Nitric oxide waste gas pollution control process method and equipment

A technology for treating nitrogen oxides and exhaust gas, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of low absorption and purification efficiency, difficult absorption liquid treatment, and high operating costs, and achieve the goal of overcoming alkali consumption Large, reduce secondary pollution, improve the effect of treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

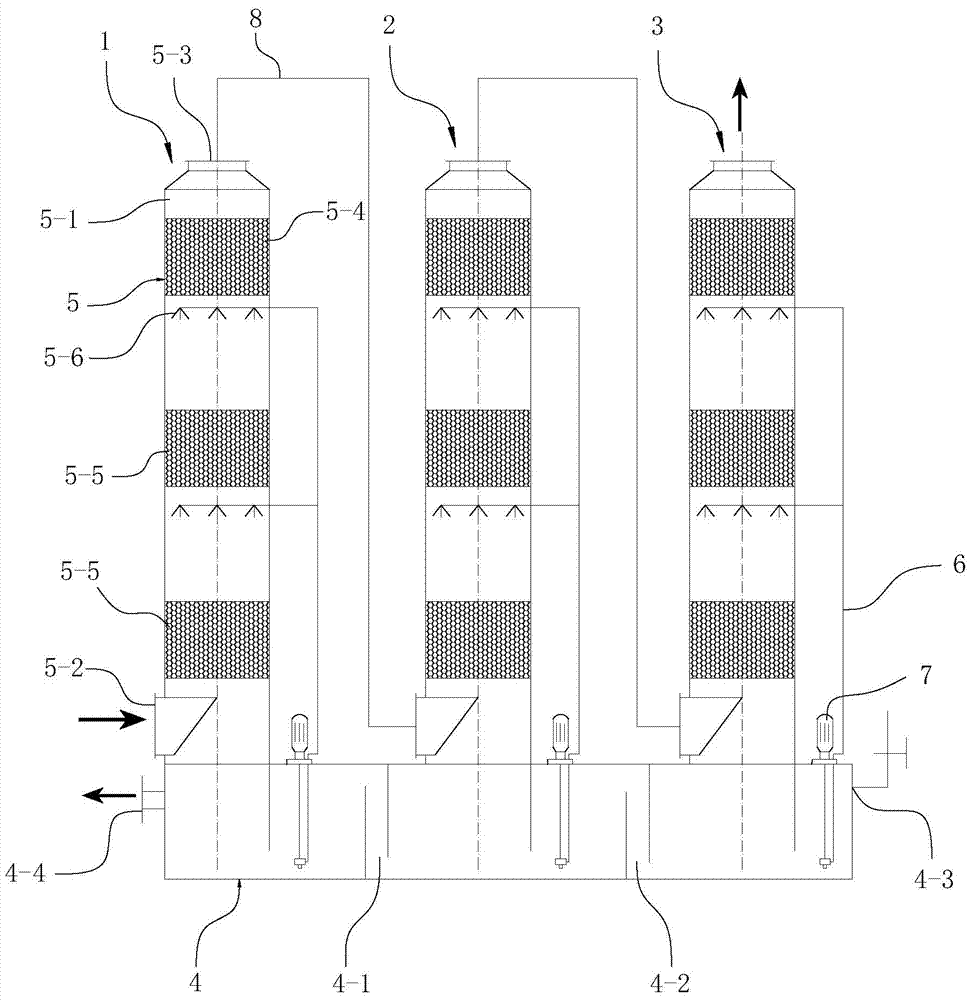

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

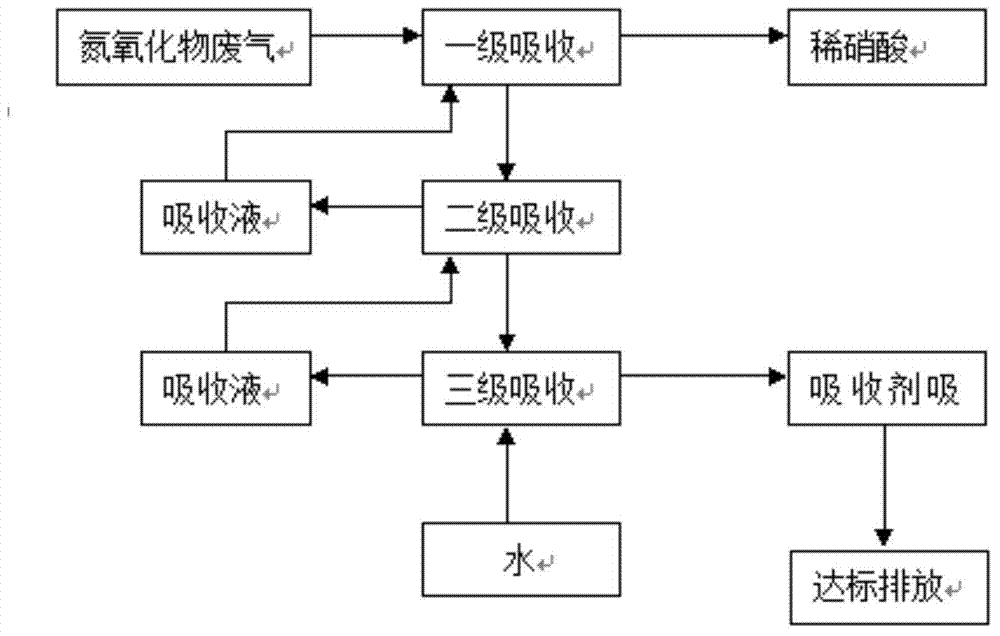

[0021] see figure 1 , a nitrogen oxide exhaust gas treatment process, characterized in that: the method includes the following steps:

[0022] a. Use water as the absorbing liquid to spray the waste gas in two layers. This step will produce the first spray recovery liquid; dehydrate the waste gas after spraying in this step;

[0023] b. Use water as the absorption liquid to carry out two-layer circular spraying on the waste gas produced in step a. This step will produce the second spray recovery liquid; dehydrate the waste gas after spraying in this step; The drenched recovered liquid is introduced into the first sprayed recovered liquid in step a;

[0024] c. Use water as the absorption liquid to carry out two-layer circular spraying on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com