Light emitting diode (LED) pixel unit device structure and preparation method thereof

A device structure and pixel unit technology, which is applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of large distance between LED chip units, different LED tube attenuation curves, poor color consistency of the display screen, etc., to reduce the size of the device Package area, solve the light blocking problem of pads and leads, and improve the effect of color consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The structure of the LED pixel unit device proposed by the present invention and its preparation method will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

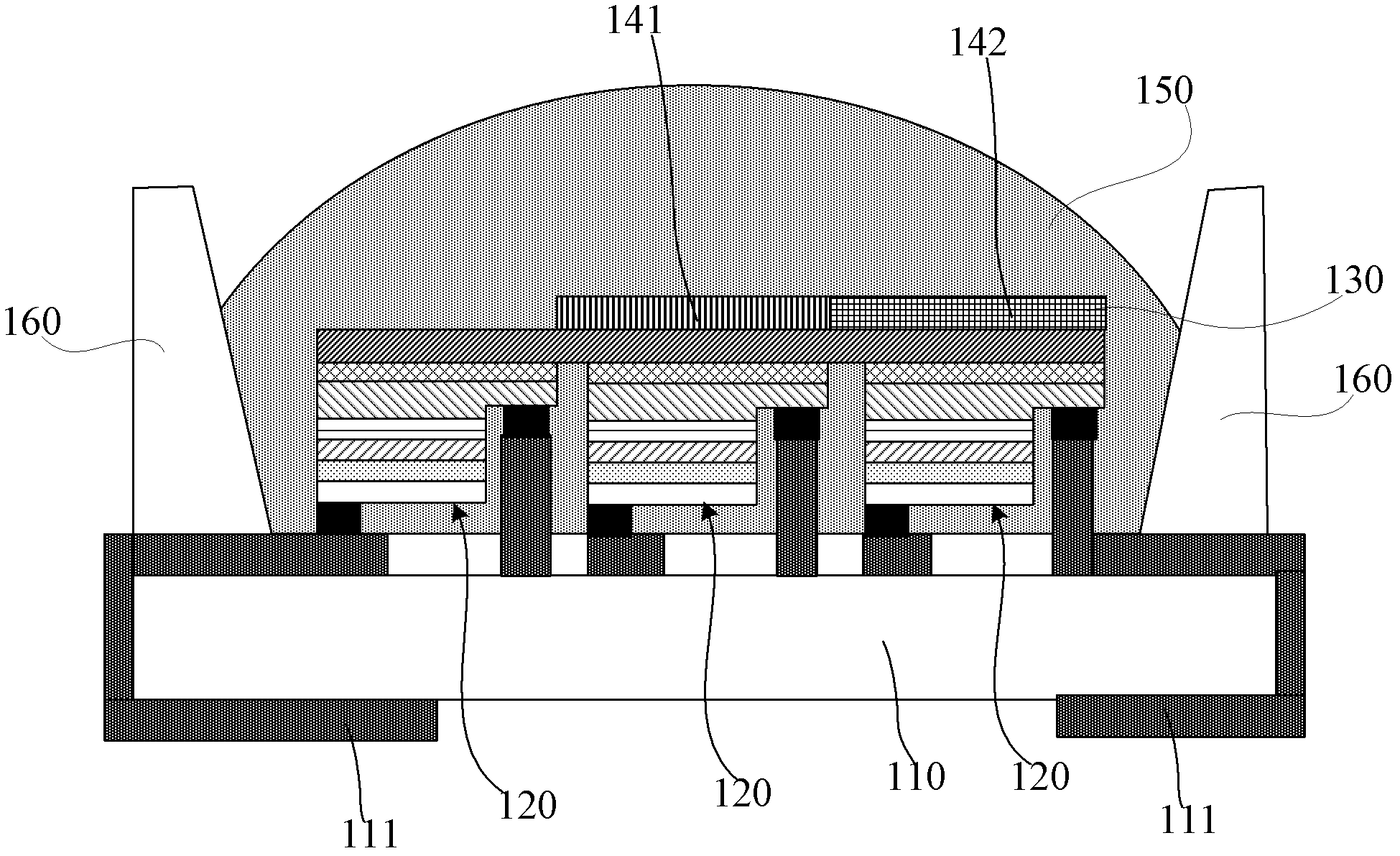

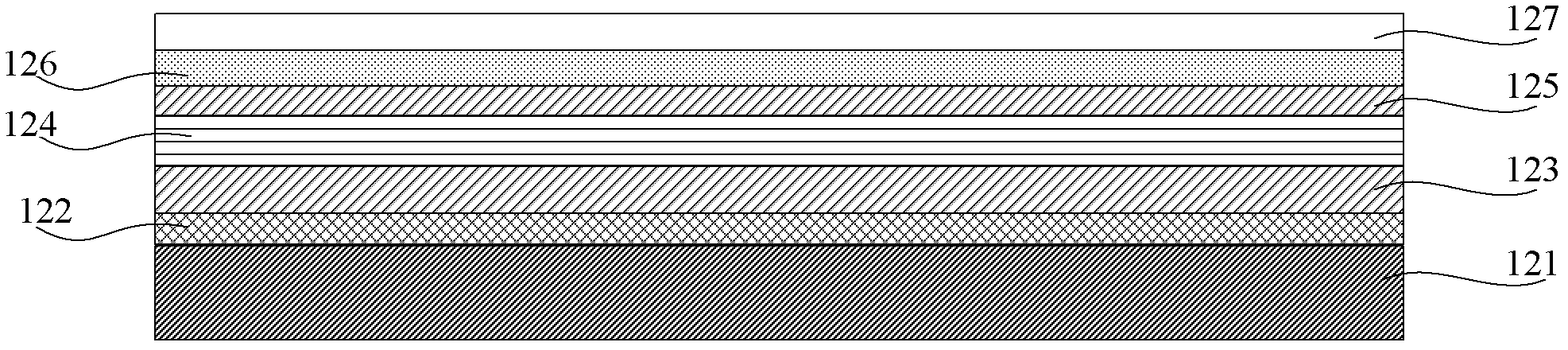

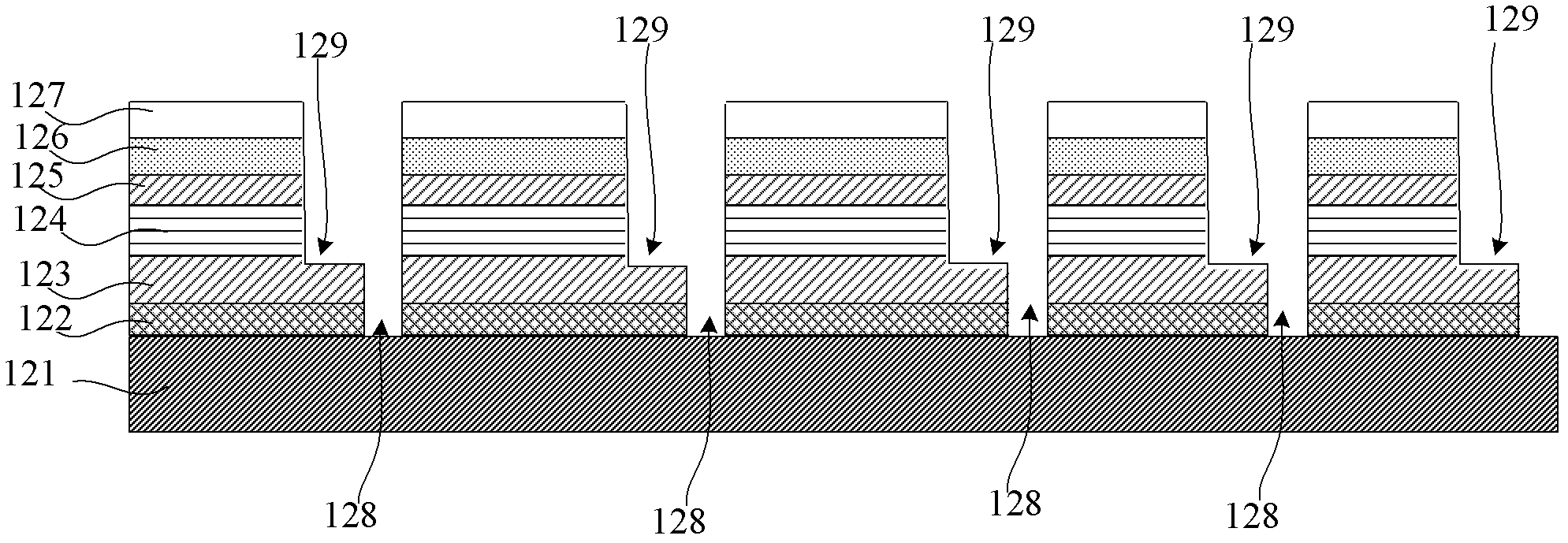

[0045]The core idea of the present invention is to provide a LED pixel unit device structure, and package three LED chip units that are connected by the same substrate but completely isolated electrically in a flip-chip structure, thereby reducing the device packaging area and improving The resolution of the LED display screen is improved; and the structures of the three LED chip units are exactly the same. By coating the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com