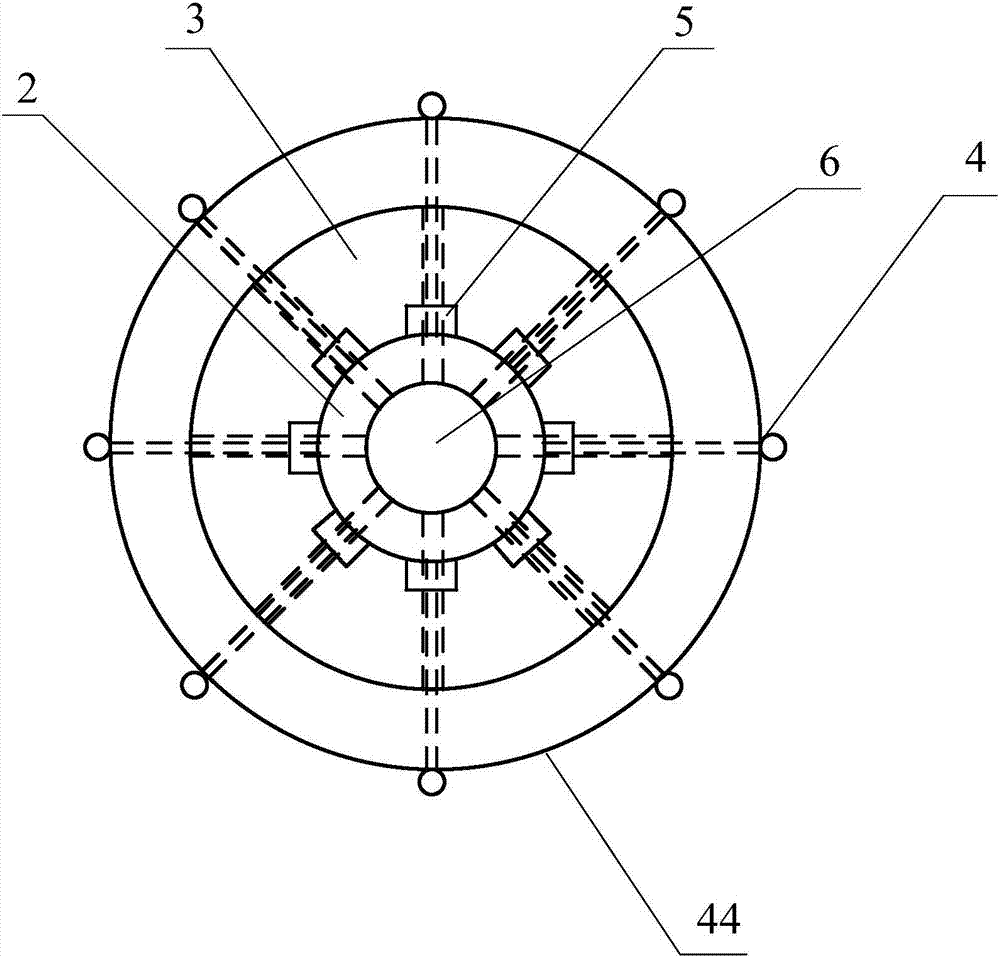

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0031] Such as figure 1 As shown, a reconfigurable centrifugal rotor micro-nano spinning forming device includes a feeding device, a spinning device and a forming device,

[0032] The feeding device is used to deliver the spinning raw material to the spinning device. The feeding device in this embodiment includes a feeding device 7 and a quantitative pump 8. The feeding device 7 provides the spinning raw material, and controls the spinning through the quantitative pump 8. The supply speed and flow rate of the silk raw materials are controlled so that different spinning raw materials can be produced and prepared corresponding micro-nano fibers under suitable spinning conditions.

[0033] The spinning device includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com