Environment-friendly type long-acting automobile cooling liquid formulation and producing technique thereof

A technology of automobile cooling and production technology, which is applied in the field of coolant, can solve the problems of poor control of foam tendency, serious foam tendency, and long service life, and achieve the effects of high promotion and application value, low production cost, and enhanced protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

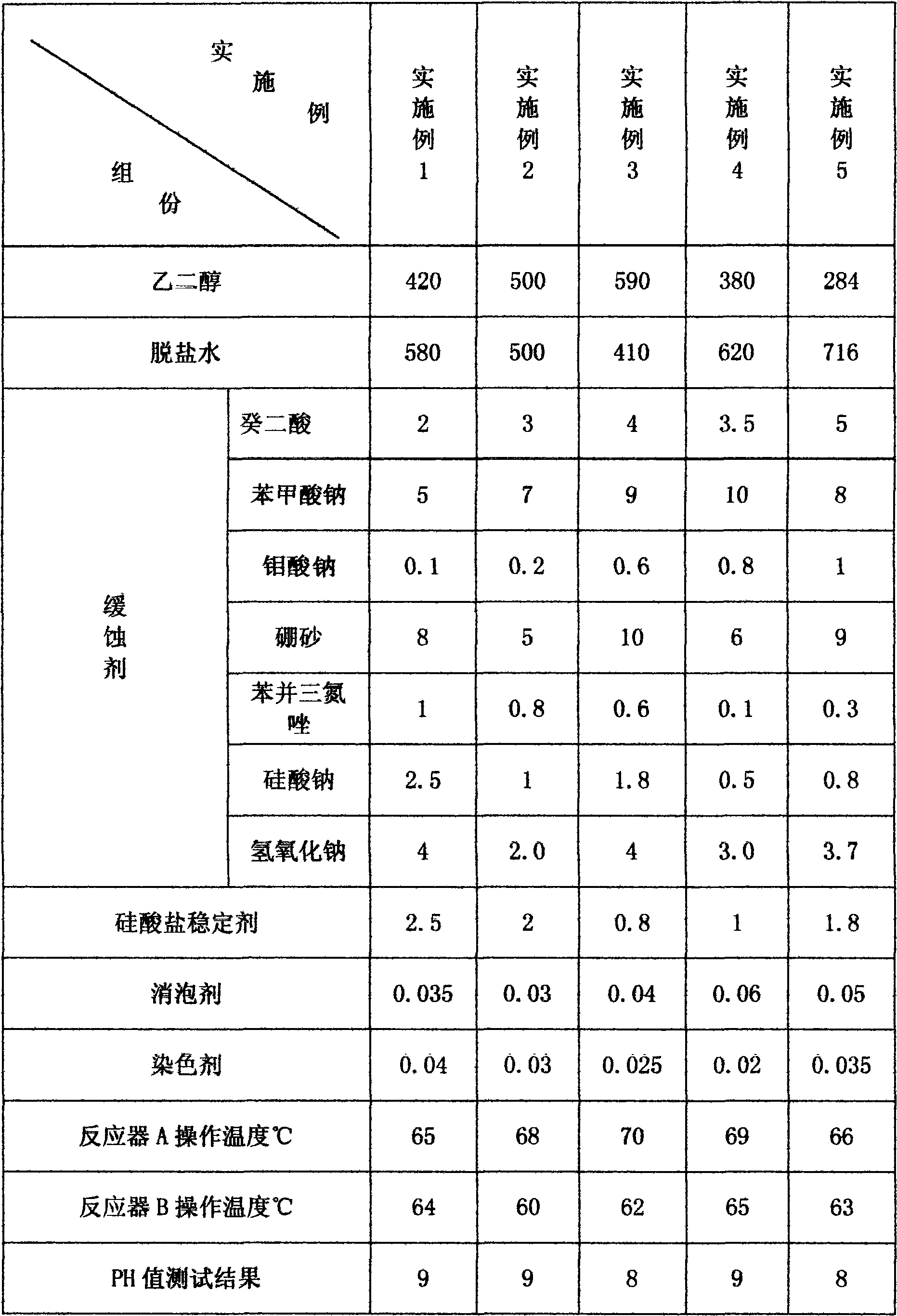

Examples

Embodiment 1

[0026] Add 420 parts of ethylene glycol, 2 parts of sebacic acid, and 2 parts of benzotriazole into reactor A, operate under normal pressure, heat to 65°C, and stir for 15 minutes until the materials are completely dissolved, then add sodium hydroxide 3-2 parts, then stir until completely dissolved; the amount of ethylene glycol is used to control the freezing point of the cooling liquid. The more you add, the lower the freezing point of the cooling liquid and the higher the production cost. The heating temperature is between 65-70 ° C. The temperature is low, the dissolution is slow, and the stirring time of the agitator is 10-20 minutes. If the speed of the agitator is fast, the time required will be less, and the solid powder is completely dissolved; add 464 parts of desalted water to the reactor B, Add 5 parts of sodium benzoate, 0.1 part of sodium molybdate, and 8 parts of borax, operate under normal pressure, heat to 64°C, and stir for 18 minutes until all solid granular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com