Ship steam turbine lubricating oil composition

A technology of lubricating oil composition and steam turbine, which is applied in the direction of lubricating composition and petroleum industry, and can solve the problems of failing to meet the anti-rust performance requirements of marine lubricating oil, corrosion of steel rods, and failure to meet the lubrication requirements of marine steam turbines, etc. , to achieve excellent anti-oxidation performance, excellent extreme pressure performance, excellent air separation effect

Inactive Publication Date: 2012-09-19

PETROCHINA CO LTD

View PDF2 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The anti-rust agent uses a compound mixture of alkenyl succinic acid / phosphate amine salt. The test shows that if the substance is subjected to a liquid phase corrosion (synthetic seawater) test after being washed with high temperature water, the steel rod will rust and cannot reach the level of marine lubrication. Oil requirements for antirust performance

At the same time, the composition has no demulsifier ingredients, and its anti-emulsification performance is poor

Therefore, the composition cannot meet the lubrication requirements of marine steam turbines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

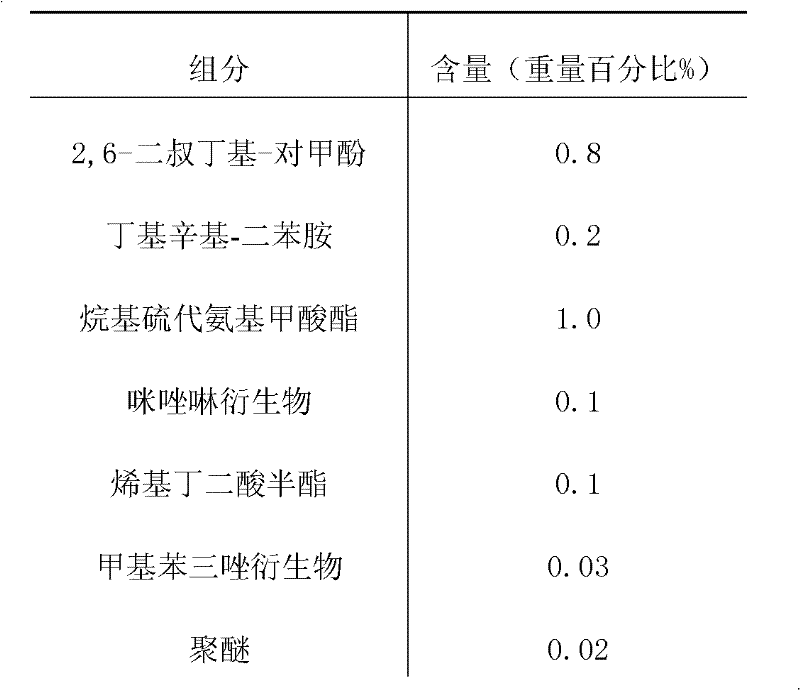

Embodiment 1

[0028]

[0029]

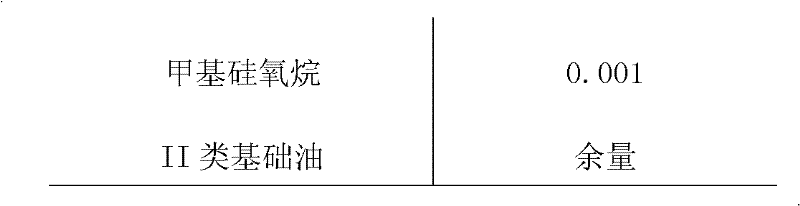

Embodiment 2

[0031]

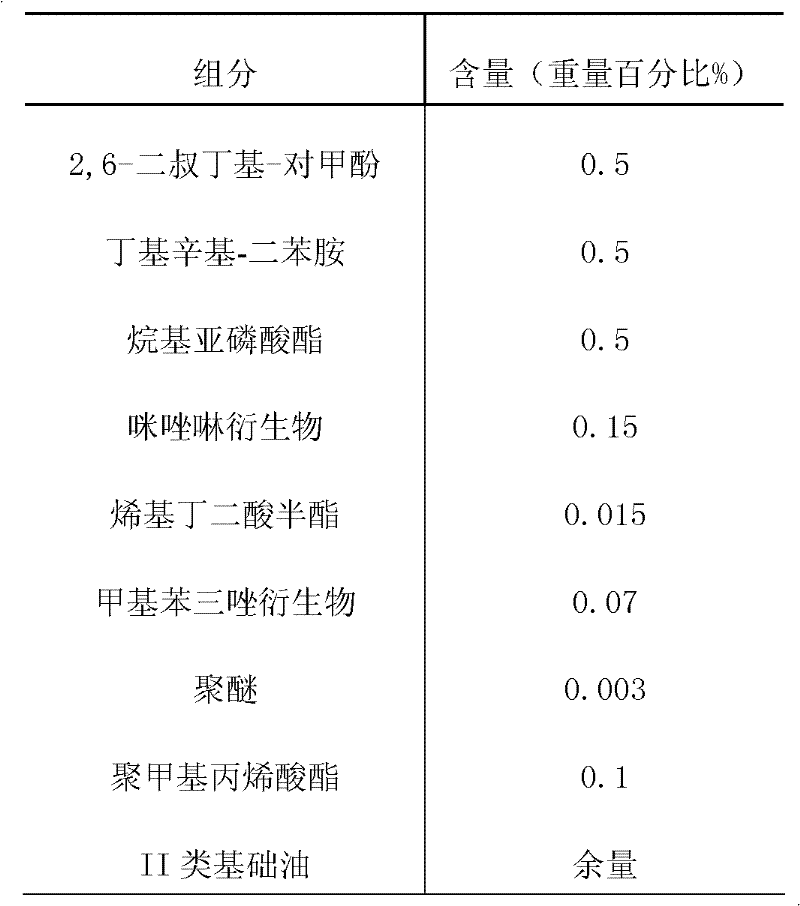

Embodiment 3

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a ship steam turbine lubricating oil composition. The ship steam turbine lubricating oil composition is characterized by comprising the following components in weight percent: 0.3-1.5% of antioxidant, 0.03-0.2% of rust inhibitor, 0.03-1% of wear-resistant agent, 0.003-0.1% of demulsifier, 0.001-0.1% of anti-foaming agent, 0.02-0.1% of metal deactivator and base oil in balancing amount. Through a direct liquid rustiness test (synthetic seawater, 24 h), the ship steam turbine lubricating oil composition is rustless; after distilled water is added at 90 DEG C and stirred for half an hour, the direct liquid rustiness test (synthetic seawater, 24 h) is further performed on a separated oil layer, and the ship steam turbine lubricating oil composition is still rustless; the anti-emulsification time in a steam method is less than 180 s; the FZG invalid level is greater than 12; the viscosity level is ISOVG68, anti-foaming performance is less than 65-65-65 / 0 (mL / mL); air is released for less than 8min; and the TOST oxidation life is longer than 10,000 h.

Description

technical field [0001] The invention relates to a lubricating oil composition, in particular to a marine steam turbine lubricating oil composition suitable for use on a marine steam turbine. Background technique [0002] Limited by the space of the ship's engine room, the volume of the steam turbine and its auxiliary equipment as the main engine of the ship is relatively small. Therefore, higher requirements are put forward for the performance of the ship's steam turbine lubricating oil. The first is the viscosity and extreme pressure performance requirements of the lubricating oil. The speed of the steam turbine is about 4000rpm. After the two-stage reduction gear, the speed is reduced to about 150rpm. The reduction ratio is very large. The viscosity of the lubricating oil is generally ISO VG 68 or ISO VG 100, the extreme pressure performance generally requires no less than 9 grades. The second is the requirement for the anti-rust performance of lubricating oil. Since the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N30/12C10N30/06C10N40/00C10N30/10C10N30/18

Inventor 王辉于军王建华孙大新刘庆国金琴华杨丽郑延波

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com