Cereal drying machine

A grain dryer and drying tower technology, which is applied in the fields of drying and preserving seeds, adapting to climate change, food processing, etc., can solve the problem of destroying the drying environment, and achieve the effect of increasing the air volume and better filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

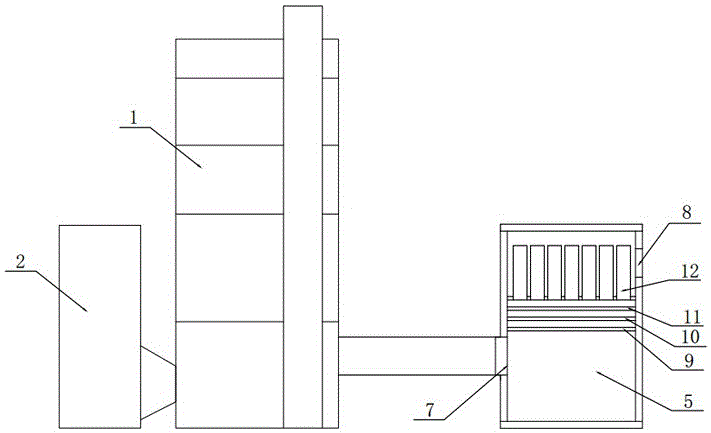

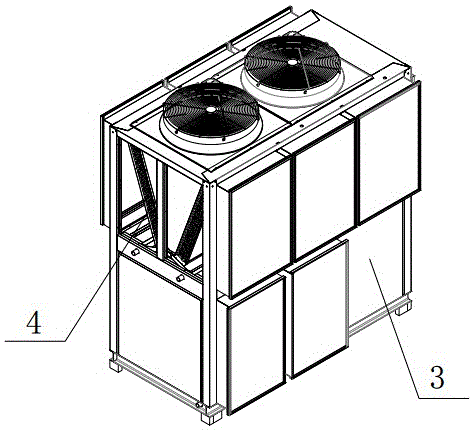

[0042] As shown in the figure: a grain dryer, including a drying tower 1 and a heat pump 2 connected to the drying tower 1 for providing hot air to the drying tower, the heat pump 2 includes a pump casing 3 and a The evaporator 4 also includes a dust collection room 5 communicating with the drying tower 1 for collecting exhaust gas discharged from the drying tower, and the evaporator 4 is provided with a heating device for defrosting.

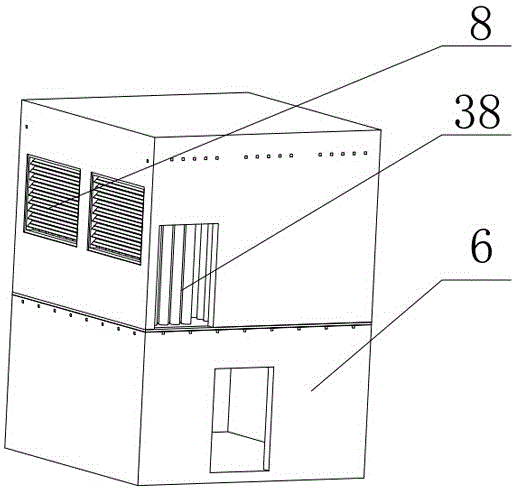

[0043] The dust collection room includes a box body 6, which is provided with a filter group that divides the inner chamber of the box body 6 into an upper chamber and a lower chamber, the lower chamber is provided with an inlet 7, and the upper chamber is There is an outlet 8 for the waste gas in the lower chamber to be discharged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com