2D hydraulic-power-assisted electro-hydraulic proportional reversing valve

A proportional reversing valve and power-assisted electric technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of leakage flow of pilot and control stages that cannot work normally, large flow of pilot-control electro-hydraulic proportional valves, Problems such as stagnant guide and control stage oil circuit, etc., to overcome adverse effects, high working pressure, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

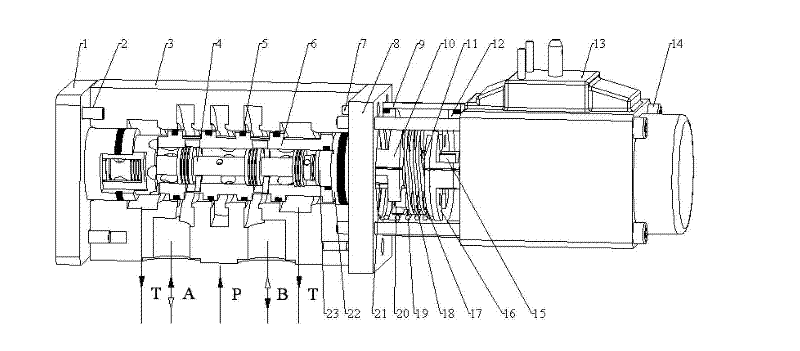

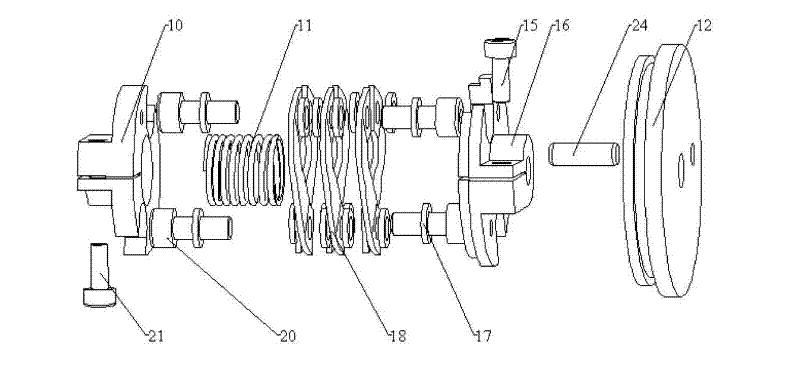

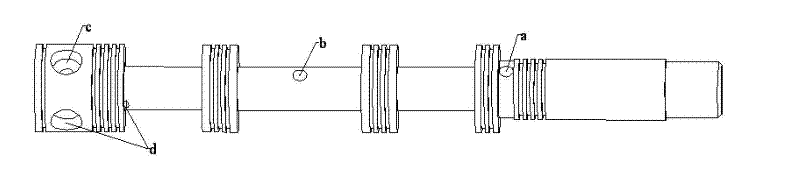

[0021] refer to Figure 1 ~ Figure 4d , a 2D hydraulic power-assisted electro-hydraulic proportional reversing valve, including a linear electro-mechanical converter (such as a proportional electromagnet, or other linear electro-mechanical converter) 13, a section 10 of a compression-torsion coupling, a sleeve 9, Centering spring 19, reed 18, washer 17, support spring 11, pressure torsion coupling section b 16, fixed plate 12, cylindrical pin 24, left cover 1, valve body 3, valve sleeve 6, valve core 4 , Right cover plate 8, right plug ring 22, concentric ring 23, O-ring 5 and screws 2, 7, 14, 15, 20, 21.

[0022] The linear electro-mechanical converter (such as a proportional electromagnet, or other linear electro-mechanical converter) 13 is used as an electro-mechanical converter to drive a 2D hydraulic power-assisted electro-hydraulic proportional reversing (thrott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com