Migration-type organic reinforced concrete anti-corrosion admixture

A reinforced concrete, migration-type technology, applied in the field of concrete admixtures, can solve the problems that the long-term performance of rust resistance cannot be guaranteed, and the later mechanical properties of concrete mixtures are affected, so as to achieve superior rust resistance, structural safety, and avoidance of rust. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

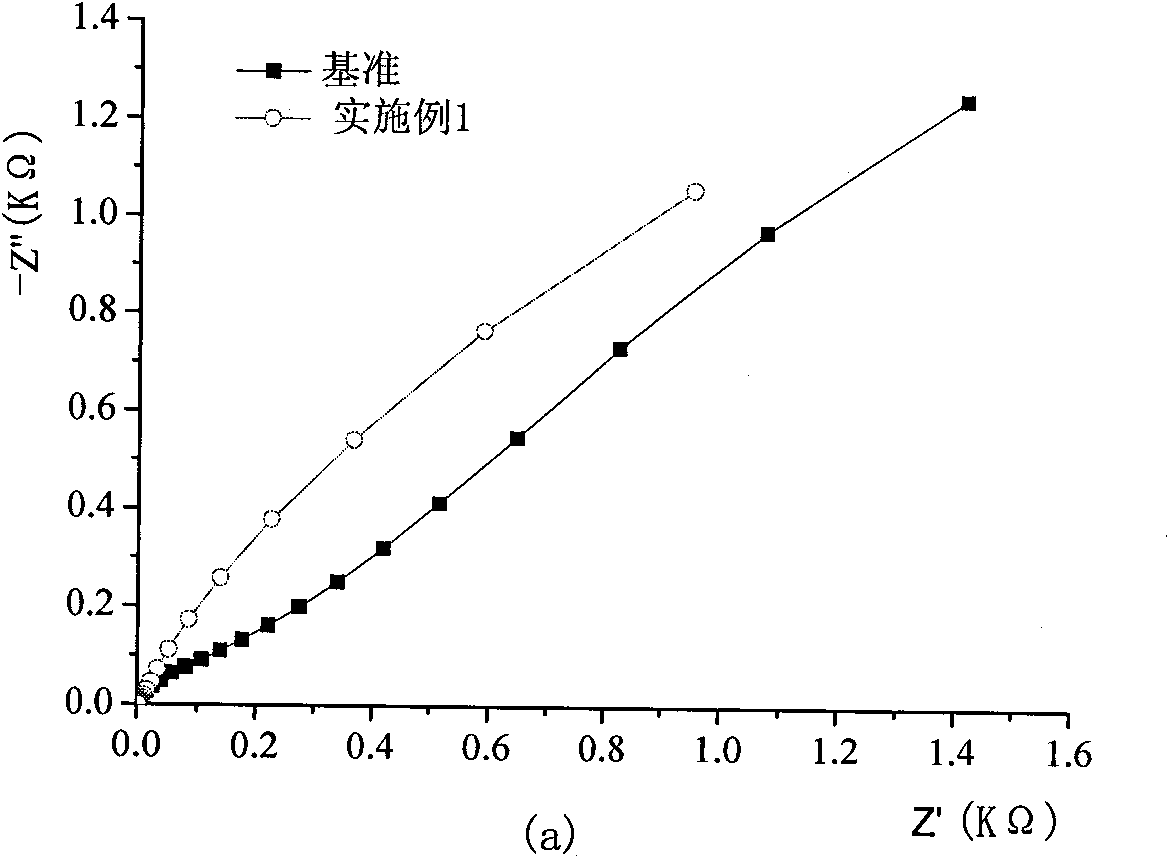

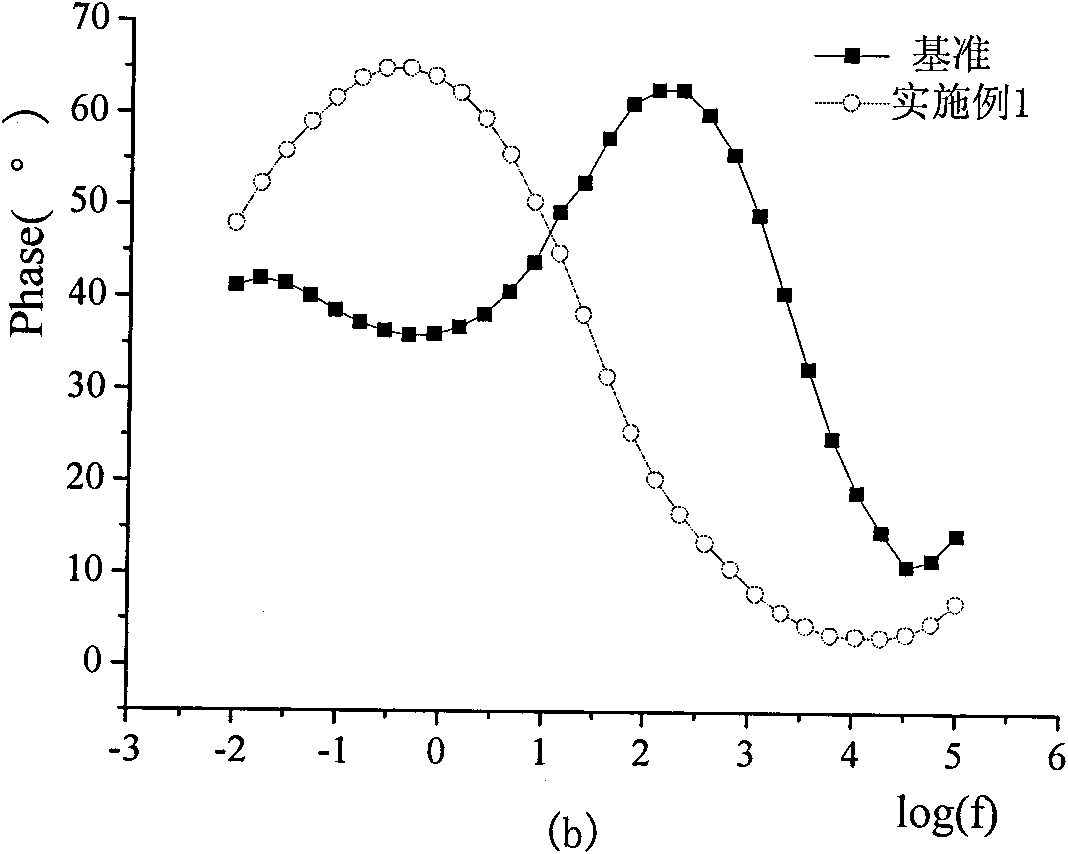

[0051] The weight ratio of the reactants is 41% of propionic acid and 59% of diethanolamine, and the same water as the total amount of the reaction product is added, heated to 60°C, stirred and reacted for 1 hour, and an aqueous solution of the reinforced concrete rust inhibitor is obtained. The experiment was carried out according to the experimental method described later, and the obtained results are shown in Fig. 1 .

Embodiment 2

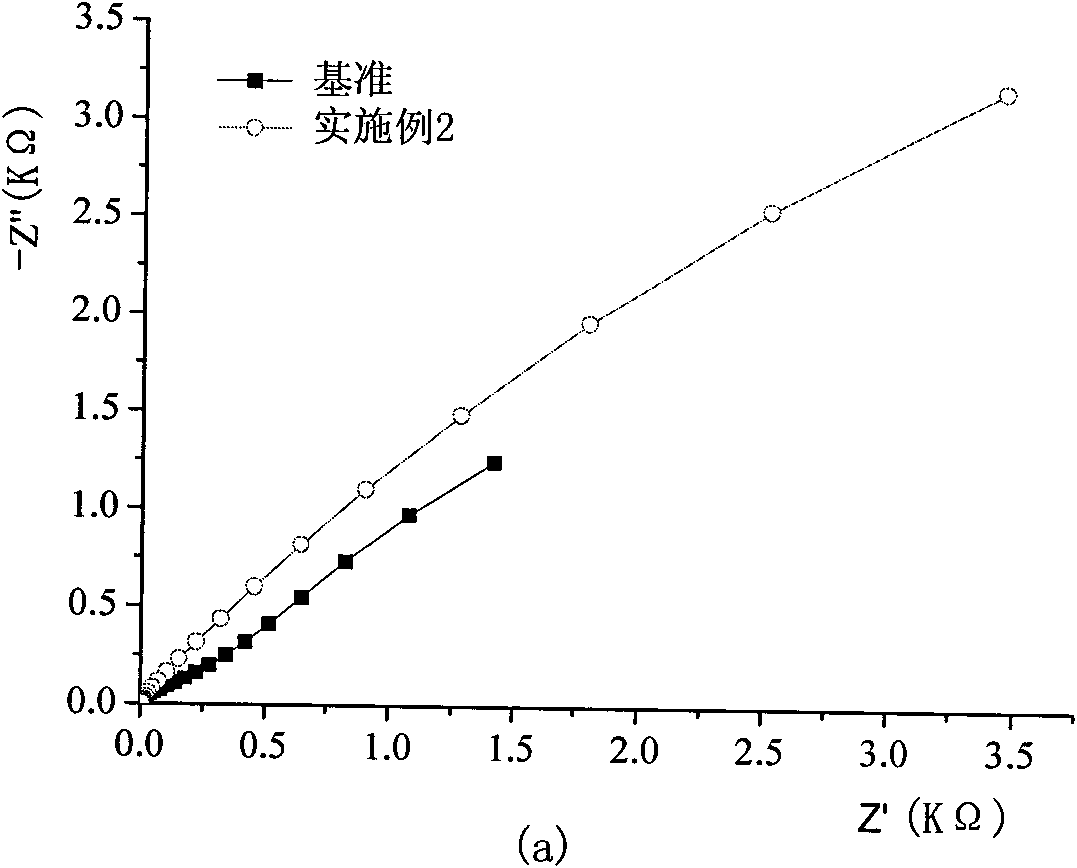

[0053] The weight ratio of the reactants is 58% of benzoic acid, 13% of cyclohexylamine, and 29% of N,N-dimethylethanolamine, and the same water as the total amount of the reaction product is added, heated to 60°C, and stirred for 1 hour to prepare Obtained reinforced concrete rust inhibitor aqueous solution. The experiment was carried out according to the experimental method described later, and the obtained results are shown in Fig. 2 .

Embodiment 3

[0055] The weight ratio of the reactants is 34% octanoic acid, 31% o-toluic acid, 25% diisopropanolamine, and 10% diethylenetriamine. Add the same amount of water as the total amount of the reaction product, heat to 60°C, and stir After reacting for 2 hours, an aqueous solution of a reinforced concrete rust inhibitor was prepared. The experiment was carried out according to the experimental method described later, and the obtained results are shown in Fig. 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com