Dehydration method of calcium hydrogen phosphate product slurry

A calcium hydrogen phosphate product technology, applied in the field of dehydration of calcium hydrogen phosphate product slurry, can solve the problems of centrifuge drum bursting, high difficulty in re-dehydration, high maintenance costs, etc., to save installed capacity, solve the problem of difficult matching and digestion, The effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

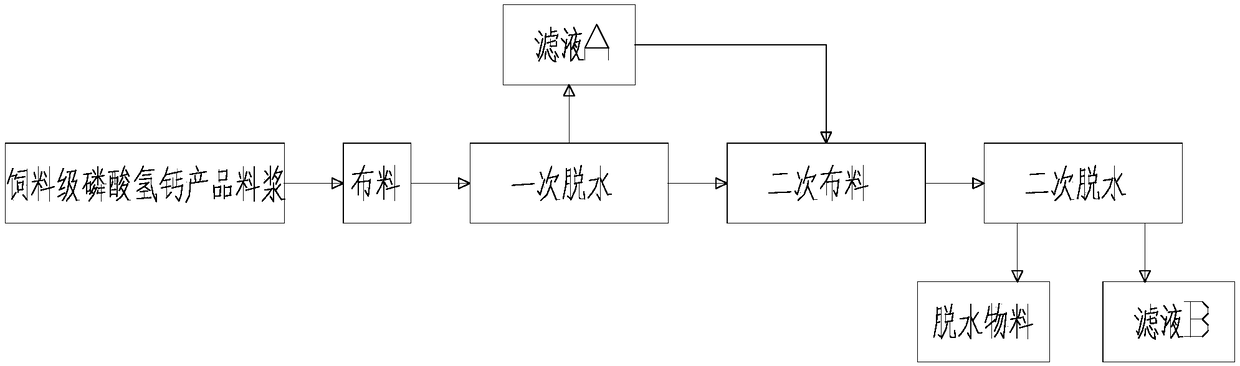

[0025] The dehydration method of the present embodiment comprises the steps:

[0026] (1) cloth: the calcium hydrogen phosphate product slurry is evenly laid in the cloth area on the adhesive tape; the length of the cloth area is within 2m, and the cloth thickness is more than 3cm;

[0027] (2) Primary dehydration: After the tape with the calcium hydrogen phosphate product slurry is rotated to the primary suction filtration area, the calcium hydrogen phosphate product slurry is suction-filtered with a vacuum filter box to obtain the material A above the tape and the suction filter The filtrate A produced; when the crystallization of the material is poor, 1-2m after entering the suction filtration area, the naked eye can see no water; The vacuum pumping volume of the vacuum filter box is configured as 6-9m 3 / m 2 , the vacuum degree is 0.04MPa;

[0028] (3) Secondary distribution: After turning the tape with material A to the secondary distribution area, in order to further ...

Embodiment 2

[0031] The dehydration method of the calcium hydrogen phosphate product slurry of the present embodiment may further comprise the steps:

[0032] (1) cloth: the calcium hydrogen phosphate product slurry is evenly laid in the cloth area on the adhesive tape above the vacuum filter box; the length of the cloth area is 1m, and the cloth thickness is more than 3cm;

[0033] (2) Primary dehydration: After the tape with the calcium hydrogen phosphate product slurry is rotated to the suction filtration area, the vacuum suction filter box performs suction filtration on the calcium hydrogen phosphate product slurry to obtain the material C above the tape and the filtrate filtered out C; The vacuum pumping capacity of the vacuum filter box is configured to be 7-8m 3 / m 2 , the vacuum degree is 0.06MPa;

[0034] (3) Secondary distribution: After turning the tape with material C to the secondary distribution area, pressurize the filtrate C with a pump and send it to the top of the tape,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com