Semiconductor manufacturing system

a manufacturing system and semiconductor technology, applied in the direction of coatings, metallic material coating processes, chemical vapor deposition coatings, etc., can solve the problems of long film-forming time, short life of ozone under elevated temperature conditions, and difficult uniform formation of dielectric films by cvd in high aspect ratio grooves with high coverage, etc., to achieve the effect of preventing the generation of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail with reference to the results of studies and experiments conducted by the present inventors to achieve the invention.

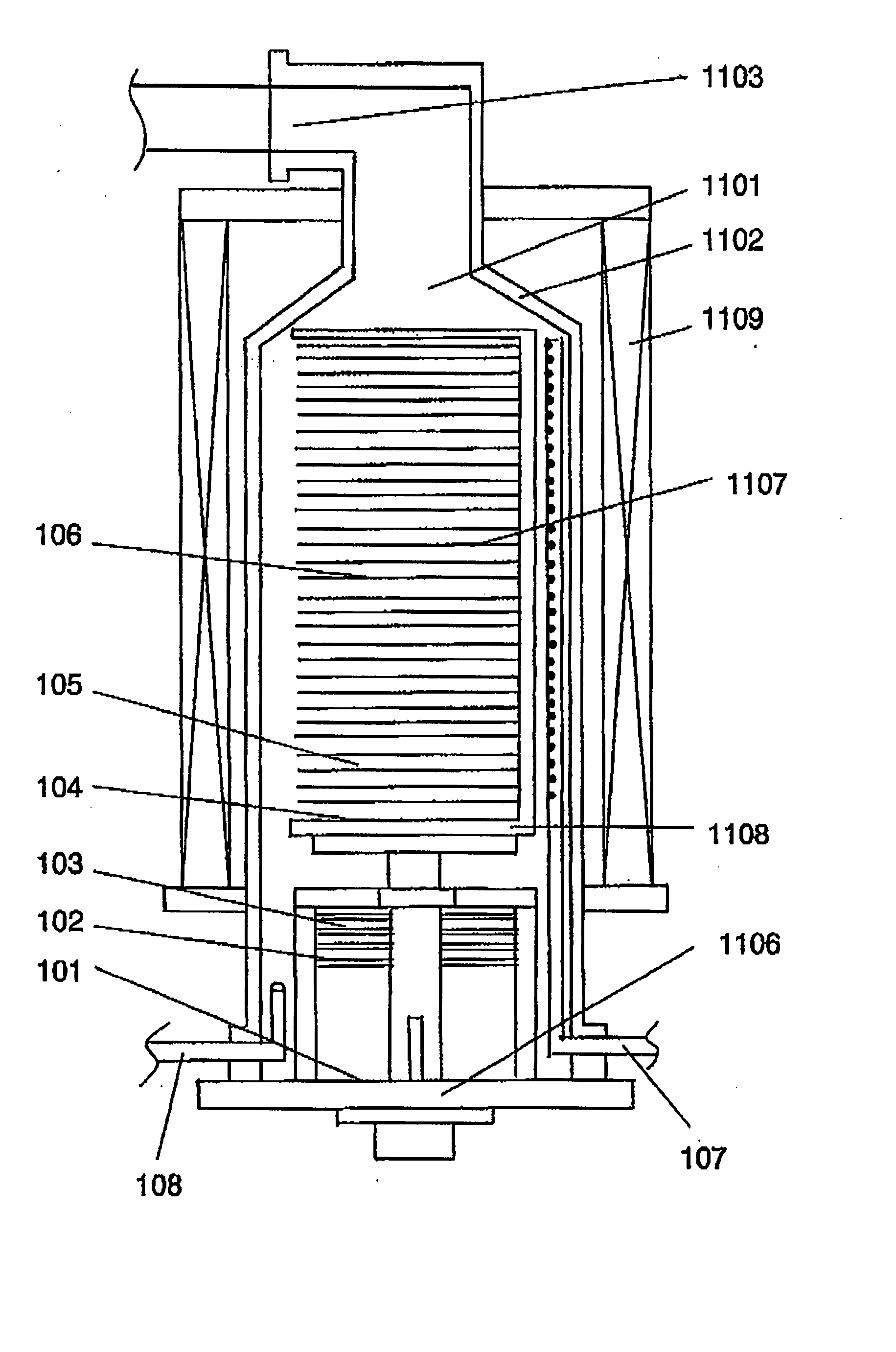

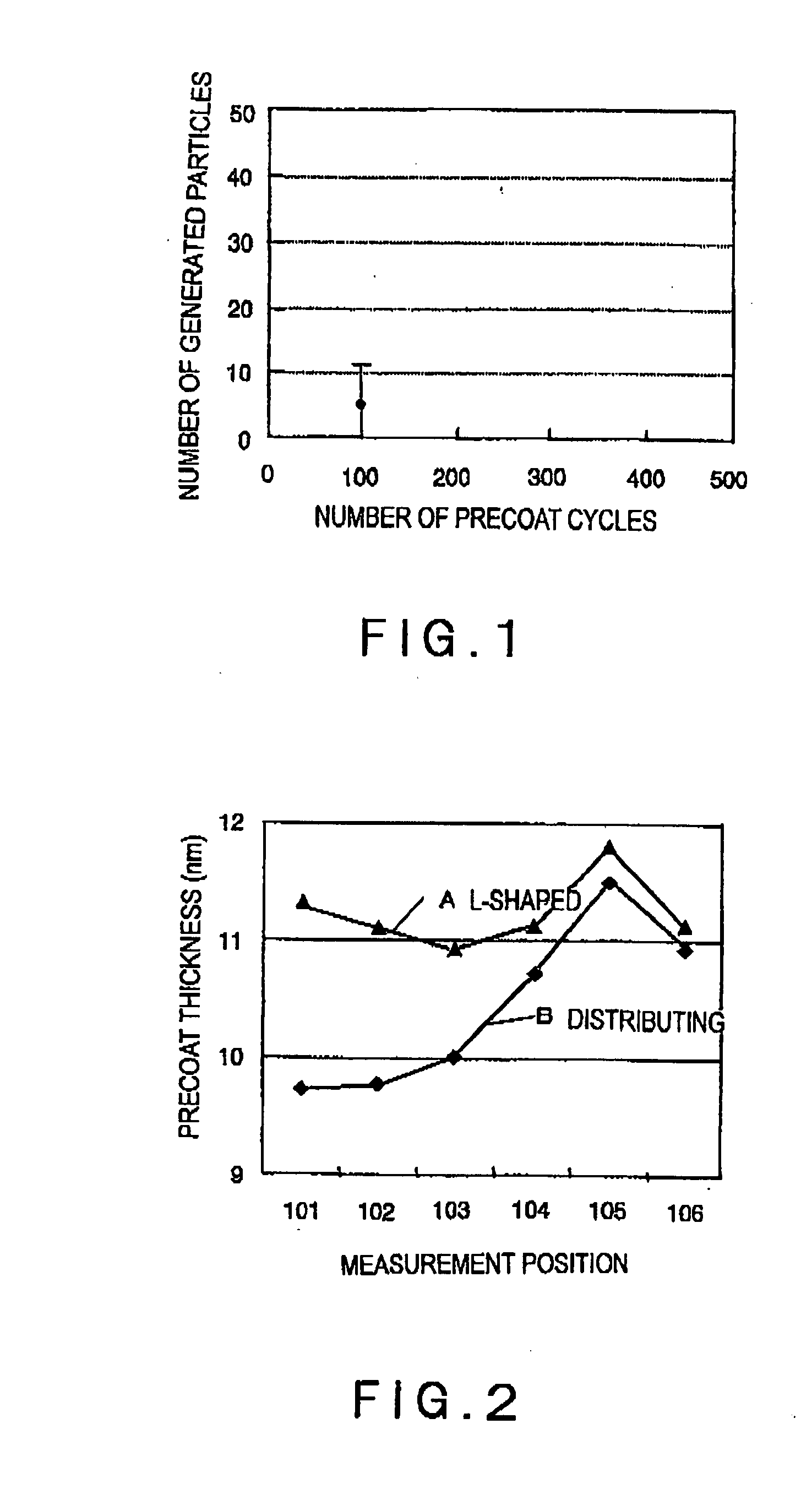

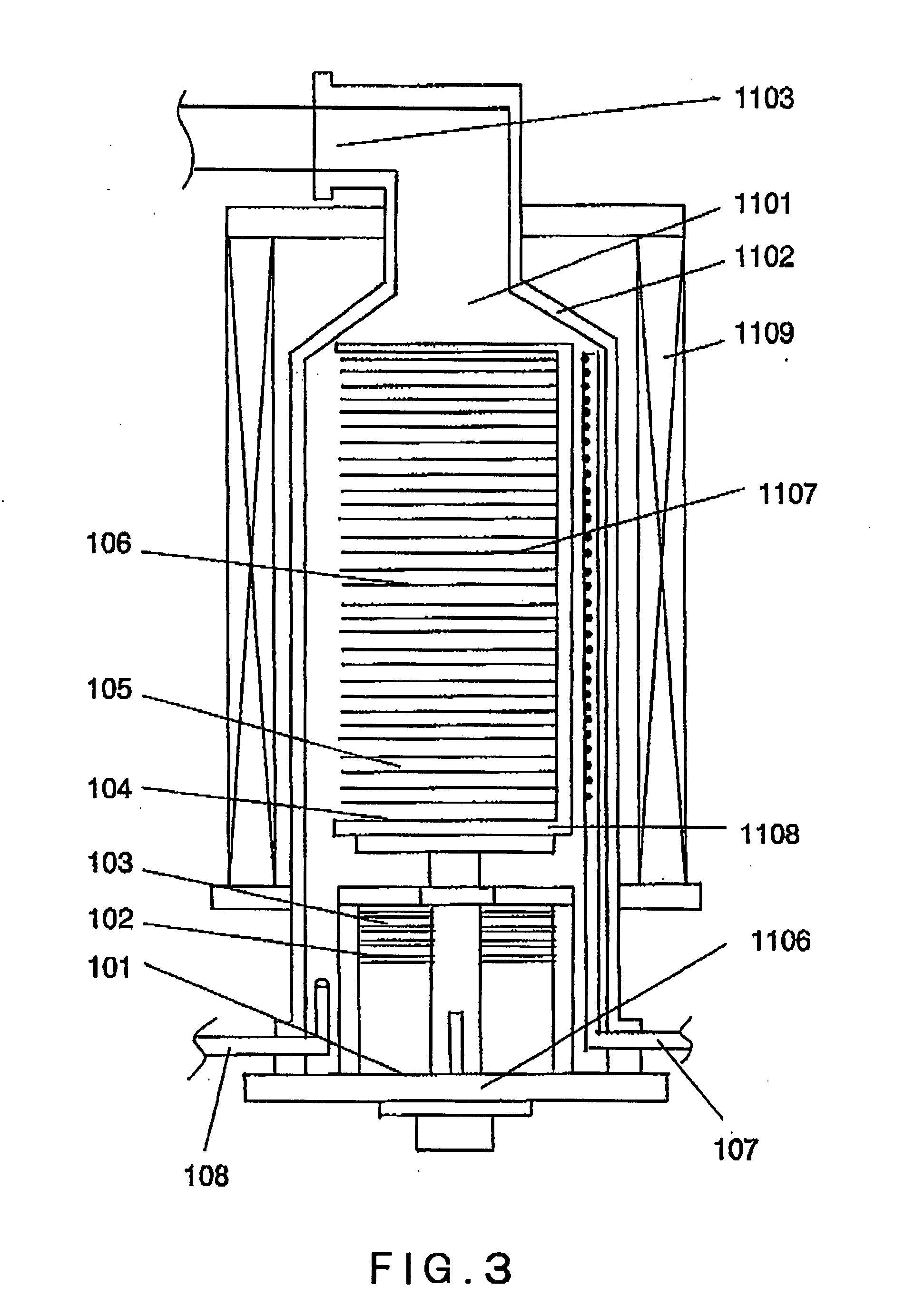

[0035] A precoating technique has been used to prevent the generation of particles resulting from peeling-off of unnecessary films in CVD apparatus. The precoating technique coats potentially peelable unnecessary films with a film (e.g., an SiO2 film) to prevent peeling-off of the unnecessary films. The present inventors have tried to extend this technique.

[0036] The present inventors conducted an experiment in which an HfO film was coated with an aluminum oxide (hereinafter referred to as an “AlO”) film. The AlO film was formed by an ALD process that repeats, a plurality of times, a deposition cycle consisting of a TMA gas flowing step, an evacuating step, a nitrogen gas flowing (purging) step, an ozone flowing step, an evacuating step, and a nitrogen gas flowing (purging) step which were performed in that or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com