Base board for optical mask, optical mask blank and optical mask

A photomask and substrate technology, which is applied in the field of large photomask substrates, can solve the problems of increased substrate weight, inability to handle photomasks safely, and easy slipping of side parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

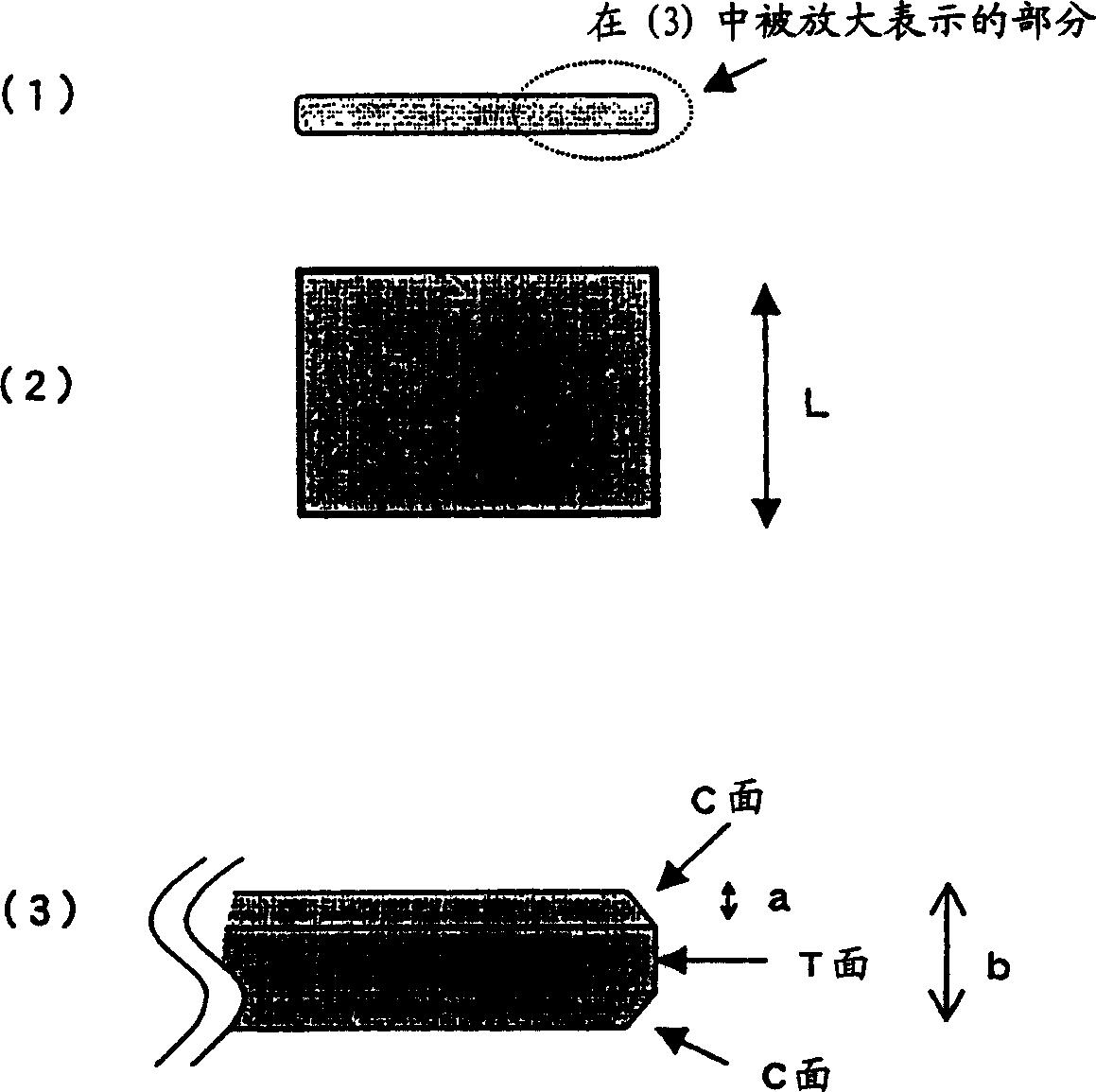

[0036] In the substrate for a large photomask described in Embodiment 1, the chamfered surface (C surface) and the end surface (T surface) constituting the side portion of the substrate for a large photomask are formed with a surface roughness on the entire circumference of the substrate. (Ra) is a rough surface of 0.03 to 0.3 μm.

[0037] Here, if the surface roughness (Ra) of the C surface and the T surface is less than 0.03 μm, it is easy to slip, and there is a danger of slipping at any time when picked up by hand. In addition, when the surface roughness (Ra) of the C surface and the T surface exceeds 0.3 μm, particles generated from the side surfaces are conspicuous.

[0038] The lower limit of the surface roughness (Ra) of the C surface and the T surface is preferably equal to or greater than 0.05 μm, more preferably equal to or greater than 0.1 μm, and most preferably equal to or greater than 0.15 μm. The upper limit of the surface roughness (Ra) of the C surface and t...

Embodiment 1

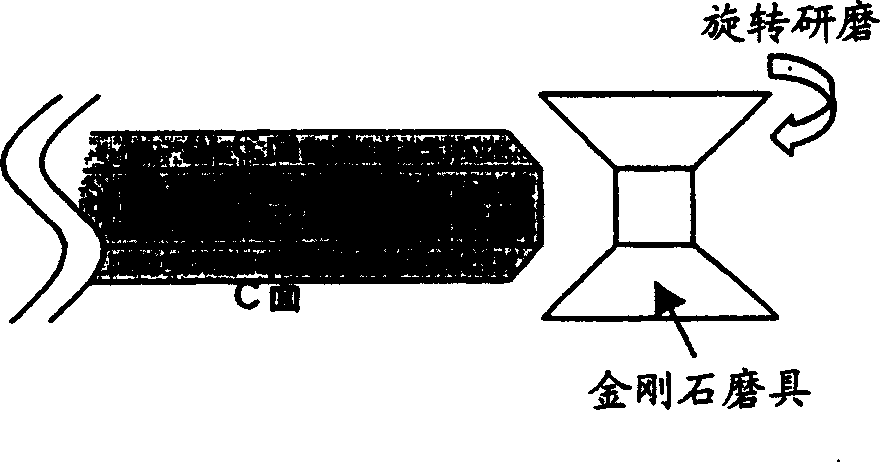

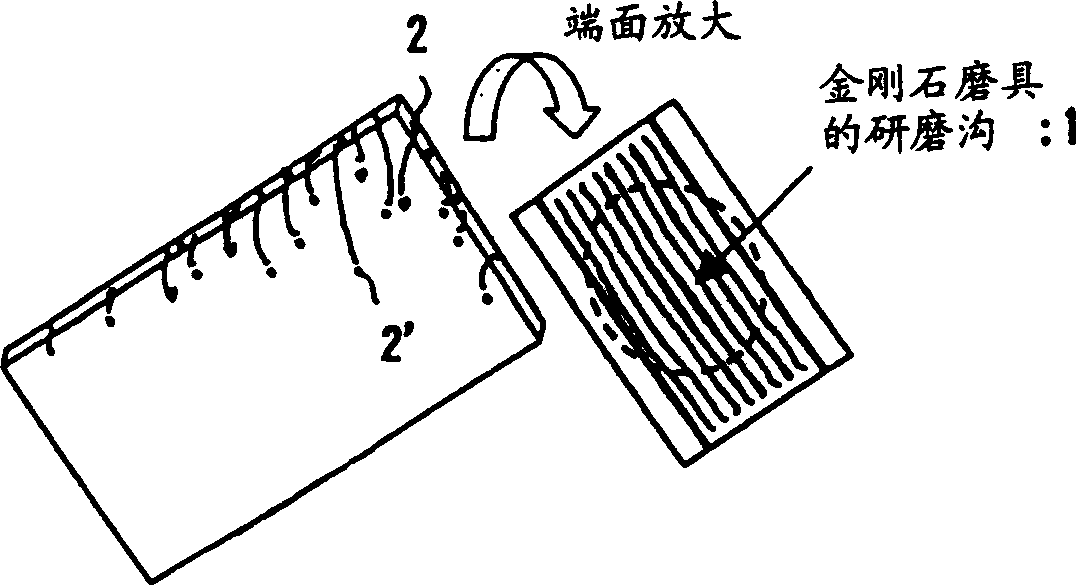

[0047] The side surfaces (C surface and T surface) of the substrate for a photomask were ground along the entire circumference of the substrate using a diamond grinder with a grain size of #800. The side surfaces (C surface and T surface) were polished to a rough surface with Ra of 0.2 μm. This surface is an opaque translucent surface when viewed visually. Here, the surface roughness Ra is measured on a line of about 10 mm at an arbitrary location of the side surface.

[0048] The photomask blank on which the light-shielding film was formed on the substrate was soaked and cleaned. Then, the surface of the cleaned photomask blank was inspected for foreign matter, and it was found that almost no particles that may be generated from the side surface of the substrate were detected.

[0049] Moreover, this board does not cause a problem particularly when it is picked up by hand.

Embodiment approach 2

[0051] In the substrate for a large photomask described in Embodiment 2, the chamfered surface (C surface) and the end surface (T surface) constituting the side portion of the substrate for a large photomask are formed on the entire circumference of the substrate, and the above-described The end surface T is formed as a rough surface, and the chamfered surface C is formed as a rough surface with a surface roughness smaller than that of the end surface.

[0052] Here, by making the chamfered surface C a rough surface smaller than the surface roughness of the end surface, there are the following advantages.

[0053] First, in the process of cleaning the substrate, photomask blank, and photomask, in addition to (1) so-called immersion cleaning in which the substrate is immersed in a cleaning solution, and (2) so-called spin cleaning in which the substrate is rotated while supplying the cleaning solution, There is also (3) so-called scrub cleaning in which the surface of the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com