Patents

Literature

49 results about "Virtual integration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual integration. A term used to describe the use of the Internet to replace physical components of a company with information. A business engaged in virtual integration owns only their brand and their clients.

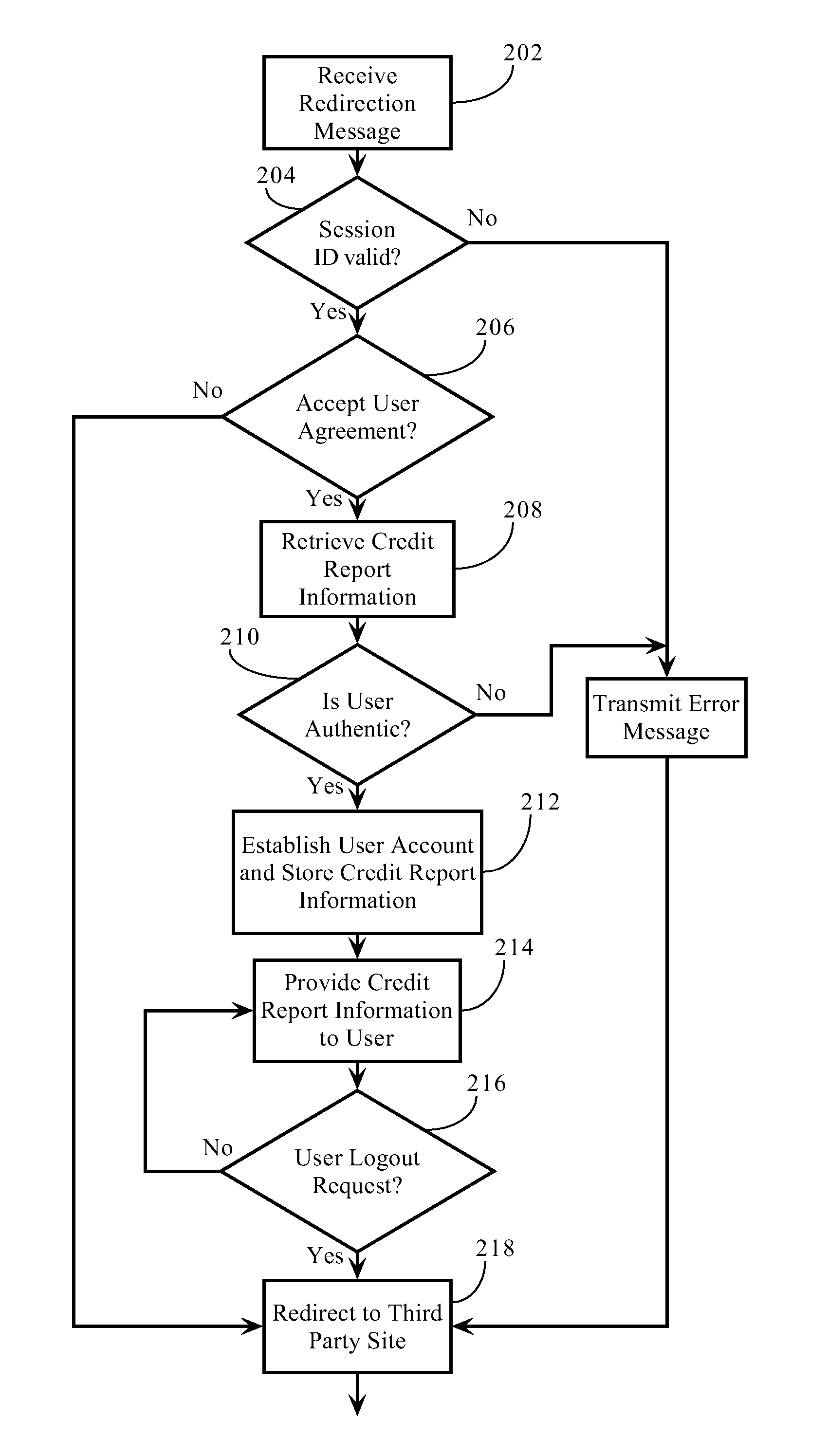

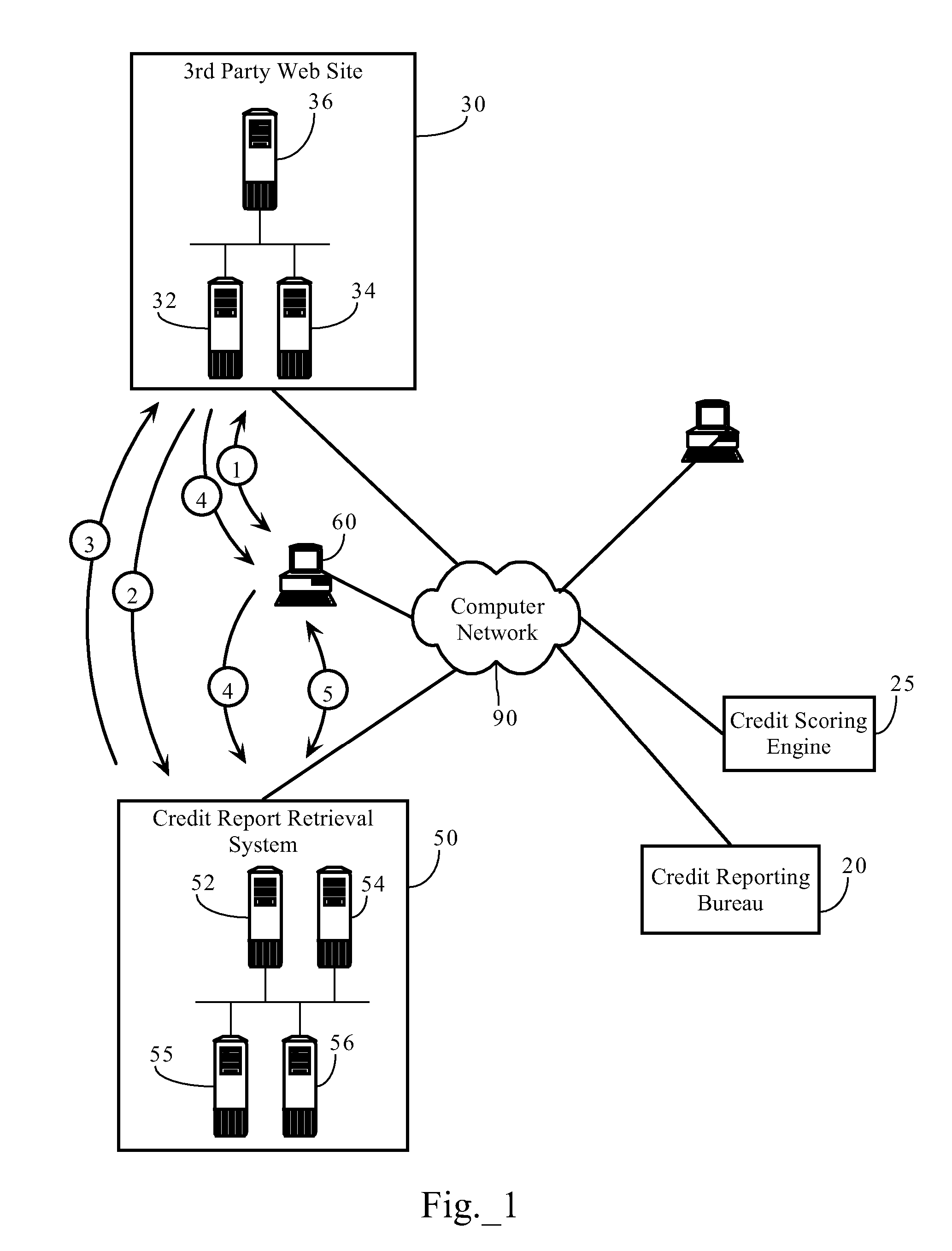

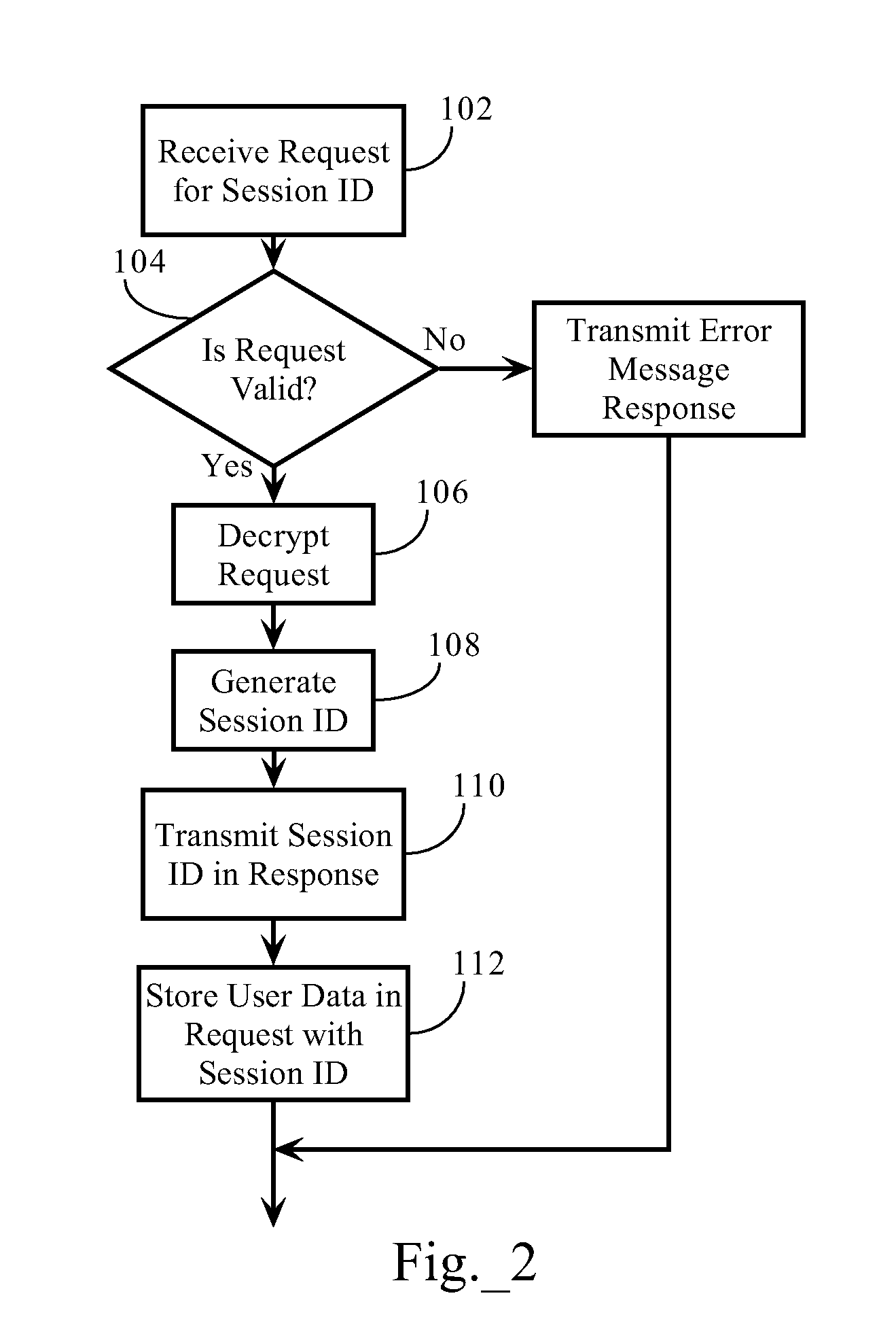

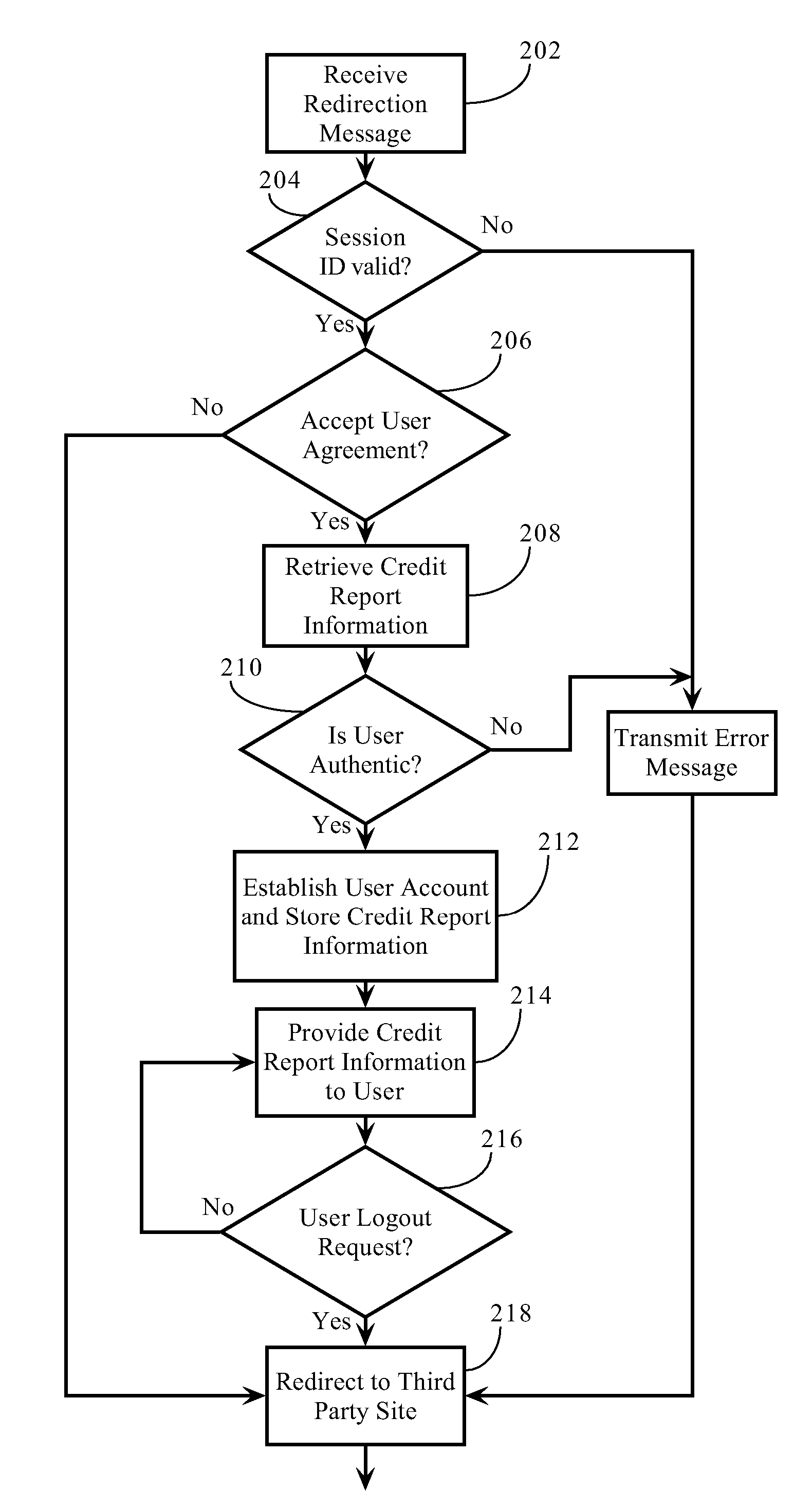

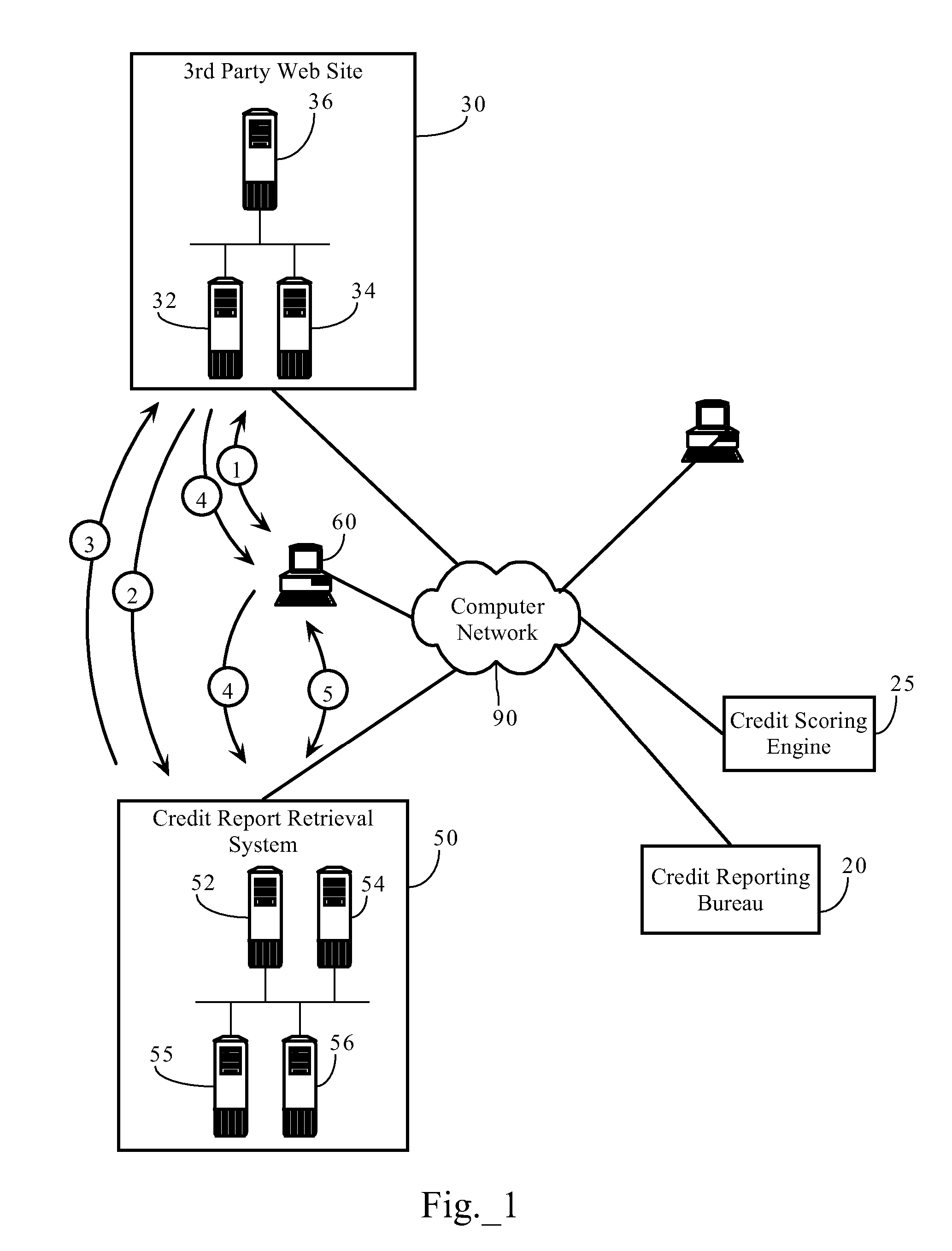

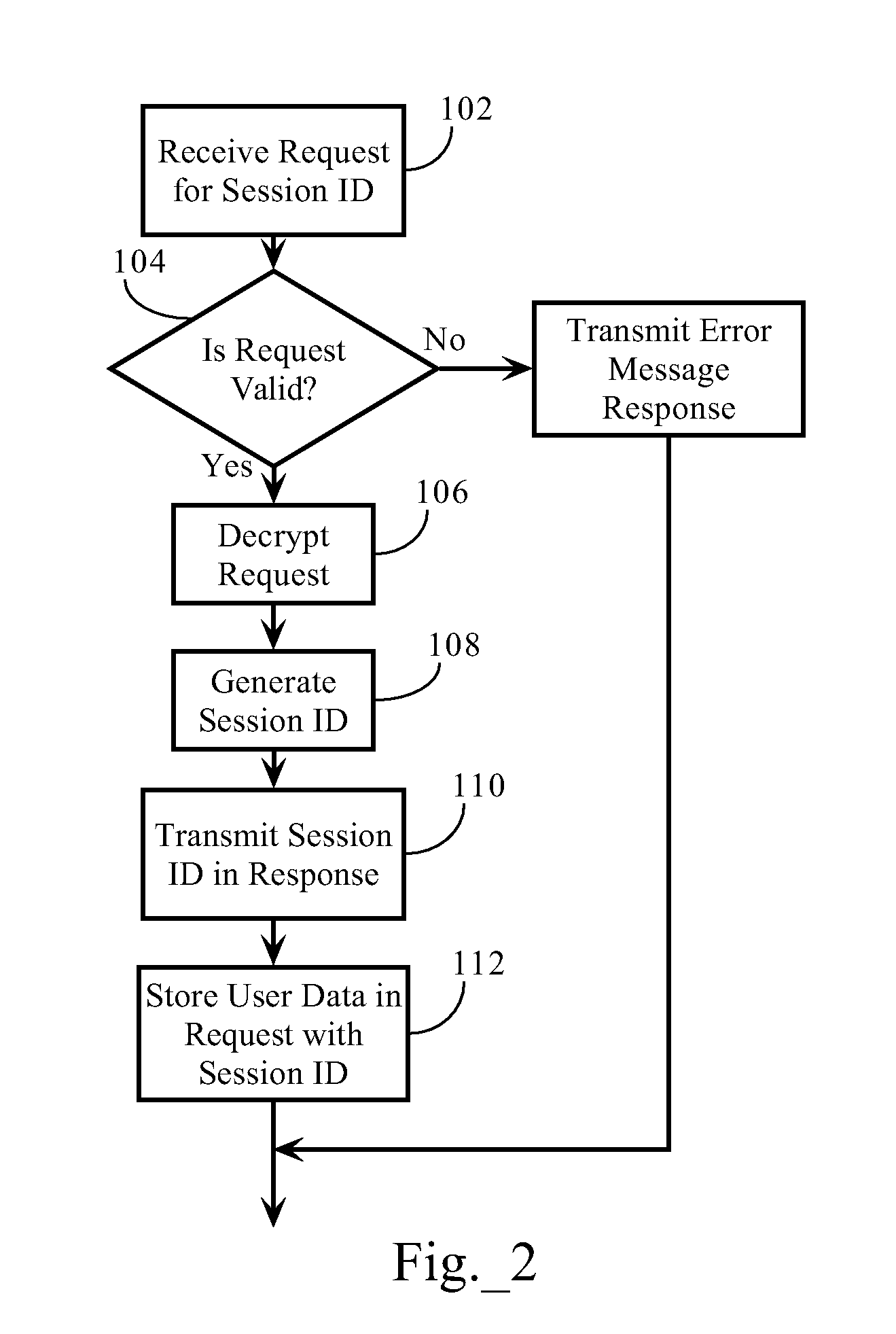

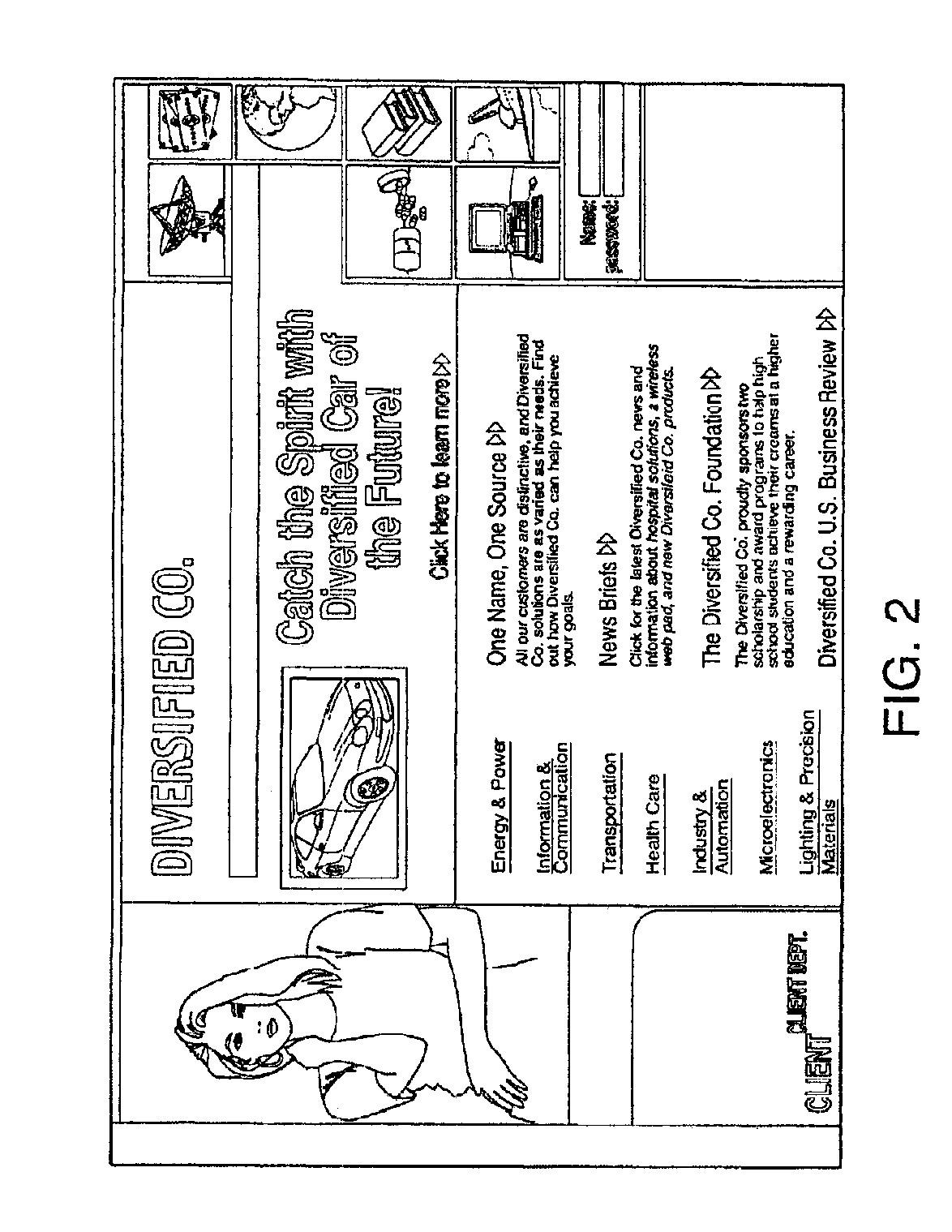

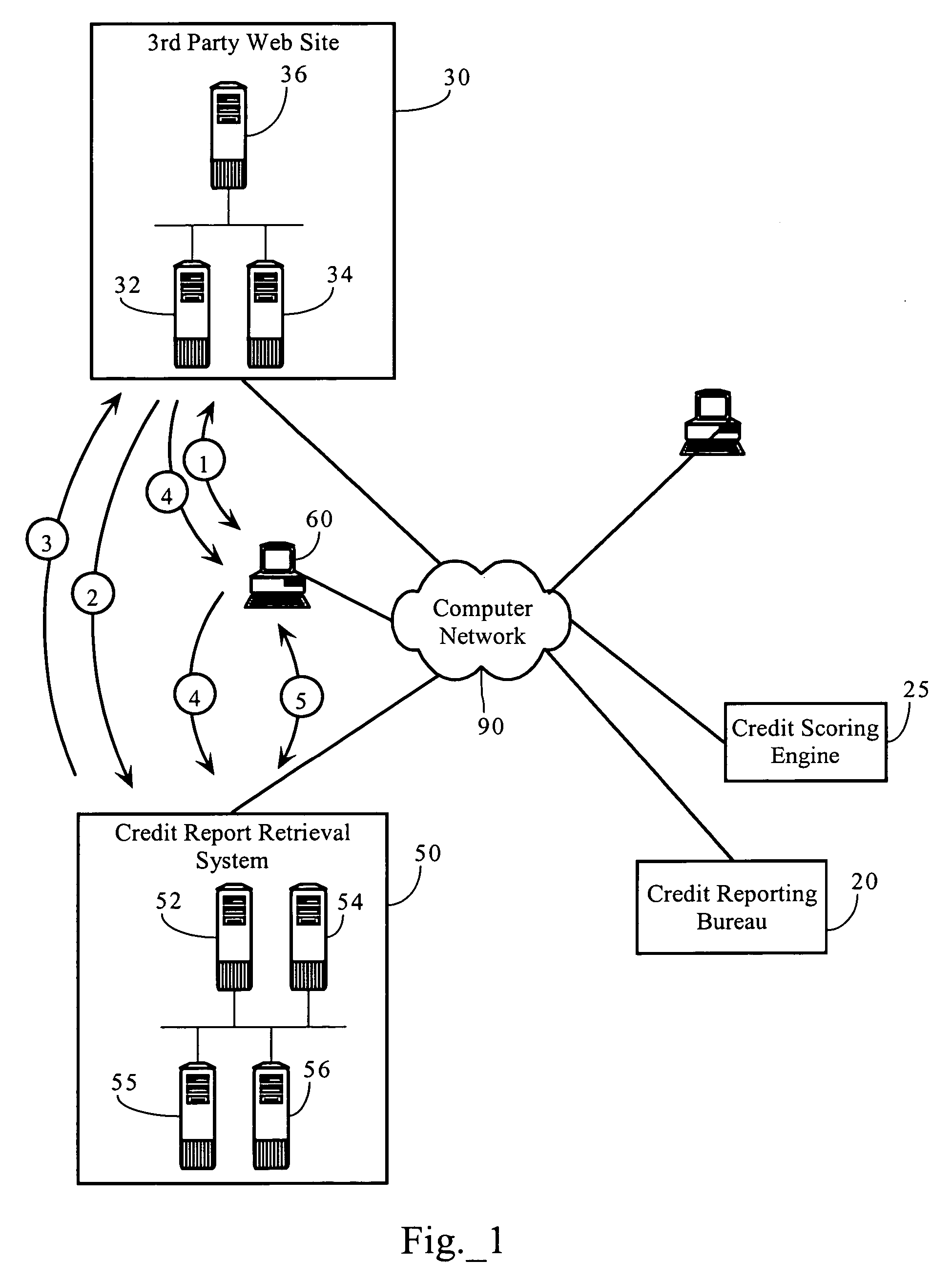

Methods, apparatuses and systems facilitating seamless, virtual integration of online membership models and services

ActiveUS7337468B2Efficient collaborationEasy to integrateDigital data processing detailsUser identity/authority verificationVirtual integrationDatabase

Owner:TRANSUNION INTERACTIVE

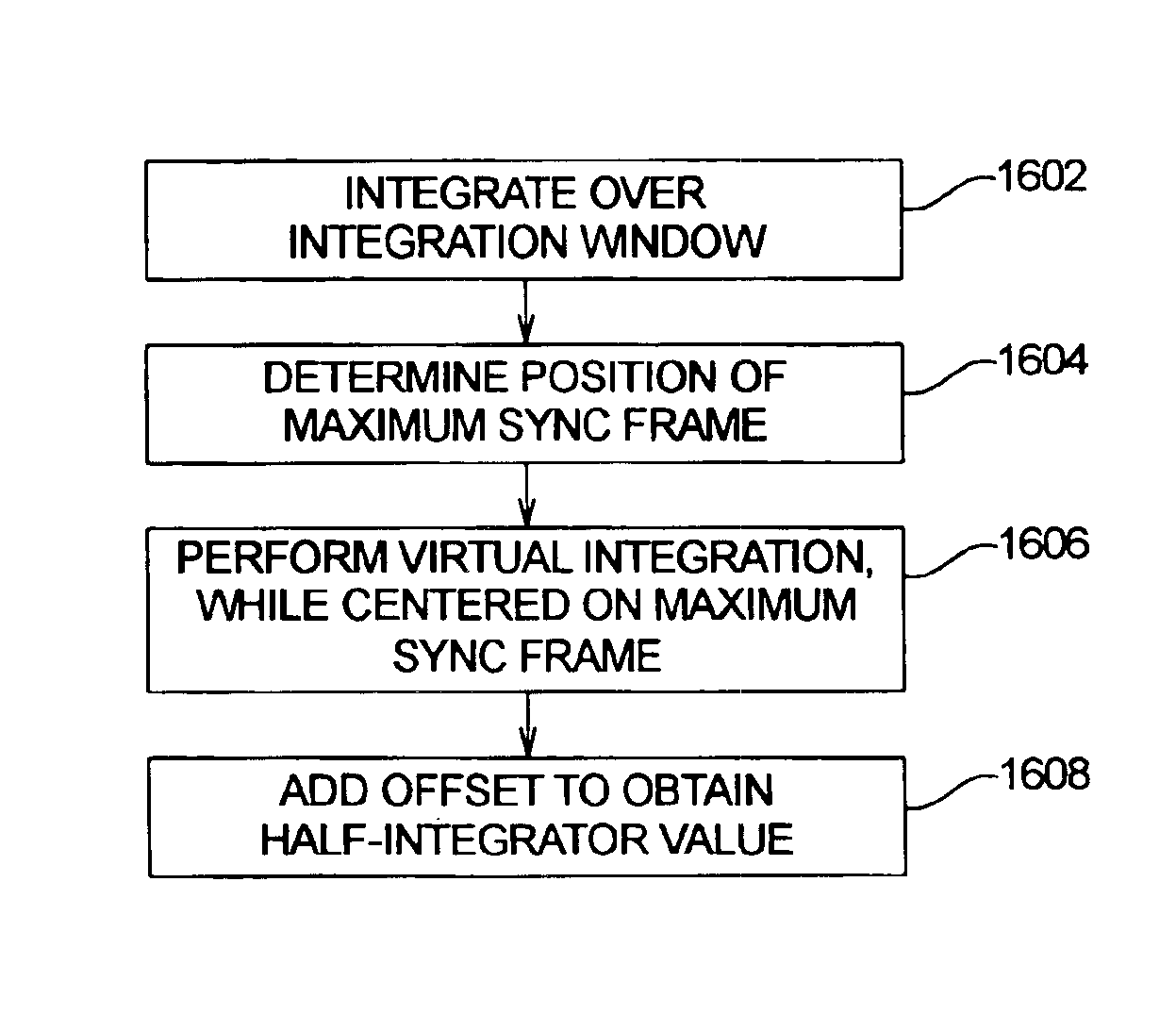

Method and apparatus for determining a transducer's reference position in a disk drive having a disk surface with spiral servo information written thereon

InactiveUS7019937B1Driving/moving recording headsRecord information storageVirtual integrationTransducer

The present invention is directed to method and apparatus for determining a transducer's reference position in a disk drive having a disk surface with spiral servo information written thereon. The transducer comprises a read head for reading spiral servo information and a read signal envelope is generated when the read head reads the spiral servo information. An integration is performed over a first integration window, wherein the first integration window includes a read signal envelope. A reference position is determined for the read head using a second integration window (virtual integration window) that is included within, and smaller than, the first integration window. In one embodiment, the integration may be performed on a frame-by-frame basis. A determination may be made of the frame in the first integration window that includes a maximum sync amplitude. The second integration window may be centered using the frame that includes the maximum sync amplitude.

Owner:MAXTOR

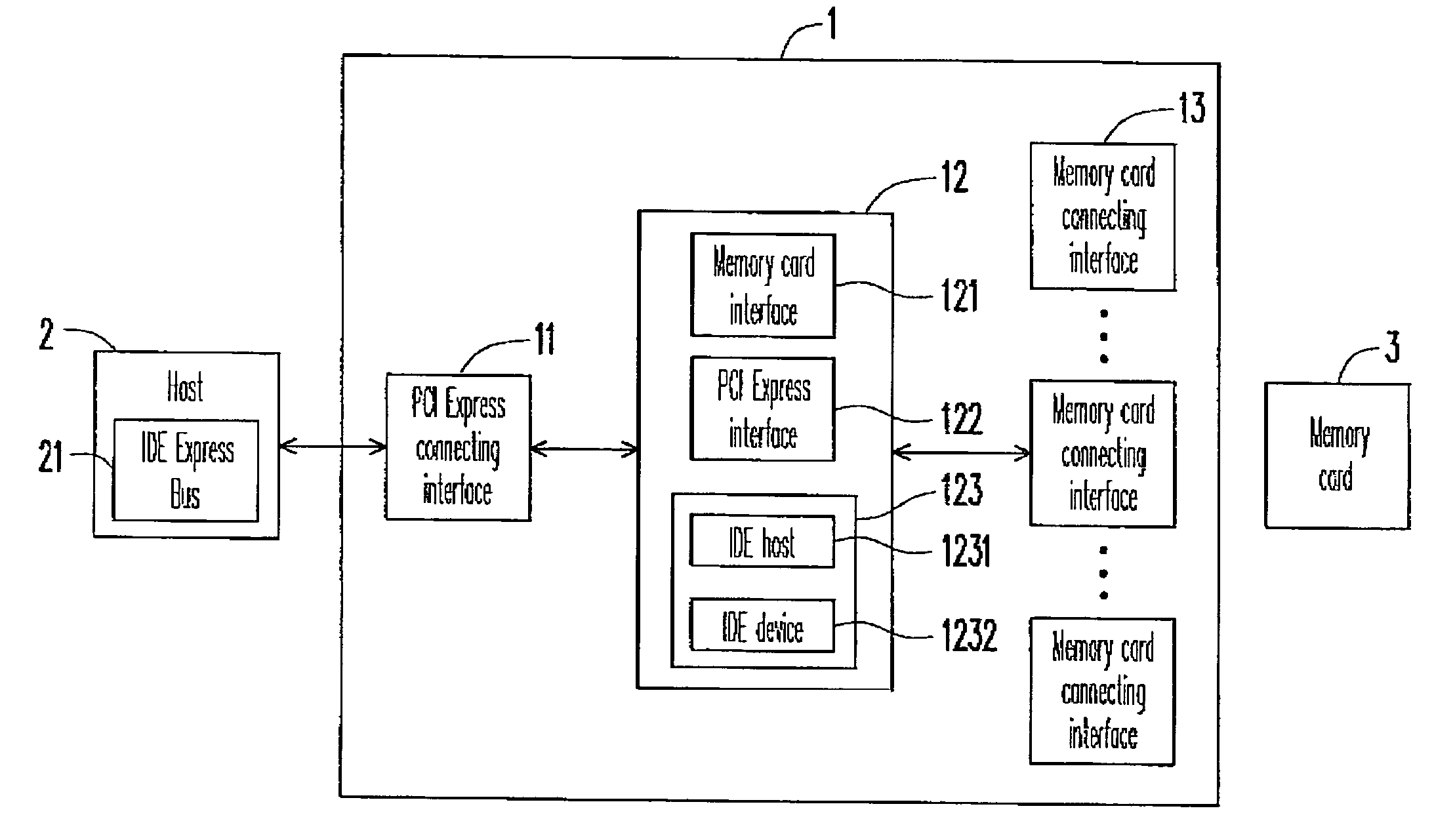

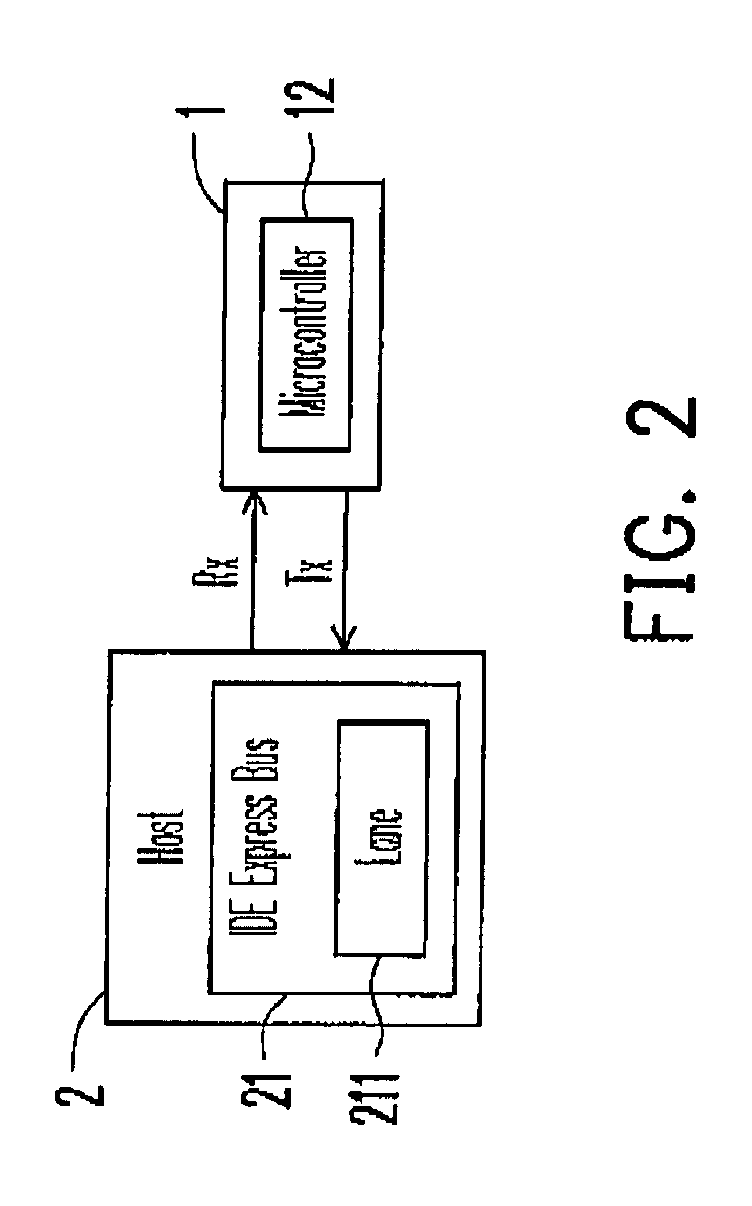

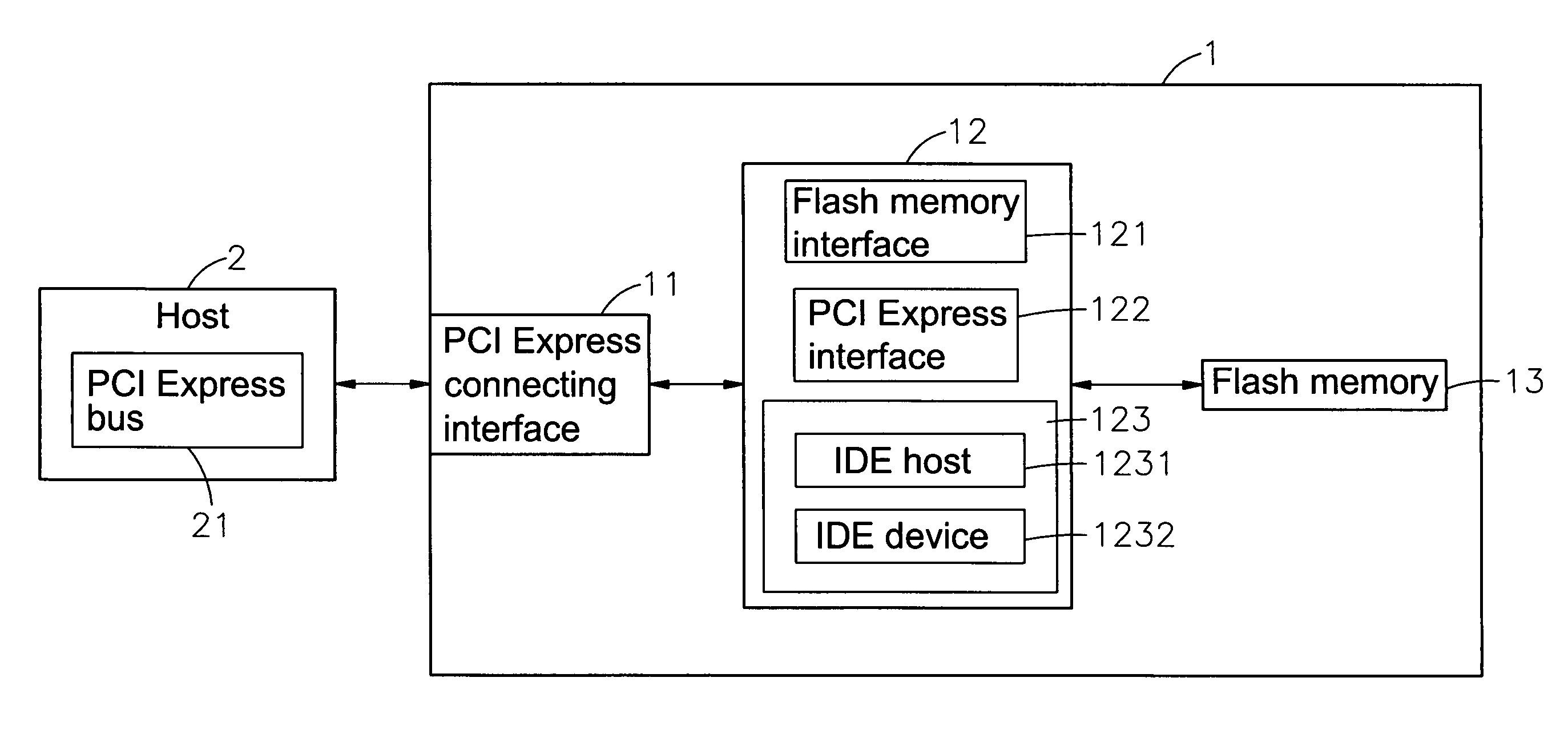

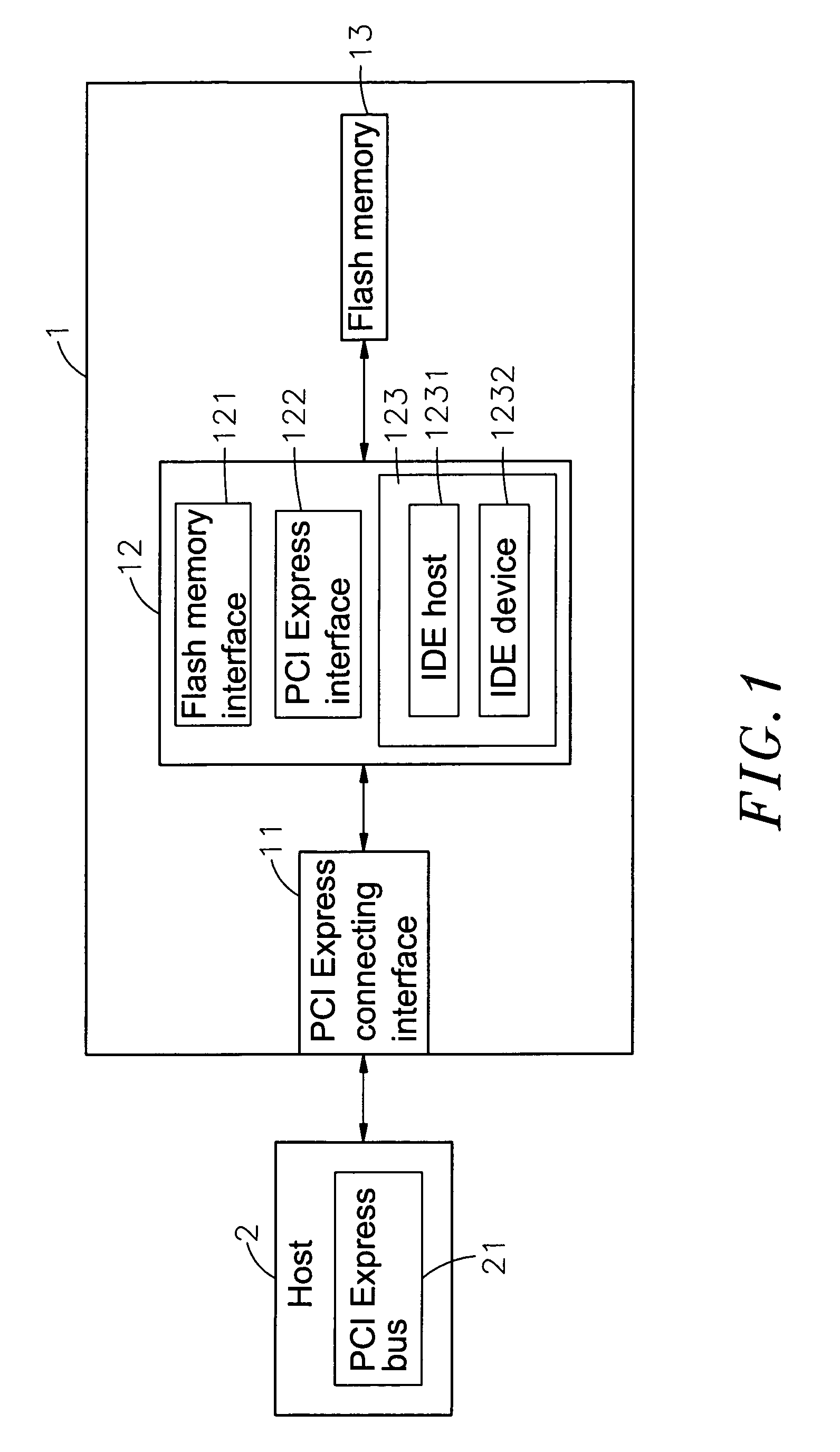

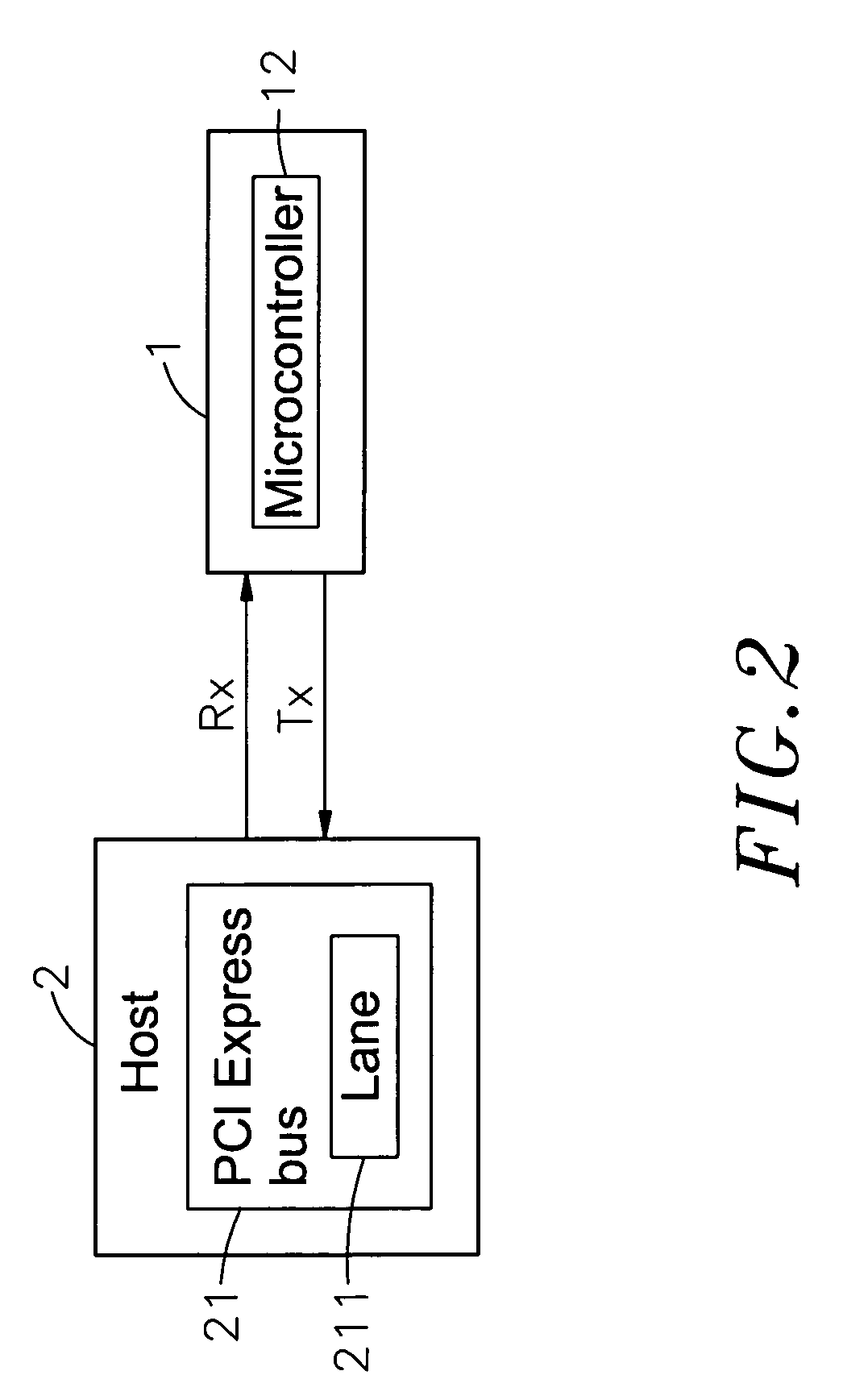

Virtual IDE storage with PCI express interface

The present invention discloses a virtual integrated drive electronics (IDE) storage device with a peripheral component interconnect (PCI) Express interface. The storage device includes a microcontroller connected to a PCI Express connecting interface and a flash memory separately. The microcontroller includes a flash memory interface, a PCI Express interface and a virtual IDE module. The virtual IDE module includes an IDE host and an IDE device. When the host sends an instruction for storing or reading data to a flash memory, the instruction will be sent to and executed in the virtual IDE module. The data in the flash memory can be transmitted at a transmission rate up to the standard of an IDE device, and the host will consider the storage device as an IDE device instead of a PCI Express device only.

Owner:PHISON ELECTRONICS

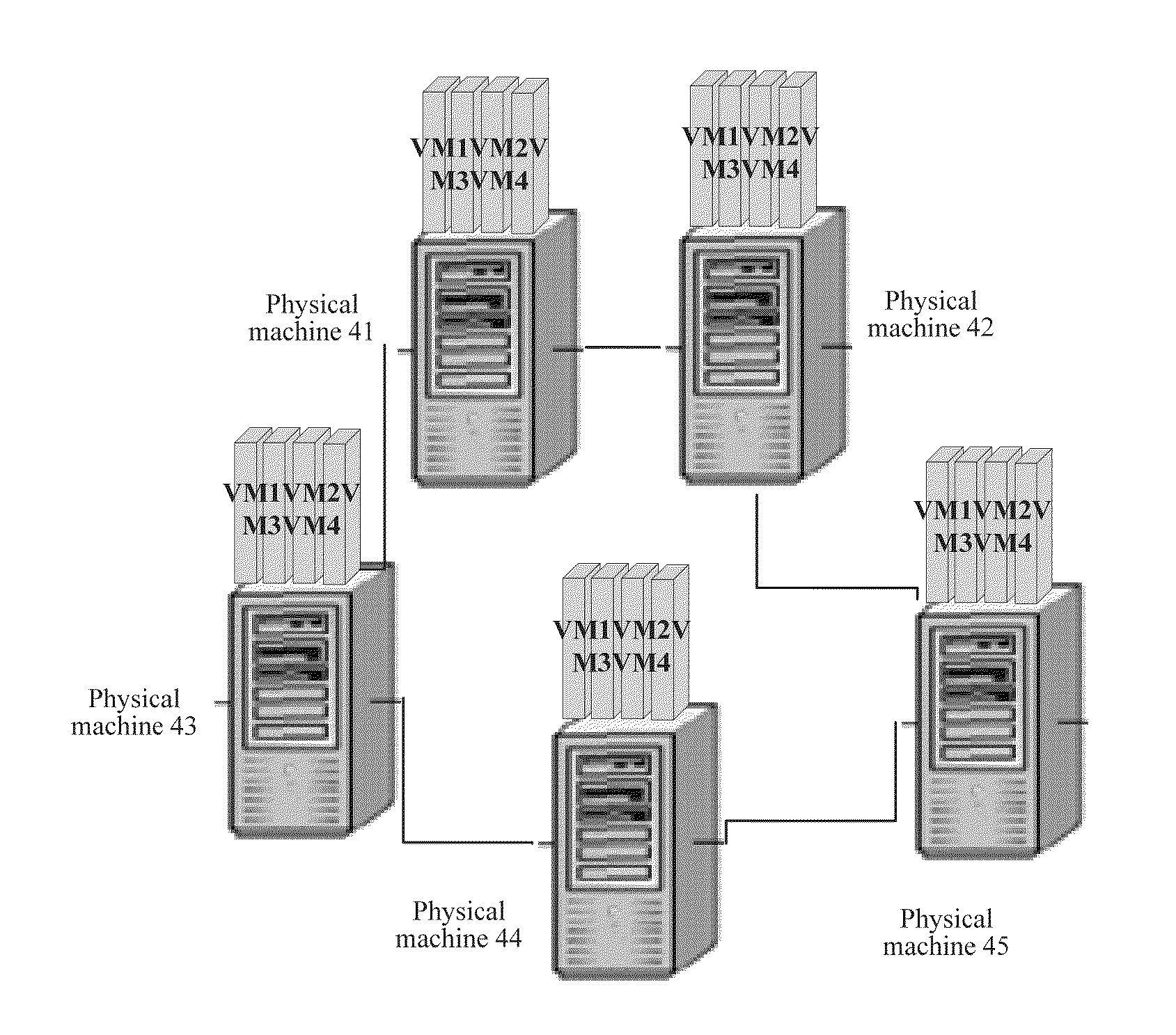

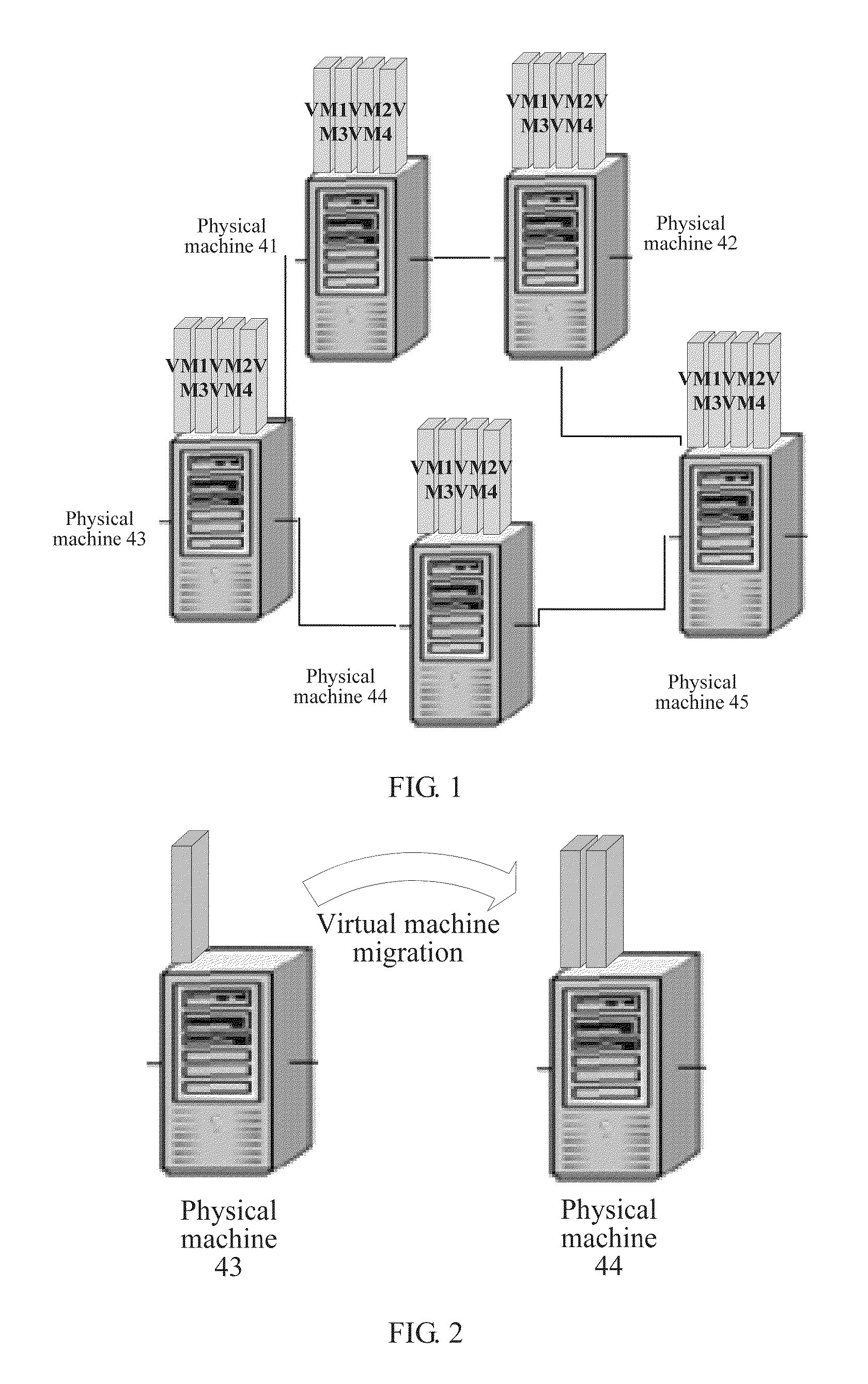

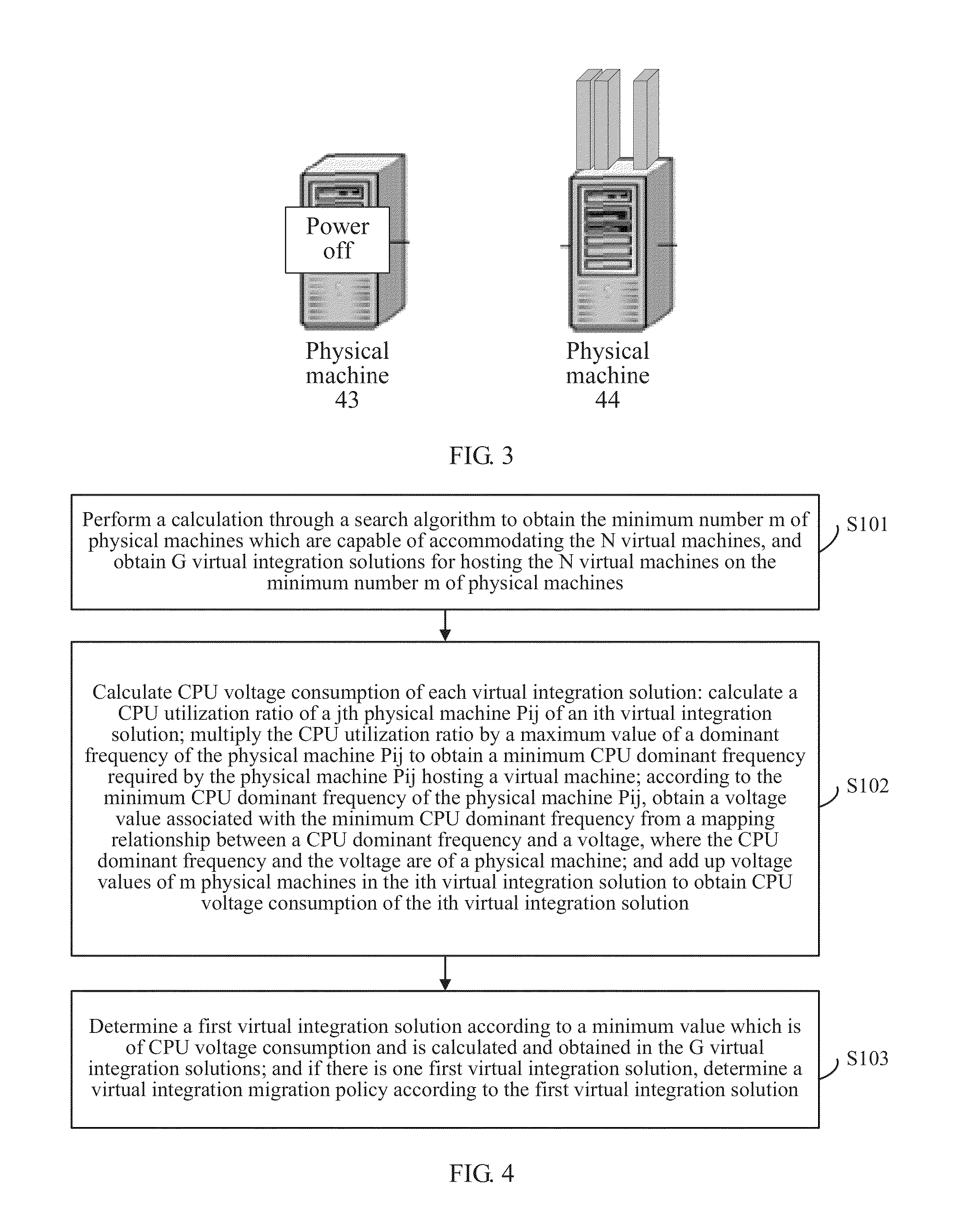

Method, apparatus, and system for virtual cluster integration

ActiveUS20130174152A1Improve energy savingImprove emission reduction effectEnergy efficient ICTElectric devicesVirtual clusterParallel computing

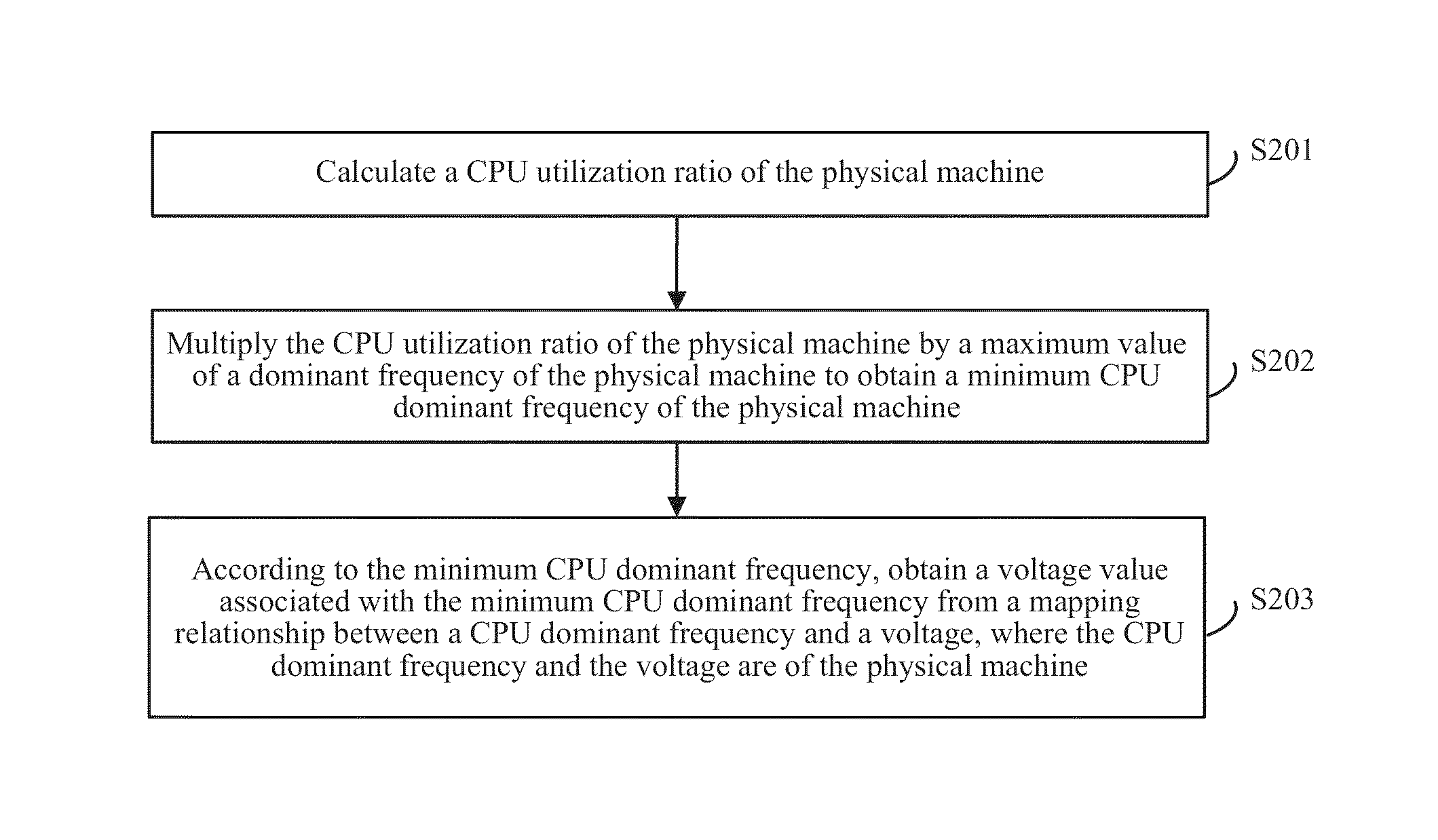

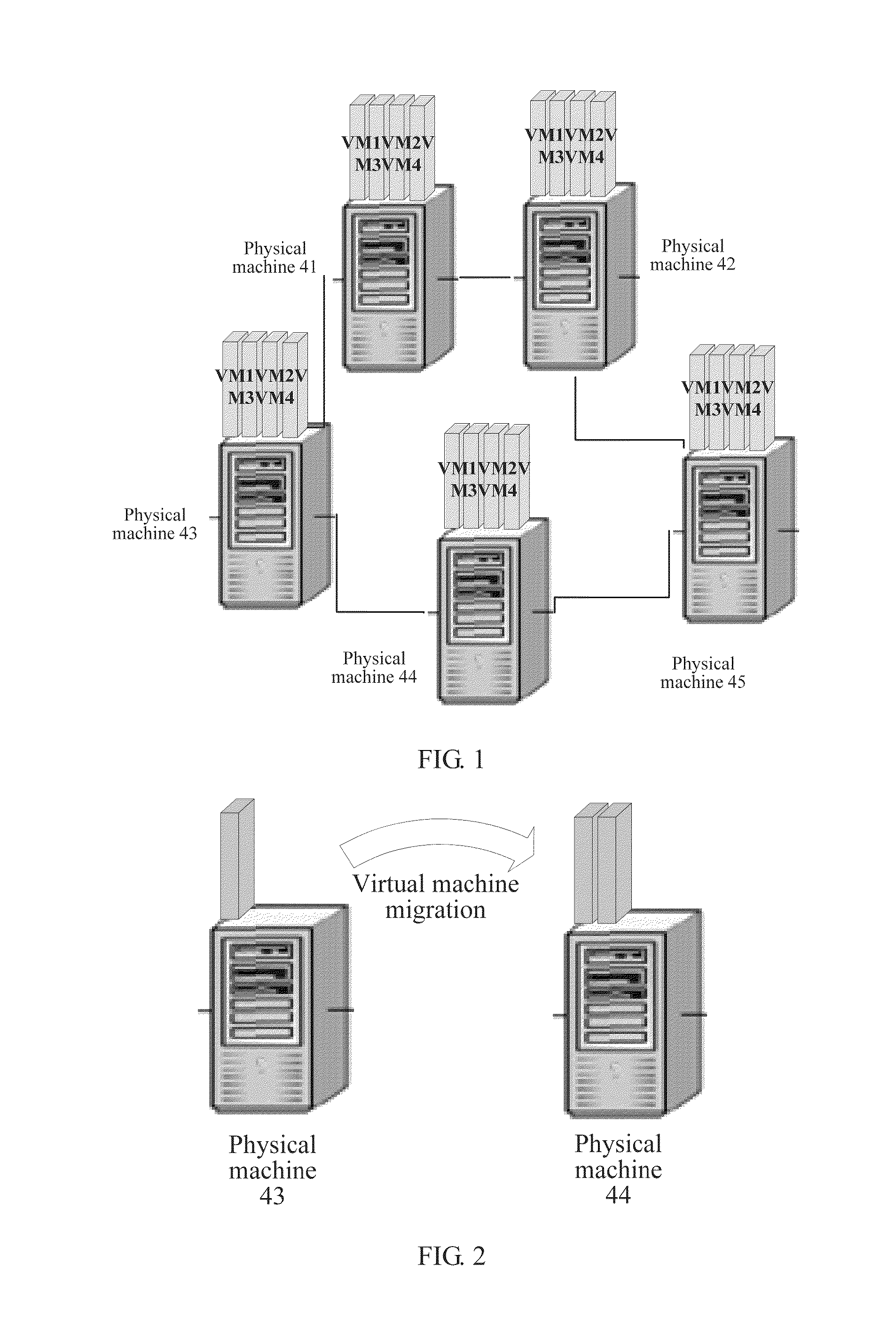

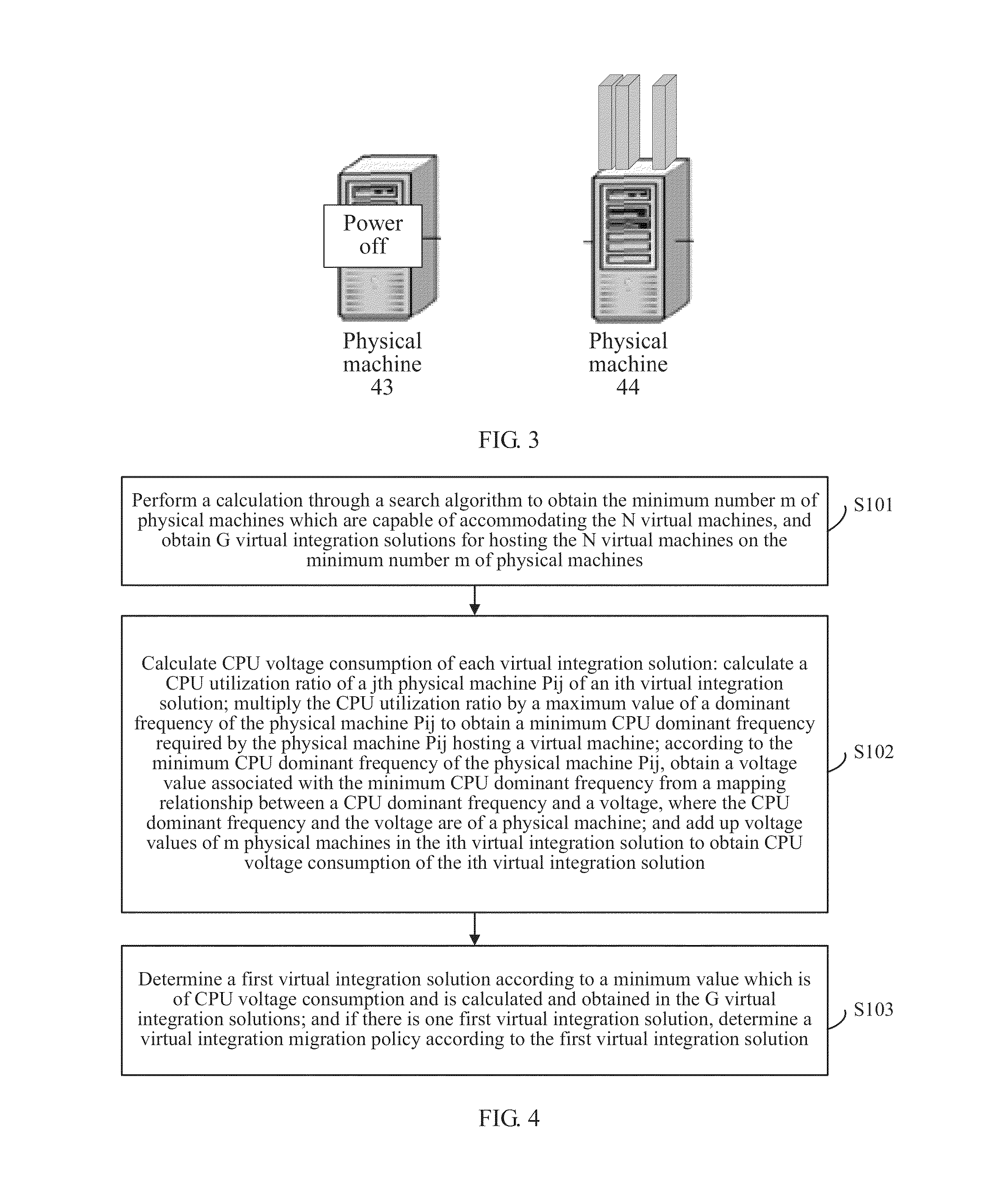

Embodiments of the present invention relate to a virtual machine integration technology, and in particular, to a method, an apparatus, and a system for virtual cluster integration. The method includes: performing a calculation through a search algorithm to obtain the minimum number of physical machines which are capable of accommodating all virtual machines in a virtual cluster, and obtaining all virtual integration solutions satisfying the minimum number of physical machines; then calculating CPU voltage consumption of each virtual integration solution, and selecting a solution with lowest CPU voltage consumption from these virtual integration solutions; and formulating a virtual integration migration policy according to the virtual integration solution with the lowest CPU voltage consumption. Therefore, through the embodiments of the present invention, a virtual integration solution with lower CPU voltage energy consumption can be obtained, thereby greatly improving an energy saving and emission reduction effect of a virtual cluster integration solution.

Owner:HUAWEI TECH CO LTD

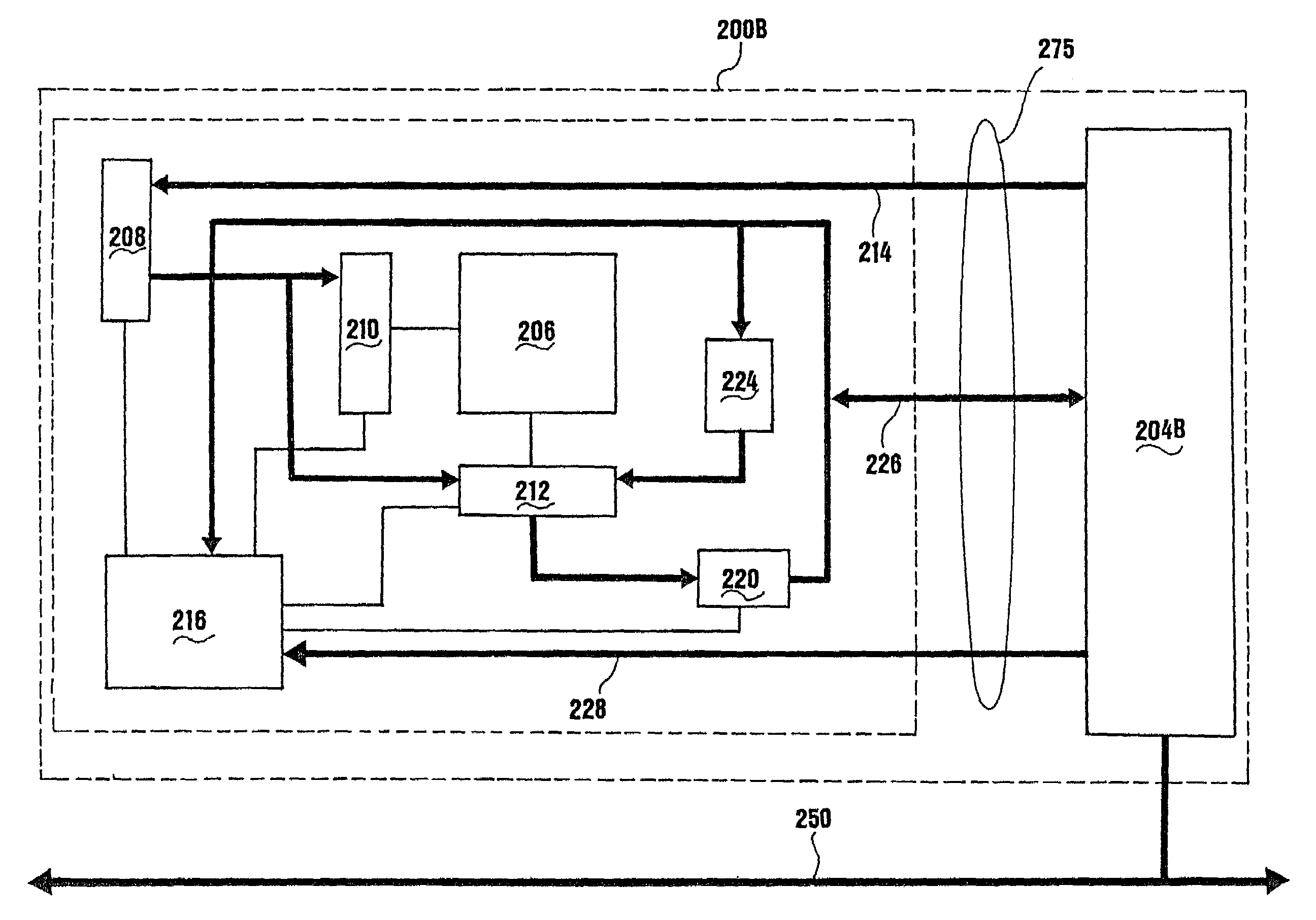

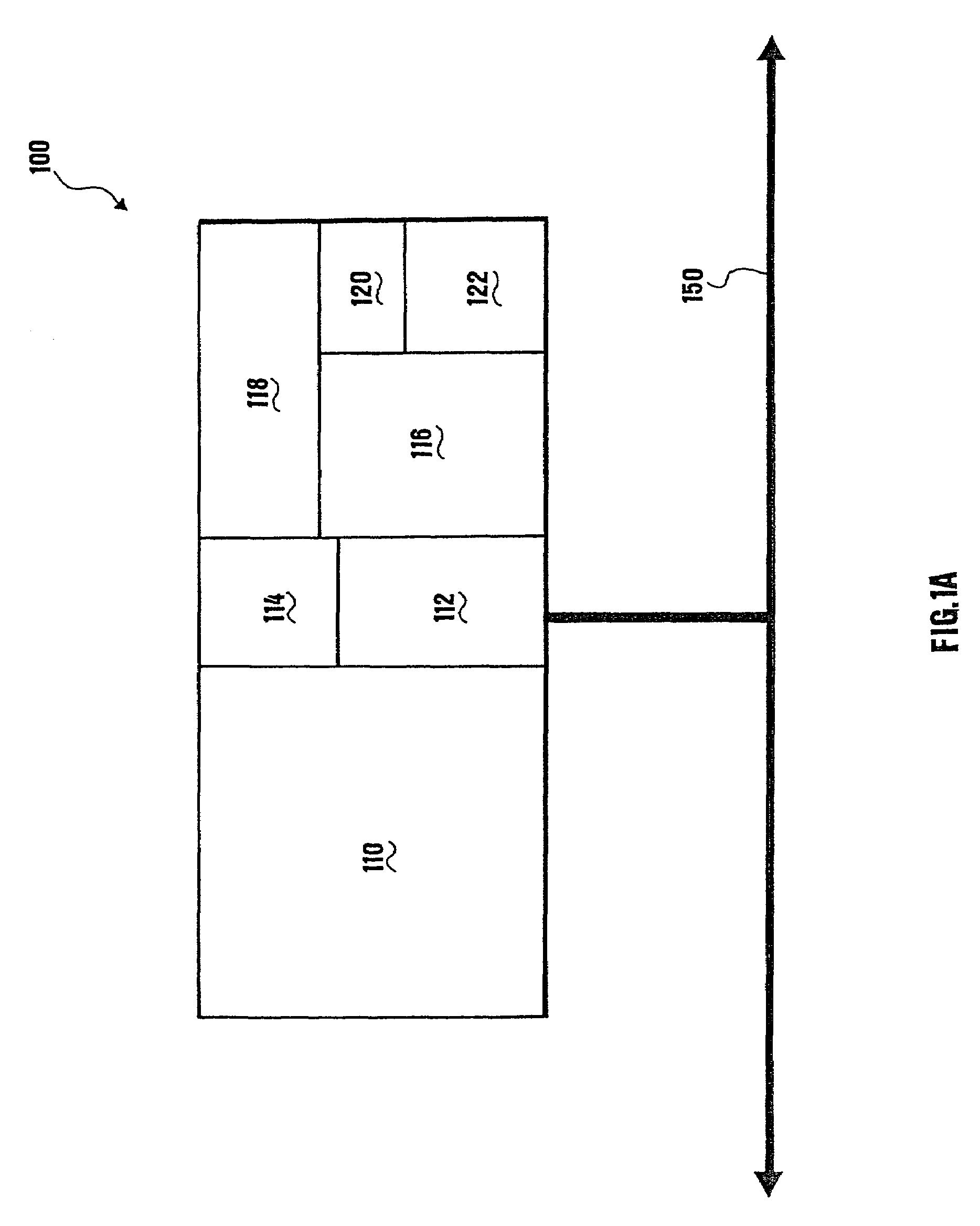

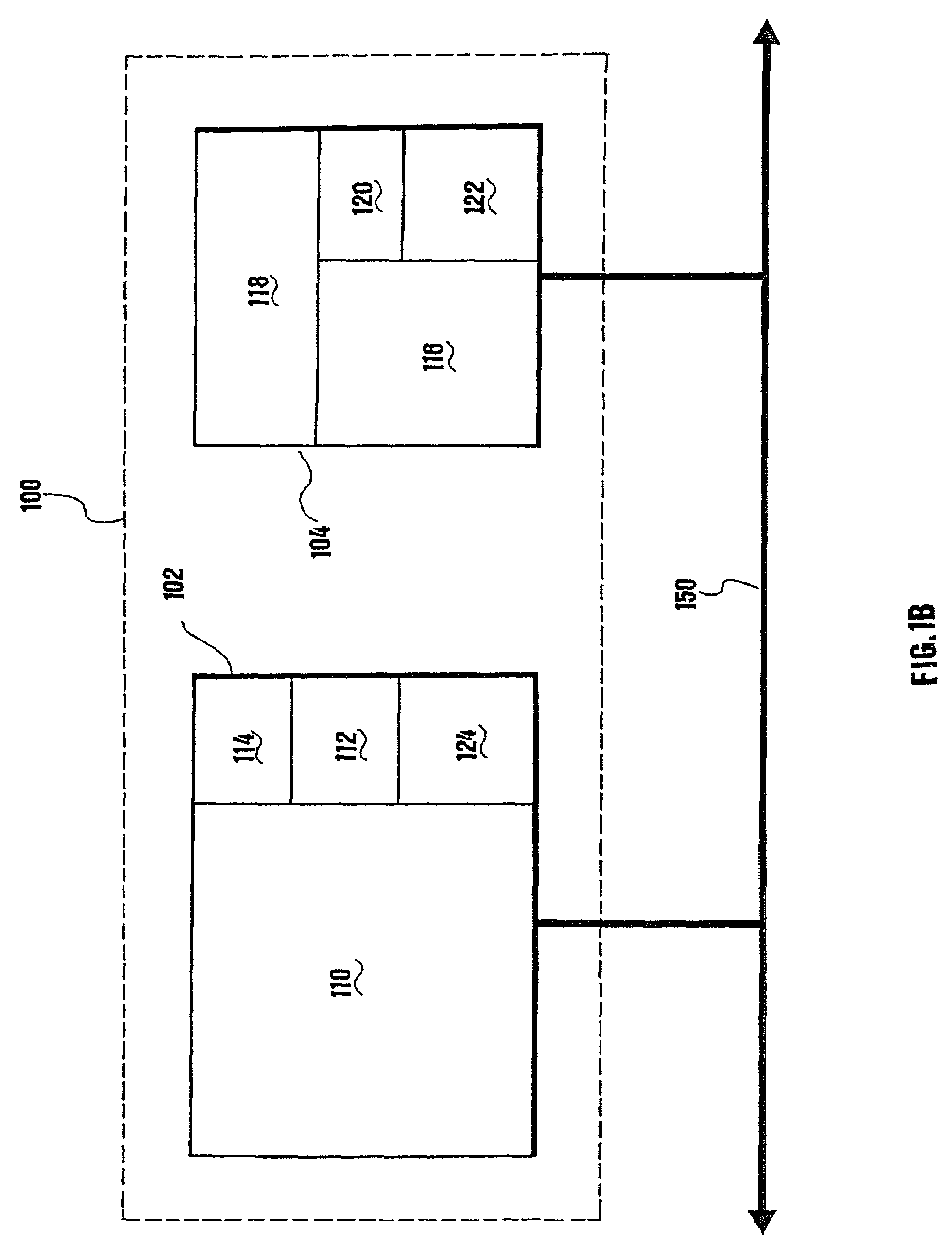

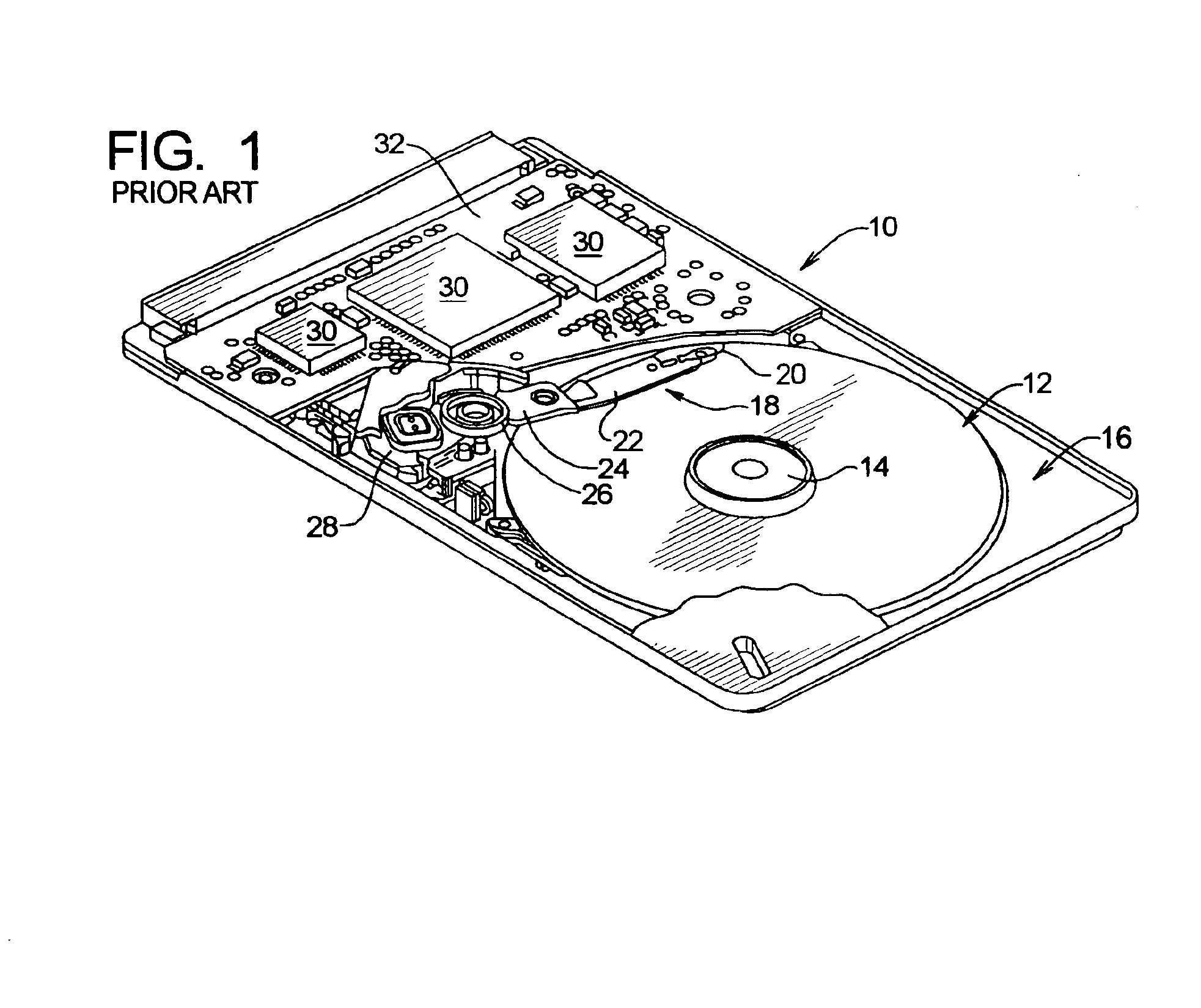

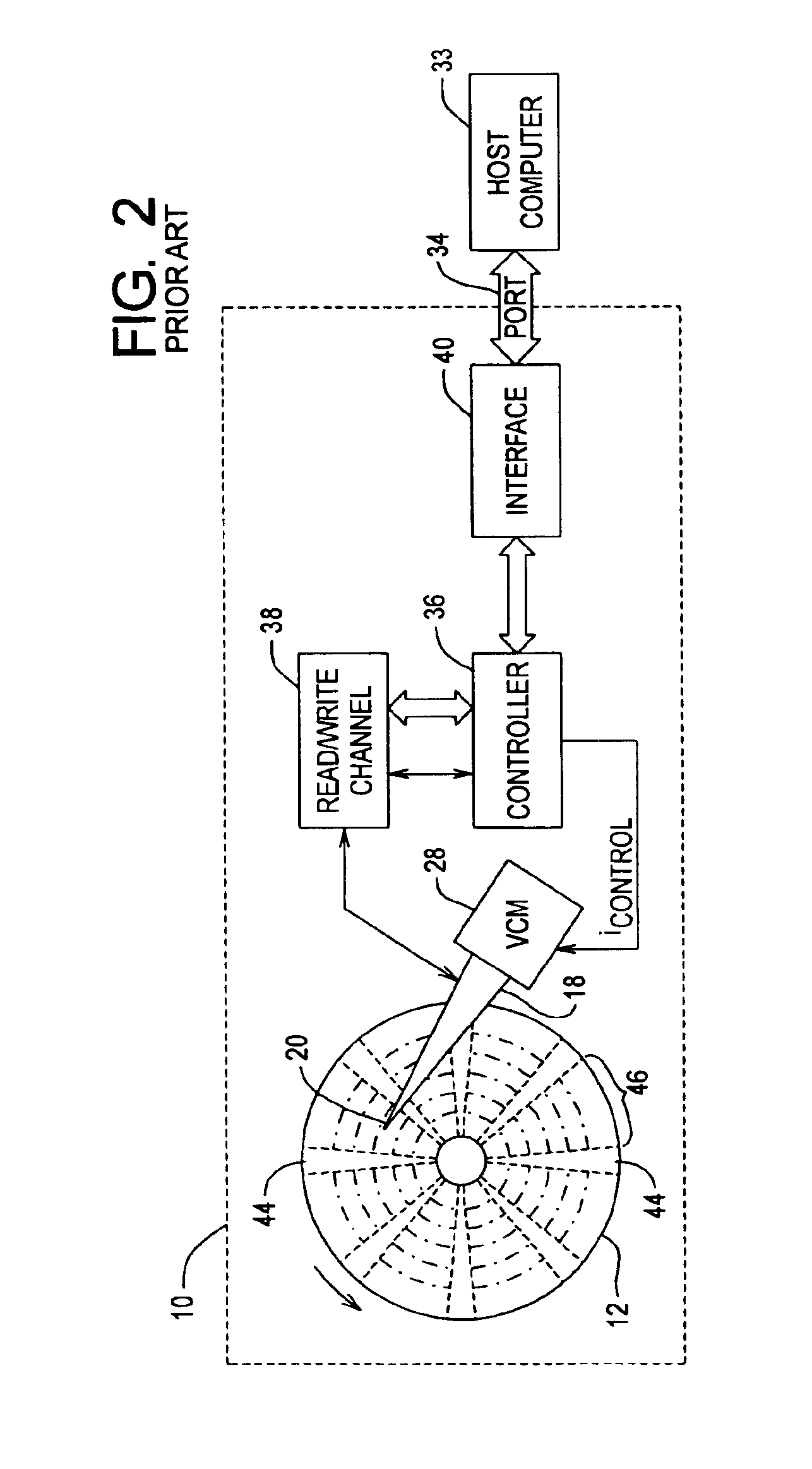

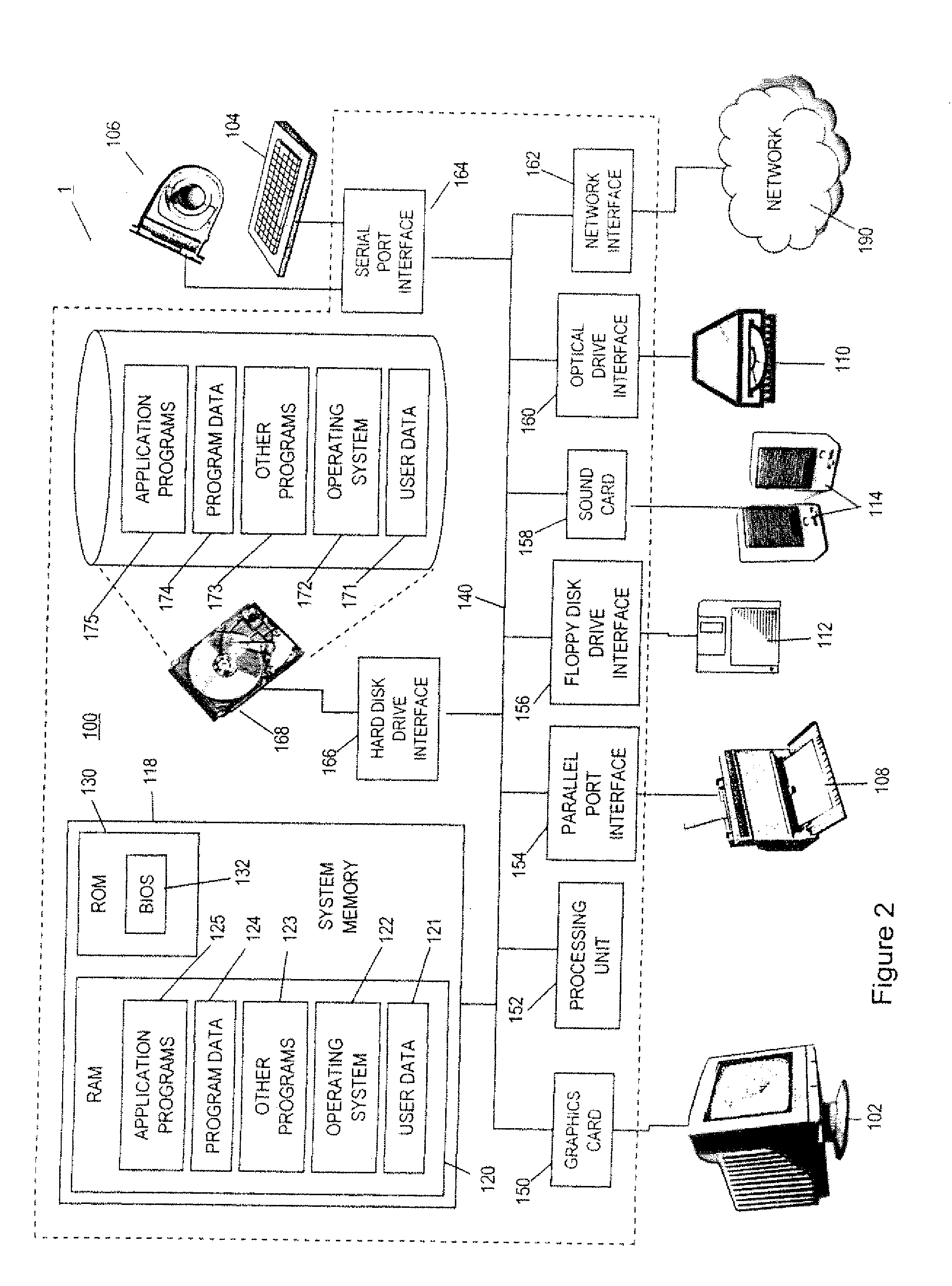

[virtual IDE storage device with PCI express]

ActiveUS20060206653A1Memory systemsInput/output processes for data processingMicrocontrollerPCI Express

The present invention discloses a virtual integrated drive electronics (IDE) storage device with a peripheral component interconnect (PCI) Express. The storage device includes a microcontroller connected to a PCI Express connecting interface and a flash memory separately. The microcontroller includes a flash memory interface, a PCI Express interface and a virtual IDE module. The virtual IDE module includes an IDE host and an IDE device. When the host sends an instruction for storing or reading data to a flash memory, the instruction will be sent to and executed in the virtual IDE module. The data in the flash memory can be transmitted at a transmission rate up to the standard of an IDE device, and the host will consider the storage device as an IDE device instead of a PCI Express device only.

Owner:PHISON ELECTRONICS

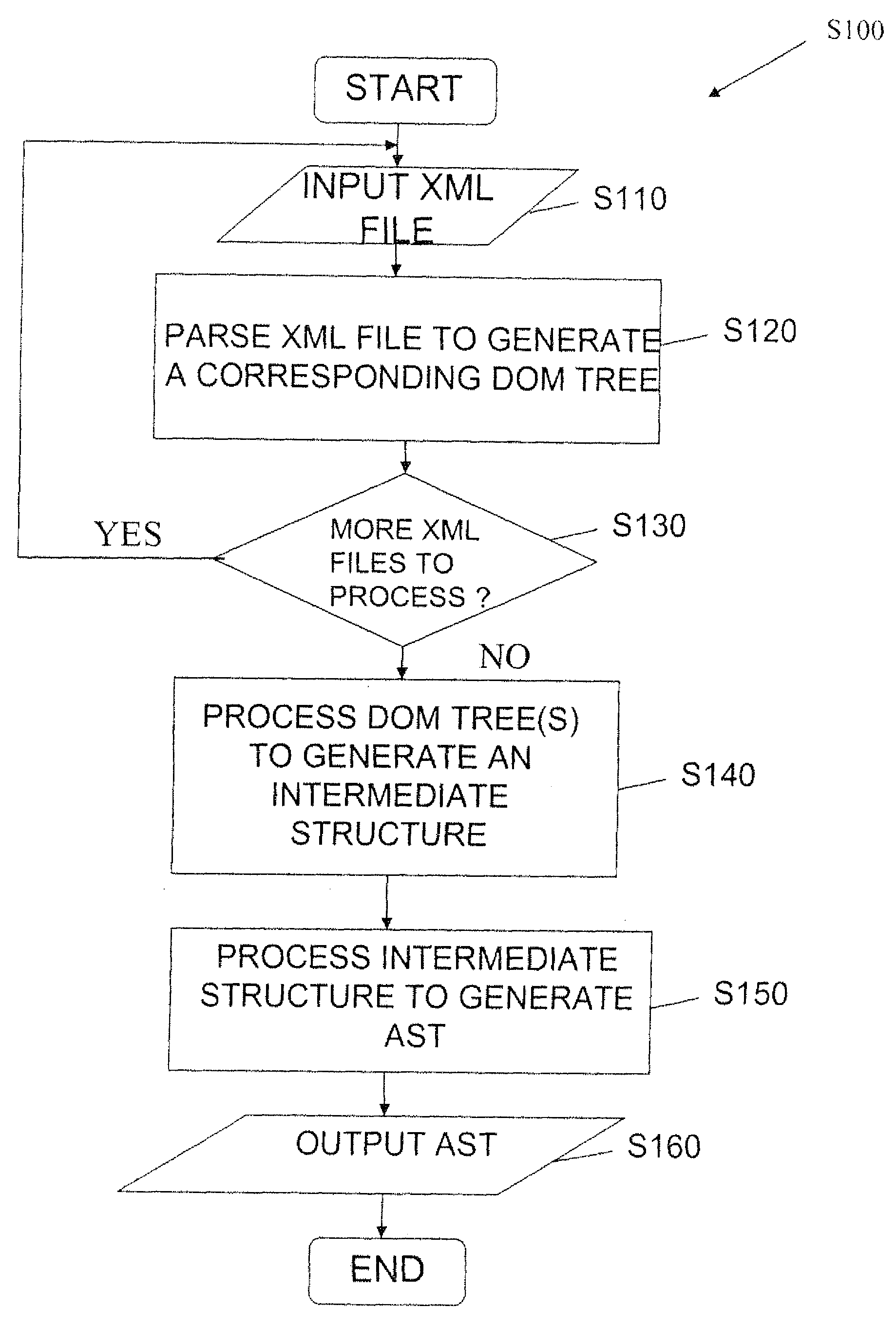

Method and apparatus for generating an integrated view of multiple databases

ActiveUS20100192057A1Easy to useEfficient processingNatural language data processingSemi-structured data retrievalDisplay deviceIntermediate structure

A computer system 1 is operable to receive a plurality of XML (or other marked-up) documents associated with heterogeneous databases 20, 30 and to process these to generate a virtual integrated view presenting a seemingly merged view of the database structures. The computer system includes an input interface for receiving a plurality of marked-up documents, a document object model generation module operable to generate a tree-structured document object model of each marked-up document; an intermediate structure generation module operable to traverse each document object model to generate an intermediate structure comprising a list of lists of elements and sub-elements; a syntax tree generation module for generating a syntax tree representation of the intermediate structure; and a virtual integrated view module operable to generate a view of the syntax tree representation which may be conveniently displayed to the user on a graphical display, wherein by providing the system with a plurality of marked-up documents reflecting the structures of a plurality of databases, the virtual integrated view module is operable to provide a virtual integrated view of the plurality of databases.

Owner:BRITISH TELECOMM PLC

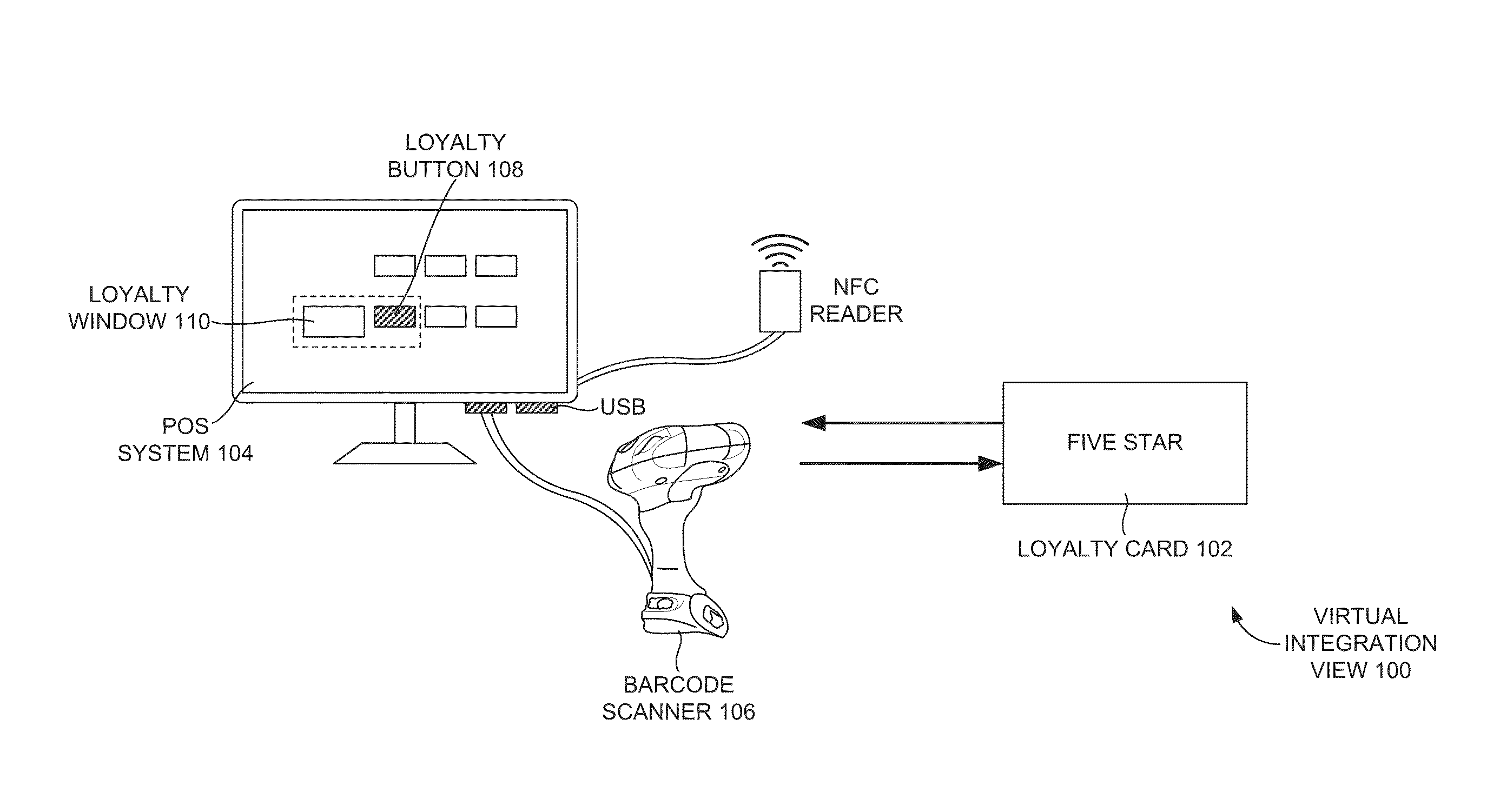

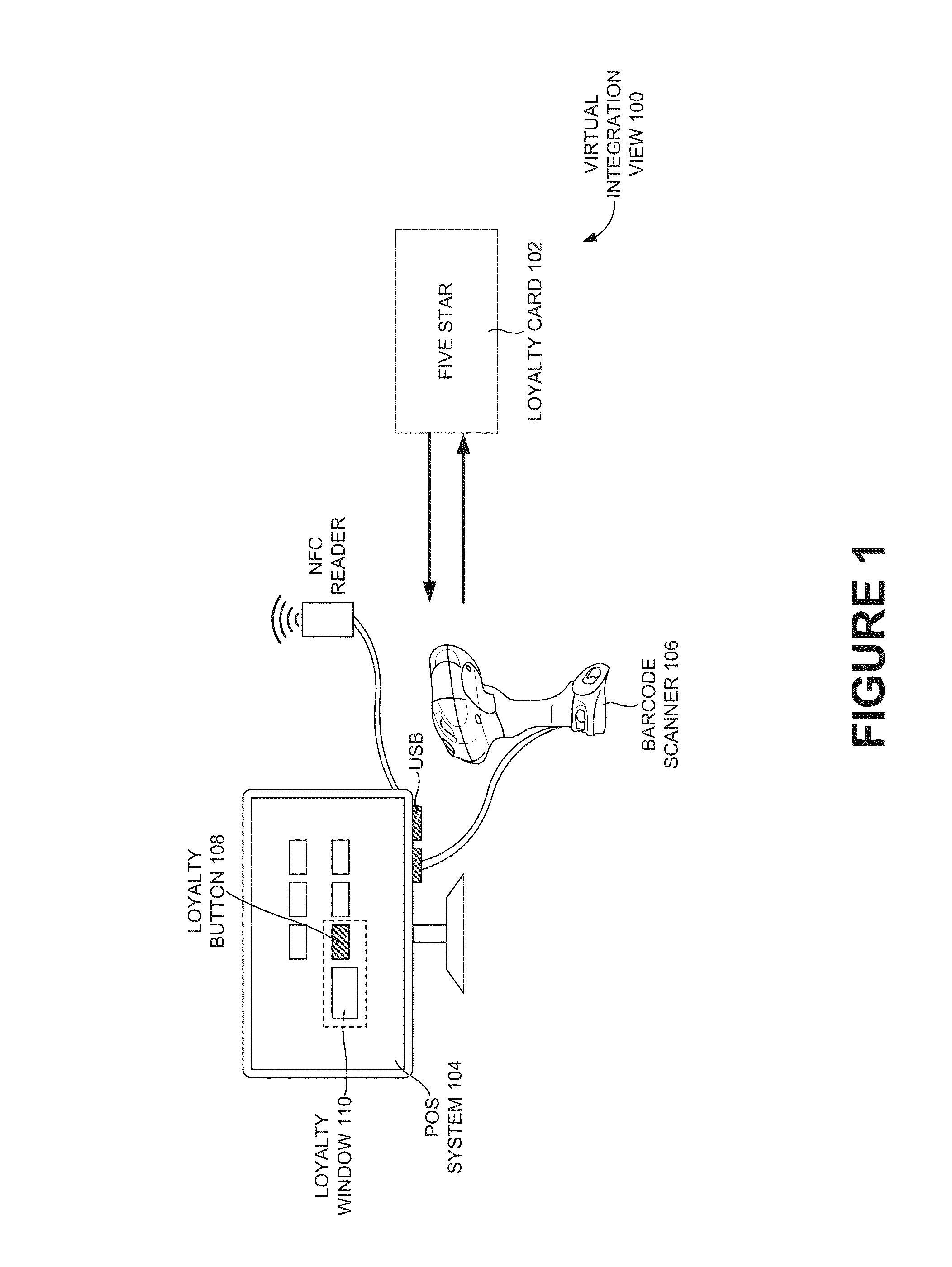

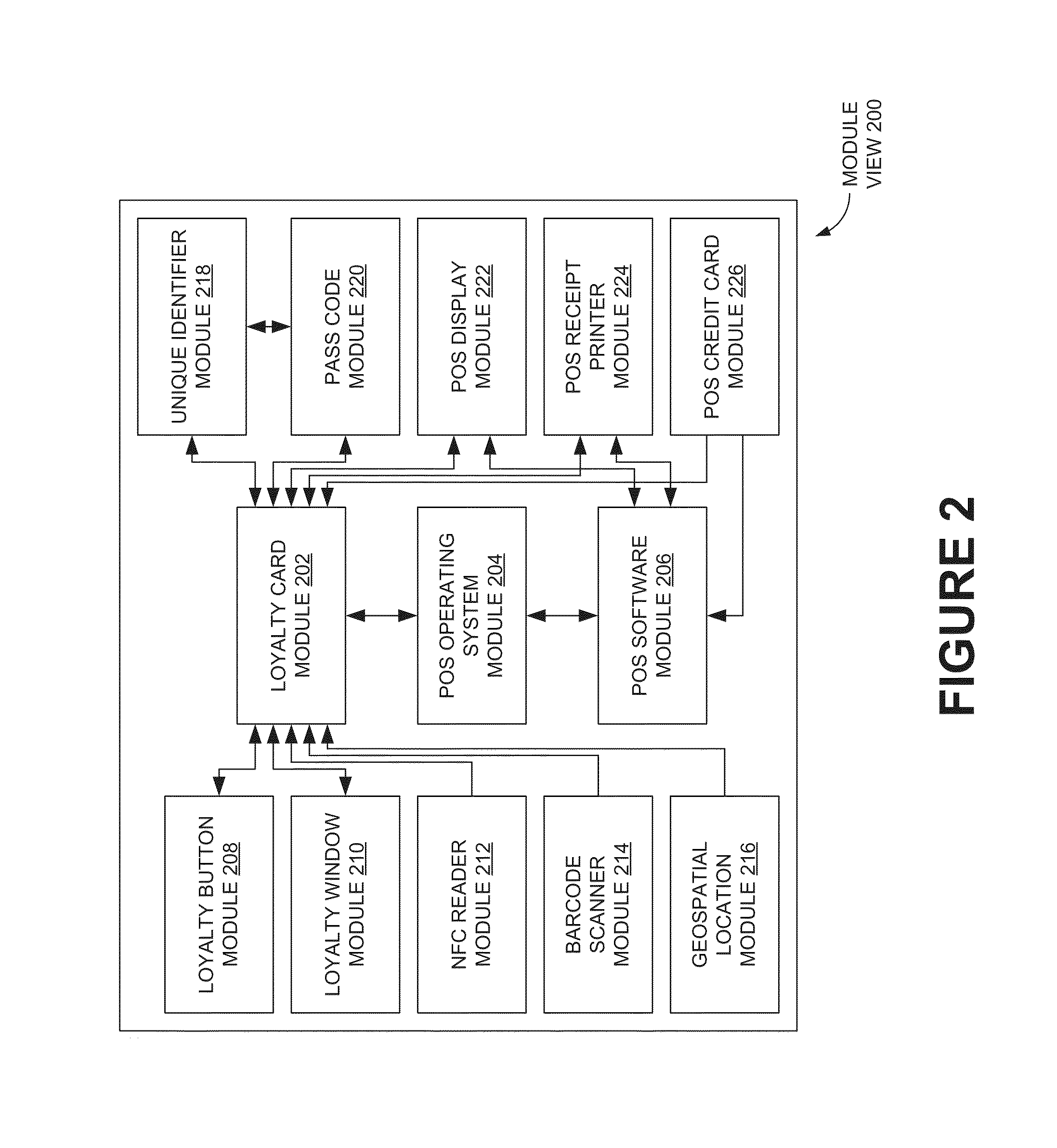

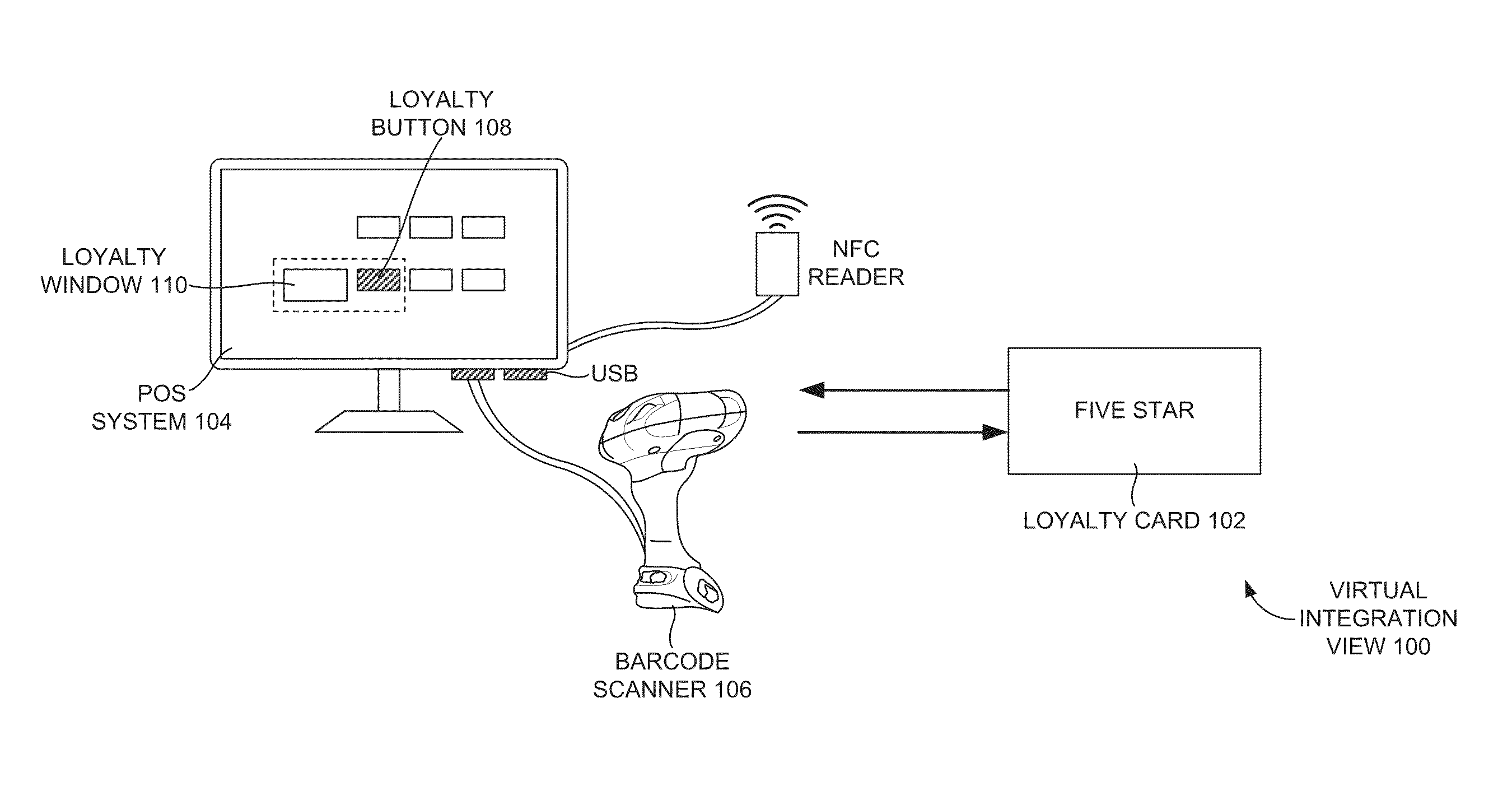

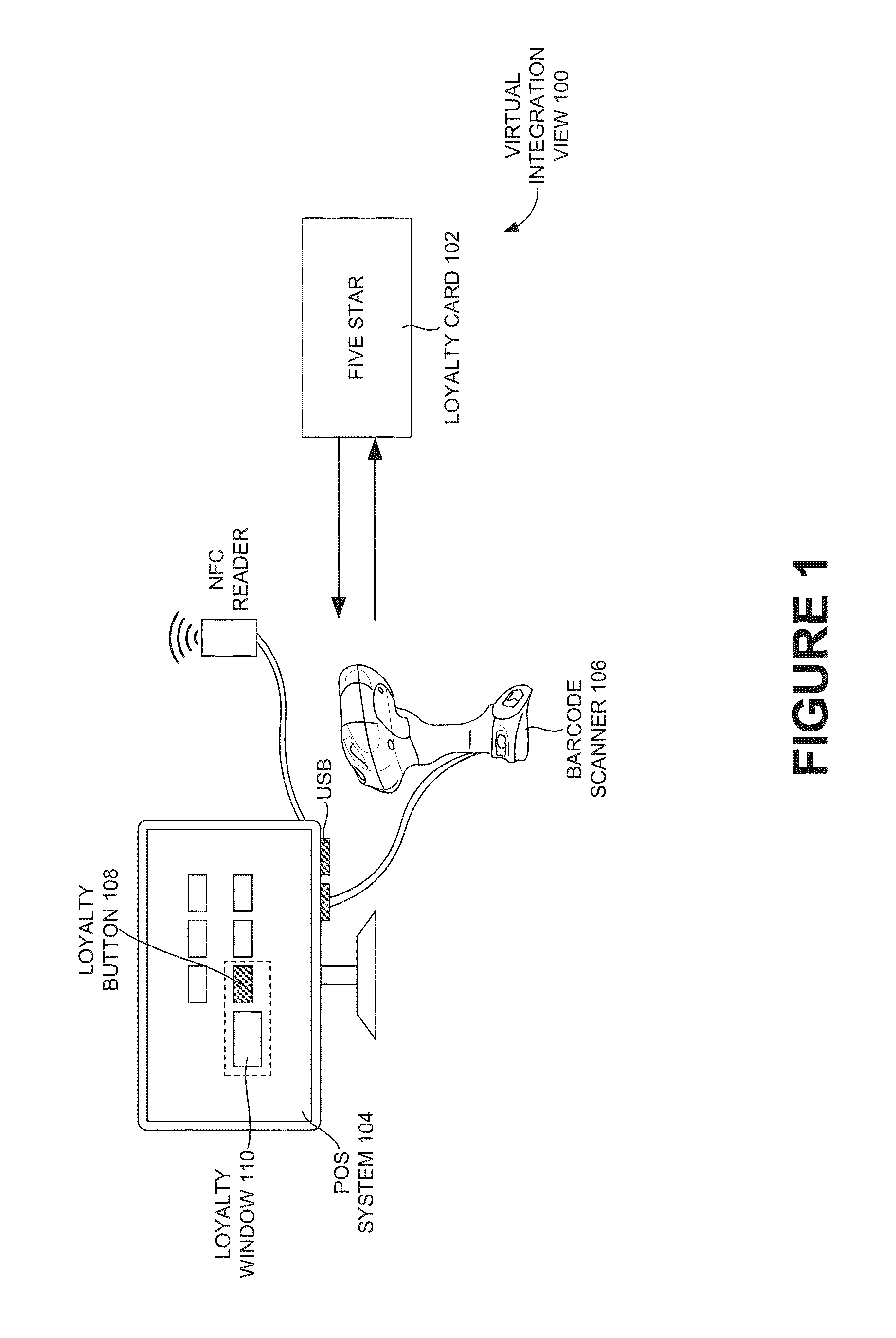

Virtual integration of a loyalty card with a point of sale system

Methods and supporting systems for administering a loyalty card program include an application residing on a plurality of heterogeneous point-of-sale devices that captures consumer transaction data, wherein the consumer transaction data include the identification of a loyalty card, While the loyalty card is uniquely attributed to an individual consumer, the card may be used to conduct transactions unrelated retail entities, each having its own respective loyalty program, such that values for the individual loyalty programs may be maintained.

Owner:FIVE STARS LOYALTY

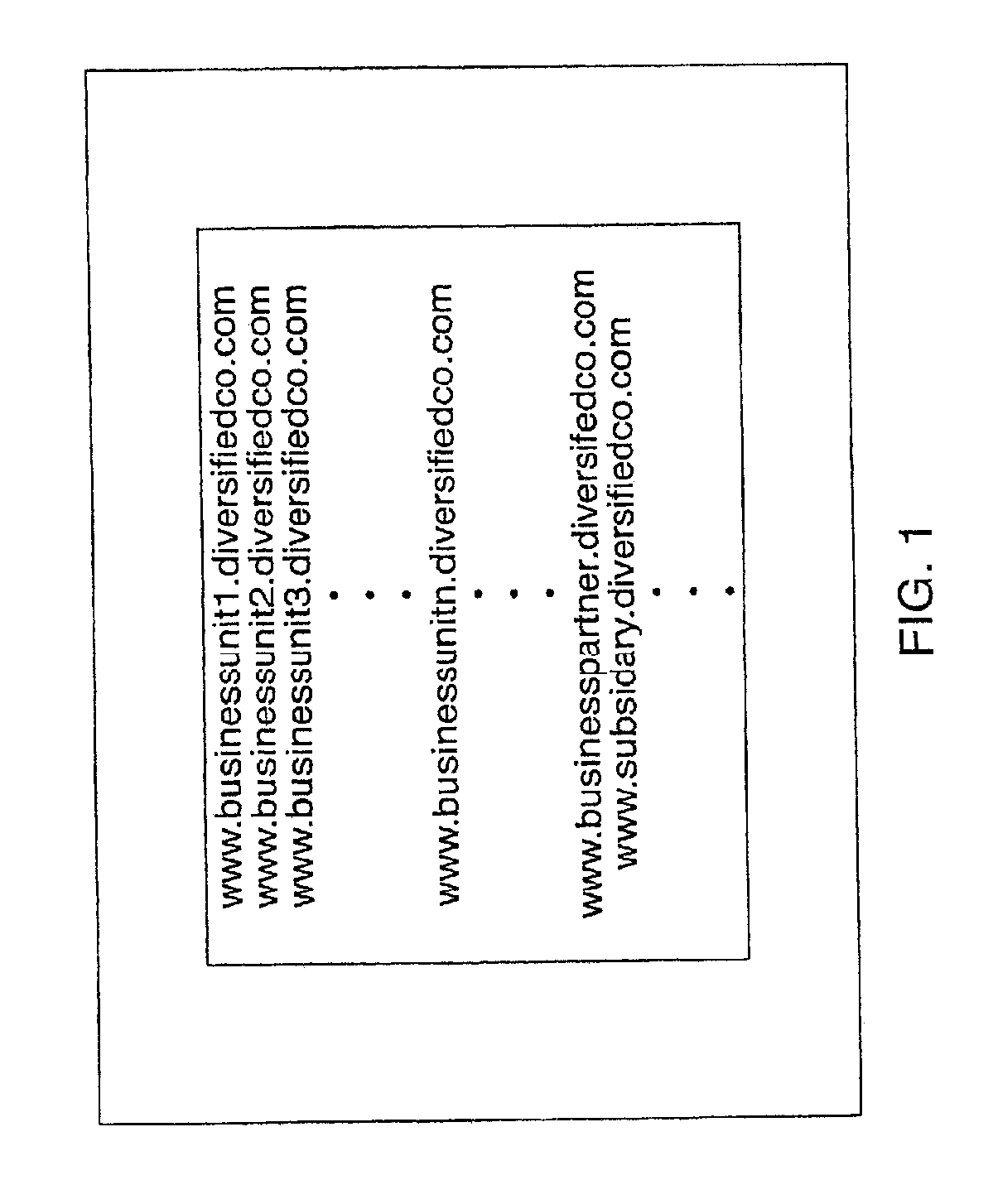

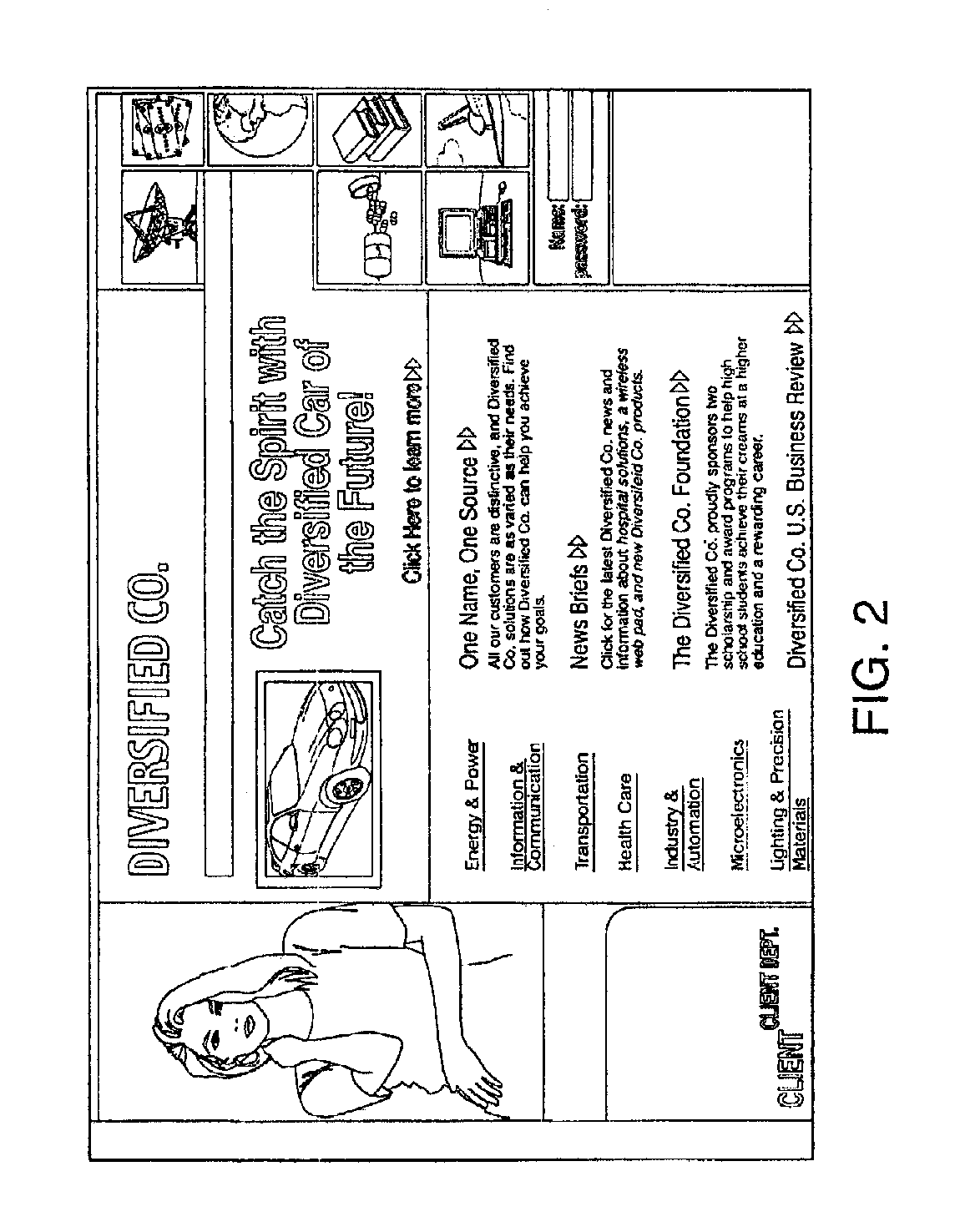

Virtual business restructuring methods

InactiveUS20070129963A1Breadth and strengthNimbleness and flexibilityBuying/selling/leasing transactionsVirtual businessBusiness enterprise

Virtual restructuring methods according to the present invention provide a mechanism for a diversified company or a joint business enterprise encompassing a plurality of business units having a degree of autonomy over their business operations, and having their own business methods and legacy information systems, to nevertheless reach customers as a virtual intergraded entity, through a common portal and a single user interface.

Owner:SIEMENS AG

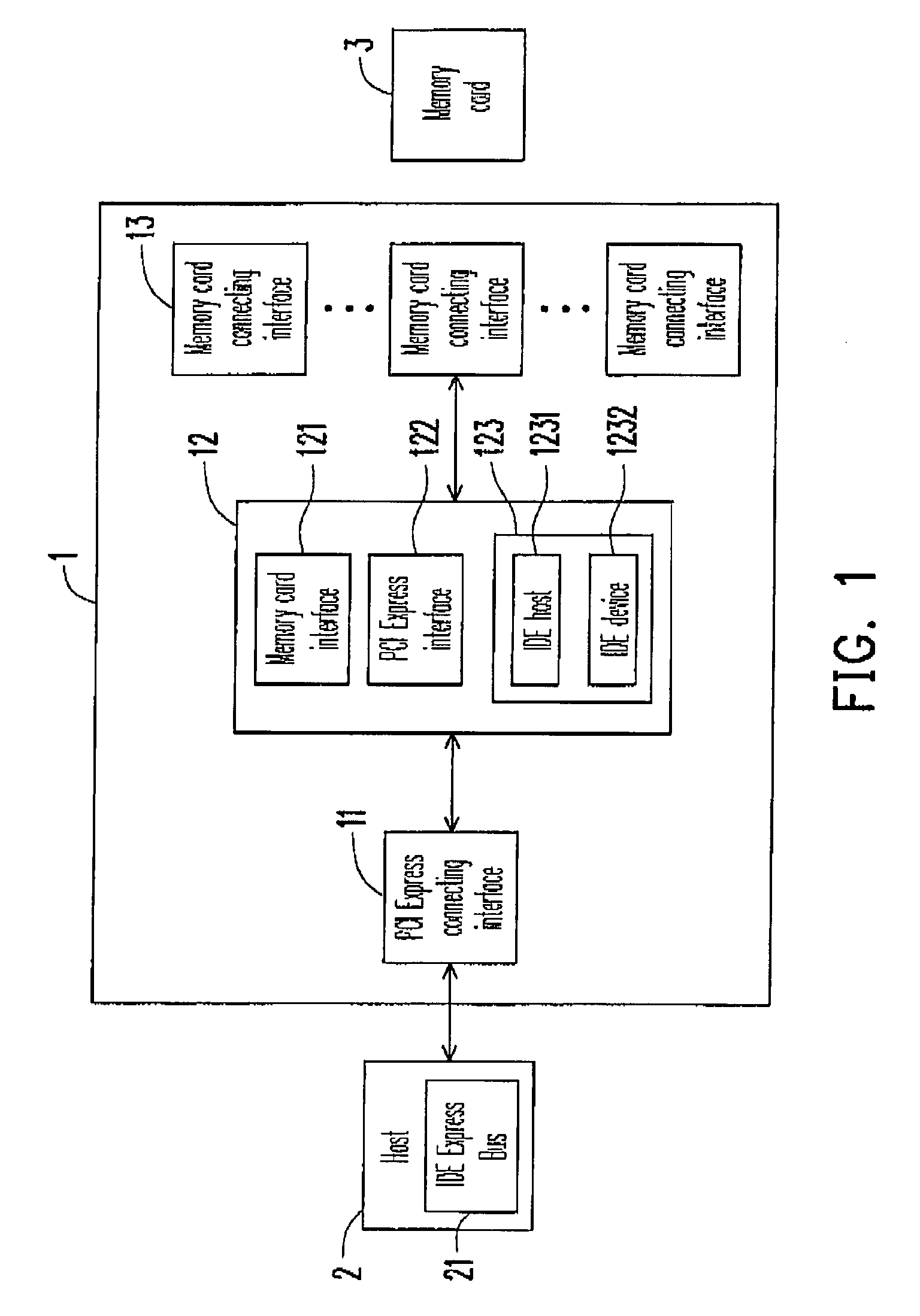

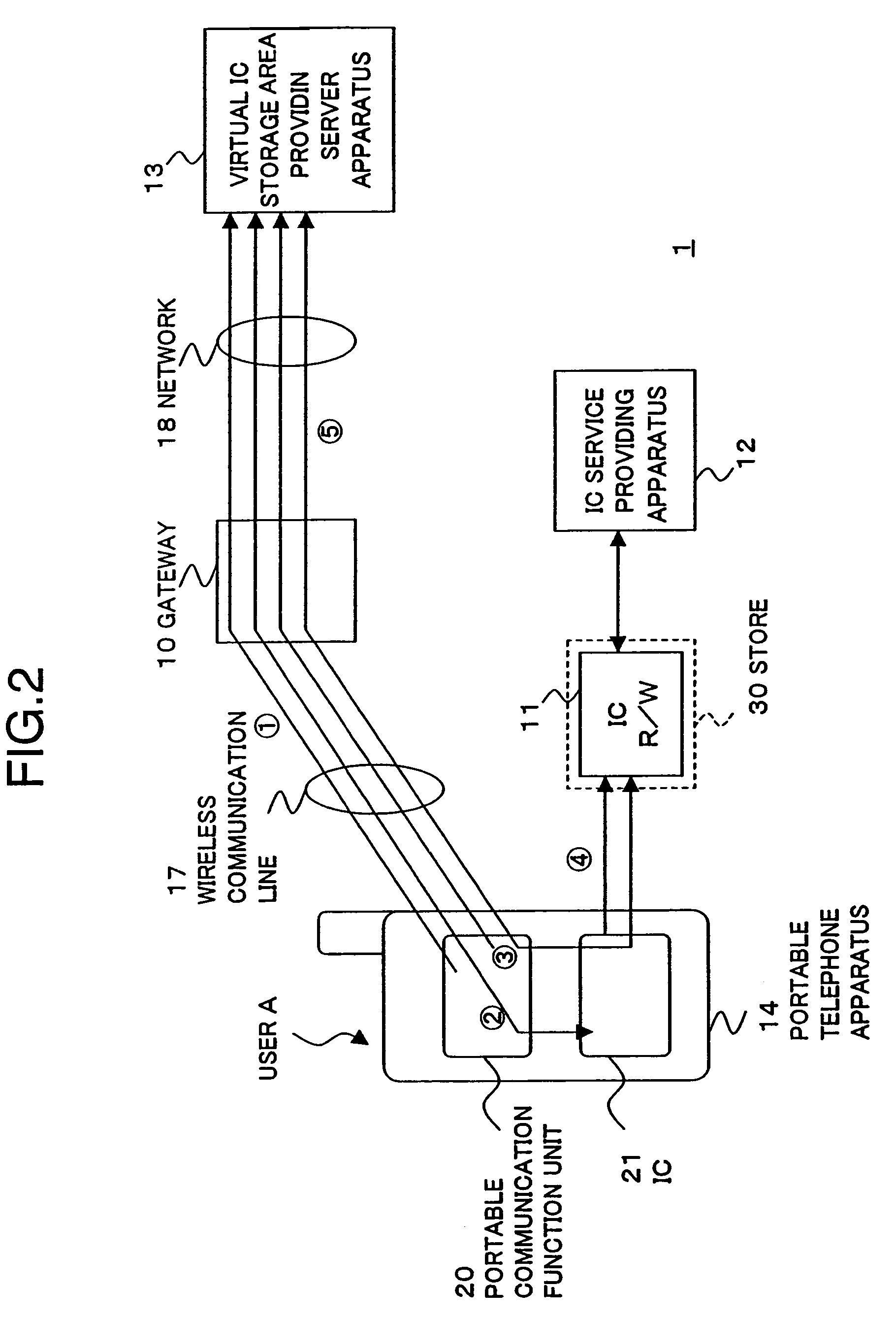

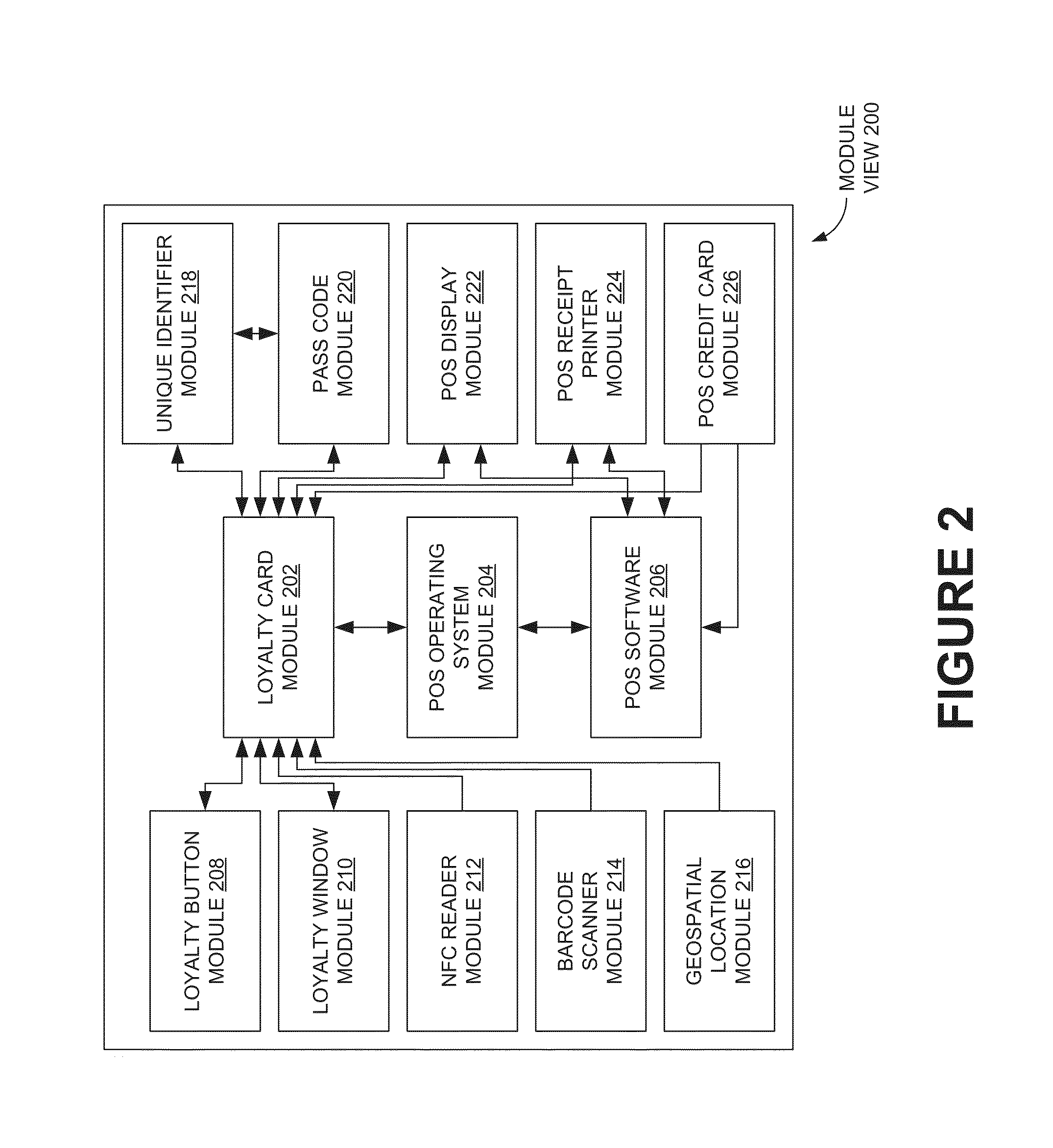

[virtual IDE card reader with PCI express]

The present invention discloses a virtual integrated drive electronics (IDE) card reader with a peripheral component interconnect express (PCI Express). The card reader includes a microcontroller connected to a PCI Express connecting interface and a memory card connecting interface separately. The microcontroller includes a memory card interface, a PCI Express interface, and a virtual IDE module. The virtual IDE module includes a IDE host and a IDE device. If the host sends an instruction for storing or reading data to a memory card connected to the card reader, the instruction will be sent to and executed in the virtual IDE module. The data in the memory card can be transmitted at a transmission rate up to the standard of an IDE device, and the host will consider the card reader as an IDE device instead of a PCI Express device only.

Owner:PHISON ELECTRONICS

Methods, apparatuses and systems facilitating seamless, virtual integration of online membership models and services

ActiveUS8359393B2Efficient collaborationEasy to integrateMultiple digital computer combinationsTransmissionVirtual integrationDatabase

Owner:TRANSUNION INTERACTIVE

Virtual integration of a loyalty card with a point of sale system

Methods and supporting systems for administering a loyalty card program include an application residing on a plurality of heterogeneous point-of-sale devices that captures consumer transaction data, wherein the consumer transaction data include the identification of a loyalty card, While the loyalty card is uniquely attributed to an individual consumer, the card may be used to conduct transactions unrelated retail entities, each having its own respective loyalty program, such that values for the individual loyalty programs may be maintained.

Owner:FIVE STARS LOYALTY

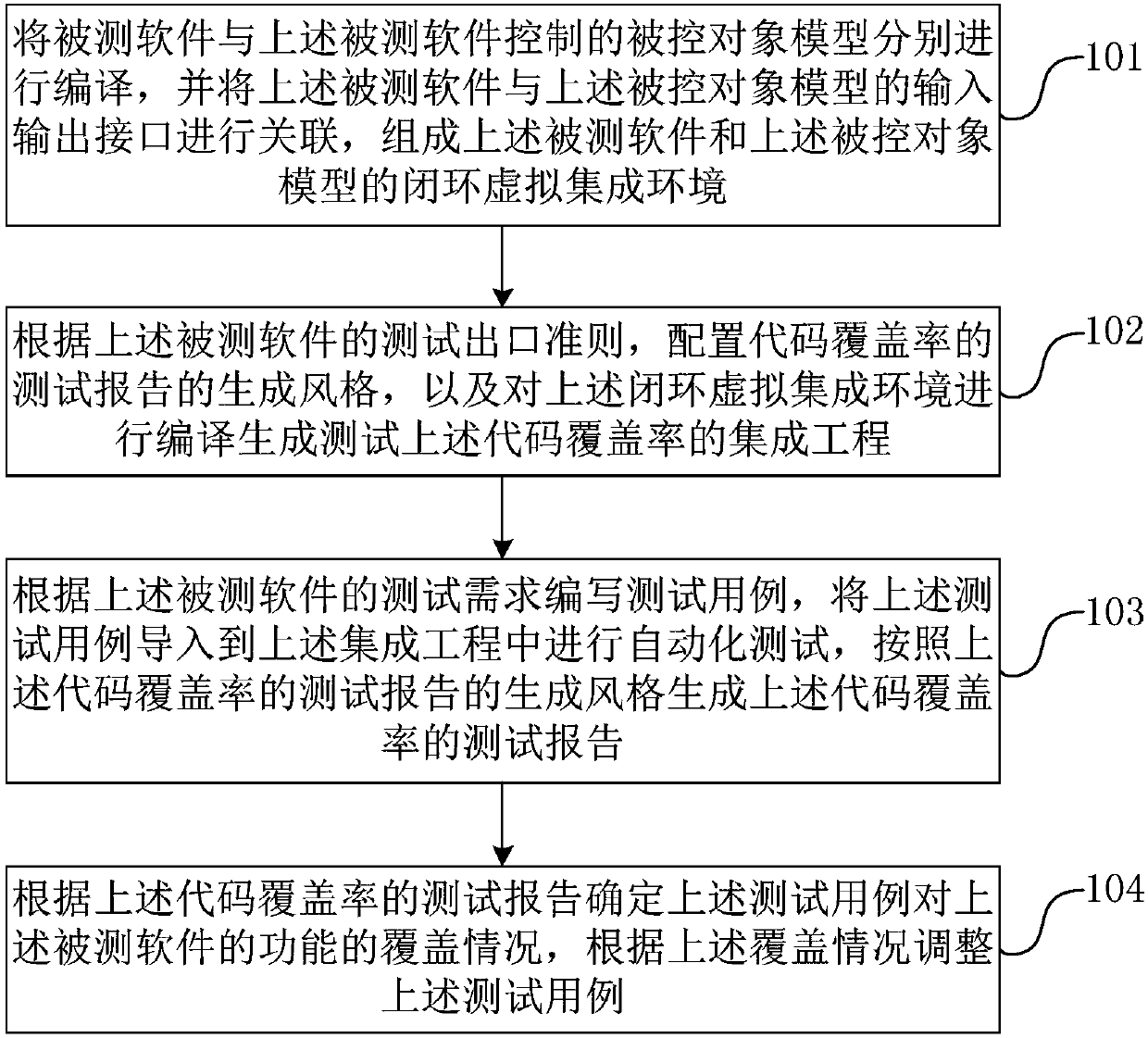

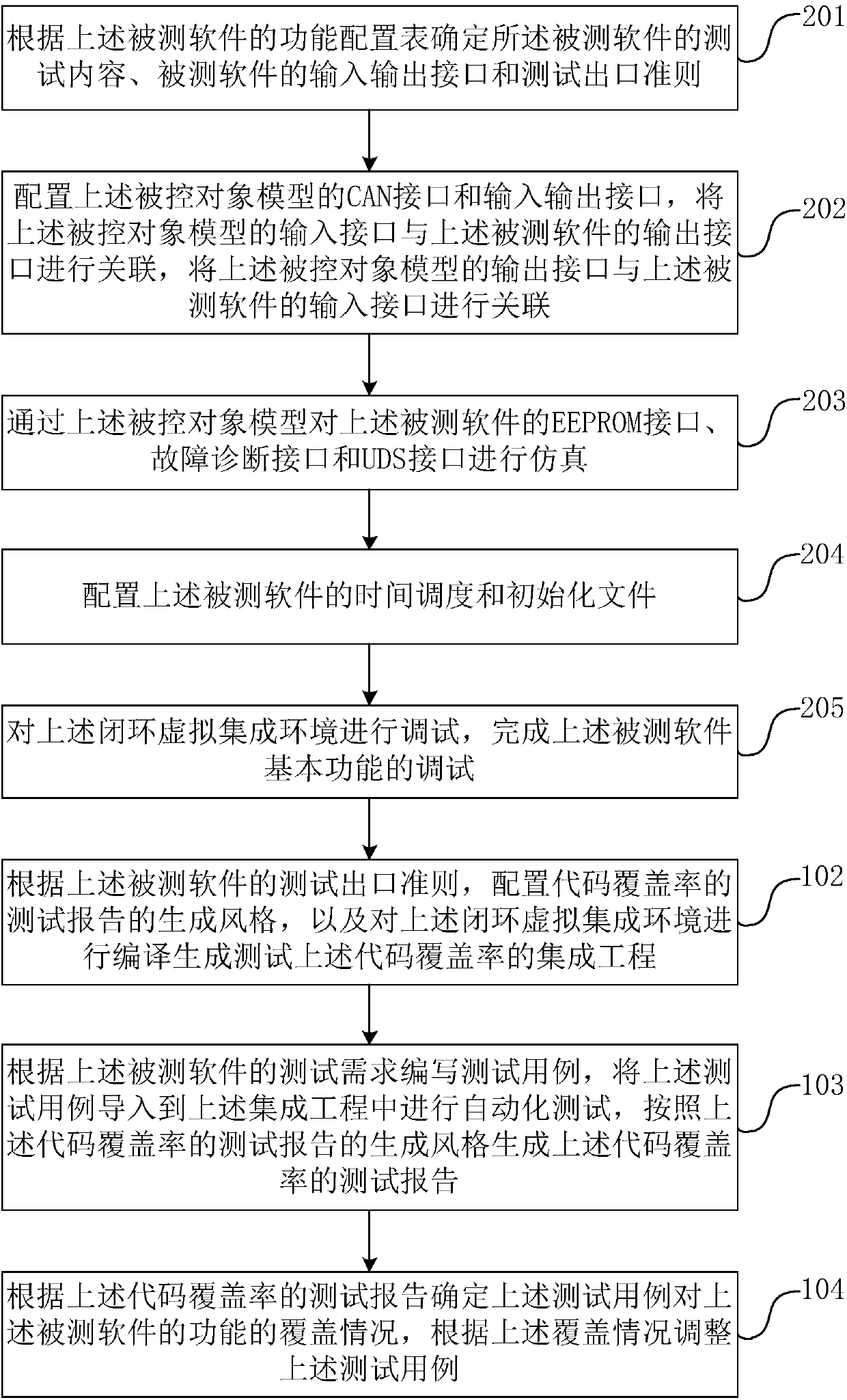

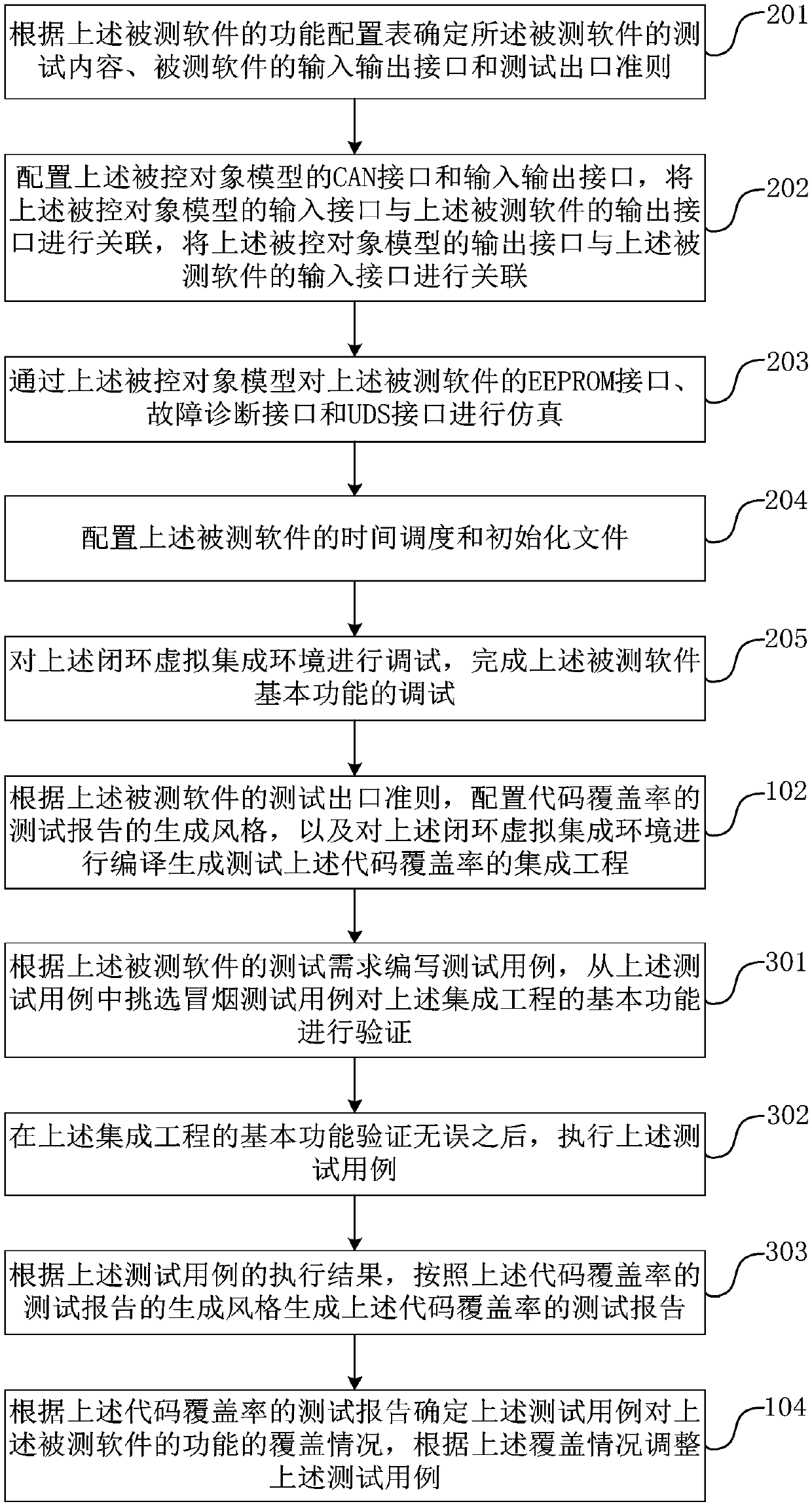

Code coverage rate test method and device and computer equipment

The invention discloses a code coverage rate test method and device and computer equipment. The code coverage rate test method comprises the following steps of: respectively compiling tested softwareand a controlled object model controlled by the tested software so as to form a closed-coop virtual integrated environment of the tested software and the controlled object model; compiling the closed-loop virtual integrated environment to generate an integrated project for testing a code coverage rate; importing a test case into the integrated project to carry out automatic test, and generating atest report of the code coverage rate according to a generation style of the test report of the code coverage rate; and determining a coverage condition, for functions of the tested software, of the test case according to the test report of the code coverage rate, and adjusting the test case according to the coverage condition. According to the method and device and the computer equipment, code coverage rates of tested software can be tested, help is provided for completing and supplementing test cases and the test quality is rapidly enhanced.

Owner:BEIJING ELECTRIC VEHICLE

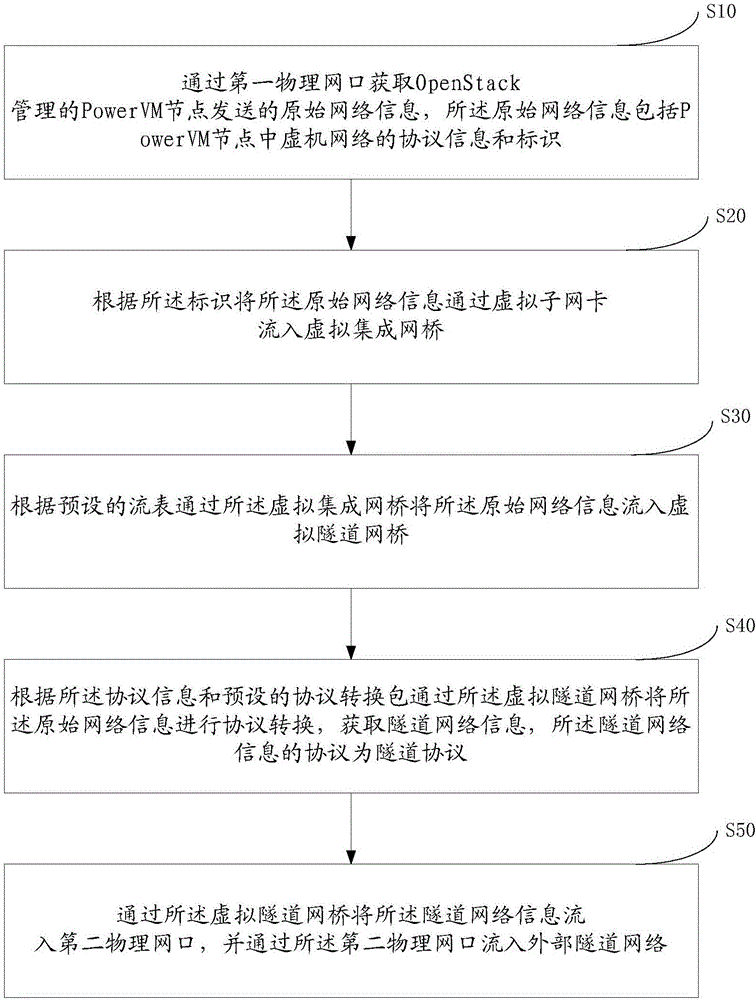

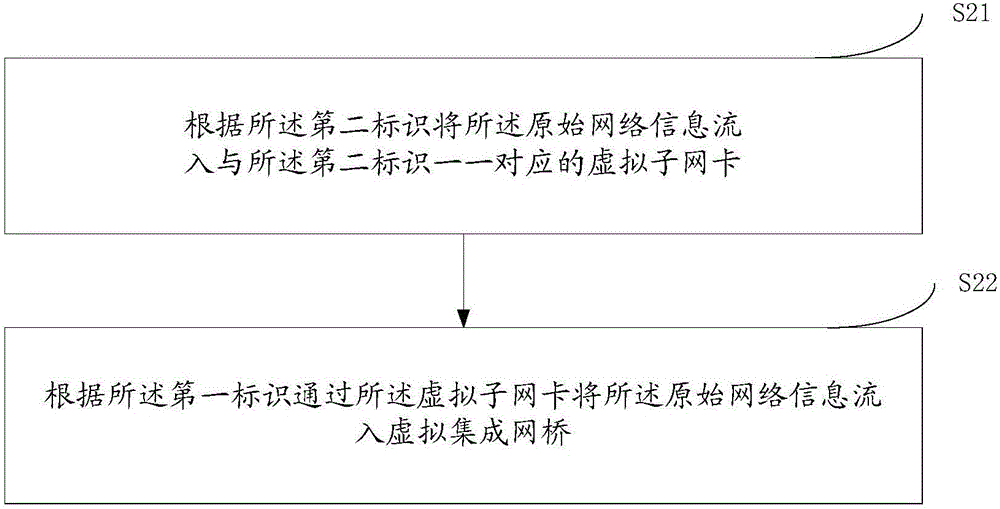

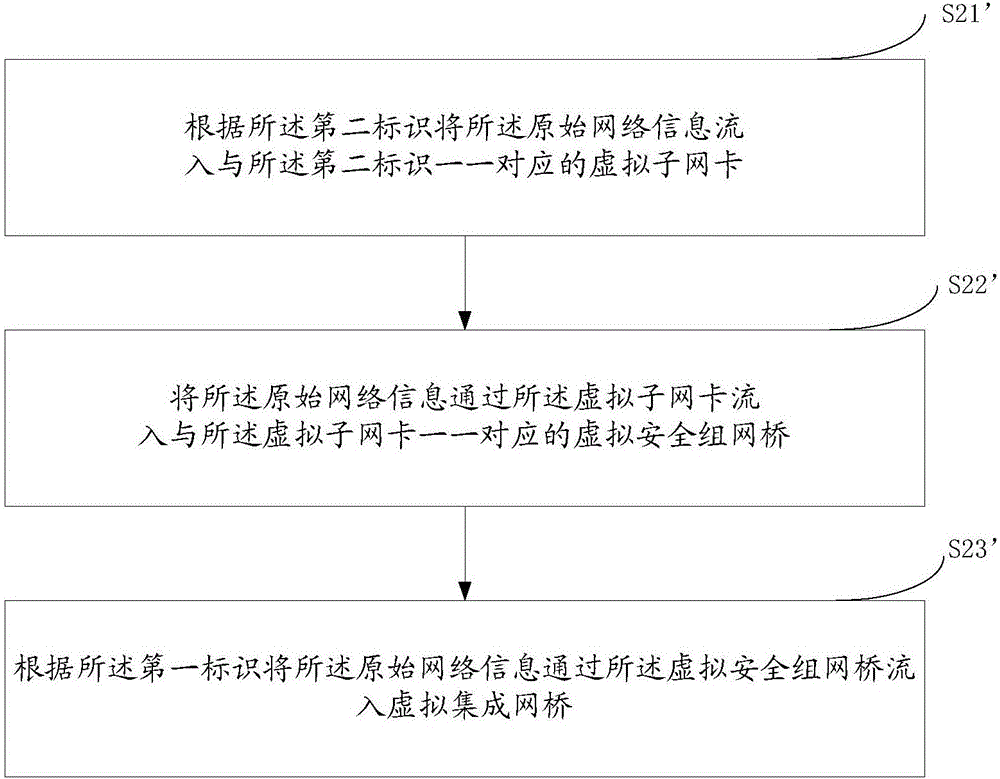

Power VM virtualized network management method and device based on Open Stack

The invention provides a Power VM virtualized network management method and device based on Open Stack. The method comprises the following steps: acquiring original network information transmitted from a Power VM node managed by Open Stack through a first physical internet access, wherein the original network information comprises protocol information and identification; enabling the original network information to flow into a virtual integrated network bridge through a virtual secondary network card according to the identification; enabling the original network information to flow into a virtual tunnel network bridge through the virtual integrated network bridge according to preset flow table; carrying out protocol conversion on the original network information according to the protocol information and a preset protocol conversion package, and acquiring tunnel network information, and the protocol of the tunnel network information is a tunnel protocol; and enabling the tunnel network information to flow into a second physical internet access through the virtual tunnel network bridge, and enabling the tunnel network information to flow into an external tunnel network through the second physical internet access. By a mode of deploying a virtual machine, flowing-in and protocol conversion of a Power VM network are finished, and Power VM virtualized network management based on Open Stack is finished.

Owner:BEIJING TEAMSUN TECH

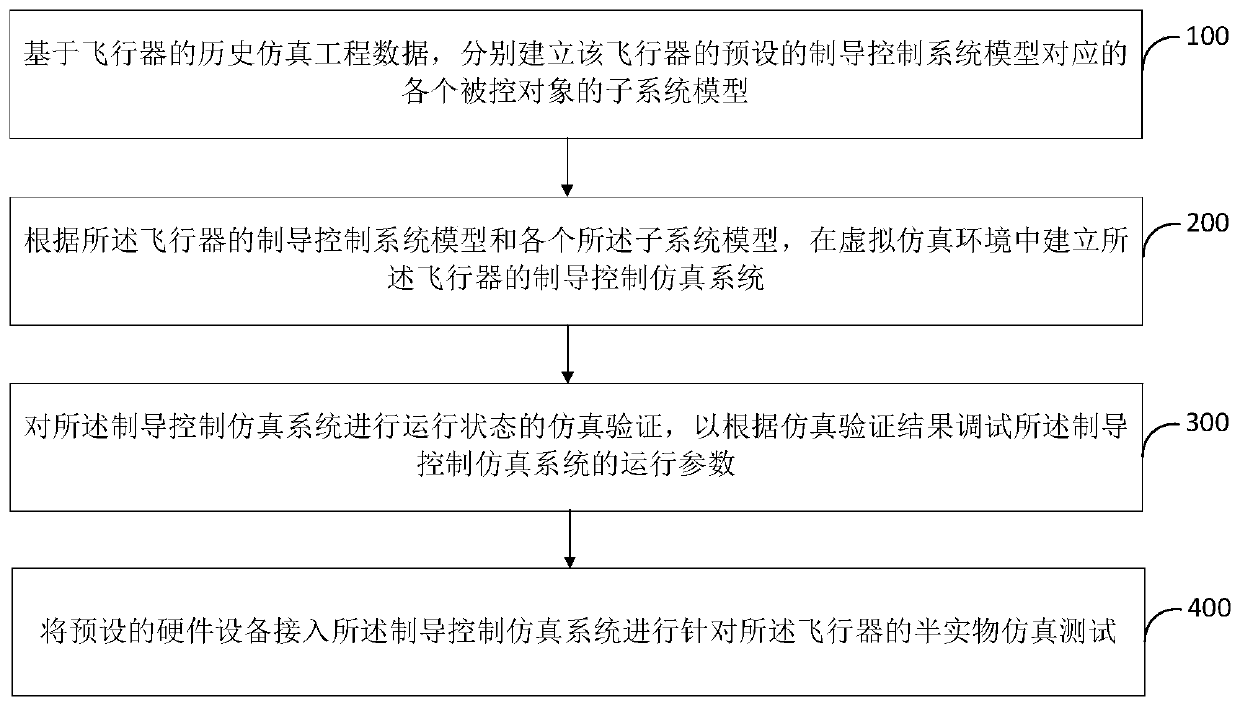

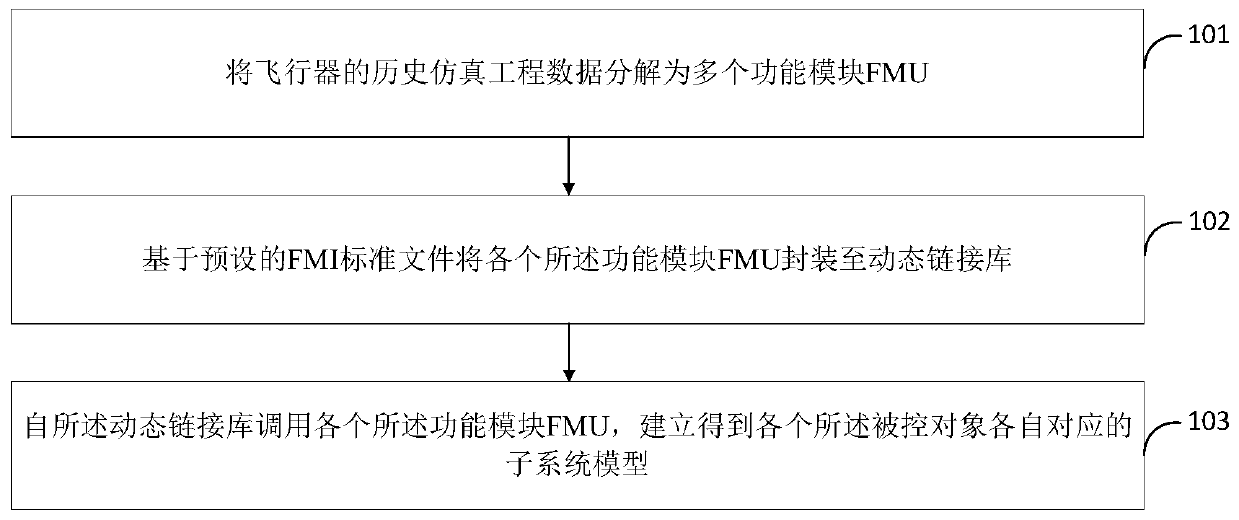

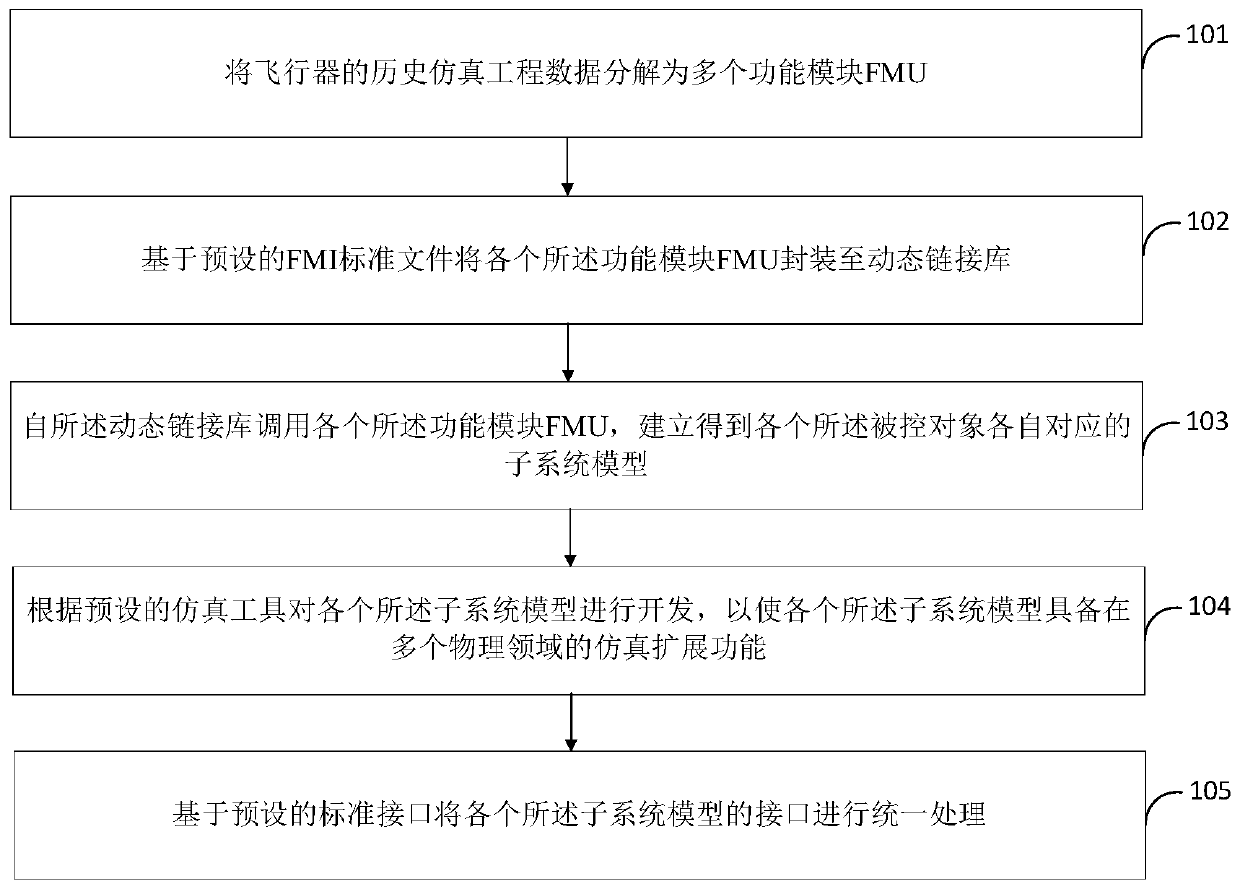

Aircraft guidance control simulation test method and device

ActiveCN111123889AImprove accuracyImprove reliabilityElectric testing/monitoringFlight vehicleGuidance control

Owner:BEIJING AEROSPACE TECH INST

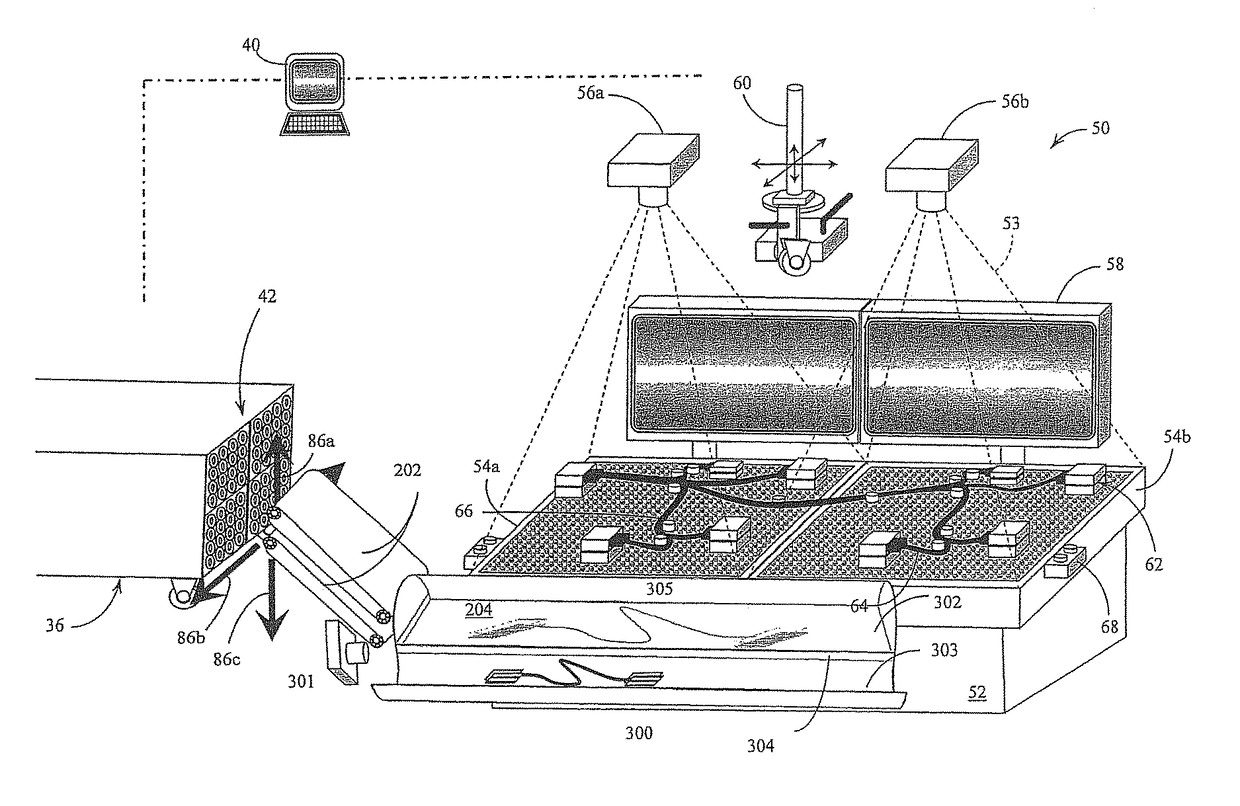

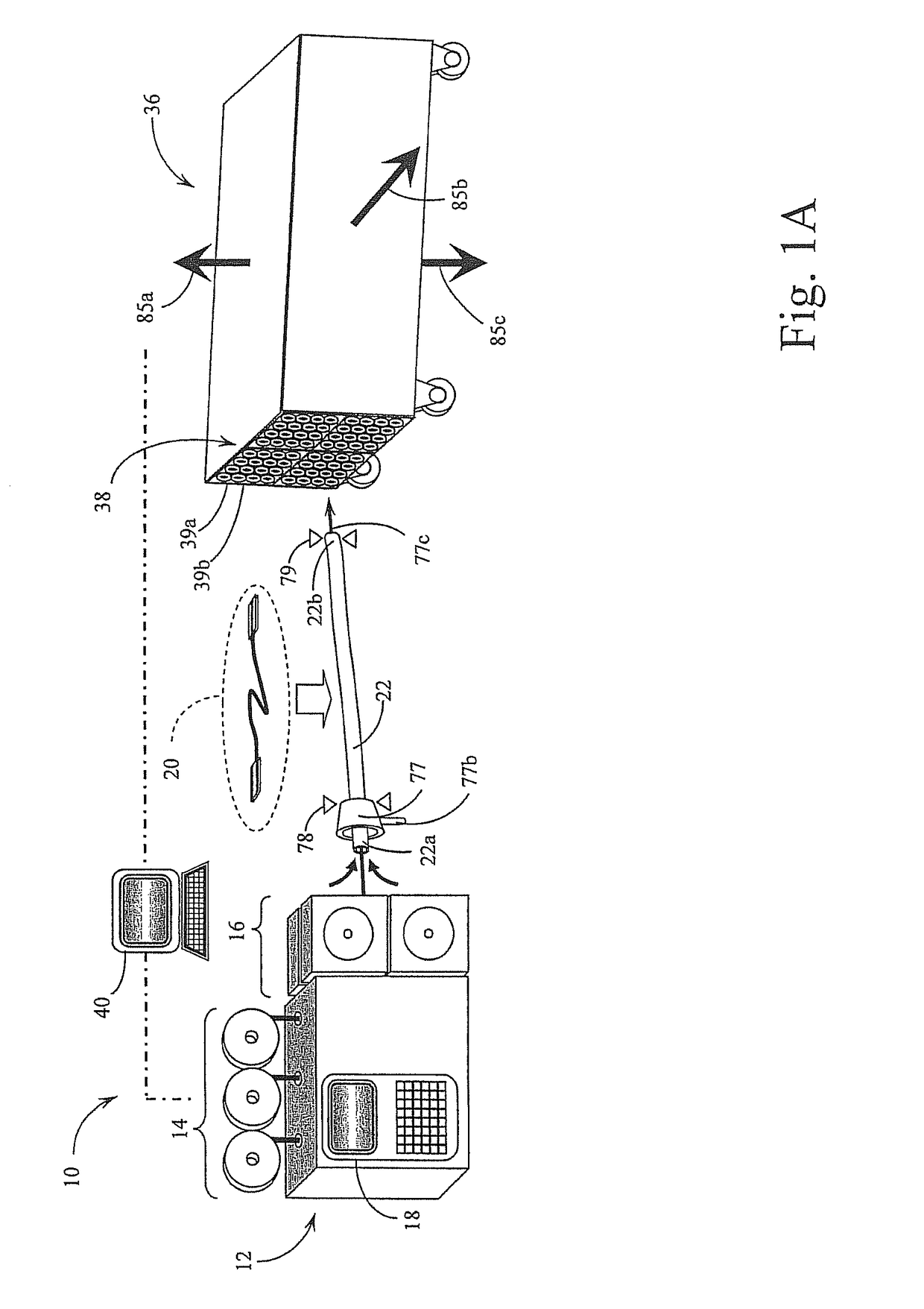

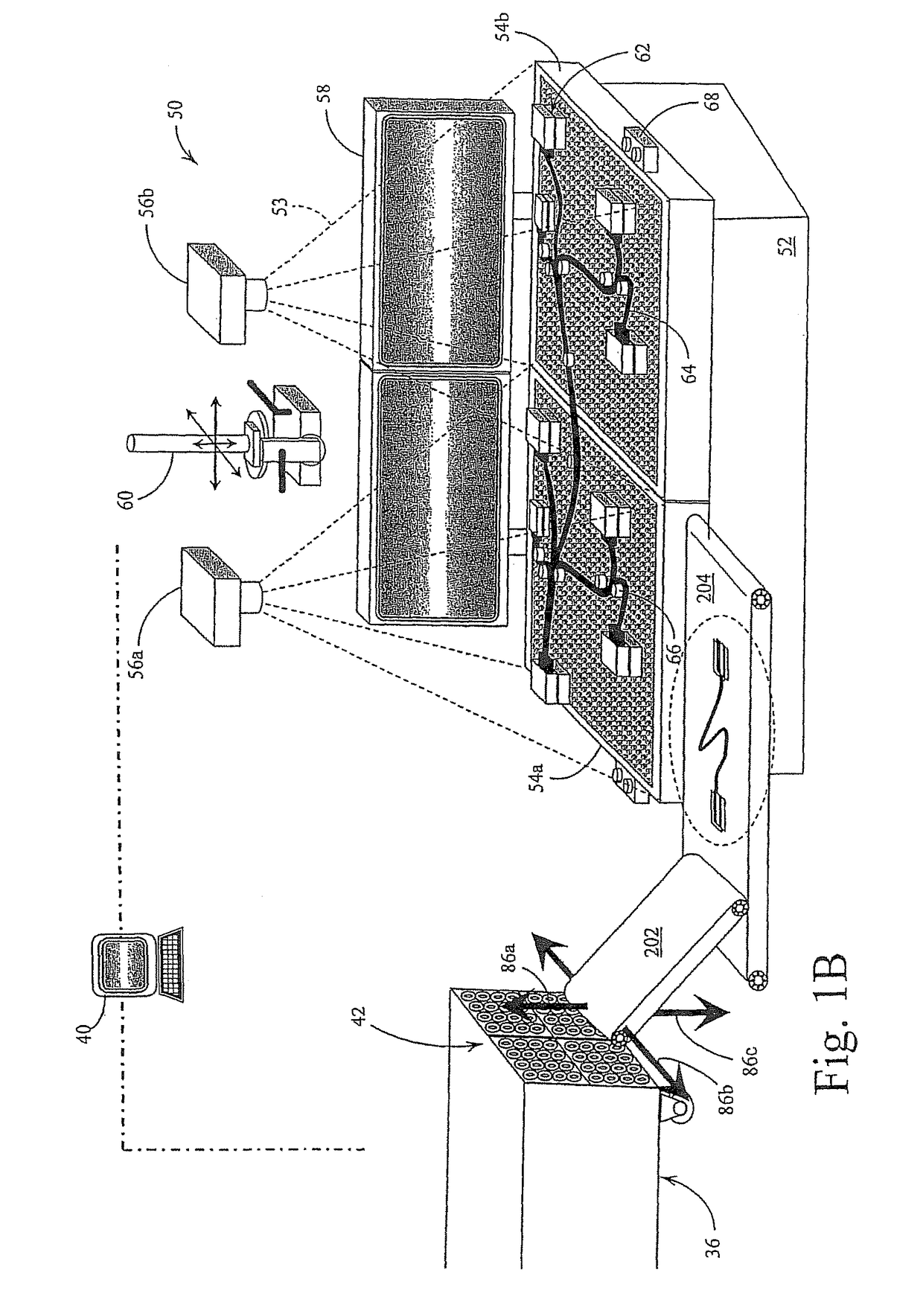

Integrated wire harness batch production with double buffer assembly systems

ActiveUS9721702B1Improve storage densityMaterial minimizationContact member assembly/disassemblyManufacturing wire harnessesVirtual integrationData management

Virtually-integrated wire harness design and automated production systems and methods that achieve completely integrated data management by automatically producing scripts to dynamically propagate production commands and data to various subsystems for handling assembling necessary circuits and wire harness layout boards to produce corresponding batches of wire harnesses while script-based methods control configuring, testing, and using wire harness layout boards, and assembling, testing, reworking, and delivering wire harnesses. As derived from CAD-created specifications, the production system uses a programmable, automated wire C&C center prepares individual wire circuits. While automatic wire indexing, sorting, and delivery systems transfer circuits into, and retrieve circuits from, a transportable programmable, automated, indexed storage system equipped with an array of individual circuit tubes, and a script-controlled assembly system sends visual, aural, and other cues to help an assembler populate and configure a wire harness layout board with connector blocks and turn posts, and guides the assembler in building, testing, reworking, and delivering the corresponding batch of wire harnesses.

Owner:AUTOMATED WIRING SYST

Virtual IDE card reader with PCI express interface

Owner:PHISON ELECTRONICS

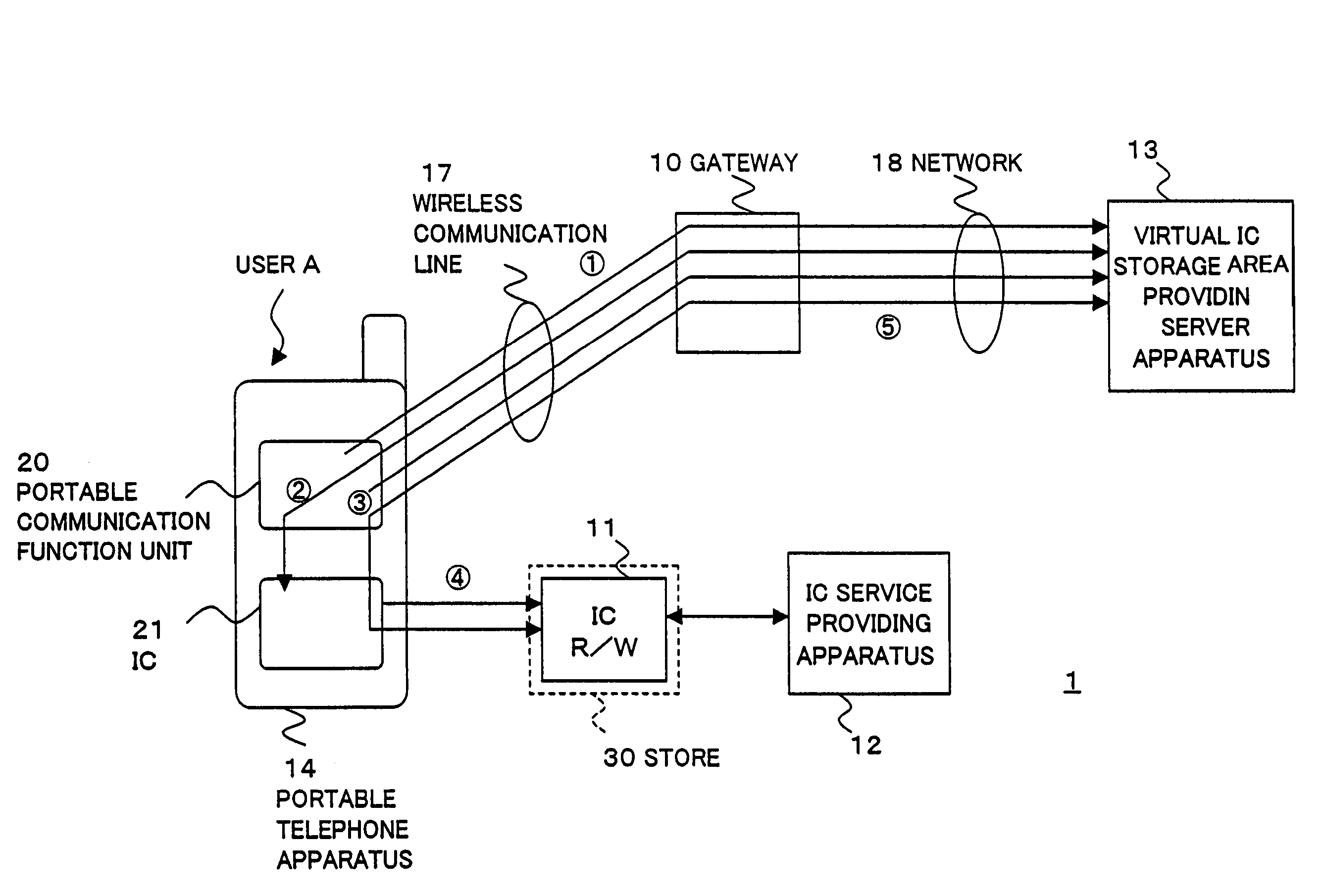

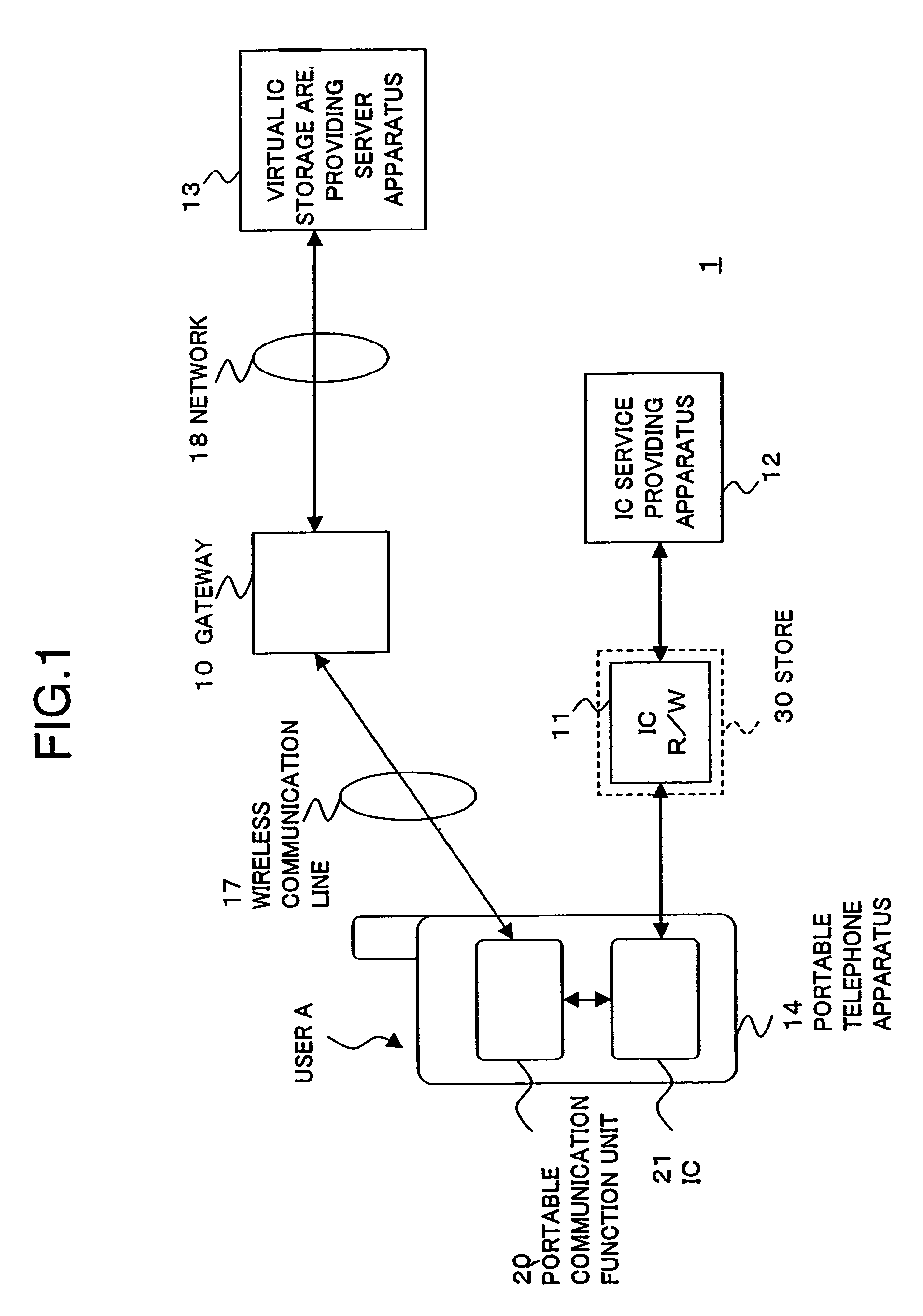

Service providing method and integrated circuit

ActiveUS7519655B2Telephonic communicationMultiple digital computer combinationsService provisionVirtual integration

An application program relating to a process of an integrated circuit 21 is stored in a virtual integrated circuit 21 storage area server apparatus 13. Following a mutual authentication between the IC 21 and the virtual IC storage area server apparatus 13 through a portable communication function unit 20, the server apparatus 13 executes the application program. Additionally, through the IC 21, the portable communication function unit 20, a wireless communication line 17, and a network 18, communicate with an IC_R / W apparatus 11 and perform a process relating to a service in collaboration with each other.

Owner:SONY CORP

Methods, Apparatuses and Systems Facilitating Seamless, Virtual Integration of Online Membership Models and Services

ActiveUS20080098122A1Efficient collaborationEasy to integrateMultiple digital computer combinationsTransmissionVirtual integrationDatabase

Owner:TRANSUNION INTERACTIVE

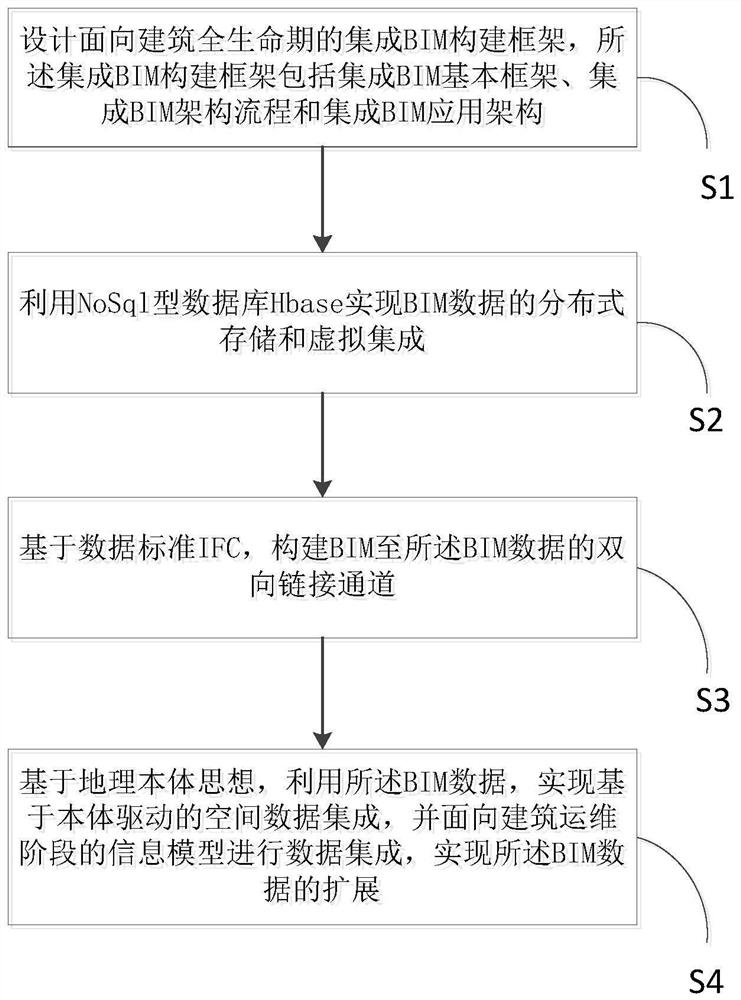

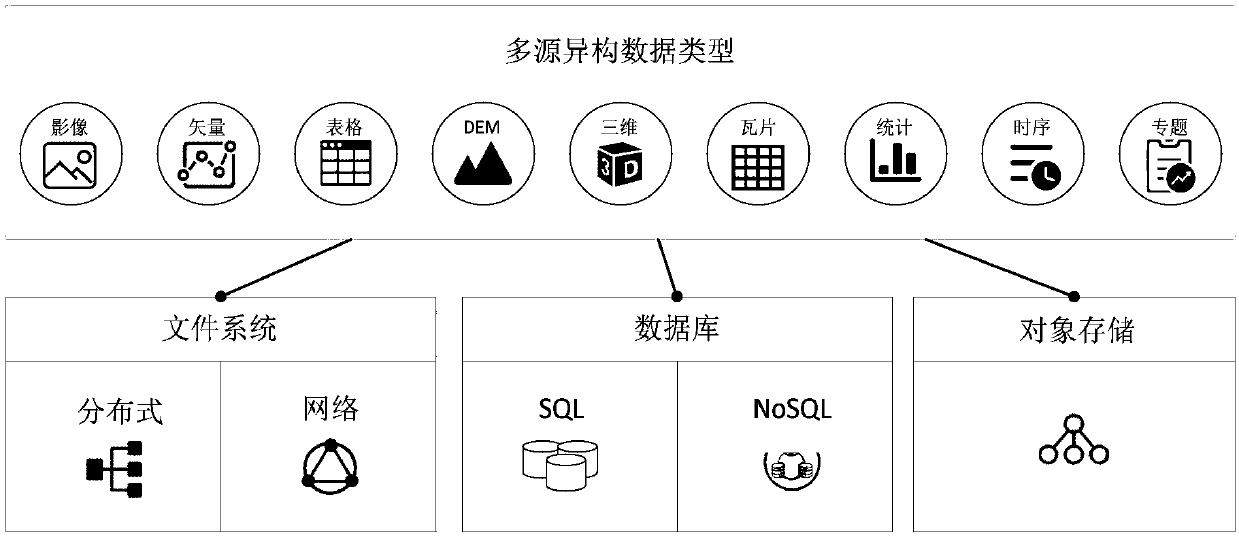

Extensible building full life cycle BIM modeling method

PendingCN113987626AAchieving Digital ConvergenceWide range of usesGeometric CADDesign optimisation/simulationData criteriaData expansion

The invention discloses an extensible building full life cycle BIM modeling method, and the method comprises the steps: designing a building full life cycle-oriented integrated BIM construction frame which comprises an integrated BIM basic frame, an integrated BIM architecture process and an integrated BIM application architecture; using a NoSql type database Hbase to achieve distributed storage and virtual integration of BIM data; based on a data standard IFC, constructing a bidirectional link channel from the BIM to the BIM data; on the basis of the geographic ontology thought, by means of BIM data, achieving spatial data integration based on ontology driving, carrying out data integration on an information model in the building operation and maintenance stage, and achieving BIM data expansion. According to the extensible building full life cycle BIM modeling method, reading and integration of multi-source heterogeneous data are supported, and the multi-source heterogeneous data are integrated into a unified information model; on the basis of the integrated information model, a user can carry out customized function development according to engineering requirements, so that the application range of the method is wider.

Owner:广州市盾建建设有限公司 +1

Method, apparatus, and system for virtual cluster integration

ActiveUS9116181B2Eliminate the effects ofWeaken energyEnergy efficient ICTElectric devicesVirtual clusterParallel computing

Embodiments of the present invention relate to a virtual machine integration technology, and in particular, to a method, an apparatus, and a system for virtual cluster integration. The method includes: performing a calculation through a search algorithm to obtain the minimum number of physical machines which are capable of accommodating all virtual machines in a virtual cluster, and obtaining all virtual integration solutions satisfying the minimum number of physical machines; then calculating CPU voltage consumption of each virtual integration solution, and selecting a solution with lowest CPU voltage consumption from these virtual integration solutions; and formulating a virtual integration migration policy according to the virtual integration solution with the lowest CPU voltage consumption. Therefore, through the embodiments of the present invention, a virtual integration solution with lower CPU voltage energy consumption can be obtained, thereby greatly improving an energy saving and emission reduction effect of a virtual cluster integration solution.

Owner:HUAWEI TECH CO LTD

Virtual business restructuring methods

InactiveUS20070129961A1Breadth and strengthNimbleness and flexibilityBuying/selling/leasing transactionsVirtual businessBusiness enterprise

Virtual restructuring methods according to the present invention provide a mechanism for a diversified company or a joint business enterprise encompassing a plurality of business units having a degree of autonomy over their business operations, and having their own business methods and legacy information systems, to nevertheless reach customers as a virtual intergraded entity, through a common portal and a single user interface.

Owner:SIEMENS AG

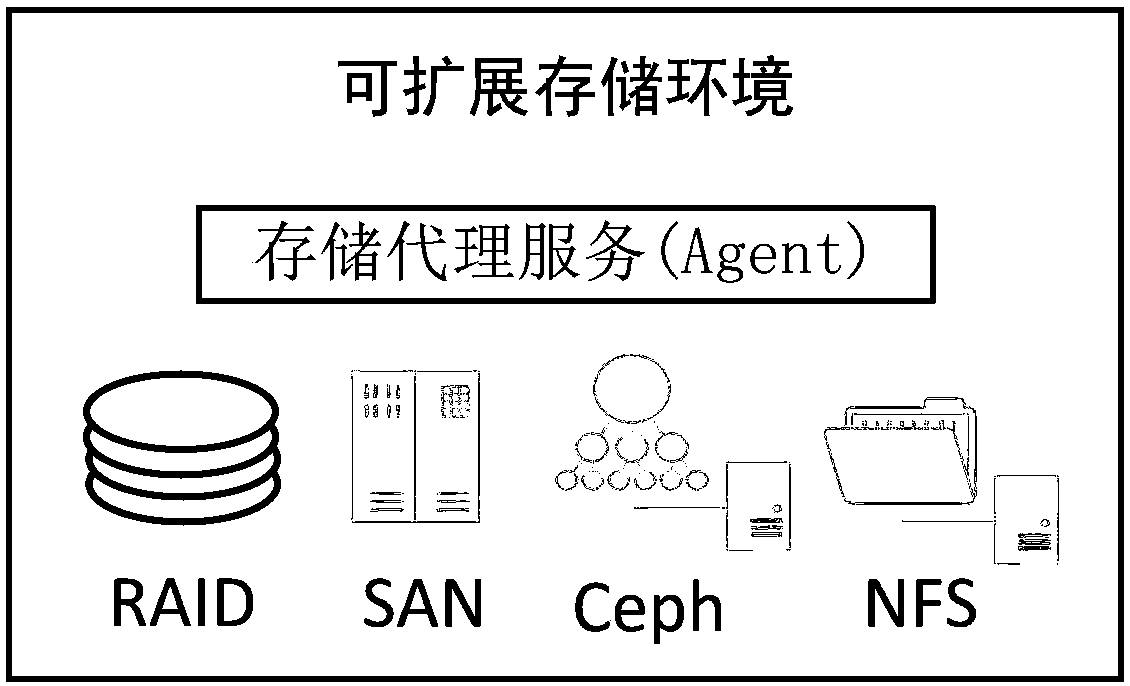

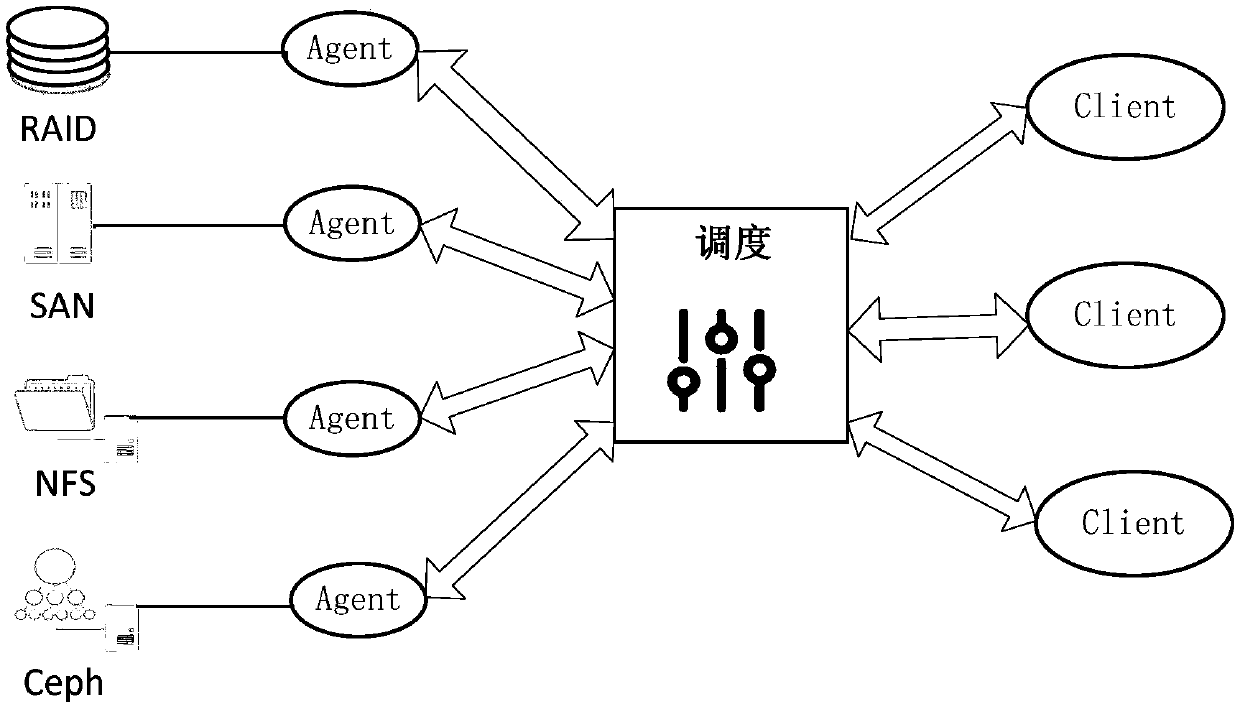

An Agent-based centerless heterogeneous space-time data storage system and method

InactiveCN109947354AImplement storageRealize managementInput/output to record carriersStorage managementVirtual integration

The invention discloses an Agent-based centerless heterogeneous space-time data storage system and method. The system comprises a storage area establishment module, a storage area scheduling module and a storage area management module, The storage area establishing module is used for establishing a plurality of storage areas, the storage areas are directories, services or equipment with storage capability, and each storage area runs an Agent service; The storage scheduling module is used for retrieving an appropriate storage area as a storage area of the data according to the storage attributeof the space-time data, operating the Agent service of the storage area and executing related operation; And the storage area management module is used for uniformly managing the storage areas. The system supports data storage of various types of data, a distributed hybrid storage engine is adopted, remote data virtual integration and intelligent storage management are adopted, and storage and management of mass heterogeneous space-time data are achieved.

Owner:BEIJING AEROSPACE TITAN TECH CO LTD

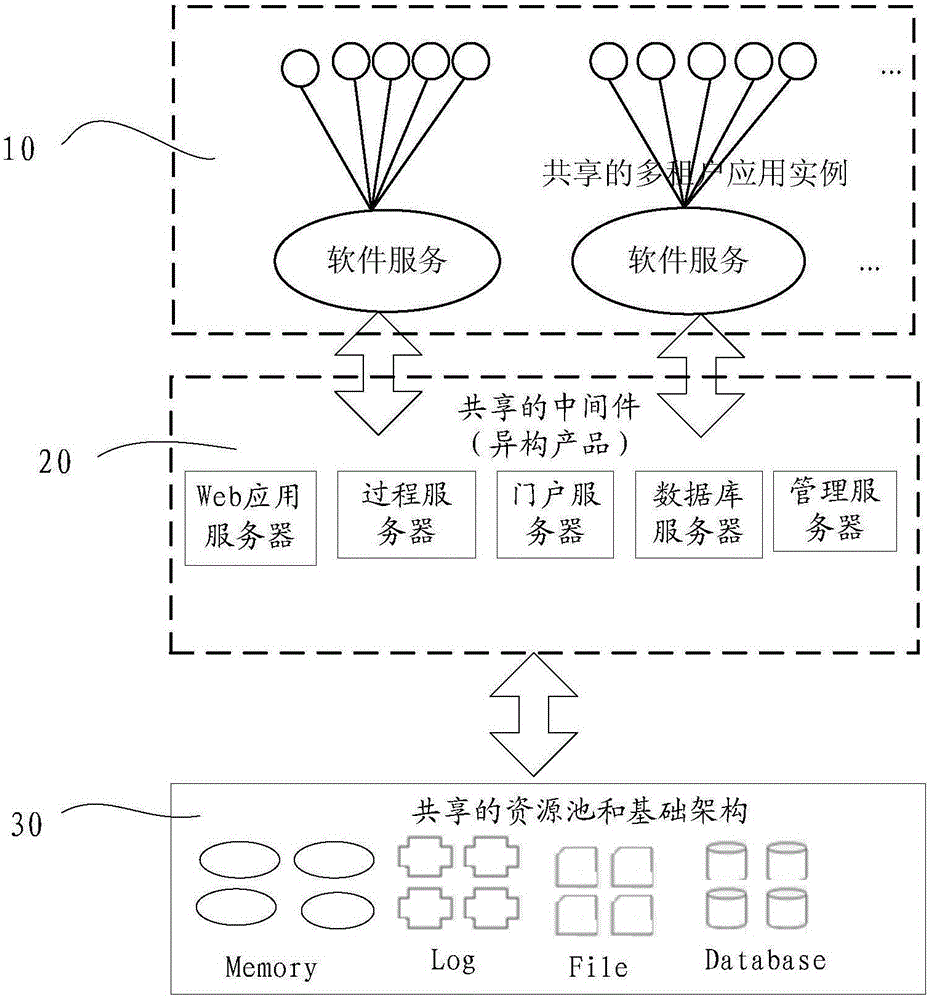

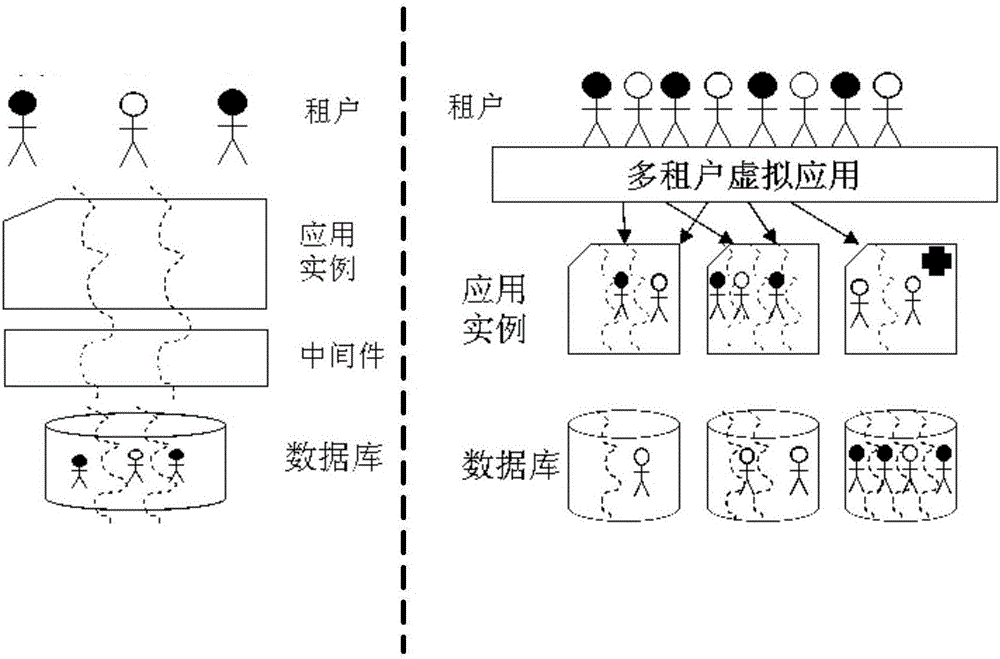

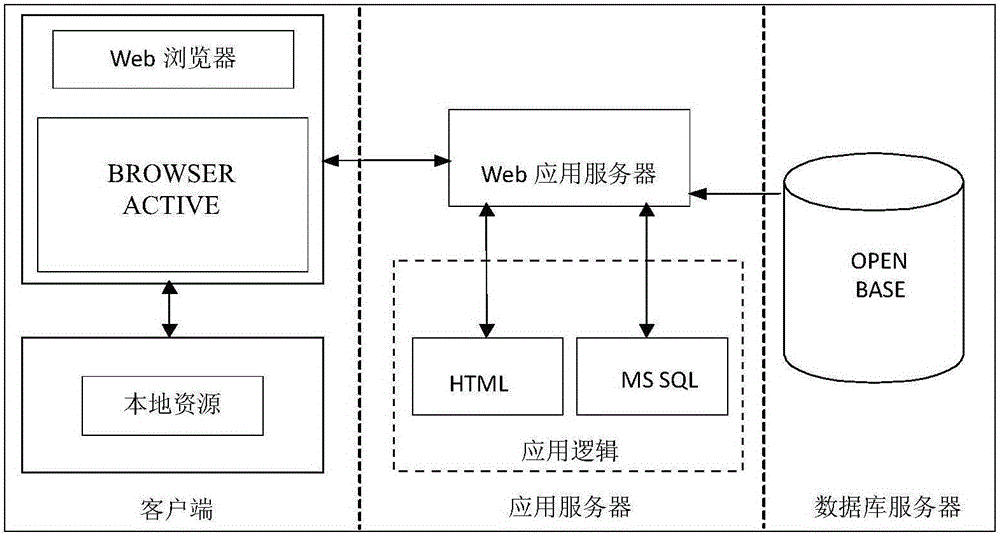

Information software leasing platform and realization method thereof

InactiveCN105915580AMeet service quality requirementsReduce facility costsData switching networksResource poolVirtualization

The invention discloses an information software leasing platform and a realization method thereof. The software leasing platform comprises a customizable Web layer which is provided for multiple lessees for customization of a Web interface so that the multiple lessees can share one example; an intermediate member which provides host service for different clients on a server farm with a balanced load, runs the same example and provides a unified service management layer; and a shared resource pool. Through virtual integration and automation, an application system shares a basic configuration resource pool, when external access pressure is increased, the system is automatically expanded to obtain calculation resources, and when the pressure is decreased, the resources are automatically released. The high-efficiency multi-lessee resource sharing and isolation mechanism provided by the invention can help to reduce the average basic facility and management cost shared by an individual lessee.

Owner:SHANGHAI DIANJI UNIV

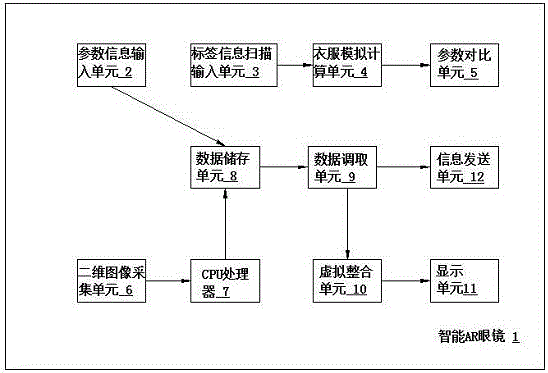

Smart AR (augmented reality) glasses based on virtual integration of two-dimensional images

ActiveCN106773050ABuy as you likeImage analysisBuying/selling/leasing transactionsHuman bodyComputer graphics (images)

The invention provides a pair of smart AR (augmented reality) glasses based on virtual integration of two-dimensional images. The AR glasses comprise a parameter information input unit, a label information scanning input unit, a clothes analog computing unit, a parameter comparison unit, a two-dimensional image collecting unit, a CPU (central processing unit), a data storage unit, a data taking unit, a virtual integration unit and a display unit. The working principle of the AR glasses is characterized in that the two-dimensional images are collected by the two-dimensional image collecting unit, the collected images are further processed by the CPU, all layers are attached and matched by the virtual integration unit finally, and a virtual fitting image is produced; besides, actual clothes parameter information is compared with human body parameter information, so that a user knows the fitting degree of chose and purchased clothes conveniently. With the adoption of the smart AR glasses, the user chooses and purchases clothes more conveniently and more intelligently, time of the user is saved, and realness of virtual fitting is improved.

Owner:广州时间网络科技股份有限公司

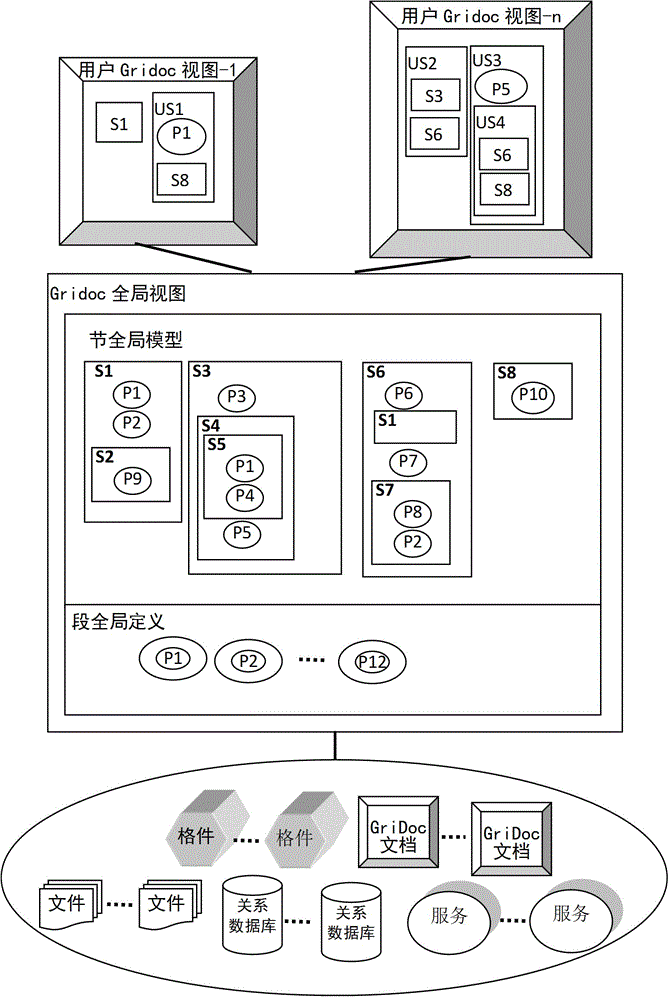

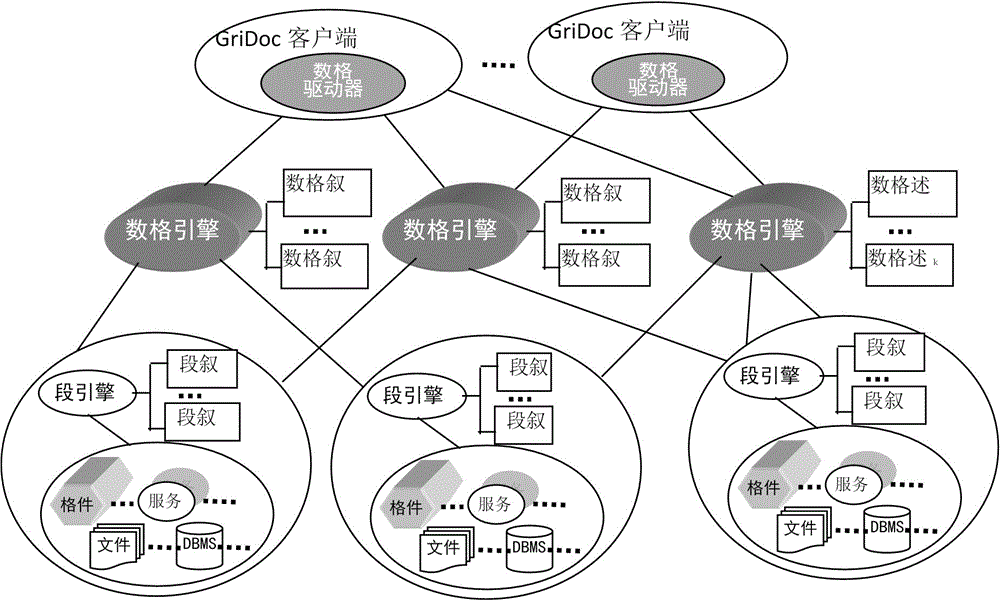

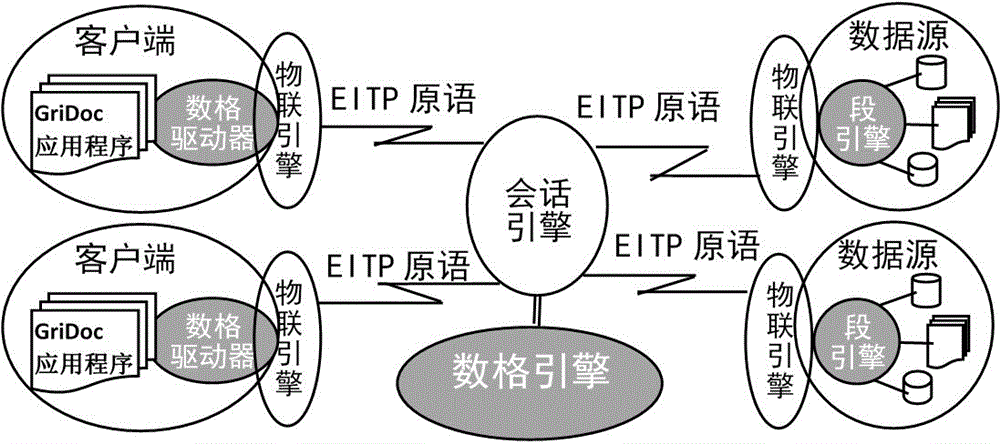

Compound document organization and access model GriDoc of big data

InactiveCN105930475ASpecial data processing applicationsDatabase indexingData synchronizationData grid

The invention discloses a big data operation access method and model (GriDoc for short). The GriDoc supports operation and access of big data in a modeling way for a user to cause big data operation and access to move towards model support, wherein the operation in the modeling way includes a visual operation and an application program operation. The GriDoc model consists of the definition of a data grid and a supporting environment system of the data grid. The data grid is a virtual integration view which is oriented to the big data operation access, serves as an operation access object agent of background data, and supports selection and virtual recombination of the data according to the modeling way. The supporting environment and tool of the data grid is computer software which supports the realization of a data grid function and all operation access, which includes positioning, acquisition, read-write, changing and the like, on the big data and transactions which include data synchronization, traffic scheduling, concurrent access control, security secrecy, identity authentication and the like, required by the operations are all realized by the supporting environment and tool.

Owner:齐德昱

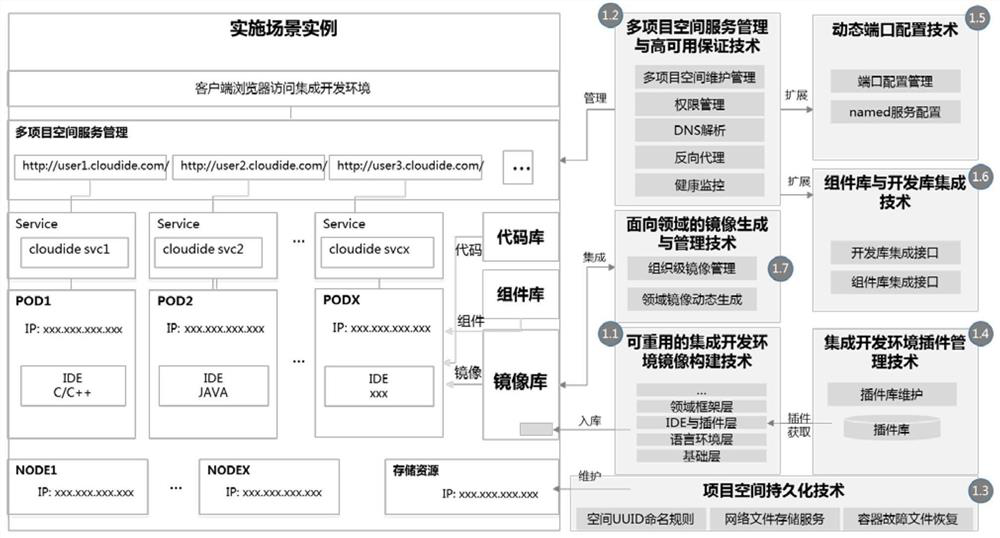

Deployment and management system of cloud virtual integrated development environment

PendingCN114047937AImprove development efficiencyImprove integration efficiencyVersion controlSoftware deploymentReverse proxyVirtual integration

The invention discloses a cloud virtual integrated development environment deployment and management system. A corresponding integrated development environment mirror image file is acquired from an organization-level private mirror image library according to project space demand parameters selected by a user, and is deployed and operated on a container through container arrangement software to generate a project space; a unique service address of the project space is released through a service reverse proxy and distribution technology; and the service address is configured to the DNS server through the DNS service. According to the method, a project team can quickly obtain an available research and development environment only by submitting an application, so that construction and initial framework configuration of the initial research and development environment of the project are greatly shortened, the project team can put main energy into research and development of specific business requirements of the project, and finally, units and organizations are helped to improve the software project research and development efficiency.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

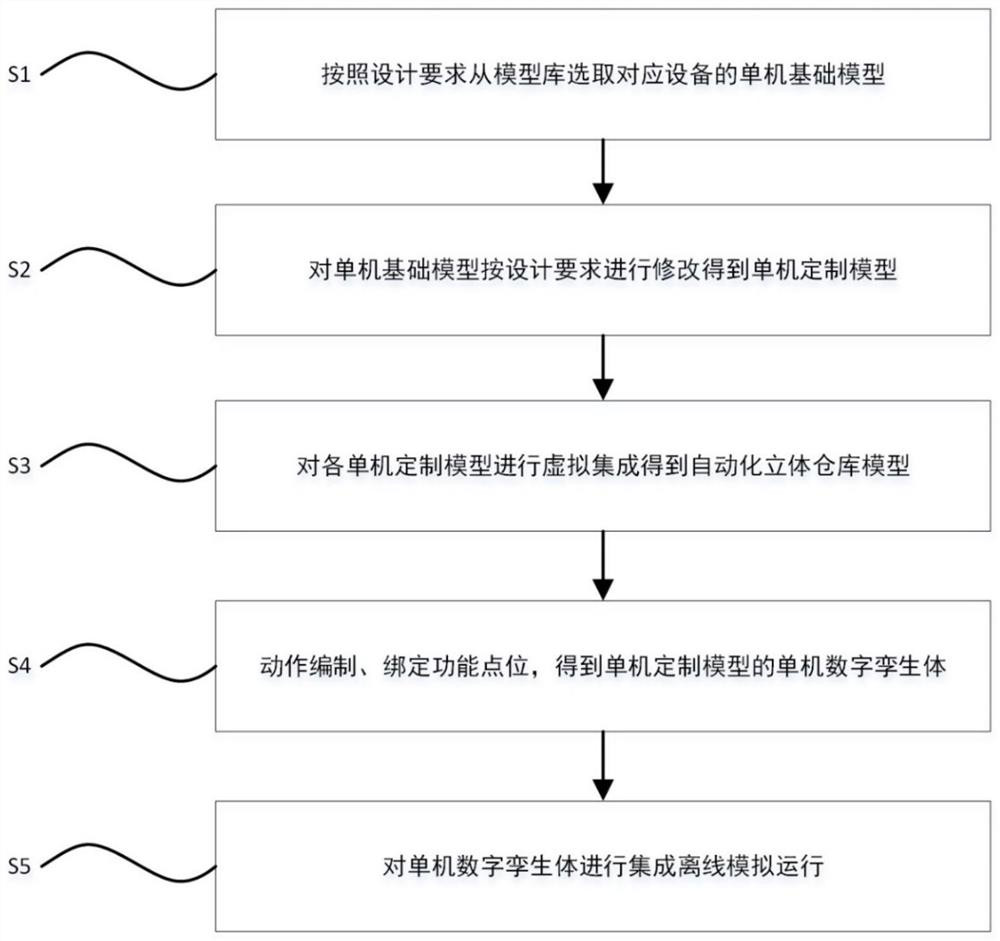

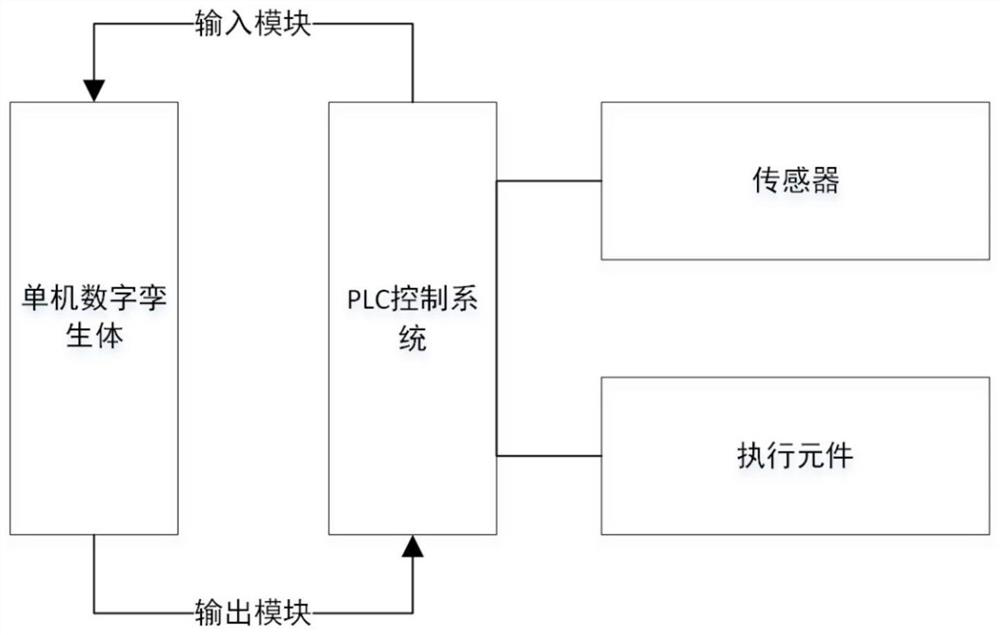

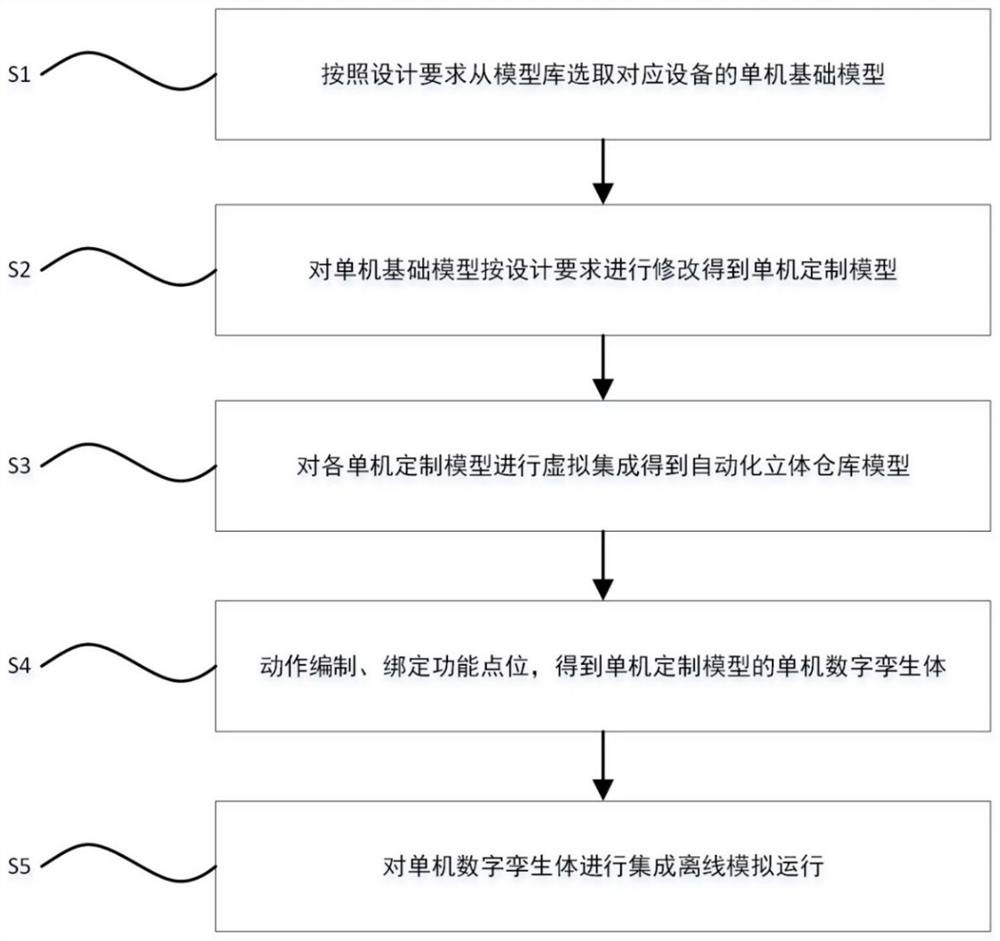

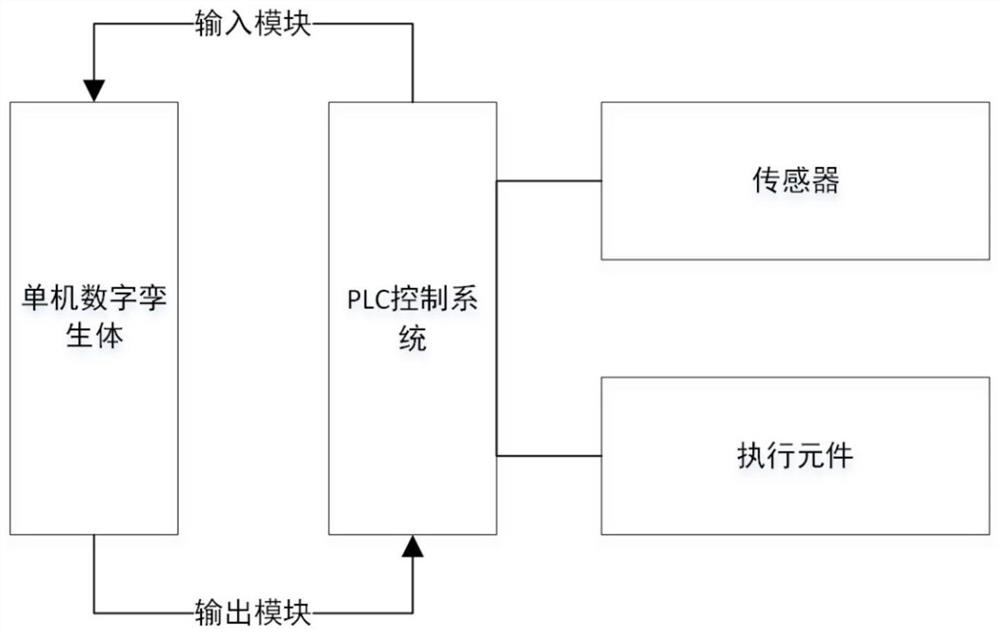

A construction method of automated stereoscopic warehouse based on digital twin

ActiveCN112949041BIntuitive operation dataReduce workloadDesign optimisation/simulationSpecial data processing applicationsAlgorithmDesign phase

A method for constructing an automated three-dimensional warehouse based on digital twins, comprising the steps of: S1 selecting a stand-alone basic model of corresponding equipment from a model library according to design requirements; S2 modifying the stand-alone basic model according to design requirements to obtain a stand-alone customized model; S3 customizing each stand-alone model The model is virtually integrated to obtain an automated three-dimensional warehouse model; S4 action compilation, binding function points, and a digital twin of a single-machine customized model; S5 integrates the digital twin for offline simulation operation. The automatic three-dimensional warehouse construction method of the invention uses past experience to build a model library, realizes the reuse of existing design results, maps the three-dimensional model and the physical equipment to establish a digital twin, achieves the debugging of the combination of virtual and real, and makes the debugging in the design stage. Compared with full digital simulation, simulation results are more credible. Compared with full physical simulation, it can shorten the design and debugging cycle, speed up the project progress, and reduce the cost of simulation experiments.

Owner:GUANGDONG UNIV OF TECH

Automatic stereoscopic warehouse construction method based on digital twinning

ActiveCN112949041AIntuitive operation dataReduce workloadDesign optimisation/simulationSpecial data processing applicationsDesign phaseSimulation

The invention discloses an automatic stereoscopic warehouse construction method based on digital twinning. The method comprises the following steps: S1, selecting a single-machine basic model of corresponding equipment from a model library according to design requirements; S2, modifying the single-machine basic model according to design requirements to obtain a single-machine customized model; S3, performing virtual integration on each single machine customization model to obtain an automatic stereoscopic warehouse model; S4, compiling actions, binding function point positions to acquire digital twin bodies of the single-machine customization model; and S5, carrying out integrated off-line simulation operation on the digital twinborn body. According to the automatic stereoscopic warehouse construction method, the model library is constructed by using previous experience, reuse of existing design results is realized, a three-dimensional model and entity equipment are mapped to establish a digital twinborn body, virtuality and reality combined debugging is achieved, debugging simulation in a design stage is more credible compared with a full-digital simulation result. And compared with full-physical simulation, the design debugging period can be shortened, the project progress can be accelerated, and the simulation experiment cost can be reduced.

Owner:GUANGDONG UNIV OF TECH

Logic and memory device integration

InactiveUS7102906B2Reduced Power RequirementsSmall sizeEnergy efficient ICTDigital storageReduced sizeVirtual integration

Memory devices are adapted for direct interface or virtual integration with a processor or other logic device through a local bus and isolated from a system bus. Such memory devices are capable of lower power requirements and reduced size due in part to the elimination of certain redundant circuitry. Direct interfacing through the local bus facilitates the elimination or reduction of input / output (I / O) buffer circuitry by eliminating the need to step up to and step down from typical system bus voltage levels. Communication between the memory device and a separate logic device occurs across the local bus at voltage levels compatible with internal logic levels of the memory device.

Owner:ROUND ROCK RES LLC

Virtual business restructuring methods

InactiveUS20070129962A1Breadth and strengthNimbleness and flexibilityBuying/selling/leasing transactionsBusiness enterpriseVirtual business

Virtual restructuring methods according to the present invention provide a mechanism for a diversified company or a joint business enterprise encompassing a plurality of business units having a degree of autonomy over their business operations, and having their own business methods and legacy information systems, to nevertheless reach customers as a virtual intergraded entity, through a common portal and a single user interface.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[virtual IDE storage device with PCI express] [virtual IDE storage device with PCI express]](https://images-eureka.patsnap.com/patent_img/afd20c80-97a7-42f1-ad84-0e17fd7bccb8/US20060206653A1-20060914-D00000.png)

![[virtual IDE storage device with PCI express] [virtual IDE storage device with PCI express]](https://images-eureka.patsnap.com/patent_img/afd20c80-97a7-42f1-ad84-0e17fd7bccb8/US20060206653A1-20060914-D00001.png)

![[virtual IDE storage device with PCI express] [virtual IDE storage device with PCI express]](https://images-eureka.patsnap.com/patent_img/afd20c80-97a7-42f1-ad84-0e17fd7bccb8/US20060206653A1-20060914-D00002.png)

![[virtual IDE card reader with PCI express] [virtual IDE card reader with PCI express]](https://images-eureka.patsnap.com/patent_img/11b11ffb-963e-43c8-89c8-1e90fdbfd6b4/US20060206639A1-20060914-D00000.png)

![[virtual IDE card reader with PCI express] [virtual IDE card reader with PCI express]](https://images-eureka.patsnap.com/patent_img/11b11ffb-963e-43c8-89c8-1e90fdbfd6b4/US20060206639A1-20060914-D00001.png)

![[virtual IDE card reader with PCI express] [virtual IDE card reader with PCI express]](https://images-eureka.patsnap.com/patent_img/11b11ffb-963e-43c8-89c8-1e90fdbfd6b4/US20060206639A1-20060914-D00002.png)