Thermoplastic elastomer composition and resin as well as preparation method and application of thermoplastic elastomer composition and resin in manufacturing of runways and courts

A thermoplastic elastomer and composition technology, used in roads, roads, buildings, etc., can solve the problems of long-term exposure to high temperature or strong ultraviolet radiation, and can not meet sports wear resistance, achieve no irritating odor, improve resistance Grinding performance, the effect of excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A kind of preparation method of thermoplastic elastomer resin, this preparation method comprises the following steps:

[0053] 1) According to the proportioning in the thermoplastic elastomer composition described in any one of claims 1-5, SEBS resin and white oil were mixed uniformly for 5-10 minutes, and left to stand for 12-24 hours to obtain the mixture;

[0054] 2) Add polypropylene, fillers, lubricants, antioxidant additives, anti-aging additives, crosslinking agents and wear-resistant additives to the above mixture, and mix well;

[0055] 3) Extrude and granulate through a twin-screw extruder to obtain

[0056] 7. The preparation method according to claim 6, characterized in that, in step 3), the temperature of the first zone of the twin-screw extruder is 150-170°C, and the temperature of the head and other zones is 190-230°C.

[0057] The fourth object of the present invention is to provide an application of a thermoplastic elastomer composition and resin in ma...

Embodiment 1

[0062] A thermoplastic elastomer resin, its specific preparation method is as follows:

[0063] 1) Add 20wt% star-shaped SEBS resin and 37wt% paraffin-based white oil to a high-speed mixer, mix for 5 minutes, and then let stand for 12 hours;

[0064] 2) Add 10wt% polypropylene copolymer, 30wt% talcum powder, 1wt% calcium stearate, 0.2wt% antioxidant 1098, 0.1wt% antioxidant 168, 0.1wt% diisoperoxide Propylbenzene, 0.2wt% UV absorber UV-9, 0.2wt% light stabilizer 770 and 1.2wt% tetraacicular zinc oxide whiskers mixed for 10 minutes;

[0065] 3) Put the mixed materials into the twin-screw extruder. The temperature of the first zone of the twin-screw extruder is 150-170°C, and the temperature of the head and other zones is 190-230°C; extrude and granulate.

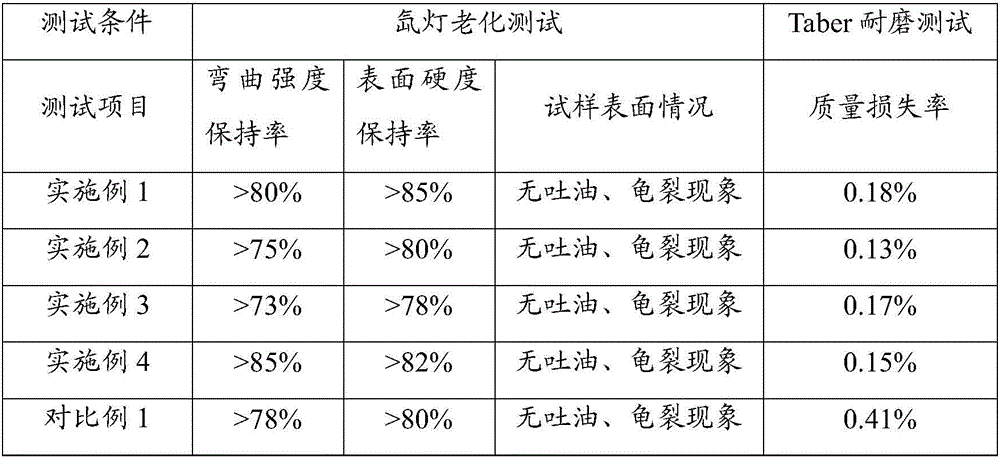

[0066] Table 1 shows the performance test data of the environment-friendly wear-resistant and weather-resistant thermoplastic elastomer composition prepared in this example.

Embodiment 2

[0068] A thermoplastic elastomer resin, its specific preparation method is as follows:

[0069] 1) Add 40wt% linear SEBS resin and 20wt% naphthenic white oil into a high-speed mixer, mix for 7 minutes, and then let stand for 15 hours;

[0070] 2) Add 20wt% homopolypropylene, 18wt% talcum powder, 0.8wt% PE wax, 0.3wt% antioxidant 245, 0.3wt% dioctadecyl thiodipropionate, 0.1wt% Dicumyl peroxide, 0.2wt% UV absorber UVP-327, 0.1wt% light stabilizer 744 and 0.2wt% tetraacicular zinc oxide whiskers mixed for 8 minutes;

[0071] 3) Put the mixed material into the twin-screw extruder, the temperature of the first zone of the twin-screw extruder is 150-170°C, the temperature of the head and other zones is 190-230°C, and granulate after extrusion.

[0072] Table 1 shows the performance test data of the environment-friendly wear-resistant and weather-resistant thermoplastic elastomer composition prepared in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com