A construction method of automated stereoscopic warehouse based on digital twin

A technology of three-dimensional warehouse and construction method, which is applied in the field of automatic three-dimensional warehouse construction based on digital twins, can solve the problems of inability to simulate debugging, inability to reuse, etc., achieve convenient archiving and analysis, reduce the cost of simulation experiments, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

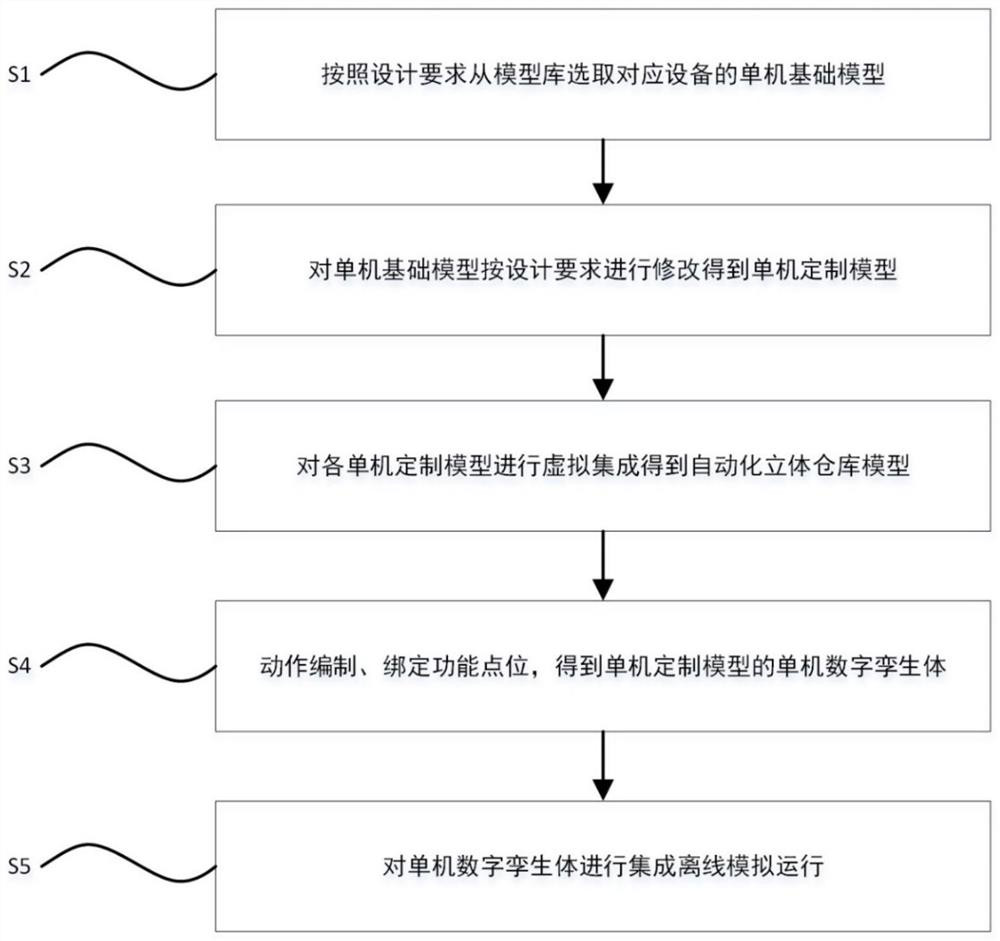

[0039] The present invention proposes a method for constructing an automated stereoscopic warehouse based on digital twins, and the flow chart of the method is as follows: figure 1 shown, including steps:

[0040] S1. Query the demand configuration comparison table according to the warehouse design requirements, and retrieve the single-machine basic model of each warehouse internal equipment corresponding to the warehouse design requirements from the model library;

[0041] The method for constructing the model library and the demand configuration comparison table includes: querying the demand configuration comparison table according to the warehouse design requirements, and when the physical entity equipment corresponding to the requirements in the design requirements cannot be queried in the demand configuration comparison table, the user Input the physical entity device corresponding to the requirement, establish a mapping relationship between the requirement and the physic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com