Steel plate for line pipes with excellent strength and ductility and process for production of same

A manufacturing method and ductility technology, applied in the field of line pipe (pipeline steel pipe), can solve the problems of reduced ductility and toughness, and achieve the effect of good strength and good ductility

Active Publication Date: 2011-07-06

NIPPON STEEL CORP

View PDF6 Cites 40 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the carbon equivalent is simply increased, the ductility and toughness will be reduced.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

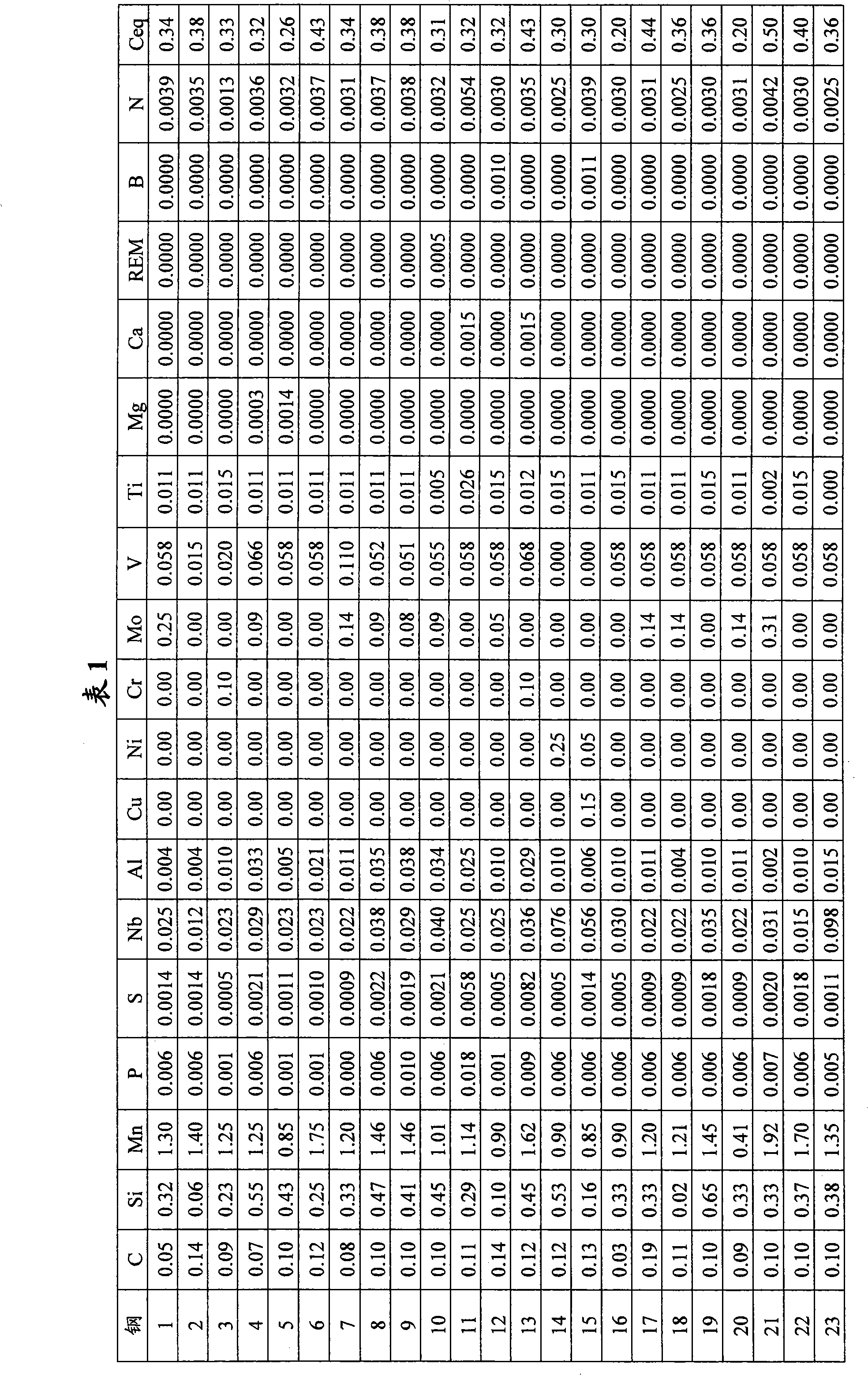

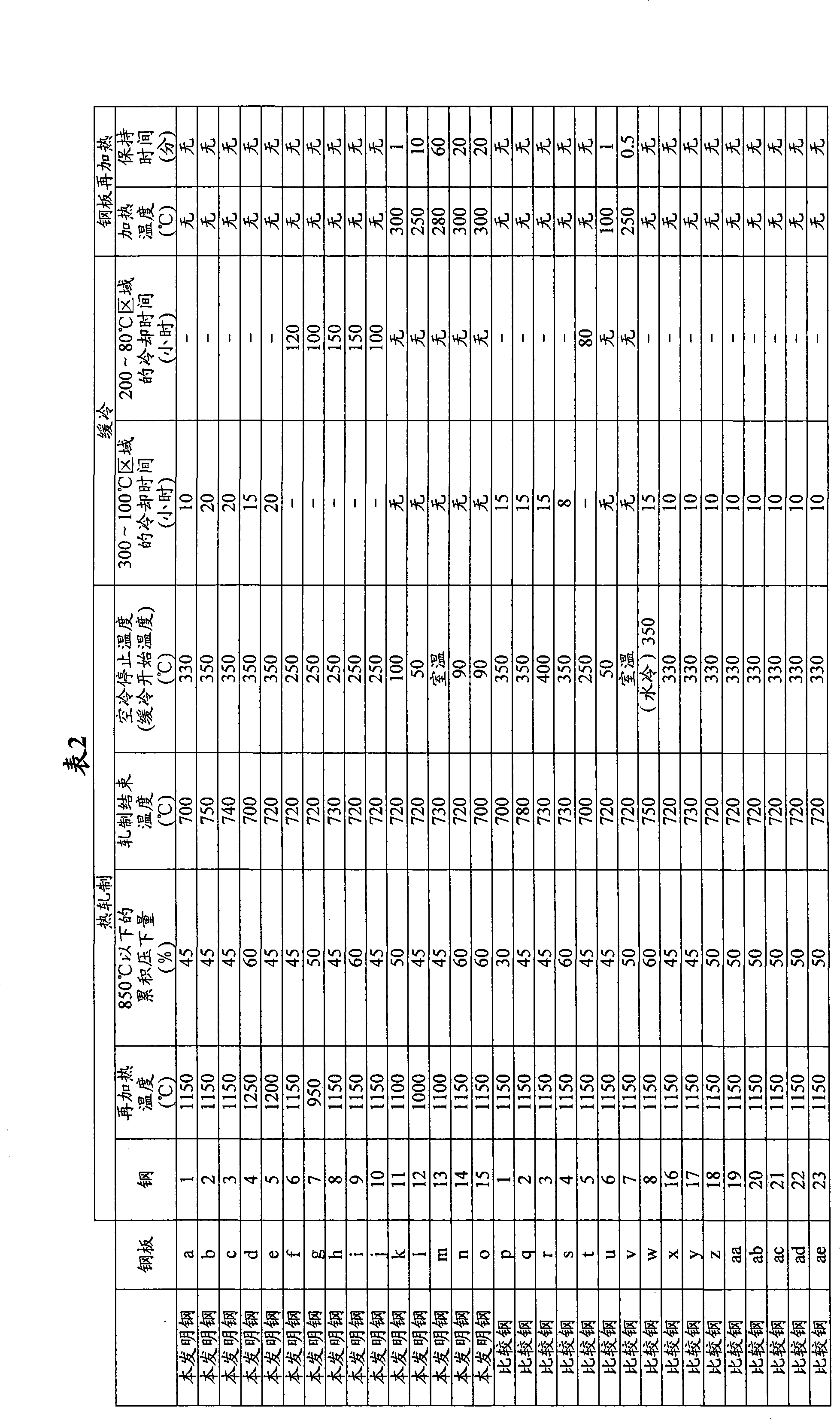

[0107] Next, examples of the present invention will be described.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Login to View More

Abstract

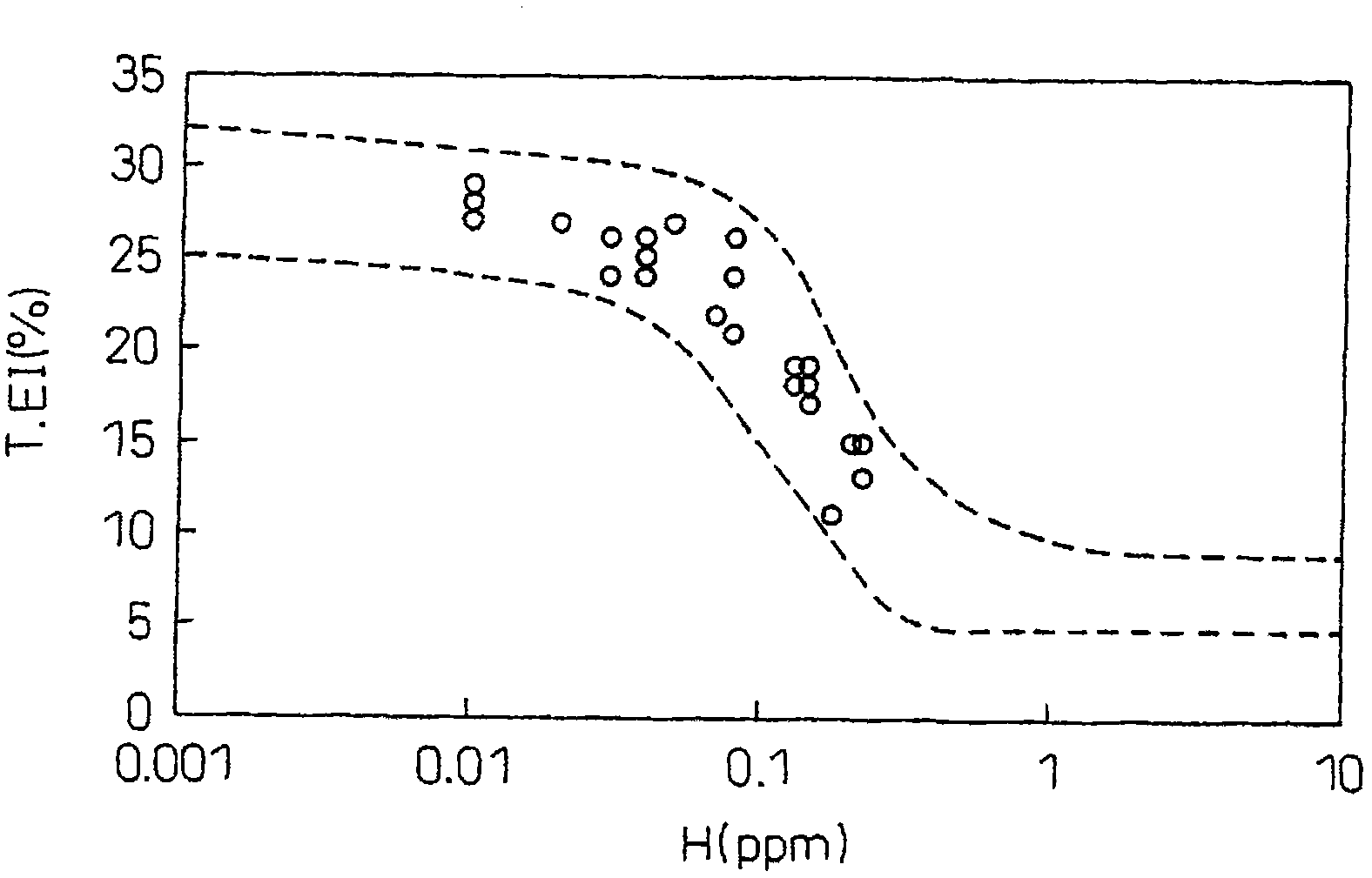

Provided is a steel plate for line pipes which exhibits excellent strength and ductility. Also provided is a process for the production of the steel plate. The steel plate is characterized by: having a steel composition which contains, by mass, 0.04 to 0.15% of C, 0.05 to 0.60% of Si, 0.80 to 1.80% of Mn, at most 0.020% of P, at most 0.010% of S, 0.01 to 0.08% of Nb, and 0.003 to 0.08% of Al with the balance being iron and unavoidable impurities, and which has a Ceq value of 0.48 or lower as defined by formula (1); having a mixed structure which is composed either of ferrite and pearlite or of ferrite and bainite-containing pearlite and which has a ferrite fraction of 60 to 95%; and exhibiting a yield strength of 450MPa or higher and a hydrogen content of 0.1ppm or lower. Ceq = C + Mn / 6 +(Cu + Ni) / 15 + (Cr + Mo + Nb + V + Ti) / 5 + 5B (1).

Description

technical field [0001] The present invention relates to a high-toughness, high-strength, and high-ductility steel plate for line pipe (pipeline steel pipe; line pipe) having sufficient strength as a steel plate for welded structures, excellent ductility properties, and excellent low-temperature toughness, and a manufacturing method thereof, In particular, it relates to a steel plate for line pipes that requires strength at low temperature toughness and good ductility in cold regions, and a method of manufacturing the same. Background technique [0002] In recent years, steel for line pipes has been required to be higher in strength in order to improve safety and / or improve work efficiency by increasing the pressure of transported gas, etc., and to reduce costs by reducing the use of steel materials. . In addition, the area of use of this steel is expanding to areas with harsh natural environments such as cold areas, and strict toughness characteristics are required. In a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/12C22C38/58C21D8/02

CPCC21D2211/005C21D2211/009C22C38/14C22C38/12C21D8/10C22C38/001C22C38/02C21D8/0205C21D8/0226C21D8/105C22C38/04C22C38/06C22C38/002

Inventor 石川肇植森龙治渡部义之侭田伸彦

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com