Integrated equipment and method for automatically treating circulating cooling water and recycling sewage water

A technology for circulating cooling water and cooling water treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as exceeding and unable to stably control the chemical content, and achieve management Reduce, reduce equipment and site construction investment, reduce the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0061] The present invention research experiment example is as follows:

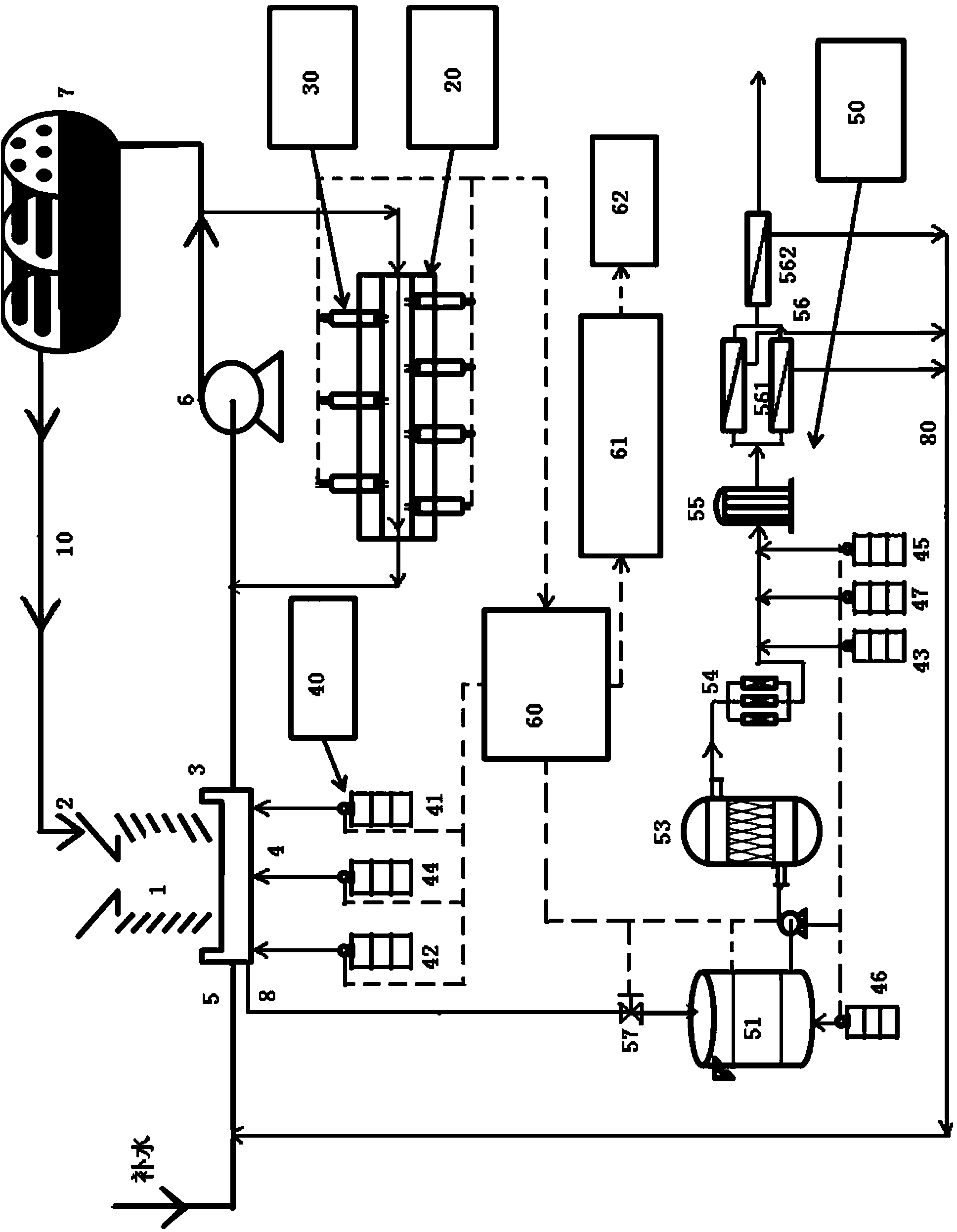

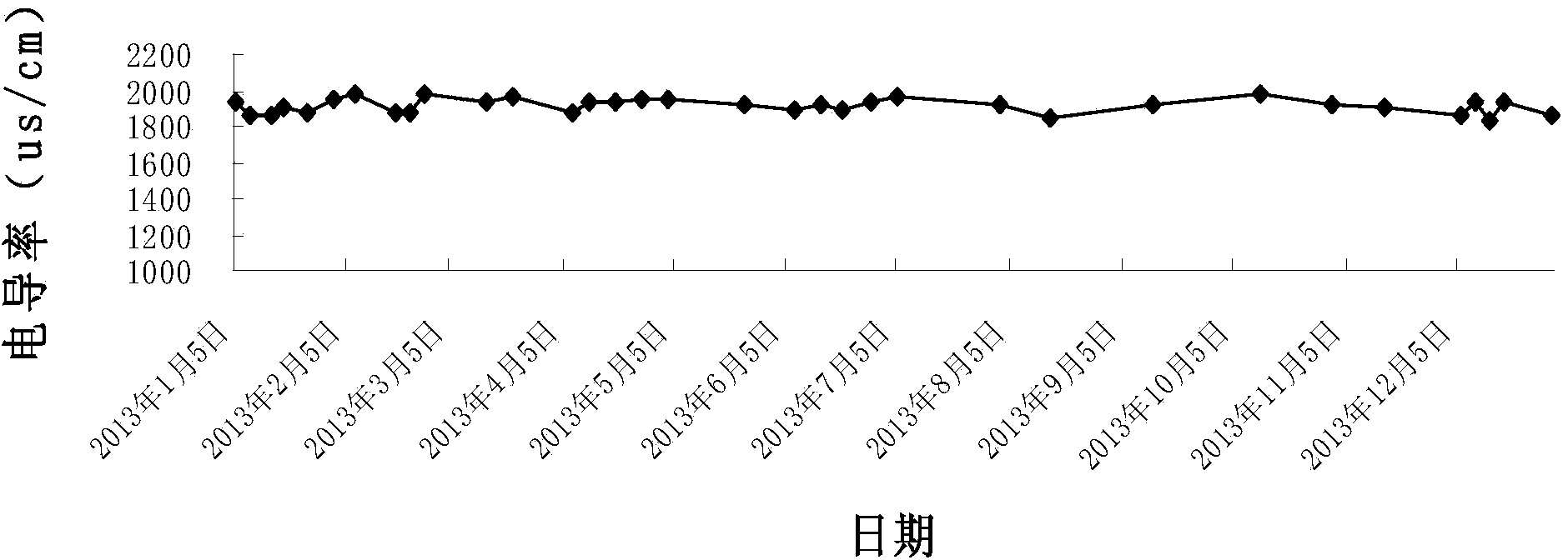

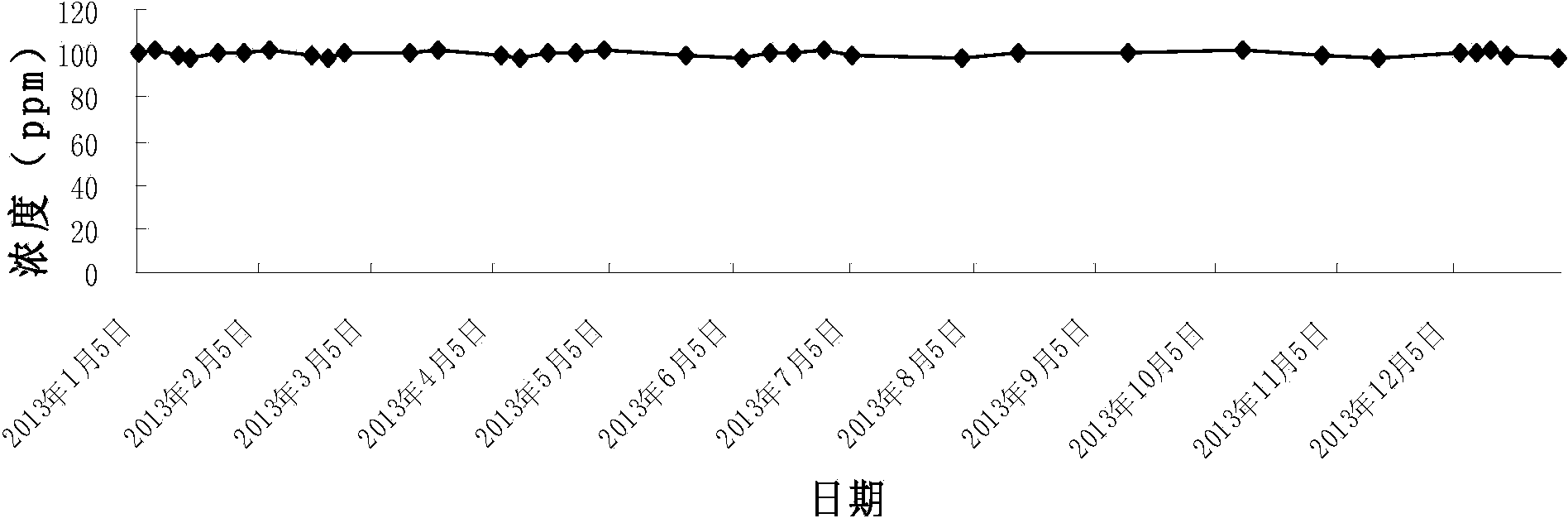

[0062] A central air-conditioning cooling water system has been in full operation since January 5, 2013. The cooling water system not only includes the online monitoring and control system of the front-end cooling water, but also when the cooling water is concentrated to the highest concentration, the concentrated water is not discharged directly. Instead, it is stored in the water tank to start the advanced treatment of the sewage. After a series of flocculation, sterilization, filtration and ultrafiltration, the cooling water is utilized to the greatest extent, and the pure water produced by the reverse osmosis system is further returned to the cooling water system. It is used for replenishing water. During the whole year’s operation, through the effective control of the intelligent dosing management and control system, the water quality indicators of the cooling water system have passed the test. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com