Polytetrafluoroethylene regenerative powder, process for producing same and bar produced thereby

A technology of polytetrafluoroethylene and recycled powder, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of high water content in powder, influence of subsequent processes, low molecular activity, etc., and achieves no foaming and uniform texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings, but it is not limited by the embodiment.

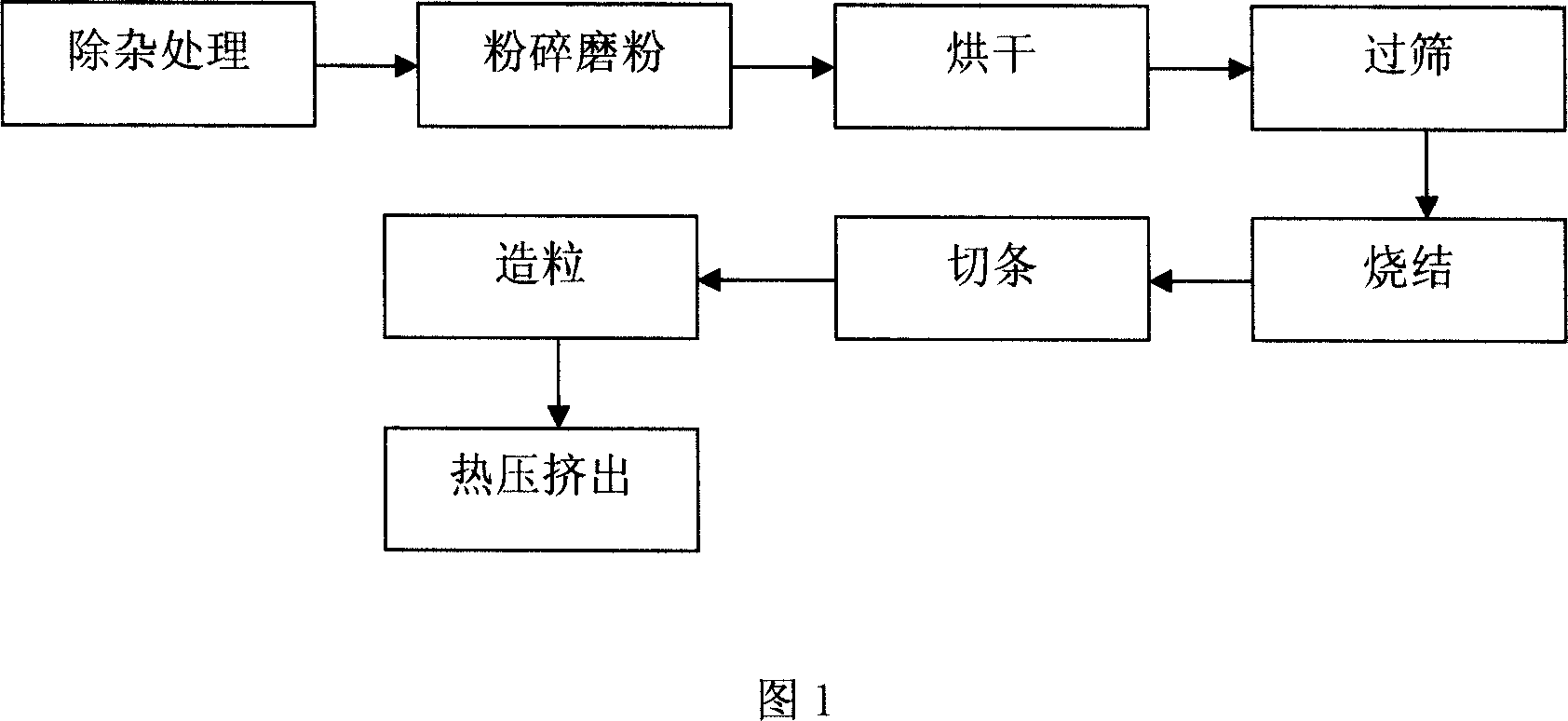

[0024] A kind of preparation method of polytetrafluoroethylene regenerated powder as shown in Figure 1, except the hot extrusion process shown in Figure 1, comprises the following steps:

[0025] 1. Impurity removal treatment. Cut off large pieces of Teflon scrap, wash, spin dry, and scrape away surface stains.

[0026] 2. Crush and grind. Cut the above-mentioned massive polytetrafluoroethylene waste into strips, and grind them into powder with emery wheels.

[0027] 3. Dry. The polytetrafluoroethylene powder obtained above is evenly dried in an oven, and the temperature of the oven is set at 100-200°C.

[0028] 4. Sieve. Sieve the powder with an iron sieve to make the powder particles evenly reach 100-350 mesh.

[0029] 5. Sintering. The powder obtained above is sintered in an oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com