Silicane crosslinked low-retraction polyethylene plastic and its preparation method and use

A polyethylene plastic and silane cross-linking technology, which is applied in the field of silane cross-linked low-shrinkage polyethylene plastic and its preparation and application, can solve the problems of limiting the development of silane cross-linking polyethylene insulating plastics, limiting production efficiency, and cables must be replaced. , to achieve the effect of improving the performance of insulation shrinkage test, improving production efficiency and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

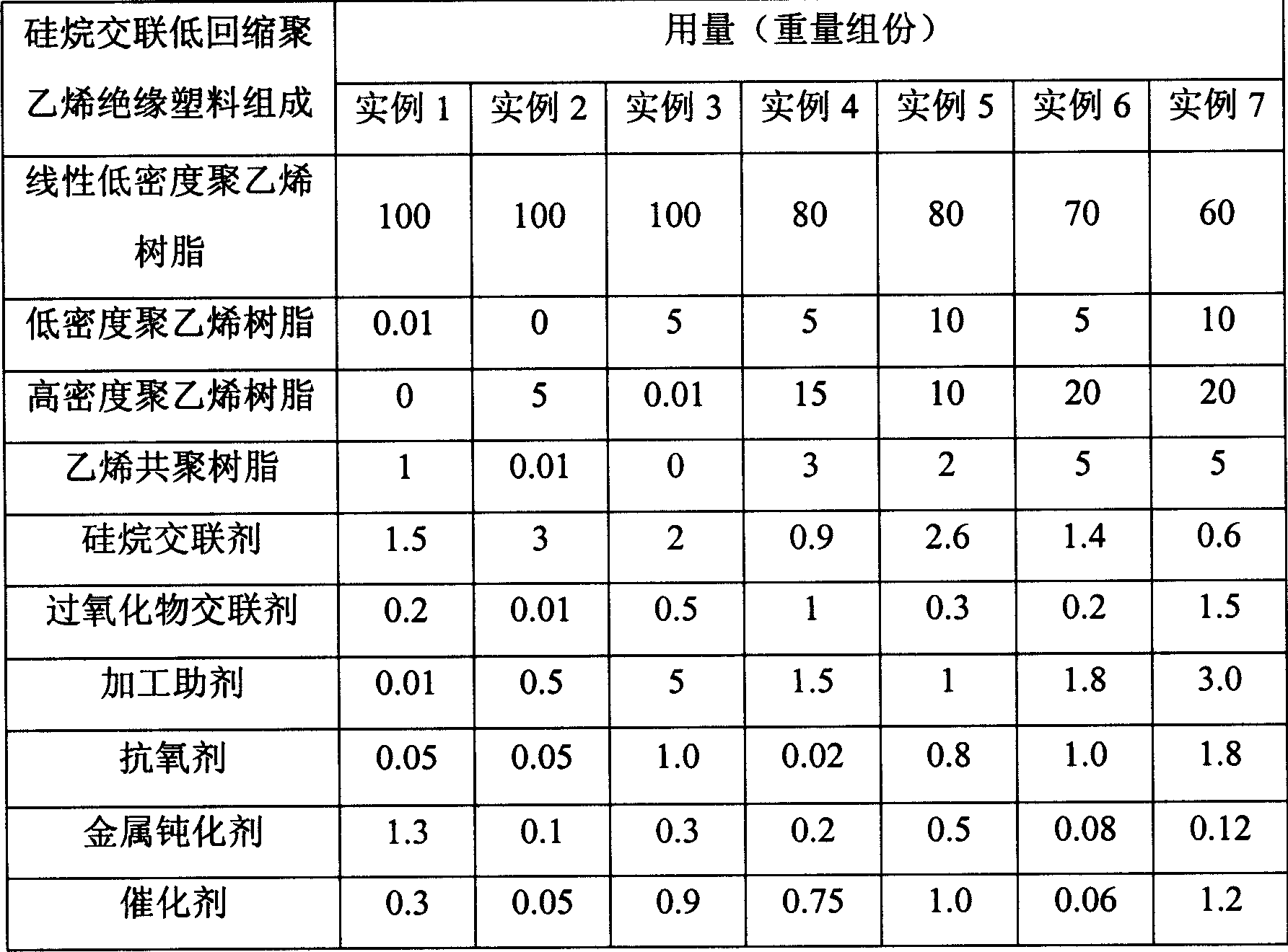

[0040] The formula is shown in Table 1 and Table 2.

[0041] Table 1

[0042]

[0043] Composition performance

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

Linear Low Density Polyethylene

Resin melt index g /

10min

0.1

10

0.5

1

2

5

8

[0044] Linear Low Density Polyethylene

Resin density g / cm 3

0.910

0.940

0.930

0.920

0.910

0.910

0.940

LDPE resin

Melt index g / 10min

10

-

5

5

10

5

0.1

LDPE resin

Density g / cm 3

0.920

-

0.925

0.924

0.917

0.923

0.922

HDPE resin

Melt index g / 10min

-

9

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com