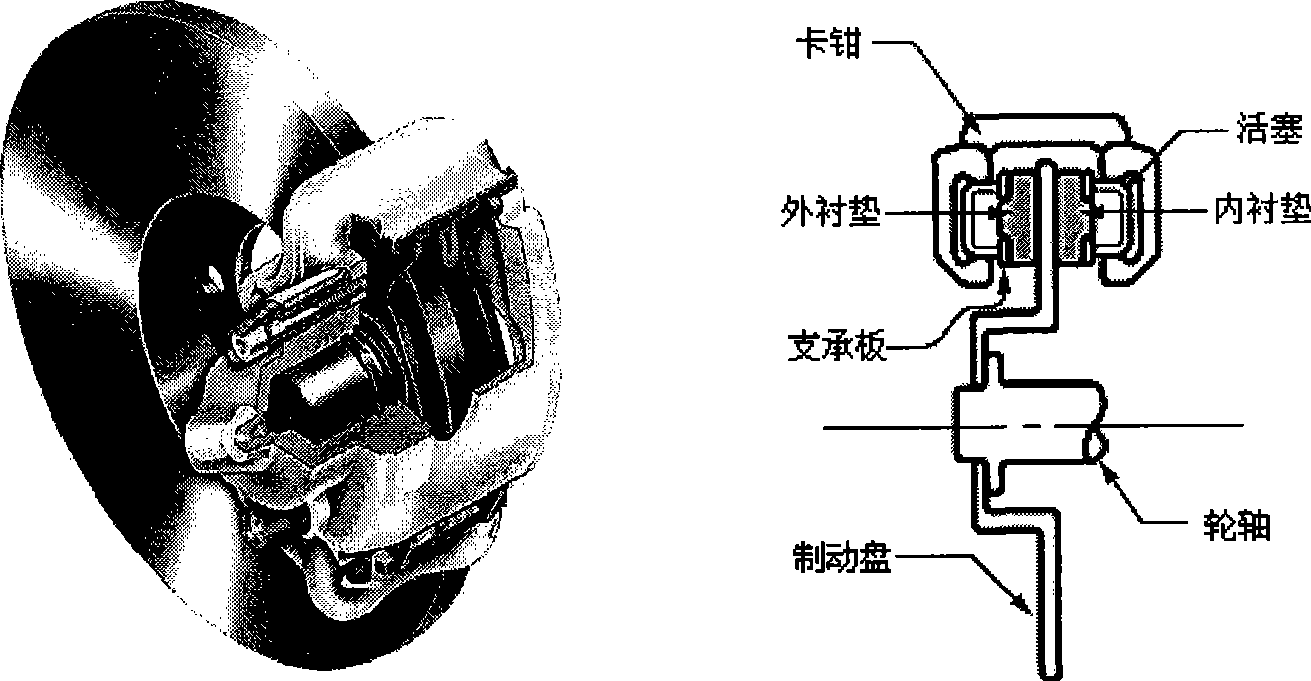

Niobium alloy cast iron brake disk material and technique for producing the same

A production process and brake disc technology, applied in the field of high carbon equivalent hypereutectic gray cast iron production, can solve problems such as complex preparation process, expensive manufacturing cost, unstable performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

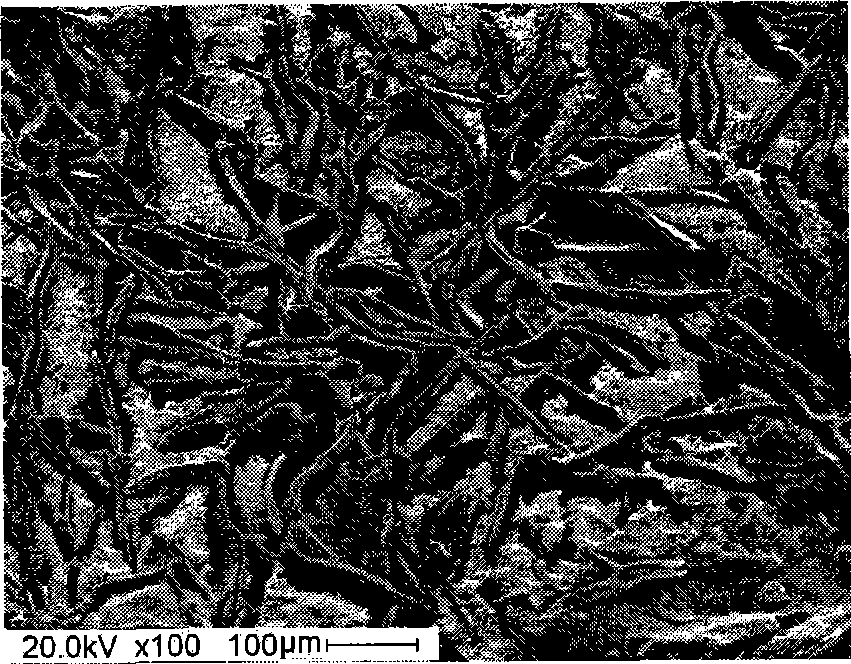

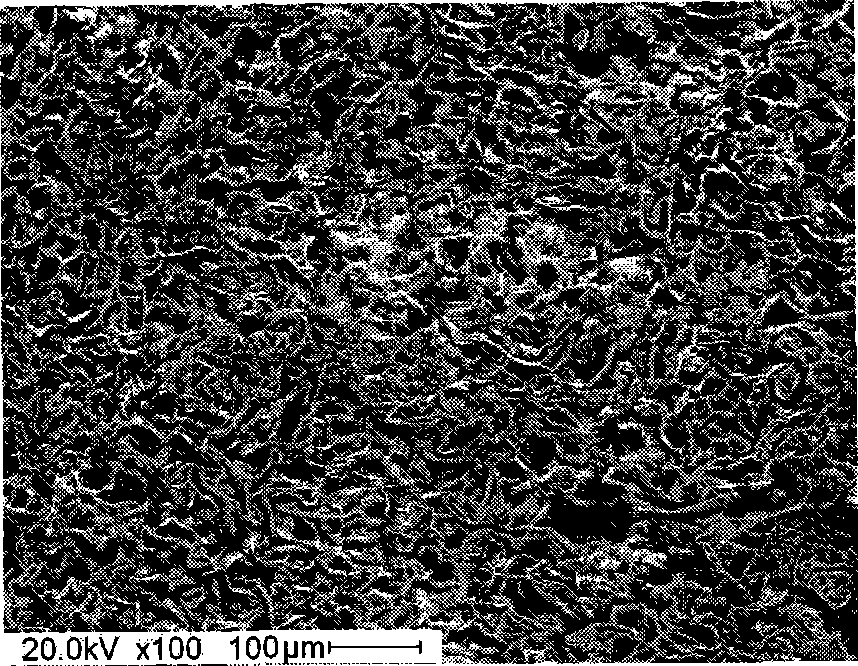

Examples

Embodiment Construction

[0024] Now the concrete implementation of the present invention is described in the following.

[0025] (1) Casting process

[0026] According to the performance of the brake disc and the requirements of the casting process, the basic composition (wt.%) of the cast iron material used in the experiment is as follows: 3.80~3.84% C; 2.03~2.08% Si; 0.71~0.74% Mn; 0.073~0.077% S; 0.08~ 0.09% P; Nb increasing from 0.042 to 1.48%; CE: 4.51-4.56%. The specific ingredients are shown in Table 1. Ductile iron pig iron, low-carbon scrap steel, similar returned iron, manganese, copper, niobium and other alloy materials are used as raw materials. The experimental ferroniobium is 65% standard ferroniobium, and the particle size after crushing is 3-5mm. After batching according to the ingredients, it is melted in a 1t intermediate frequency induction furnace. The feeding sequence and casting process are as follows:

[0027] Part of the charge (returned iron + scrap steel)→pig iron→iron fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com