A quartz sand purification system without water washing process

A technology of quartz sand without water washing, which is applied in the equipment system field of quartz sand purification process, which can solve the problems of hidden dangers in the quality of quartz sand, harmful salt-containing waste residue, high operating costs, etc., to save environmental protection and production investment, reduce production costs, save The effect of going to running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

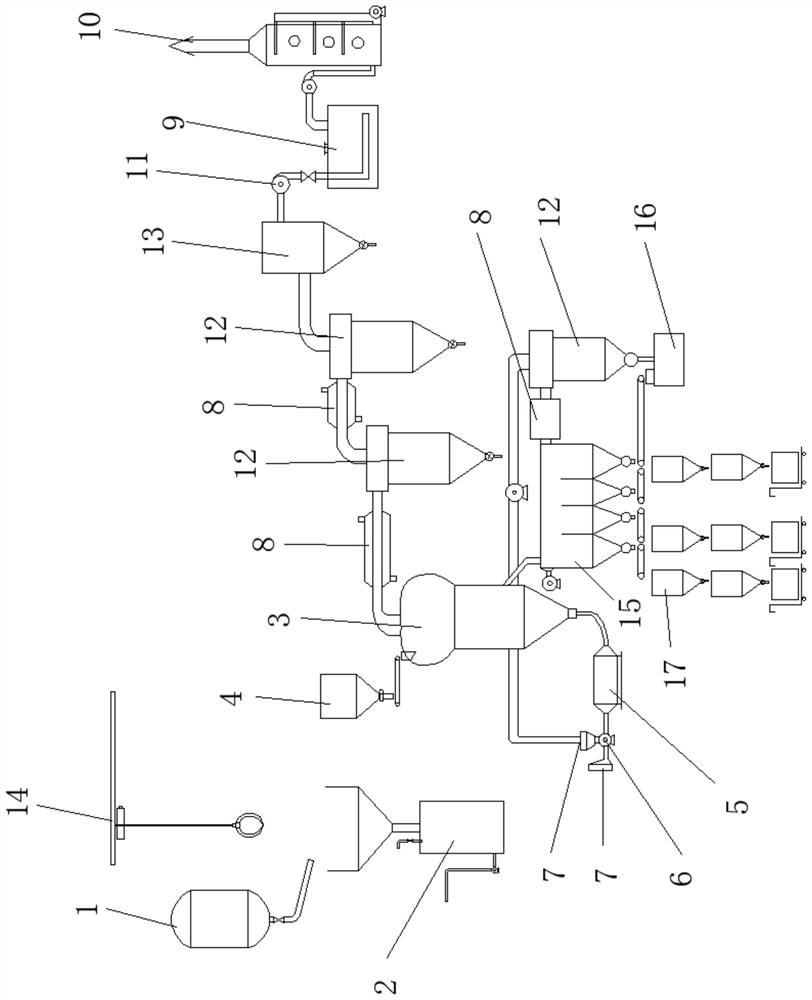

[0025] A quartz sand purification system without a water washing process, comprising a pickling device 1, a filtering device 2, a drying device and a finishing device, and the quartz sand material is sequentially transferred between the four; the drying device includes a fluidized bed dryer 3 , the material inlet of the fluidized bed dryer 3 is connected to the silo 4, and the material outlet is connected to the collection bin; the hot air inlet of the fluidized bed dryer 3 is sequentially connected with a heating furnace 5, a blower 6 and an air filter 7, and the hot air The outlet is sequentially connected to the cooler 8, the multi-stage dust removal device, the multi-stage water absorption device 9 and the acid mist absorption tower 10 through pipes, and the gas outlet of the acid mist absorption tower 10 is connected to the atmosphere. Carbon fiber, silicon carbide, titanium carbide or tungsten carbide are used for the material of the part in the fluidized bed dryer 3 that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com