High temperature biobased lubricant compositions comprising boron nitride

A lubricant, boron nitride technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of limited viscosity protection, poor anti-oxidation performance, poor oxidative performance and flow performance of lubricants, etc. Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

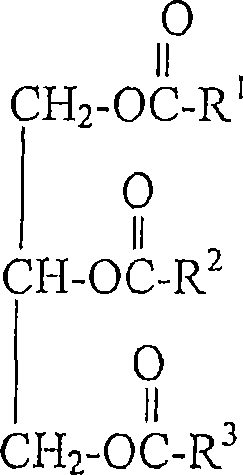

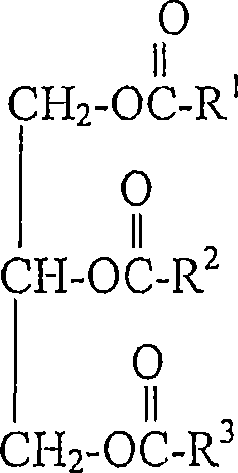

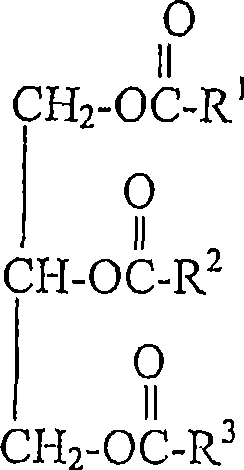

Method used

Image

Examples

no. 1 approach no. 2 approach

[0145] components first embodiment second embodiment third embodiment

[0146] (A) 5-99.9 65-99.9 95-99.998

[0147] (B) 0.002-50 0.002-35 0.002-5

[0148] When the composition comprises components (A), (B), (C) and (D), the parts by weight range of these components are given below:

[0149] components first embodiment second embodiment third embodiment

[0150] (A) 5-90 40-80 60-90

[0151] (B) 0.002-80 0.002-35 0.002-5

[0152] (C) 20-80 10-20 1-10

[0153] (D) 0.001-80 0.001-40 0.001-20

[0154] It should also be recognized that concentrates of the present invention can be prepared. Concentrates containing minor amounts of (A) and major amounts of (B), minor amounts of (A) and major amounts of (B), (C), (D), or minor amounts of (A), (C) , a composition of (D) and a major amount of (B).

[0155] The term "minor" in the specification and appended claims means that when referring to a composition containing a "minor" amount of a substance, it means an amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com