Energy storage driving pendant in motor

A technology of active suspension and suspension, which is applied in the direction of suspension, elastic suspension, transportation and packaging, etc., and can solve the problems of high energy consumption, complex structure and poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings.

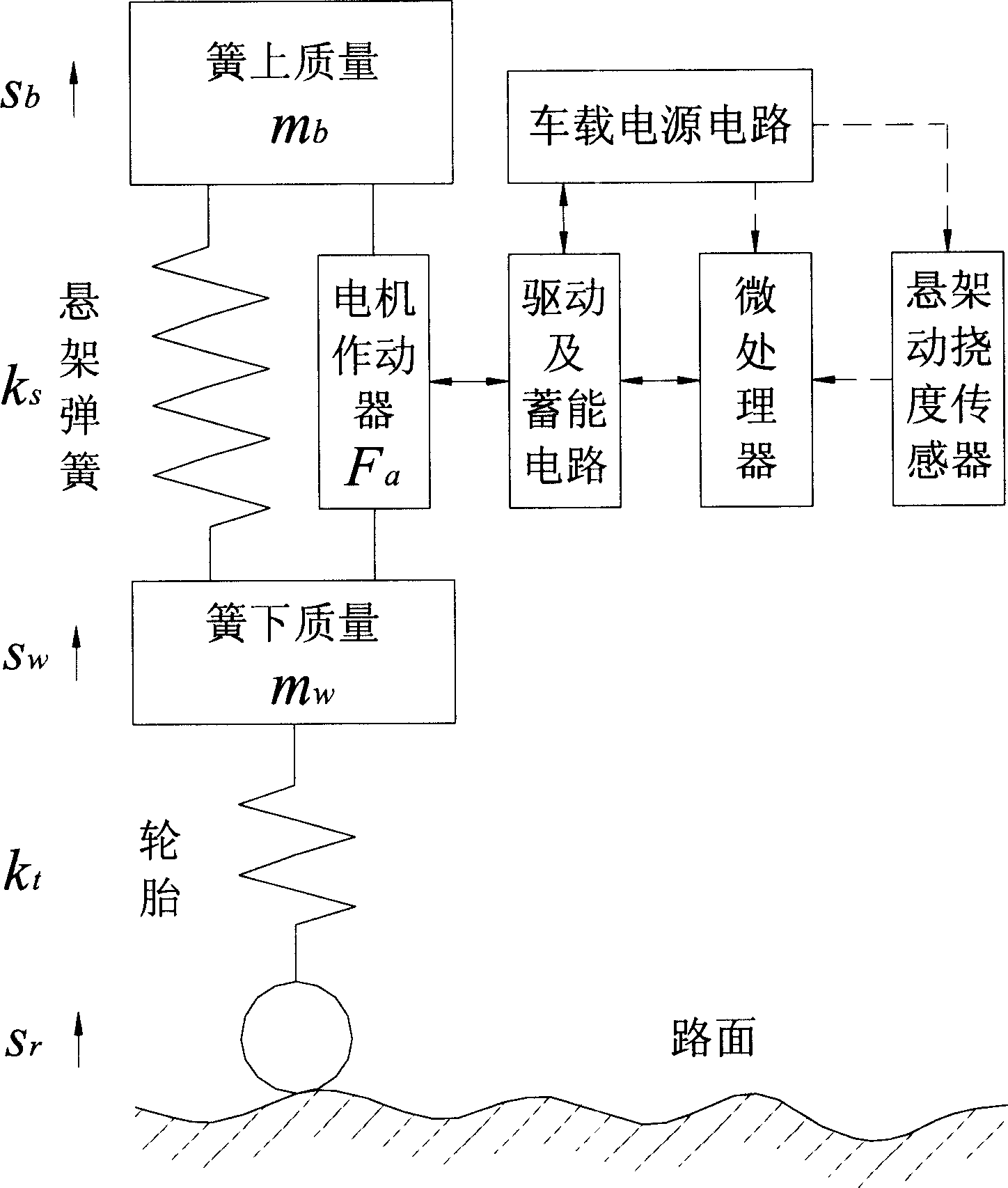

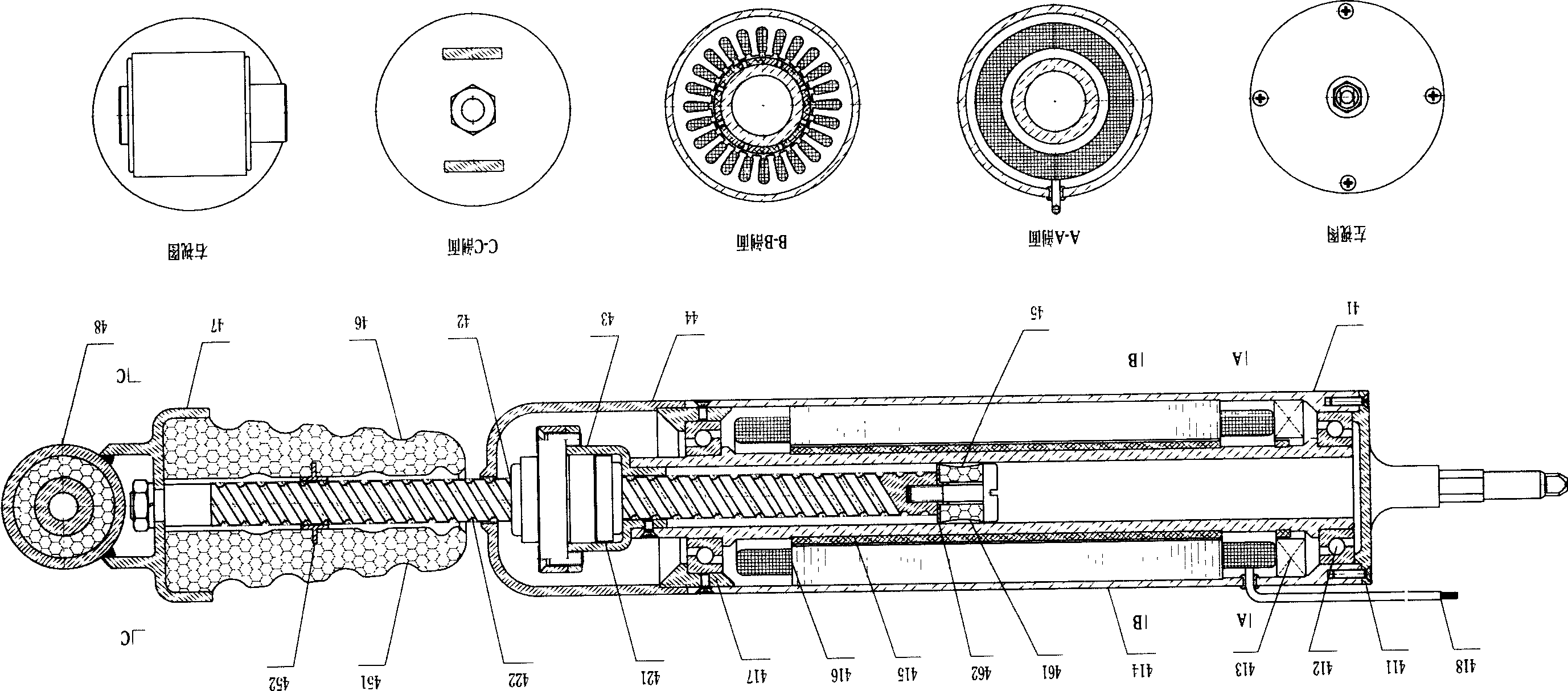

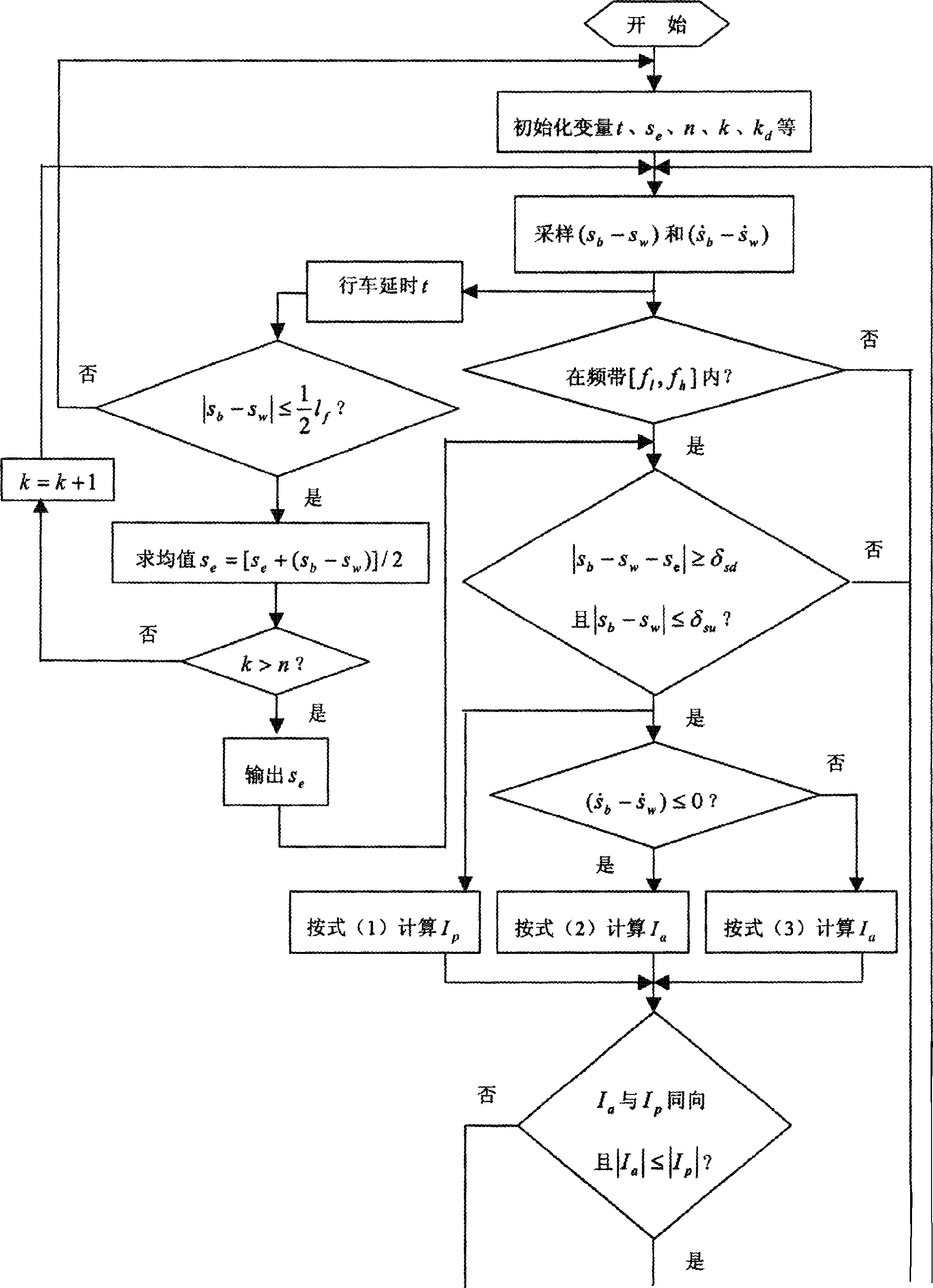

[0014] 1. In figure 1 In the embodiment shown, the single-wheel model (1 / 4 vehicle body model with two degrees of freedom) of the overall structure of the present invention consists of: sprung mass (or body) (1), unsprung mass (or wheel) (2), Suspension spring (3), motor actuator (4), drive and energy storage circuit (5), microprocessor (6), suspension dynamic deflection sensor (7), vehicle power supply circuit (8) and other parts, Among them: the suspension spring, the motor actuator and the suspension dynamic deflection sensor are installed in parallel between the body and the wheel. Its working principle is: input the coded signal obtained by the suspension dynamic deflection sensor and the pulse signal obtained by the motor rotor position sensor into the microprocessor, after processing by the brushless motor commutation logic, the electromagnetic energy storage con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com