Filtering pipeline type septic tank reaching standards

A pipeline type and pipeline technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve problems such as inability to meet straight discharge or reuse standards, and achieve blockage prevention, investment reduction, The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

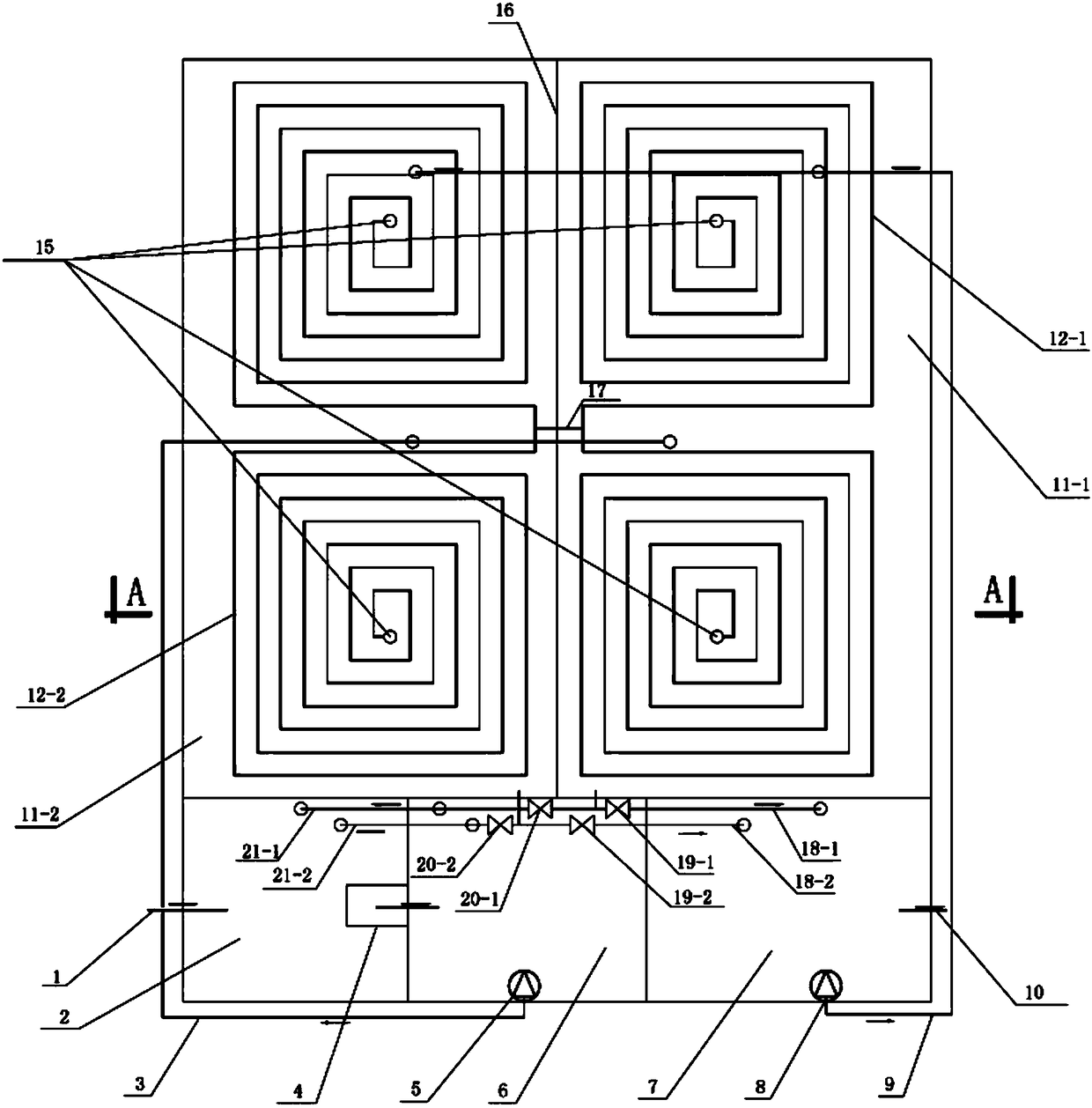

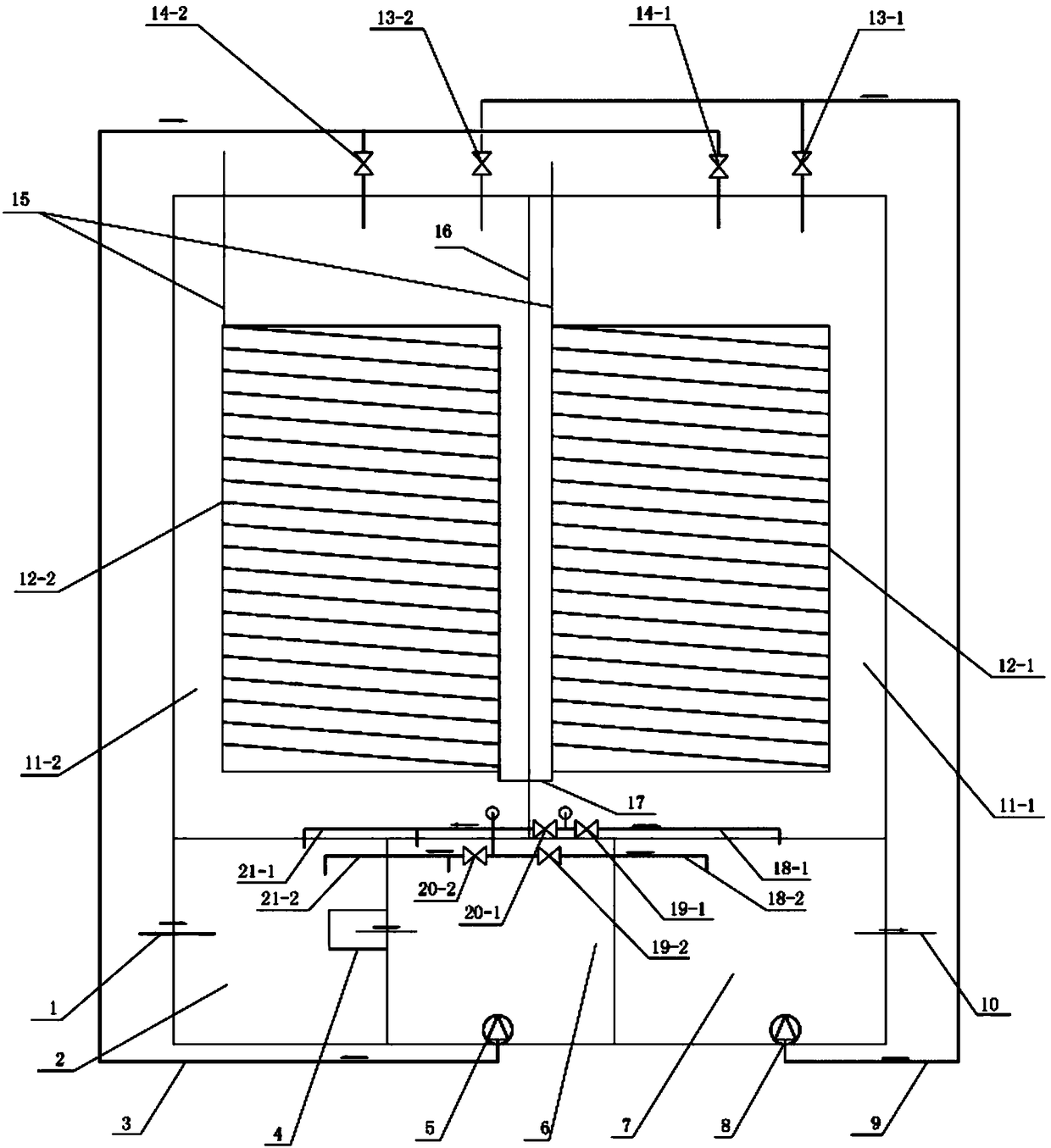

[0043] Filtered piped compliant septic tank. Its main structures include septic tank 2, sump 6, clear water tank 7 and filter pipeline pool 11; among them, septic tank 2 is equipped with pipeline grille 4; sump 6 is equipped with sewage lifting pump 5; clear water tank 7 is equipped with The backwash pump 8; the filter pipe pool 11 is located above the slag tank 2, the sump 6 and the clean water pool 7, the filter pipe pool 11 is divided into two or more grids, and each filter pipeline pool 11 is provided with one group and one group The above filter pipes 12 and the filter pipes 12 are connected to each other by the filter pipe connecting pipe 17; the pollutants in the sewage pass through biological contact oxidation, anaerobic biochemical reaction, aerobic biochemical reaction, filtration and Precipitation removal.

[0044] The sewage treatment of the present invention includes the following steps.

[0045] (1) Grid slag removal

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com