Synthetic rubber wastewater treatment system and its treatment method

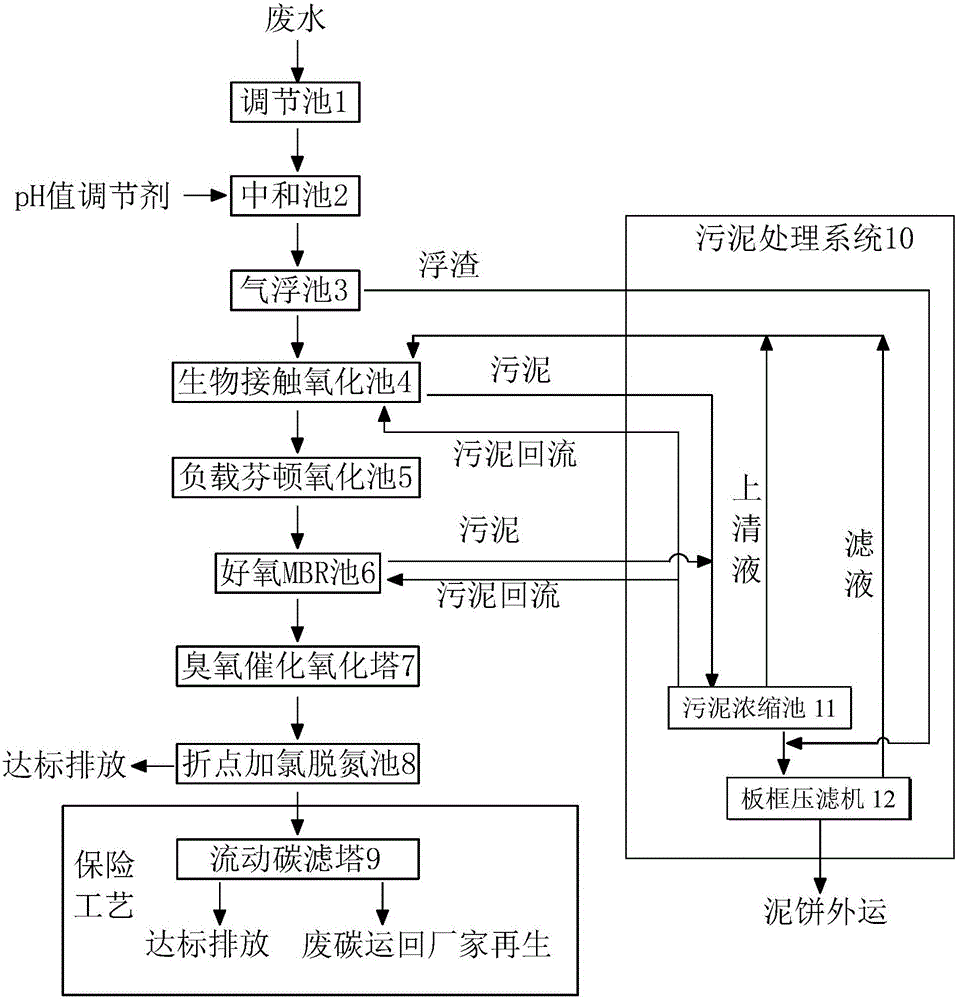

A technology for synthetic rubber and a treatment method, which is applied in the field of synthetic rubber wastewater treatment systems, can solve the problems of difficult discharge of synthetic rubber wastewater and difficult treatment of synthetic rubber wastewater, and achieves the effect of solving the problem of difficult discharge to meet the standard and saving operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A synthetic rubber manufacturer with a waste water volume of 150m 3 / h, pH is 6, COD Cr The average is 810mg / L, and the average ammonia nitrogen is 75mg / L. See Table 1 for design influent water quality standards.

[0041] The synthetic rubber waste water treatment system of the present invention is adopted, and the treatment is carried out according to the treatment method provided by the present invention.

[0042] The water quality and quantity of incoming water (wastewater) are adjusted through the regulating tank 1, and the effluent from the regulating tank 1 enters the neutralization tank 2; After the air flotation treatment, the wastewater enters the biological contact oxidation tank 4, and the bottom of the tank is equipped with a microporous aeration disc to provide the oxygen required by the microorganisms. The residence time of the pool is 11h.

[0043] Adjust the pH of the wastewater to 5-6 at the front end of the load-type Fenton oxidation tank 5, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com