Techhnique for reclaiming metal concentrate in obsolete PCB physically

A technology for waste circuit boards and metals, which is applied in the field of physical recovery process of metal-rich groups in waste circuit boards, can solve the problems of low sorting efficiency, many classifications, and inaccuracy, and achieves avoiding secondary pollution and sorting level. The effect of wide, broad utility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

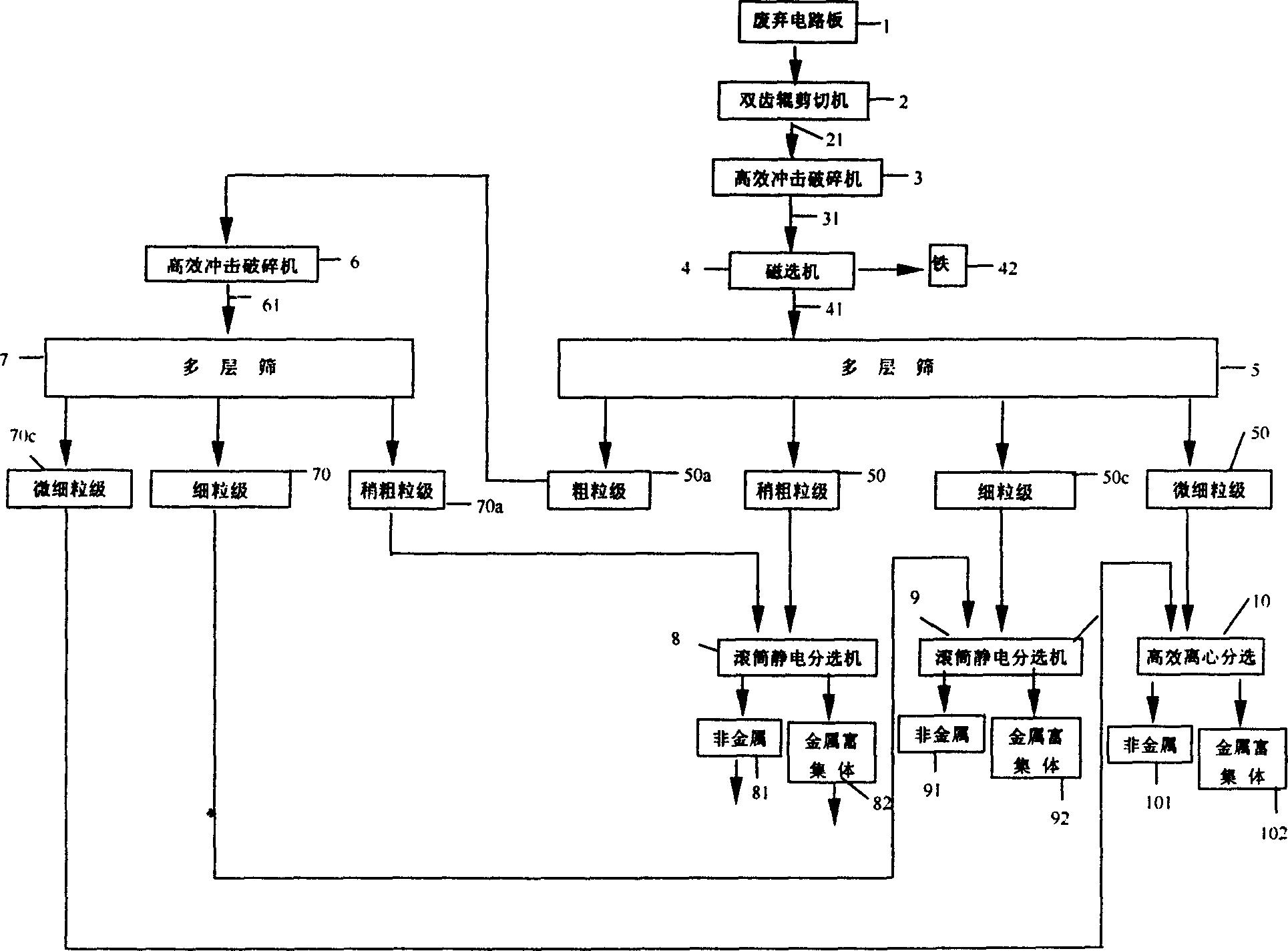

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0016] The dry physical recycling process of the valuable components on the electronic waste boards of the present invention, the pretreated waste printed circuit board 1, through the special double-toothed roller shearing machine 2, cuts the entire circuit board into a size of 30 Small pieces 21 of × 30mm; then sent to the high-efficiency impact crusher 3 for further crushing to obtain fine-grained materials 31; through the magnetic separator 4, ferromagnetic substances 42 and non-ferromagnetic substances 41 are recovered by the magnetic field, and the non-ferrous The magnetic material 41 is sent to the multi-layer sieve 5 for classification. The multi-layer sieve 5 is composed of overlapping sieve plates of coarse-grained grade, slightly coarse-grained grade, fine-grained grade and fine-grained grade. The number of layers can be set from 2 to 5 layers, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com