Composition of cold rolling sheet rolling oil

A cold-rolled thin plate and composition technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of poor lubricating performance of rolling oil, achieve excellent lubricating performance, smooth surface, good resistance to oil burning and anti-rust performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

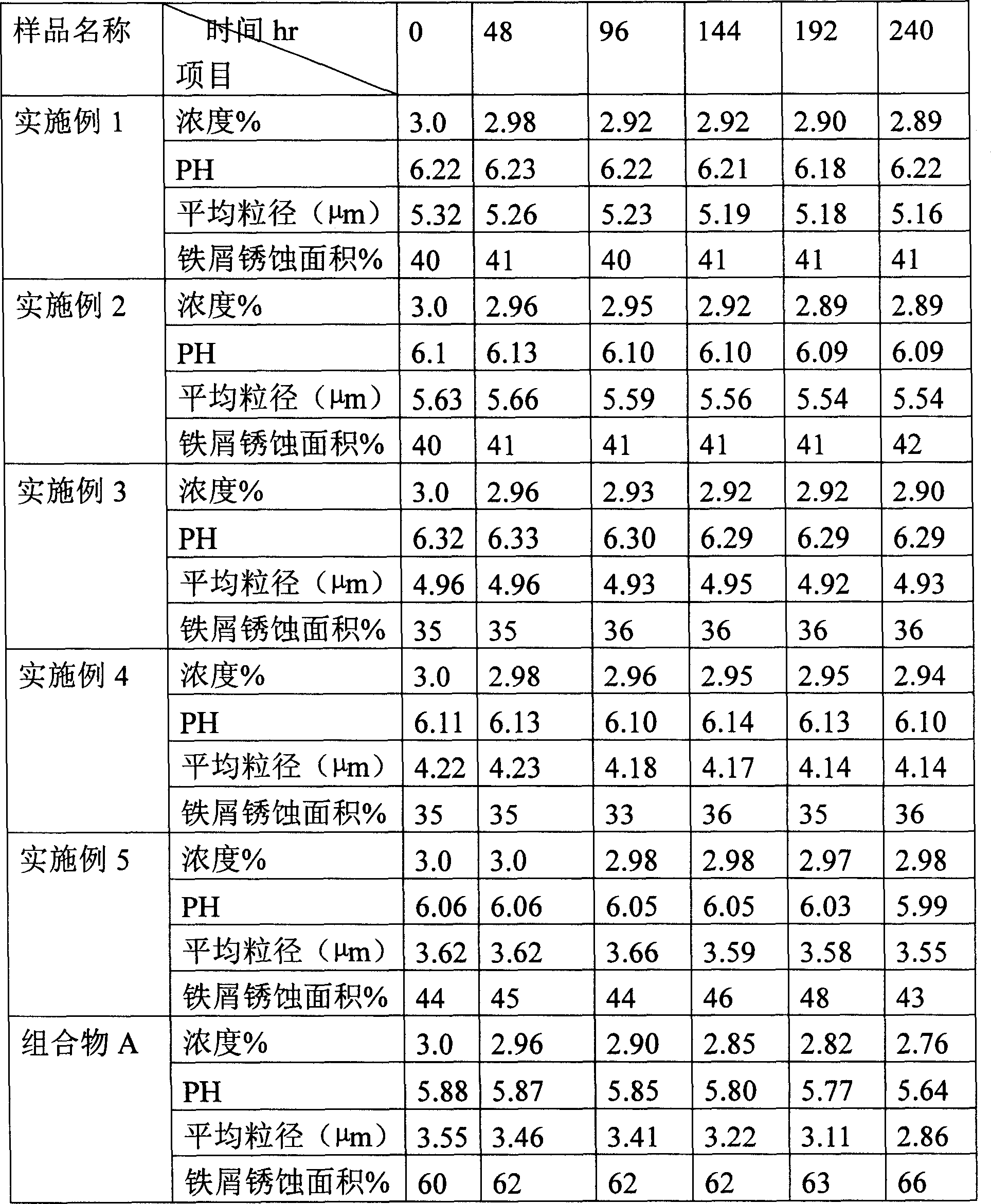

Examples

Embodiment 1

[0035] 750 grams of trimethylolpropane coconut oleate, 20 grams of nonylphenol polyoxyethylene (4) ether (NP-4) oleate, 15 grams of nonylphenol polyoxyethylene (7) ether oleate, 20 grams of polyisobutylene (molecular weight 1000) polyethylene glycol succinate (molecular weight 3500) ester, 30 grams of vulcanized lard, 30 grams of vulcanized cottonseed oil, 15 grams of benzotriazole derivatives (T551), 5 grams of 2.6-ditert Butyl p-cresol (T501), 100 grams of oleic acid, 15 grams of tricresyl phosphate (T306), and 5 grams of benzotriazole were added to a container at a temperature of 75 to 76°C and stirred for 1.5 hours. To dissolve evenly, forming a transparent liquid.

Embodiment 2

[0037] With 800 grams of pentaerythritol dimer acid oleate, 70 grams of fatty alcohol polyoxyethylene (6) ether (O-6) stearate, 40 grams of nonylphenol polyoxyethylene (7) ether oleate, 15 grams Polyisobutylene (molecular weight 1100) polyethylene glycol succinate (molecular weight 1200) ester, 26 grams of sulfurized olefin, 26 grams of sulfurized mineral oil, 15 grams of thiadiazole derivatives (T556), 5 grams of phenyl-alpha naphthylamine, Add 50 grams of palmitoleic acid, 25 grams of di-n-butyl phosphite, and 15 grams of zinc naphthenate into a container at a temperature of 75 to 76°C, and stir for 1.5 hours until it dissolves evenly and forms a transparent liquid.

Embodiment 3

[0039] 420 grams of pentaerythritol palm oleate, 450 grams of trimethylolpropane laurate, 5 grams of nonylphenol polyoxyethylene (7) ether (NP-7) palmitoleate, 40 grams of octylphenol polyoxy Ethylene (4) ether laurate, 10 grams of tetrapolyisobutylene (molecular weight 1200) polyethylene glycol adipate (molecular weight 800) ester, 25 grams of dibenzyl disulfide (T322), 25 grams of vulcanized vegetable oil, 10 grams of tribenzene Azole derivatives (T551), 5 grams of 2.6-di-tert-butyl-p-cresol (T501), 15 grams of tricresyl phosphate (T306), 15 grams of dodecenylsuccinic acid, added to a container at 75 to Stir for 1.5 hours at a temperature of 76°C until it dissolves evenly and forms a transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com