Rare earth permanent magnet and method of manufacturing the same

A rare earth permanent magnet, rare earth element technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as poor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

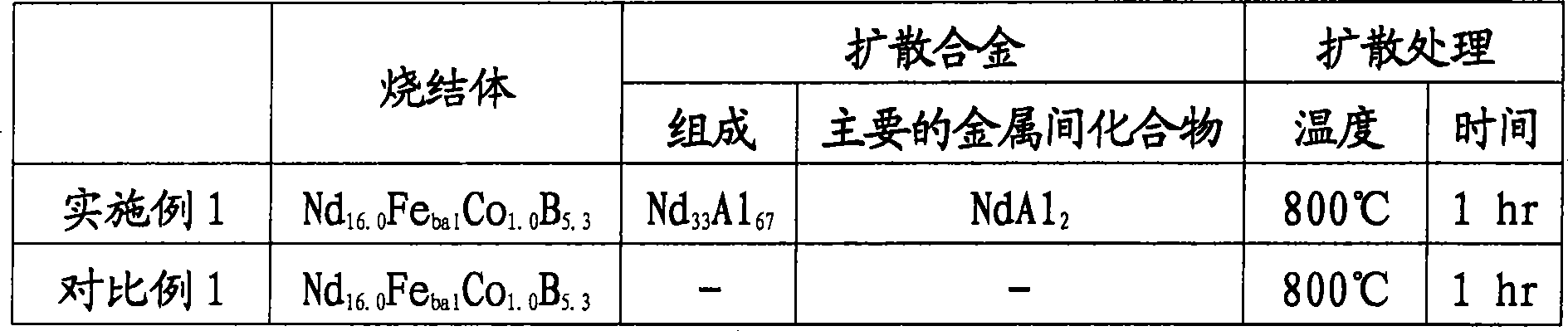

Embodiment 1 and comparative example 1

[0056] The magnet alloy is prepared as follows: Nd, Fe and Co metals with a purity of at least 99% by weight, and iron-boron alloy are melted by high-frequency heating in an argon atmosphere, and then the alloy melt is poured into a copper mold. The alloy was ground on a Brown mill to a coarse powder with a particle size of up to 1 mm.

[0057] Subsequently, the coarse powder was finely pulverized into a fine powder having a mass median particle diameter of 5.2 μm on a jet mill using high-pressure nitrogen. At about 300kg / cm 2 The fine powder is compacted under the pressure of 1592kAm -1 orientation in the magnetic field. Then, the green body was put into a vacuum sintering furnace where it was sintered at 1060° C. for 1.5 hours to obtain a sintered block. The agglomerate was machined on all surfaces into a shape with dimensions 4 x 4 x 2 mm using diamond grinding tools. Wash it with alkaline solution, deionized water, nitric acid and deionized water successively, and dry ...

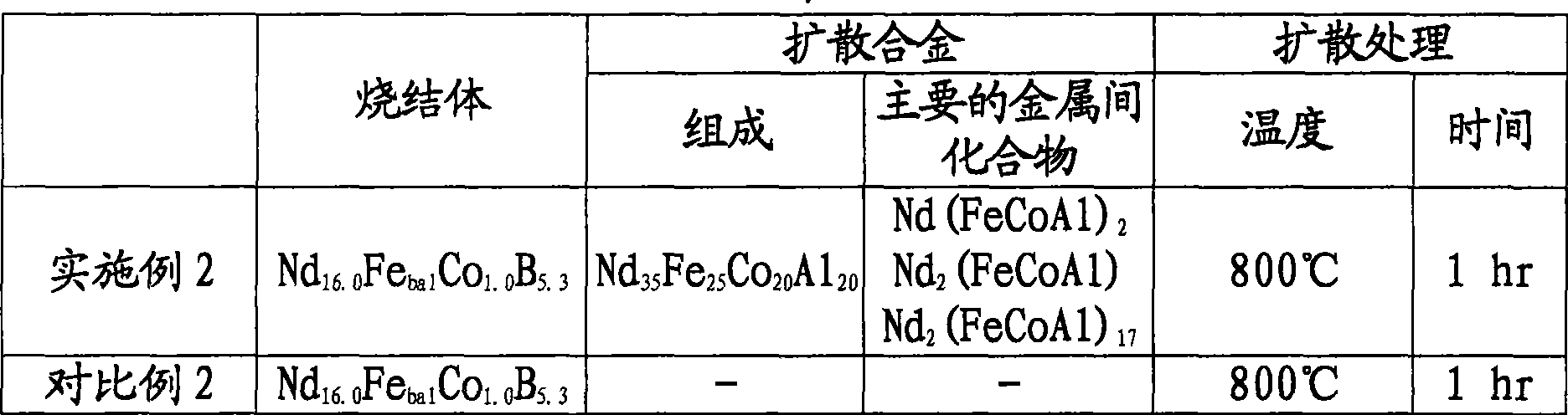

Embodiment 2 and comparative example 2

[0067] The magnet alloy is prepared as follows: Nd, Fe and Co metals with a purity of at least 99% by weight, and iron-boron alloy are melted by high-frequency heating in an argon atmosphere, and then the alloy melt is poured into a copper mold. The alloy was ground on a Brown mill to a coarse powder with a particle size of up to 1 mm.

[0068] Subsequently, the coarse powder was finely pulverized into a fine powder having a mass median particle diameter of 5.2 μm on a jet mill using high-pressure nitrogen. At about 300kg / cm 2 The fine powder is compacted under the pressure of 1592kAm -1 orientation in the magnetic field. Then, the green body was put into a vacuum sintering furnace where it was sintered at 1060° C. for 1.5 hours to obtain a sintered block. The agglomerate was machined on all surfaces into a shape with dimensions 4 x 4 x 2 mm using diamond grinding tools. Wash it with alkaline solution, deionized water, nitric acid and deionized water successively, and dry ...

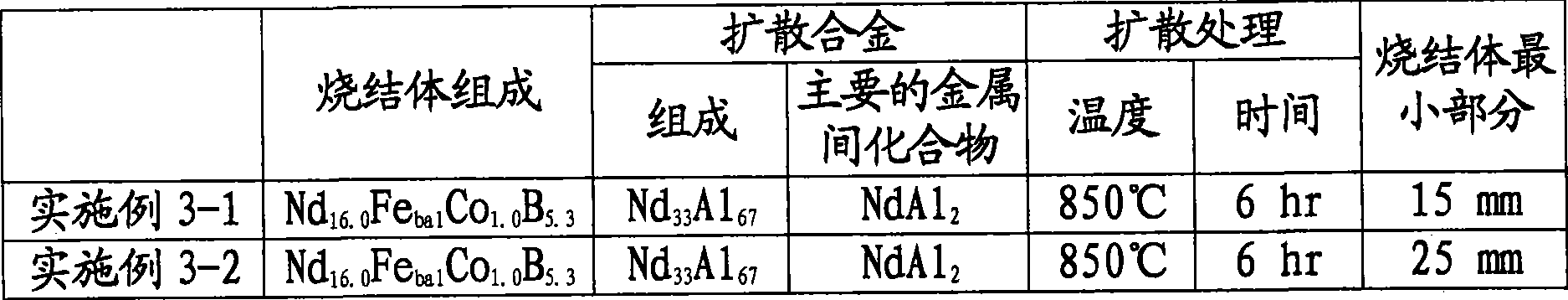

Embodiment 3

[0078] The magnet alloy is prepared as follows: Nd, Fe and Co metals with a purity of at least 99% by weight, and iron-boron alloy are melted by high-frequency heating in an argon atmosphere, and then the alloy melt is poured into a copper mold. The alloy was ground on a Brown mill to a coarse powder with a particle size of up to 1 mm.

[0079] Subsequently, the coarse powder was finely pulverized into a fine powder having a mass median particle diameter of 5.2 μm on a jet mill using high-pressure nitrogen. At about 300kg / cm 2 The fine powder is compacted under the pressure of 1592kAm -1 orientation in the magnetic field. Then, the green body was put into a vacuum sintering furnace where it was sintered at 1060° C. for 1.5 hours to obtain a sintered block. The agglomerate was machined on all surfaces into a shape with dimensions 50 x 50 x 15 mm (Example 3-1) or a shape with dimensions 50 x 50 x 25 mm (Example 3-2) using a diamond grinding tool . Wash it with alkaline solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com