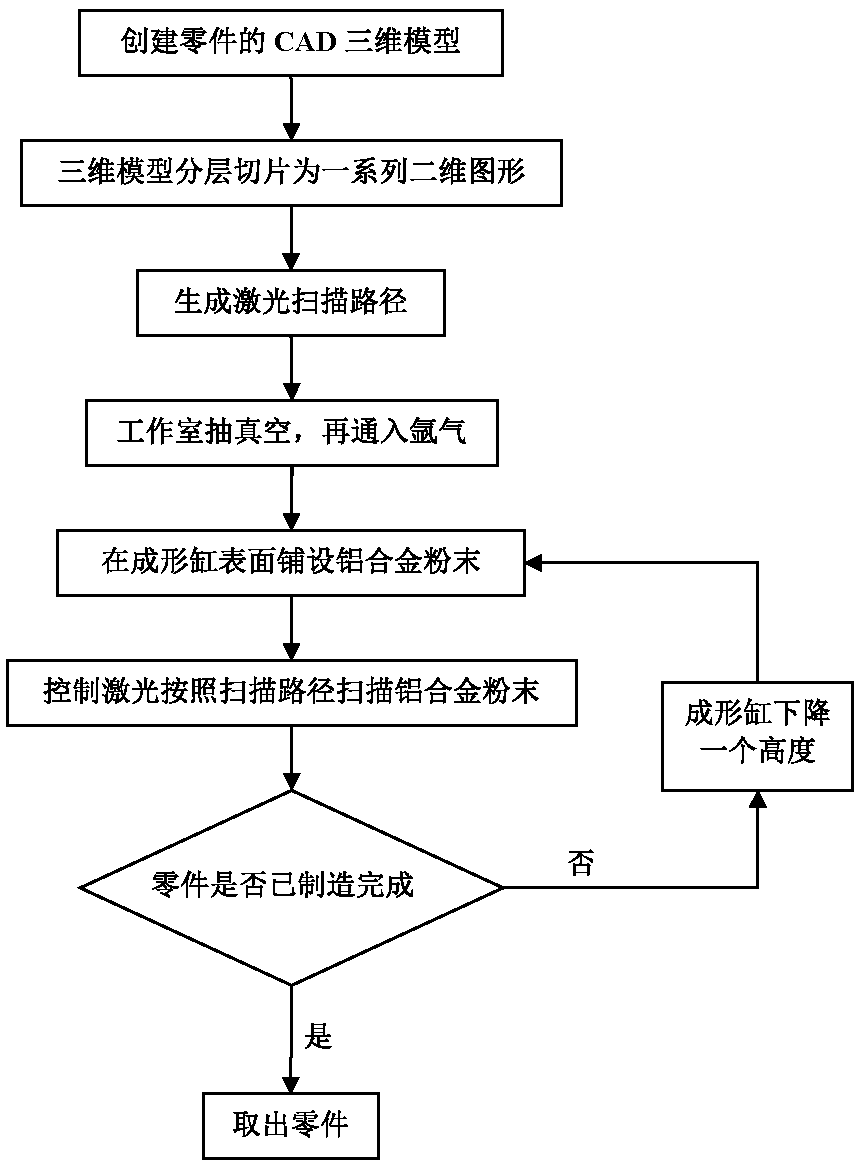

3D printing manufacturing device and method of metal parts

A metal parts, 3D printing technology, applied in the field of parts processing and manufacturing, to achieve the effect of improving material utilization, high mechanical properties, ensuring usability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto, and the process parameters not specifically indicated can be carried out with reference to conventional techniques.

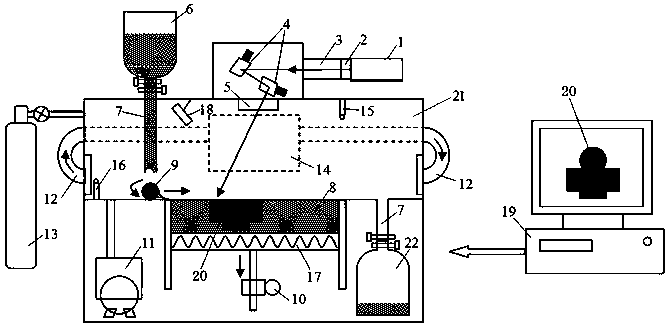

[0057] A 3D printing manufacturing device for metal parts, such as figure 2 As shown, including laser system, powder spreading system, atmosphere protection system, heating system and control system.

[0058] The laser system includes a laser 1 , an optical isolator 2 , a beam expander 3 , a scanning galvanometer 4 , and a focusing lens 5 . The laser 1 is a fiber laser, the laser output power is 200W, the wavelength is 1065nm, and the working mode is TEM 00 Mode, beam quality ≤ 1.2, spot diameter 5mm. The beam expansion factor of the beam expander 3 is 3. The scanning angle range of the scanning galvanometer 4 is ±20°. The focal length of the focusing lens 5 is 360mm. Laser 1 em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com