Low-temperature worm and gear lubricating grease composition and preparation method thereof

A lubricating grease composition and worm gear technology, applied in the field of lubricating grease, can solve problems such as difficult start-up, frequent maintenance and oil changes, etc., and achieve the effects of high output efficiency, excellent low-temperature start-up performance, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

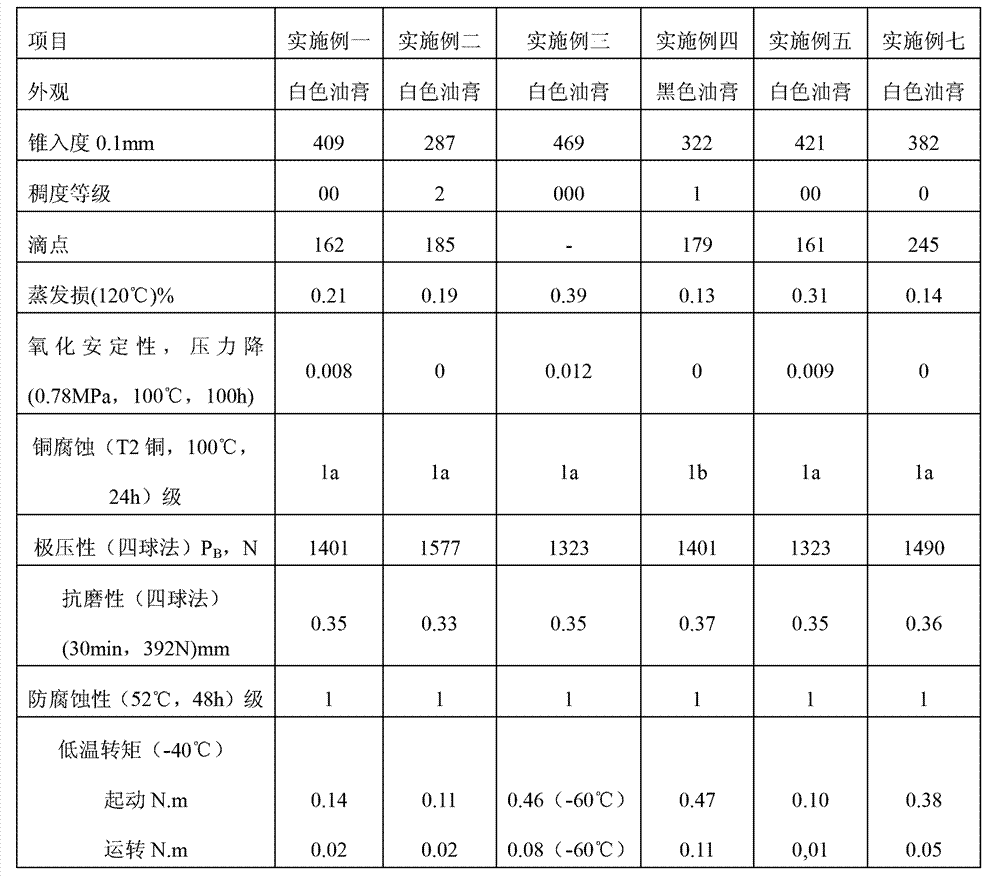

Examples

Embodiment 1

[0045] Embodiment one (normal pressure method)

[0046] 1) 180 kg of polyethylene glycol ether (V40=69.22mm 2 / s, the same below), 50 kg of 12-hydroxystearic acid were added to the reaction kettle in sequence, stirring and heating was started to raise the temperature to 90±10°C, all the mixture in the kettle became liquid, and 7.5 kg of LiOH·H 2 O and 37.5 kg of distilled water mixed solution, saponification reaction at constant temperature between 100-110°C for 30-90 minutes (12-hydroxystearic acid, LiOH·H 2 O reacts with distilled water mixture to generate lithium soap as a thickening agent).

[0047] 2) Continue to heat up to 160±10°C, add 167kg of polyethylene glycol ether, further stir and heat up to 210±15°C, and add metal deactivator: 2kg of benzene Triazole (T706) and antioxidant: 20 kg of phenyl-α-naphthylamine (T531), stirred for 10±5 minutes.

[0048] 3) 300 kilograms of polyethylene glycol ether and 150 kilograms of trimethylolpropane saturated fatty acid ester ...

Embodiment 2

[0049] Embodiment two (prefabricated soap method)

[0050] 1) Base oil: 380 kg polyalphaolefin oil (V40=146.98mm 2 / s, the same below) and thickener: 92 kg of 12-hydroxy lithium stearate were added to the reaction kettle in turn, and the temperature was raised to 210±15°C with heating and stirring. Agent: 3 kilograms of benzotriazole (T706), antioxidant: 5 kilograms of phenyl-α-naphthylamine (T531) and 5 kilograms of 2,6-di-tert-butyl-p-cresol (T501), stirred for 10 ± 5 minutes.

[0051] 2) The material is discharged into a blending kettle in which 190 kg of polyalphaolefin oil and 192 kg of bis-(2-ethylhexyl) sebacate have been added, stirred and cooled to 70±15°C, and extreme pressure anti-wear Agent: 3 kg amine phosphate, 30 kg oily potassium borate (T361), friction modifier: 15 kg isomeric monoglyceride stearate, rust inhibitor: 5 kg barium dinonyl naphthalene sulfonate (T705), solid Lubricant: 30 kg polytetrafluoroethylene ultrafine powder (PTFE) and 50 kg boron nitrid...

Embodiment 3

[0052] Embodiment three (prefabricated soap method)

[0053] 1) 393 kilograms of polyalphaolefin oil (V40=19.14mm 2 / s, the same below) and thickener: 45 kg of lithium stearate were added to the reaction kettle in turn, and the temperature was raised to 210±15°C with stirring and heating. Diphenylamine and 2.5 kg of diisooctyldiphenylamine were stirred for 10 ± 5 minutes.

[0054] 2) The material is discharged into the blending kettle that has added base oil: 200 kg of polyalphaolefin oil and 180 kg of di-(2-ethylhexyl) adipate, stirred and cooled to 70±15°C, and then added polar Pressure antiwear agent: 15 kg tricresyl phosphate (T306), 45 kg oily potassium borate (T361), friction modifier: 15 kg isomeric monoglyceride stearate, rust inhibitor: 5 kg dimer oleic acid, 3 kilograms of dodecenylsuccinic acid (T746), metal deactivator: 1.5 kilograms of benzotriazole derivatives (T551), solid lubricant: 30 kilograms of polytetrafluoroethylene ultrafine powder (PTFE) and 70 kilogr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com