Hill holding brake system for hybrid electric vehicles

a hybrid electric vehicle and holding brake technology, applied in the direction of braking systems, electric devices, propulsion by batteries/cells, etc., can solve the problems of limited power capacity, limited range of electric vehicles, and substantial amount of time for battery recharge, so as to improve the operating efficiency and driveability of hybrid electric vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

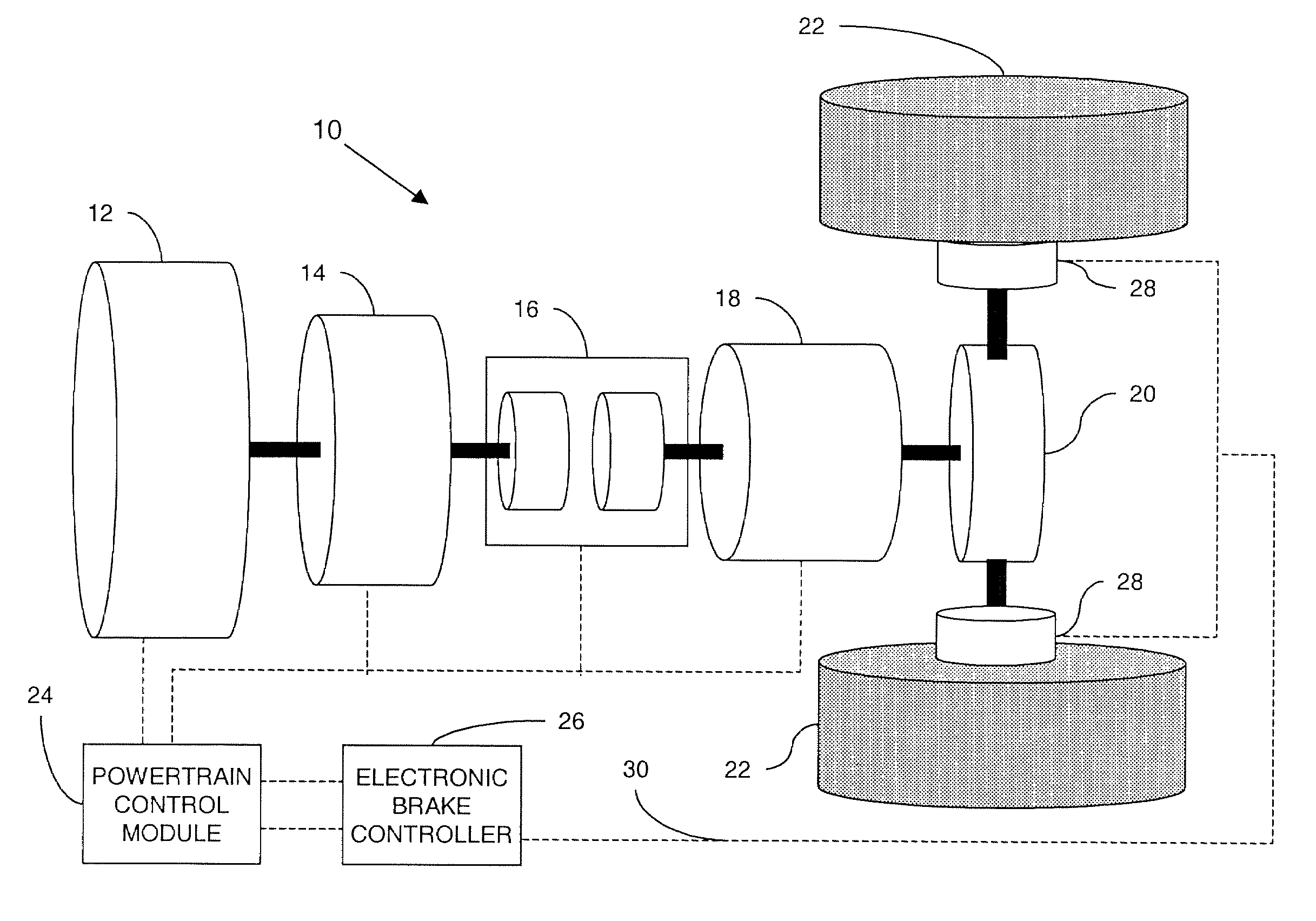

[0035] Referring now to the drawings figures, there is illustrated in FIG. 1 a representative configuration of a hybrid electric vehicle 10 having a internal combustion engine 12 coupled to an integrated starter generator motor 14. The two powerplants are coupled by a clutch 16 to a transmission 18, and a differential 20 to provide torque to a set of vehicle wheels 22. A powertrain control module 24 controls the operating parameters of the internal combustion engine 12 and the integrated starter generator motor 14. An electronic brake control system 26 controls a set of electro-hydraulic brakes 28. Both controllers are shown as logical units, and can be embodied in one or more separate controller or computer-controlled devices. A vehicle communication data network 30 enables communications between the hybrid electric vehicle components, the electronic brake controller 26 and the powertrain control module 24 at suitable update rates.

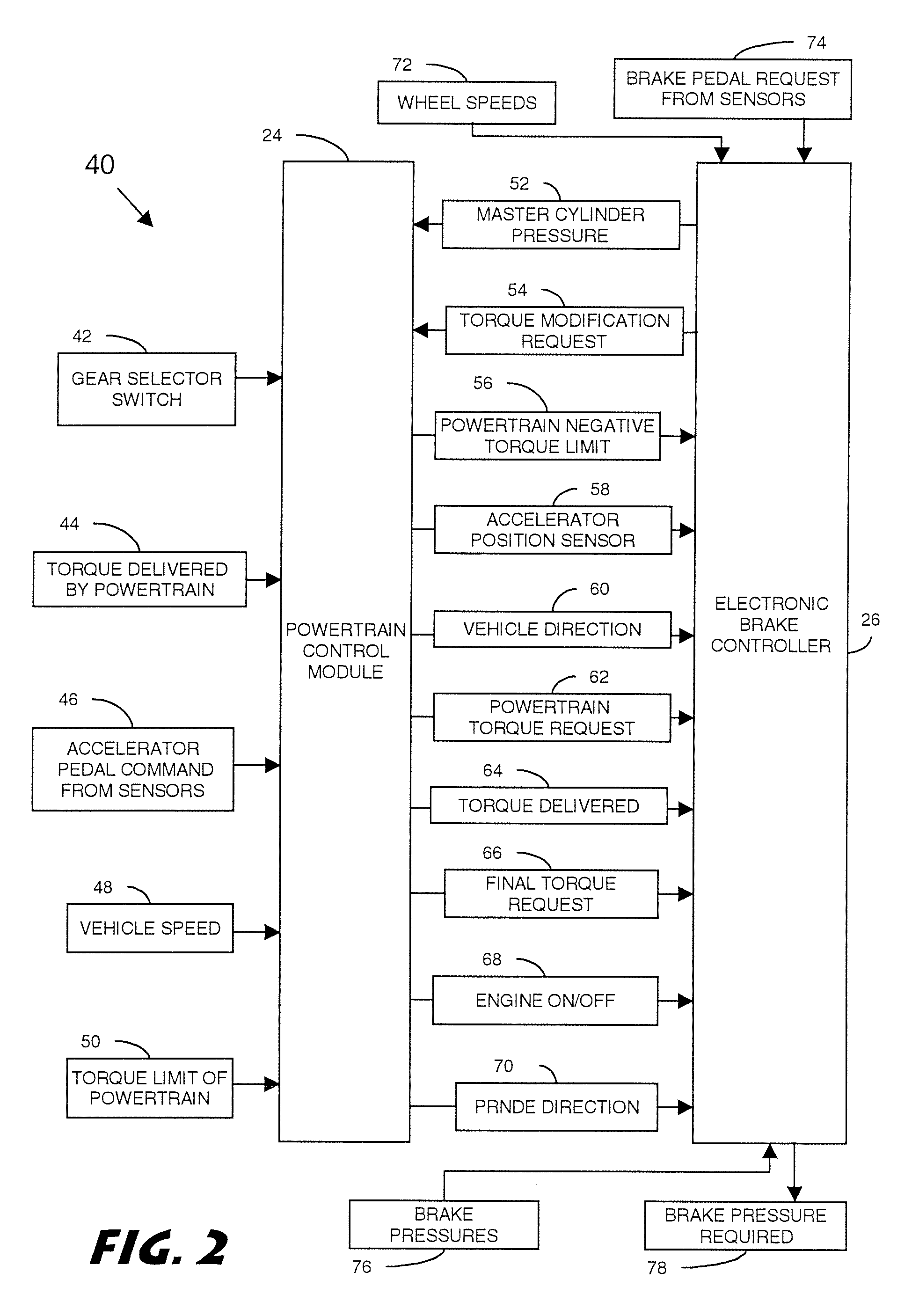

[0036] The powertrain control module 24 provides a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com