Method for treating polymer-containing sewage of oil field

A sewage treatment method and oilfield technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of reducing filtration load, etc., and achieve reduction of filtration load and backwash intensity Small, reduce the loss of filter material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

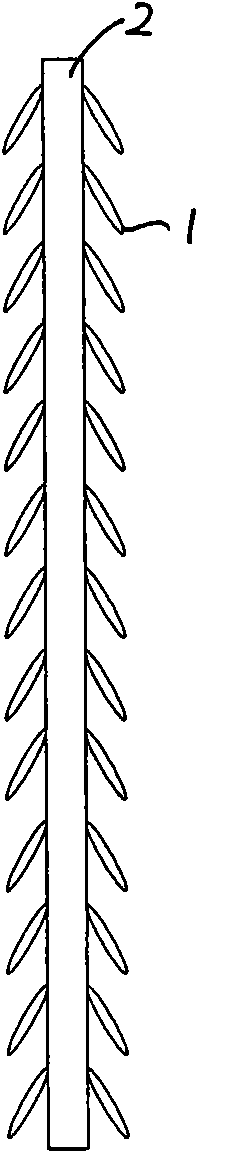

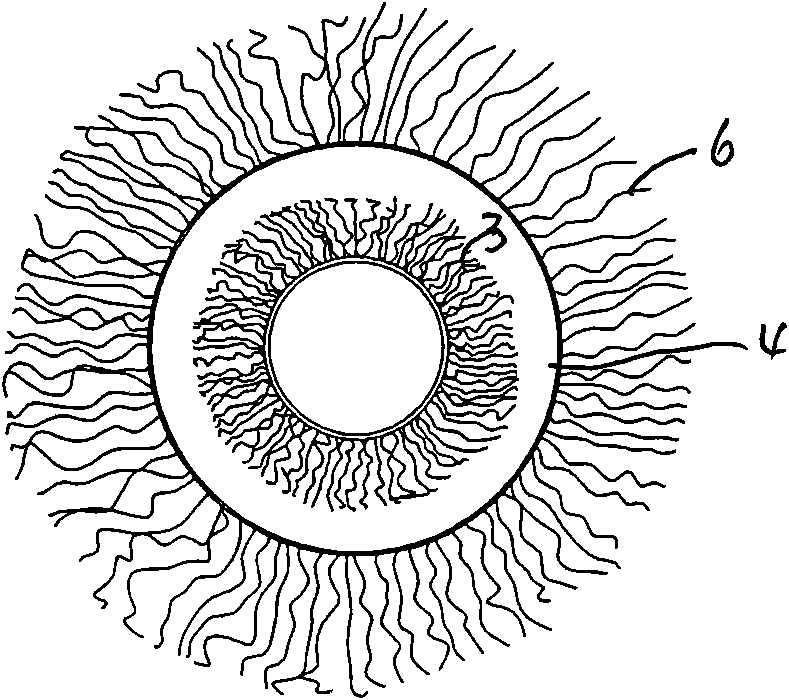

[0025] Embodiment 1: see Figure 1-4 , the surface of the present invention is used for contact oxidation with fiber silk cloth sheet suspension packing, which is composed of synthetic fiber cloth sheet 2 and fiber silk 1 uniformly distributed on both sides; the combined semi-soft suspension packing is composed of middle plastic clip ring 4 and uniform inner and outer circumference The distributed fiber filaments 3 and 6 form a sheet structure, which is composed of a central rope 5 connected in series. Both have a relatively high density, which is beneficial to increase the contact time between the treated water and the filler and prevent short flow.

Embodiment 2

[0026] Example 2: The treated incoming water is the effluent of the secondary settling tank, and the average water quality index is: oil content 750 mg / l, suspended matter 220 mg / l, polymer 450 mg / l. The process of the present invention is adopted: microbial reaction + primary quartz sand filtration. Wherein the microbial reaction adopts the contact oxidation reaction tank, the filler adopts the semi-soft combined filler of Example 1, the filling rate is 75V / V%, the gas-water ratio is 20:1, and the residence time is 8 hours; the microorganism adopts Bacillus cereus selected from the laboratory (Bacillus cereus), Bacillus megaterium, Bacillus subtilis, Candida lipolytica, Bacillus brevis, Pseudomonas fluorescens mixed bacteria, various bacteria Roughly equal proportions, the treated effluent enters the quartz sand filter after solid-liquid separation, and the final treated effluent contains 2.8mg / l of oil, 4.5mg / l of suspended solids, and a median particle size of 1.32μm. The b...

Embodiment 3

[0027] Example 3: The incoming water is also the effluent of the secondary settling tank, the average water quality index: oil content 750mg / l, suspended matter 220mg / l, polymer 450mg / l. The process of the present invention is adopted: microbial reaction + primary quartz sand filtration. Wherein the microbial reaction adopts the activated sludge method, the air-water ratio is 30:1, the sludge concentration is 8000mg / l, and the residence time is 13 hours. , the average oil content of the treated water is 3.2mg / l, the suspended solids are 4.8mg / l, the median particle size is 1.35μm, the backwashing cycle of the filter tank is once every 10 days, and the sludge oil content is less than 0.3wt%, which meets the environmental protection discharge requirements. The filter tank backwash water returns to the microbial reaction tank without additional treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com