ZSM-5 type molecular sieve and method for preparing the same

A ZSM-5, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of no aluminum source found, no aluminum source found, and achieve the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

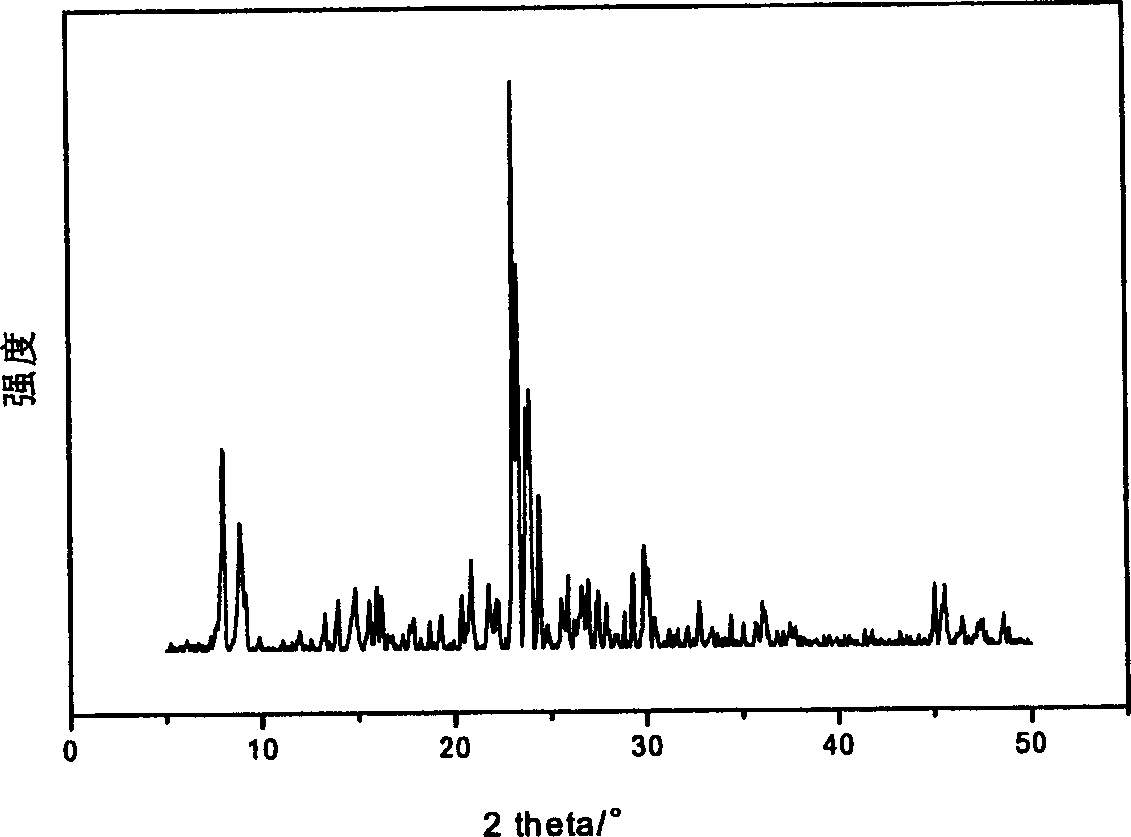

[0059] Using commercially available 400-mesh perlite (product of Dalian Zhongde Perlite Factory, see attached table 1 for composition) as raw material, 15 g was roasted in a muffle furnace at 700°C for 5 hours. Water glass (containing SiO 2 20.9 wt%, Na 2 O 6.9wt%) 200g, 1.5g ZSM-5 seed crystal (Nankai University Catalyst Factory, silicon-aluminum ratio 38), distilled water 350g, concentration is that the about 55g of 3M sulfuric acid aqueous solution and the perlite after roasting process drop into stainless steel reactor, stir The mixture was formulated into a gel (pH about 11.0) in 40 minutes. The molar ratio of each component in the gel according to its oxide is: SiO 2 / Al 2 o 3 =49; (Na 2 O+K 2 O) / SiO 2 =0.26;H 2 O / SiO 2 =33. After sealing, heat up to 180°C and crystallize at a constant temperature for 24 hours under stirring. After the crystallization is completed, cool and filter to remove the mother liquor, wash and dry the filter cake to obtain a crystalli...

Embodiment 2

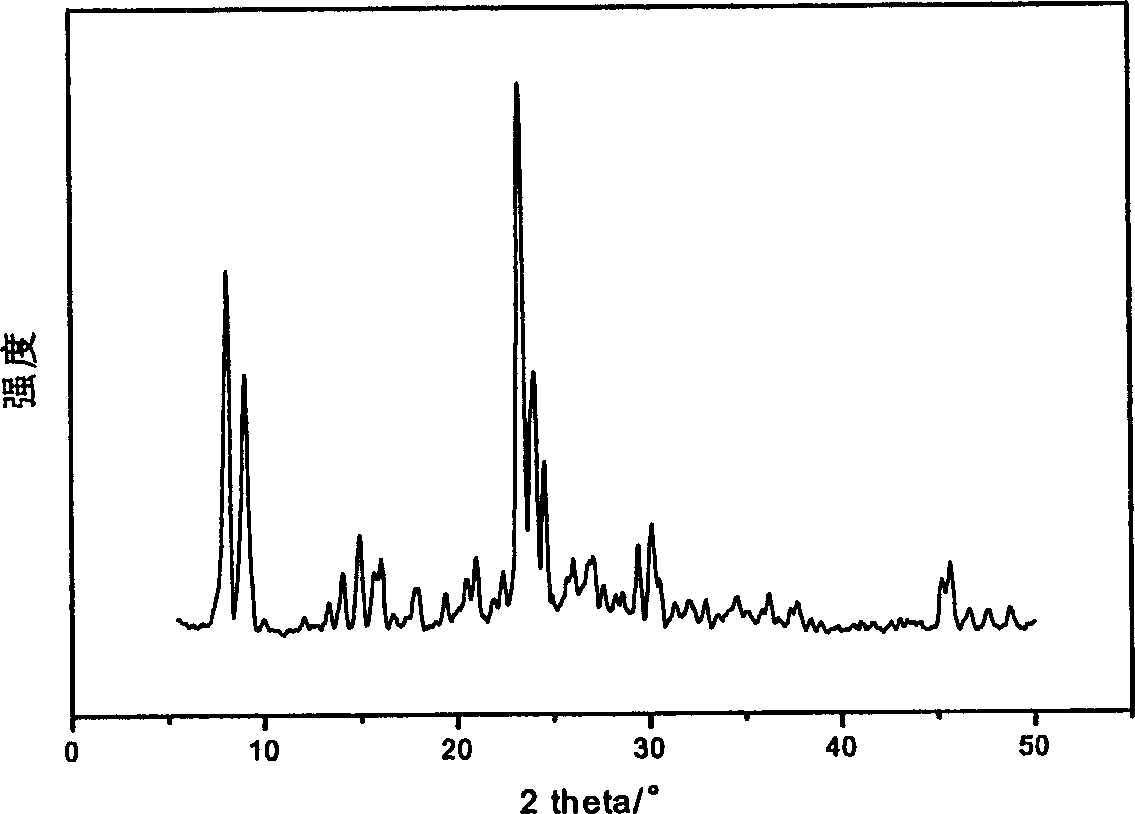

[0062] Using fine-grained commercially available kaolin as raw material (50% of the particle size is not greater than 3.1 μm, see attached table 2 for the composition), 15 g was roasted in a muffle furnace at 950° C. for 6 hours. Water glass (containing SiO 2 20.9 wt%, Na 2 (06.9wt%) 200g, 2g ZSM-5 crystal seed (commercially available commodity of Nankai University Catalyst Factory, silicon-aluminum ratio 38), water 250g, concentration is that the kaolin after the about 55g of 3M sulfuric acid and the above-mentioned roasting process drops into the stainless steel reactor, Stir for 30 minutes to form a mixture gel (pH about 10.6). The molar ratio of each component in the gel according to its oxide is: SiO 2 / Al 2 o 3 =14; (Na 2 O+K 2 O) / SiO 2 =0.26;H 2 O / SiO 2 =28. After the stainless steel reactor was sealed, the temperature was raised to 180°C for crystallization for 20 hours. After the crystallization is completed, the temperature is lowered, the mother liquor i...

Embodiment 3

[0065] All reaction raw materials are with example 2, and wherein kaolin roasting condition is 930 ℃ of roasting 7 hours, with water glass 250g, 1g ZSM-5 crystal seed (Nankai University Catalyst Factory, silicon-aluminum ratio 38), deionized water 300g, and roasting treatment The last 18g of kaolin is dropped into the stainless steel reactor, and the molar ratio of the oxide in the gel is: SiO 2 / Al 2 o 3 =14; (Na 2 O+K 2 O) / SiO 2 = 0.26. Under stirring, add 1M nitric acid aqueous solution to adjust the pH value of the system to about 10.5, and stir for 30 minutes. After the stainless steel reactor was sealed, the temperature was raised to 150°C for crystallization for 10 hours, and then the temperature was raised to 180°C for 10 hours for crystallization. After the crystallization is completed, the mother liquor is removed by filtration, and the filter cake is washed and dried to obtain a crystallized product. As determined by X-ray diffraction, the phase is ZSM-5 mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com