Patents

Literature

39results about How to "Improve sharding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

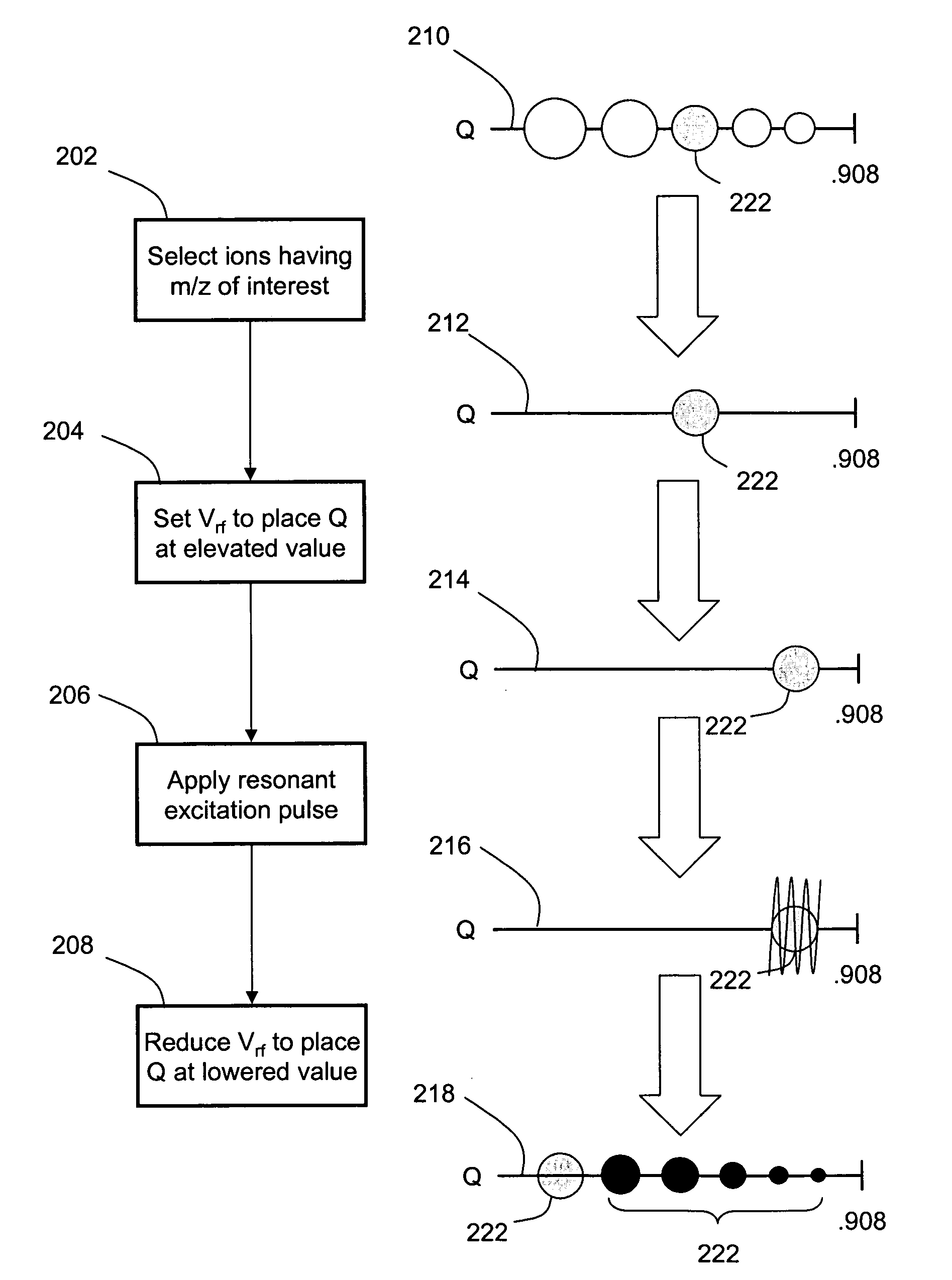

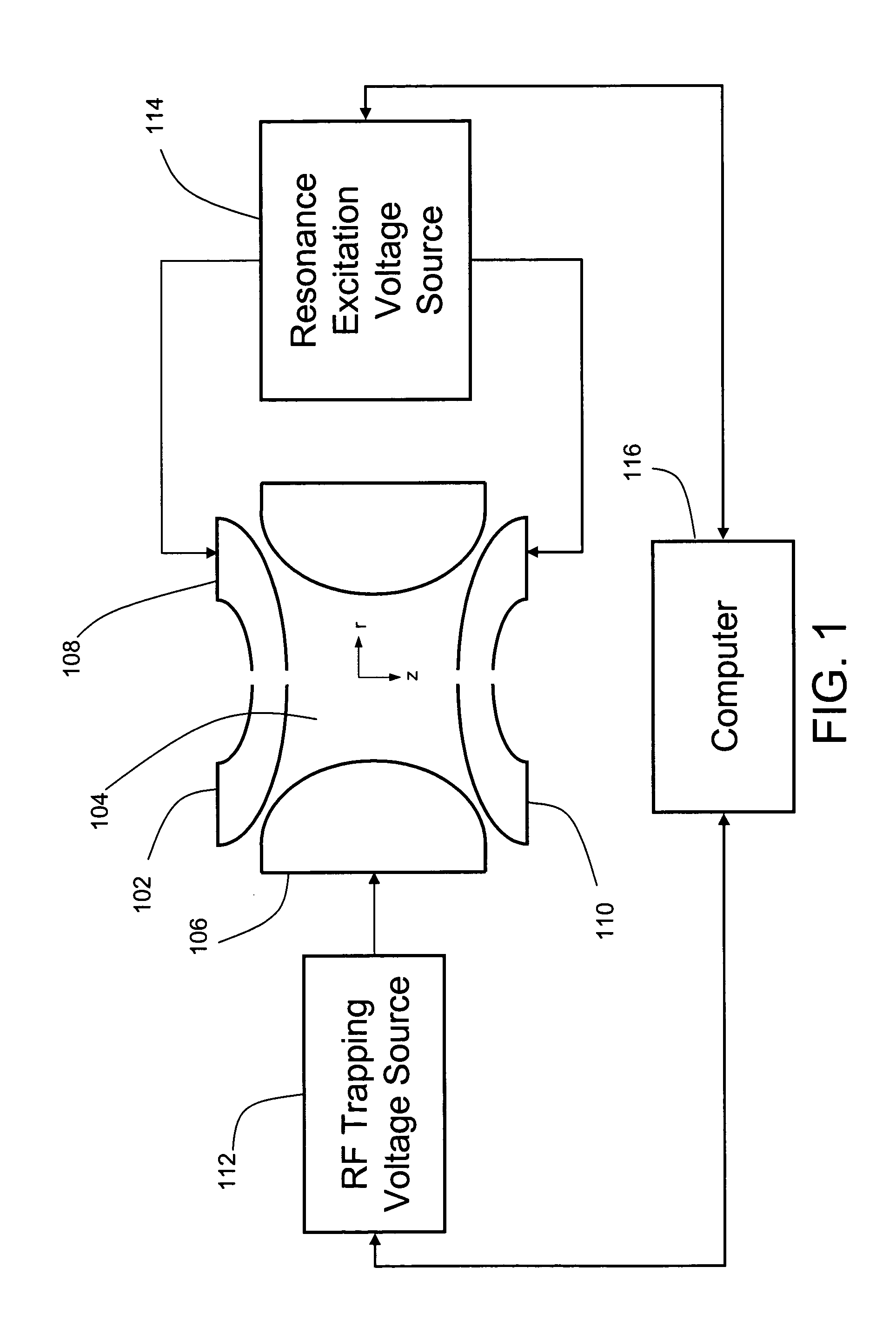

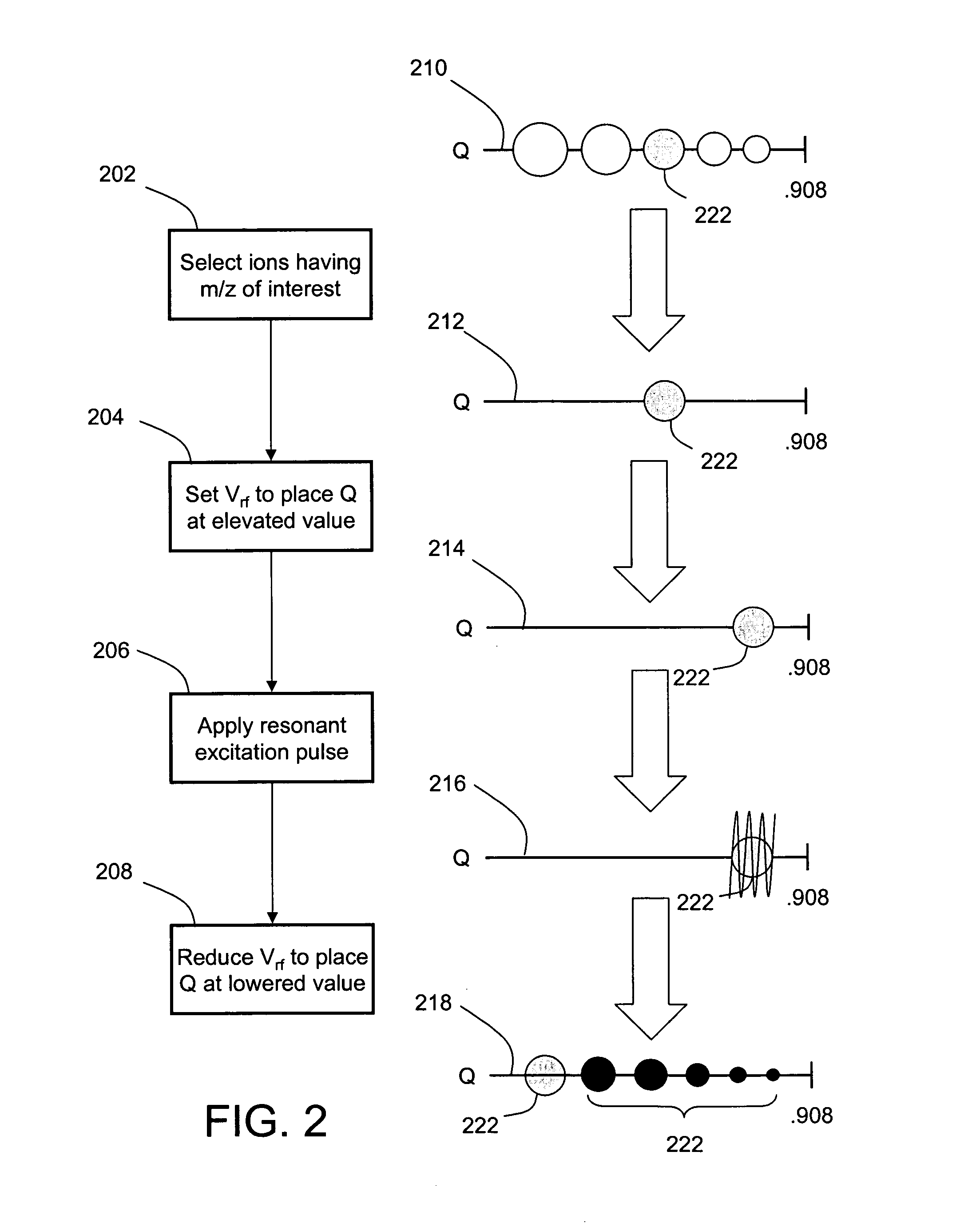

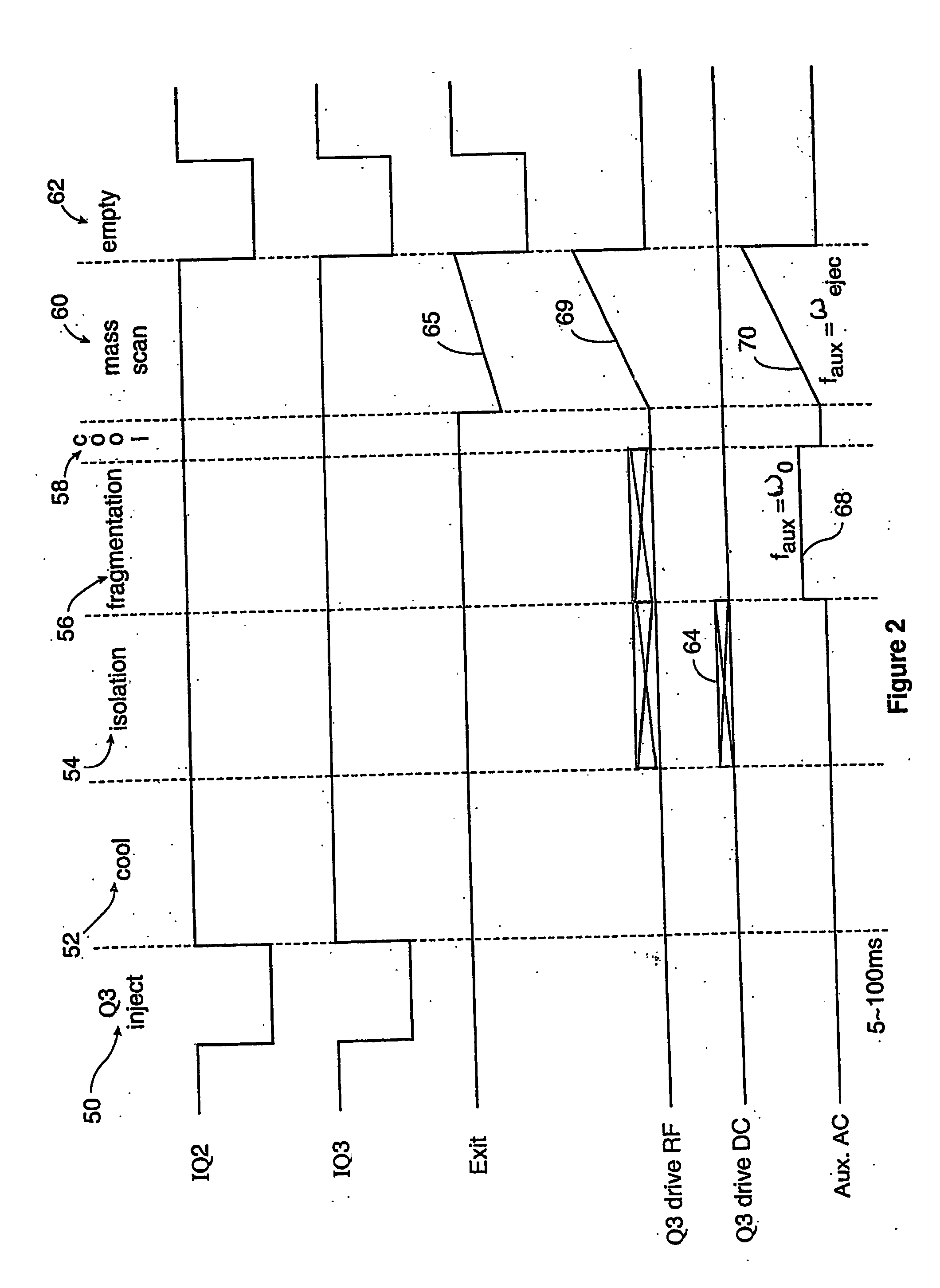

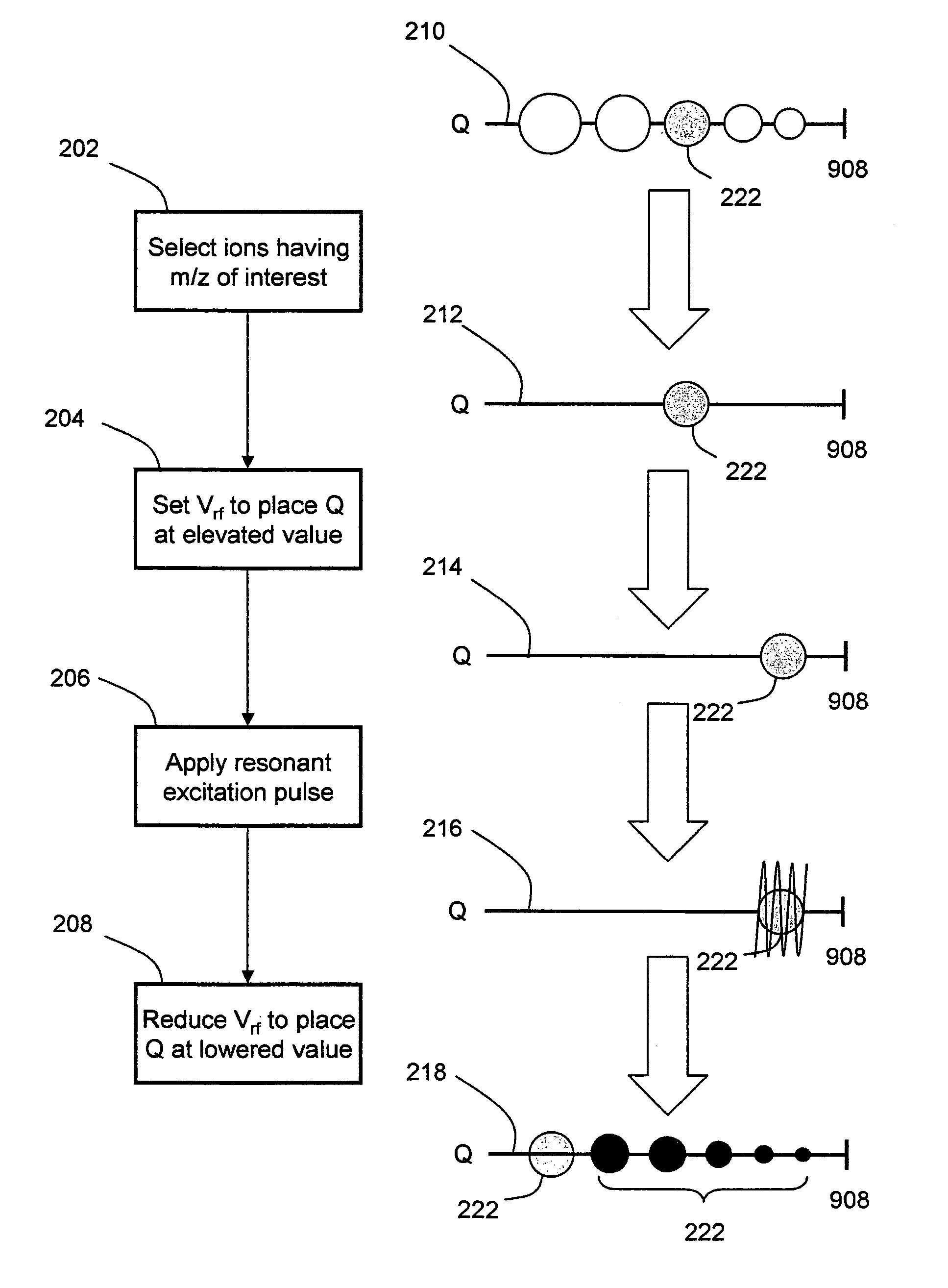

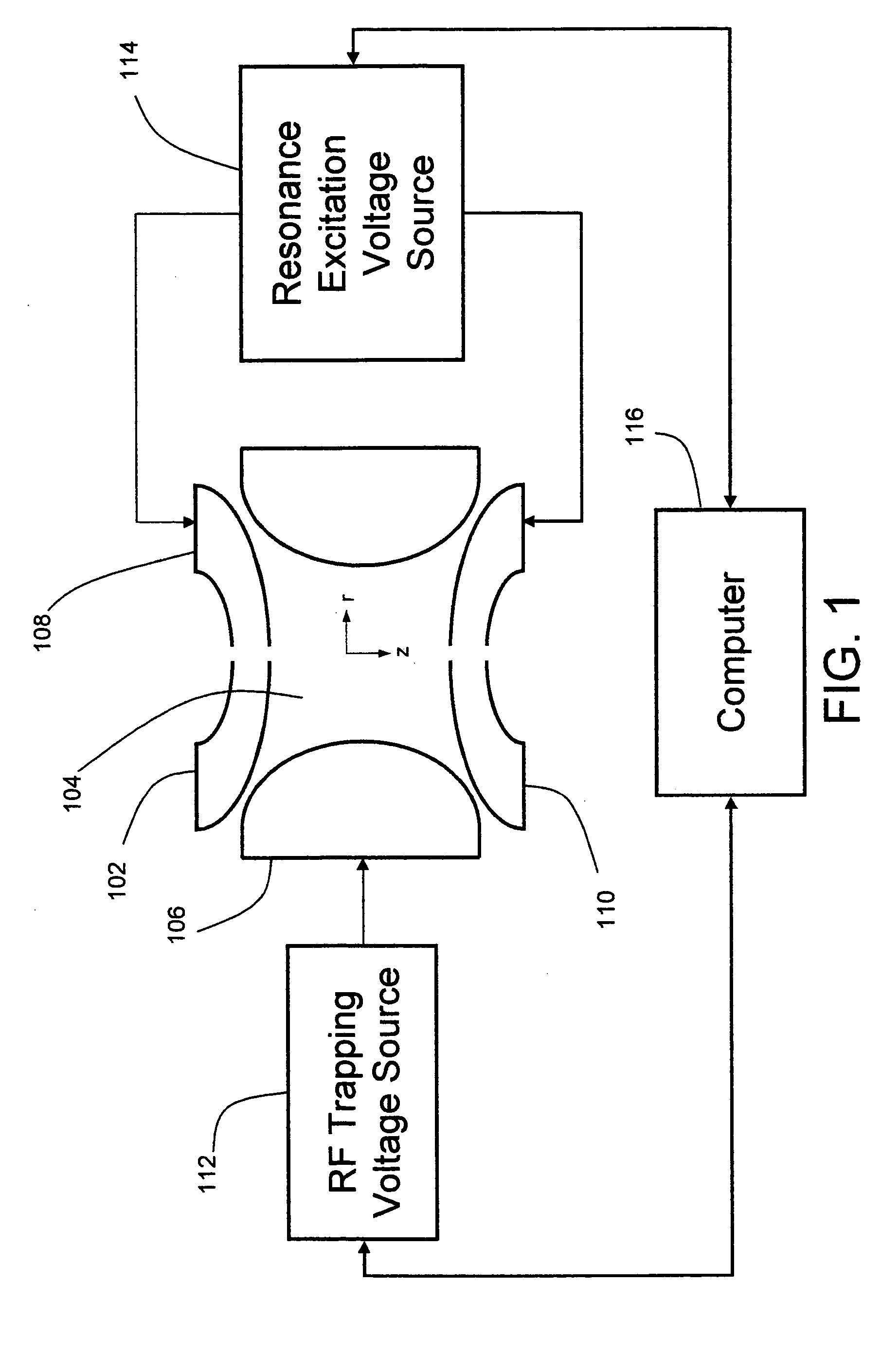

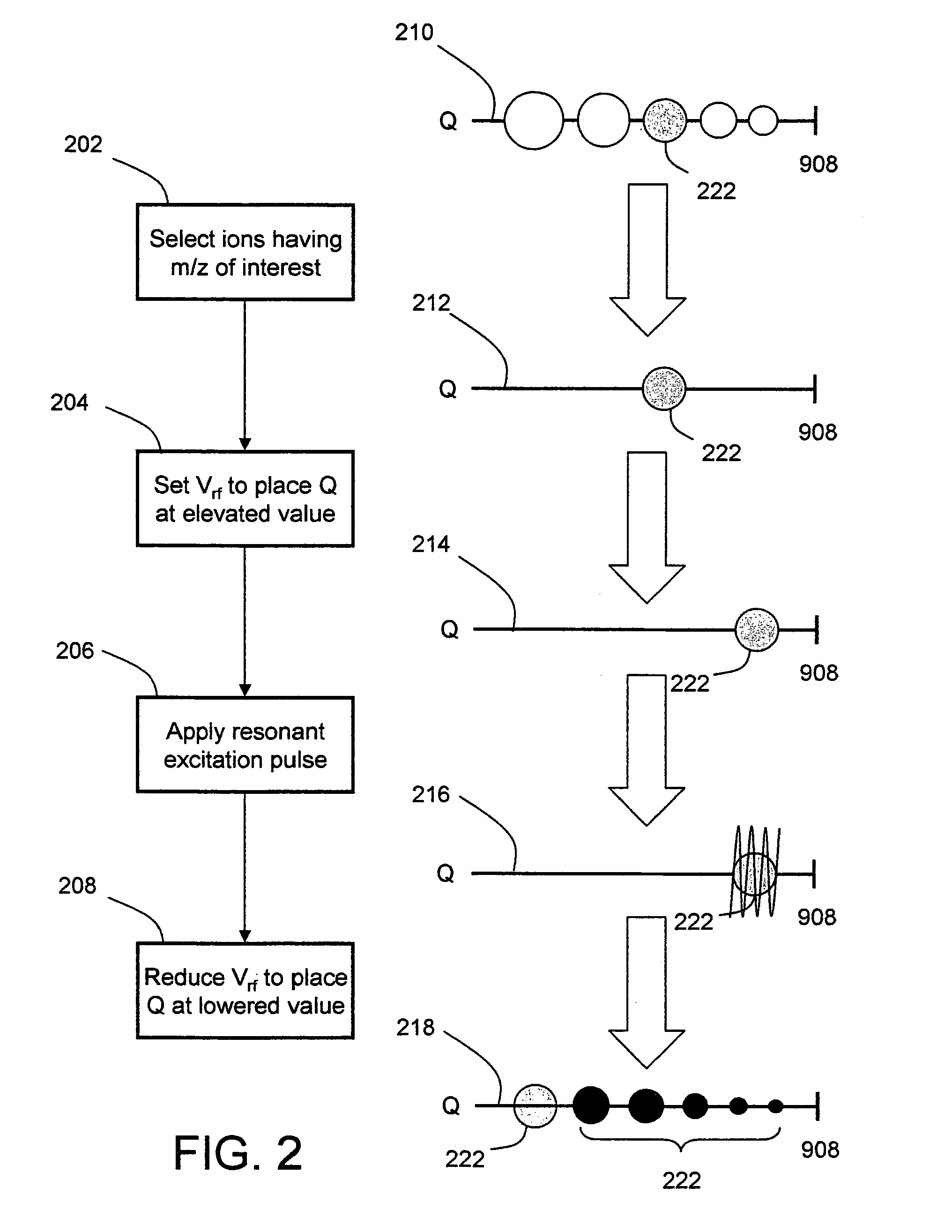

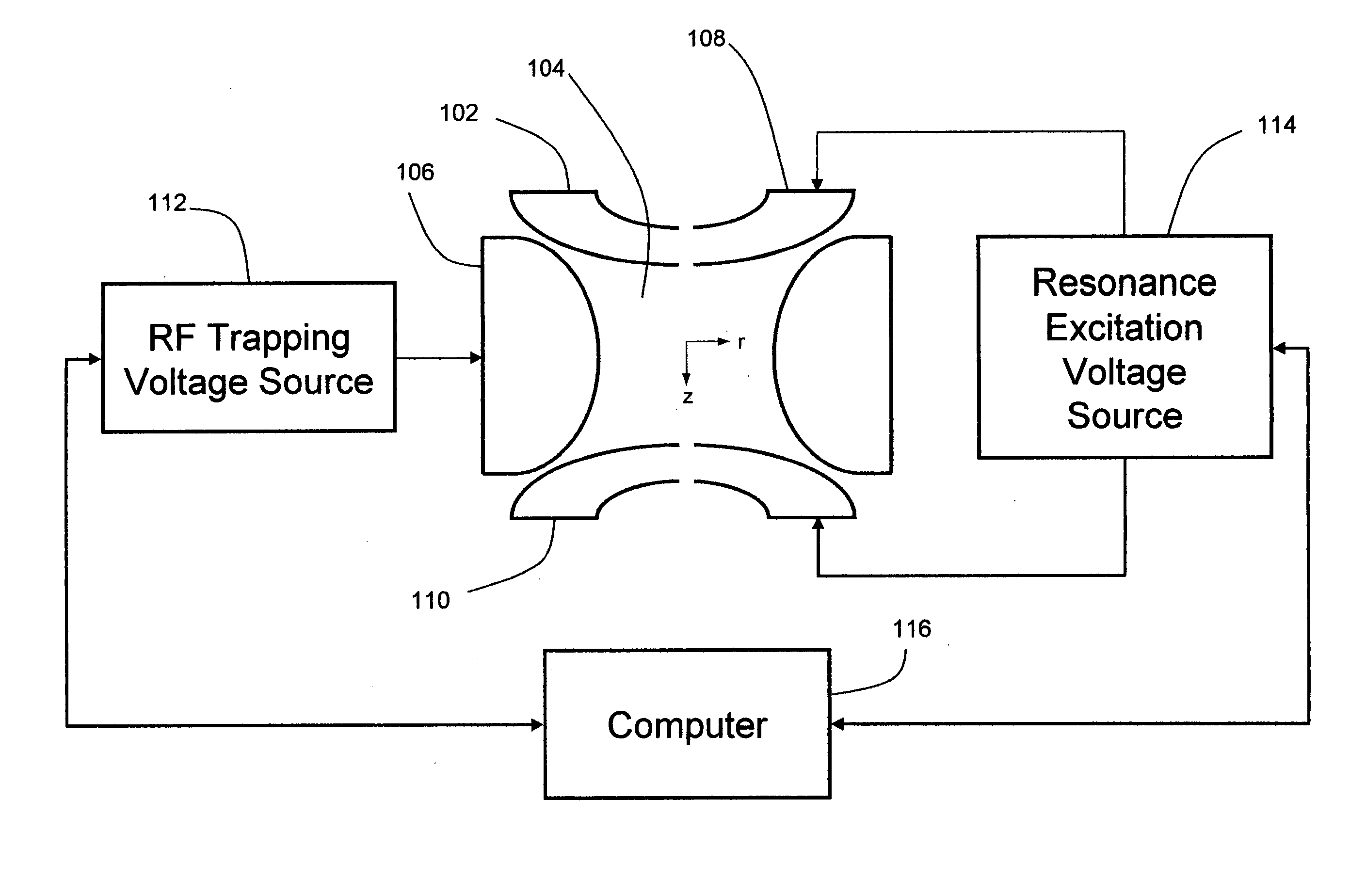

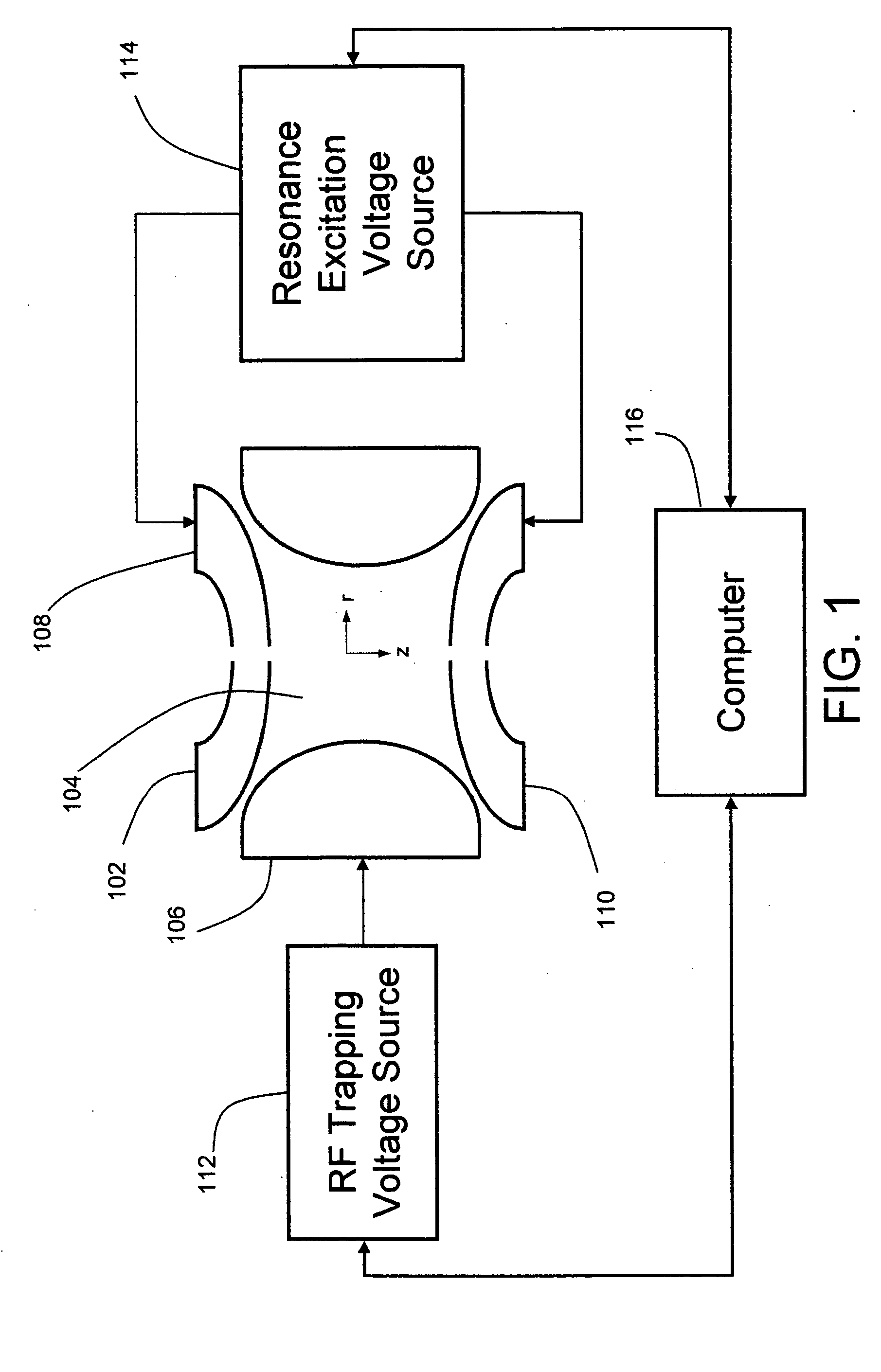

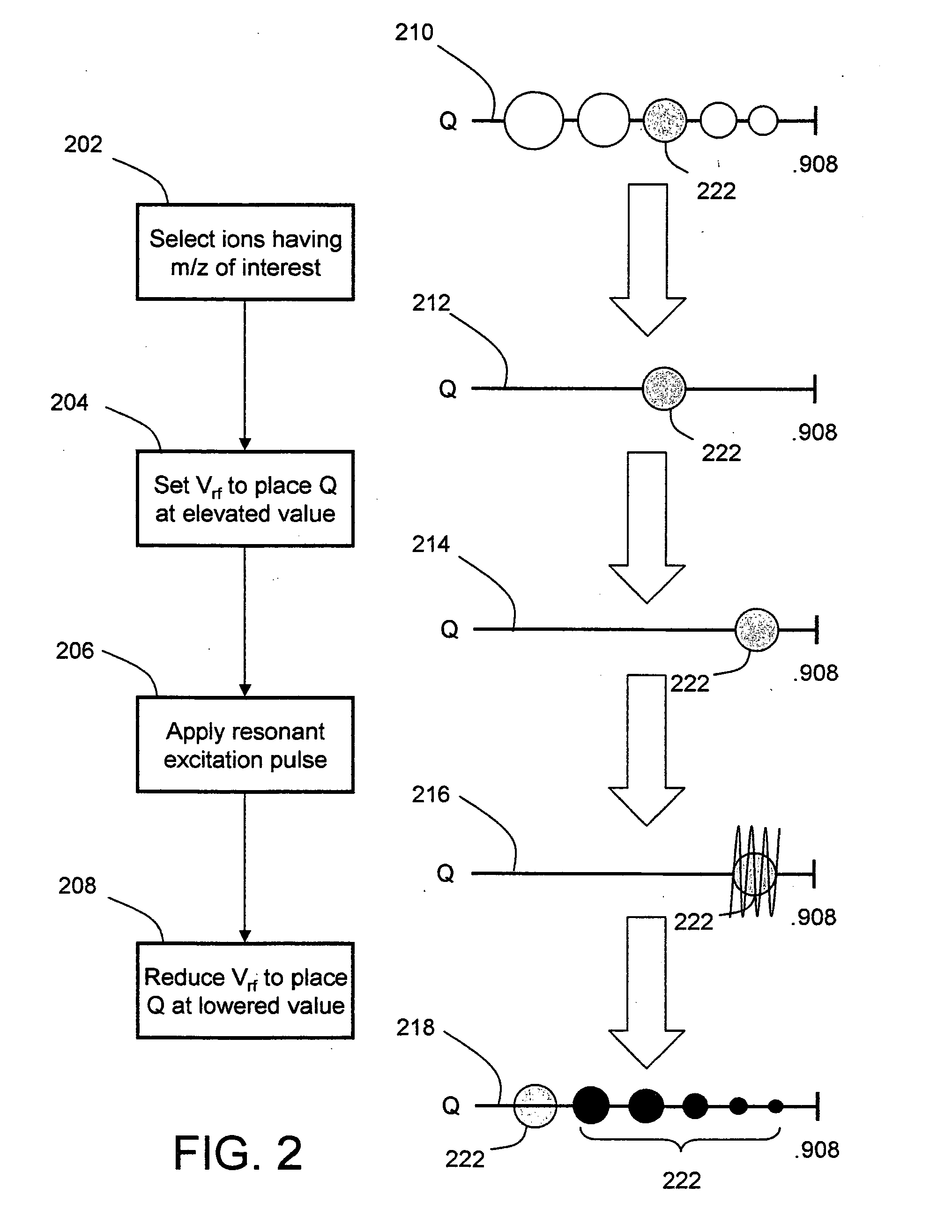

High-Q pulsed fragmentation in ion traps

ActiveUS6949743B1Low QLower LMCOStability-of-path spectrometersIsotope separationElevated valueIon trap mass spectrometry

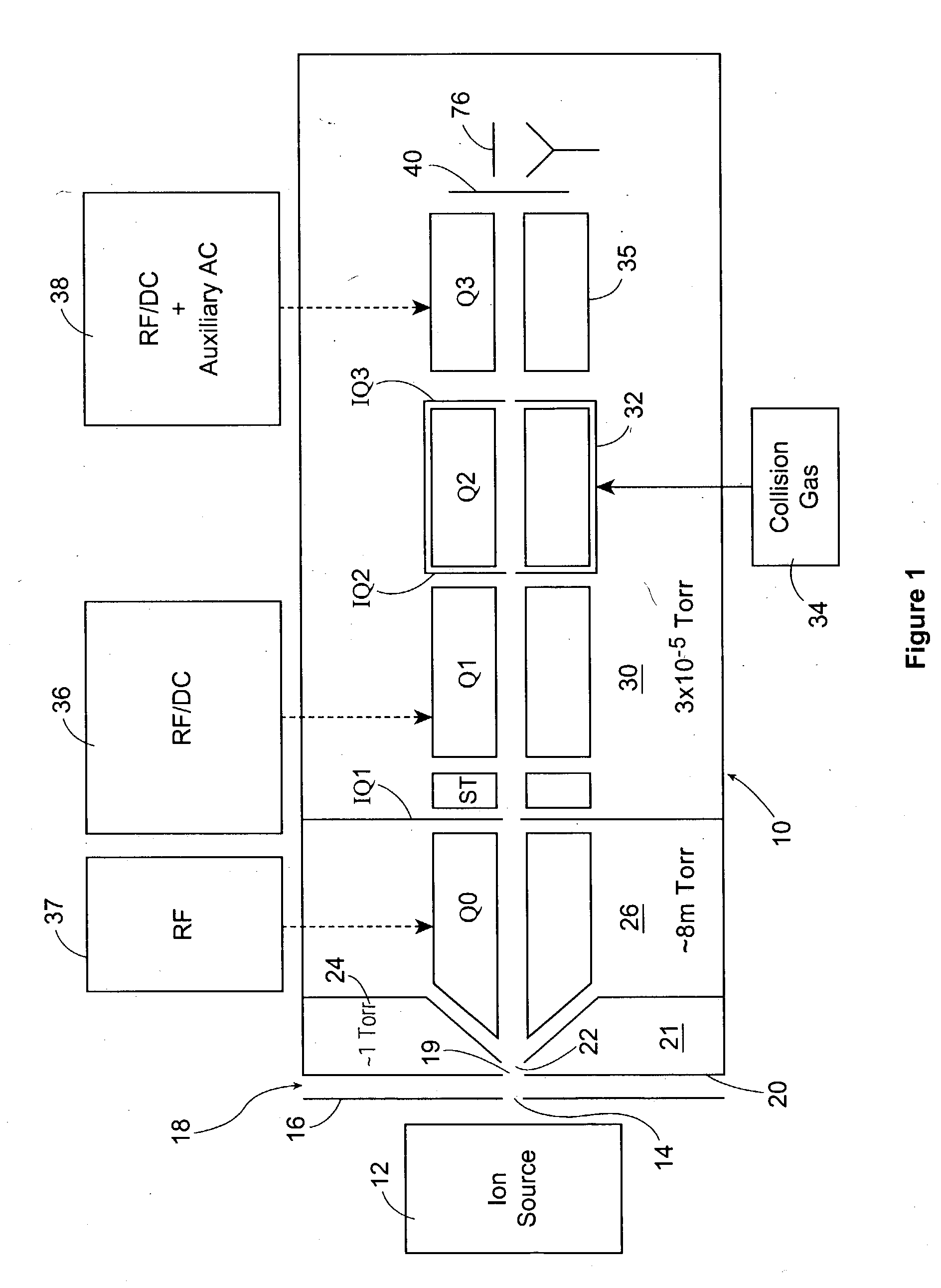

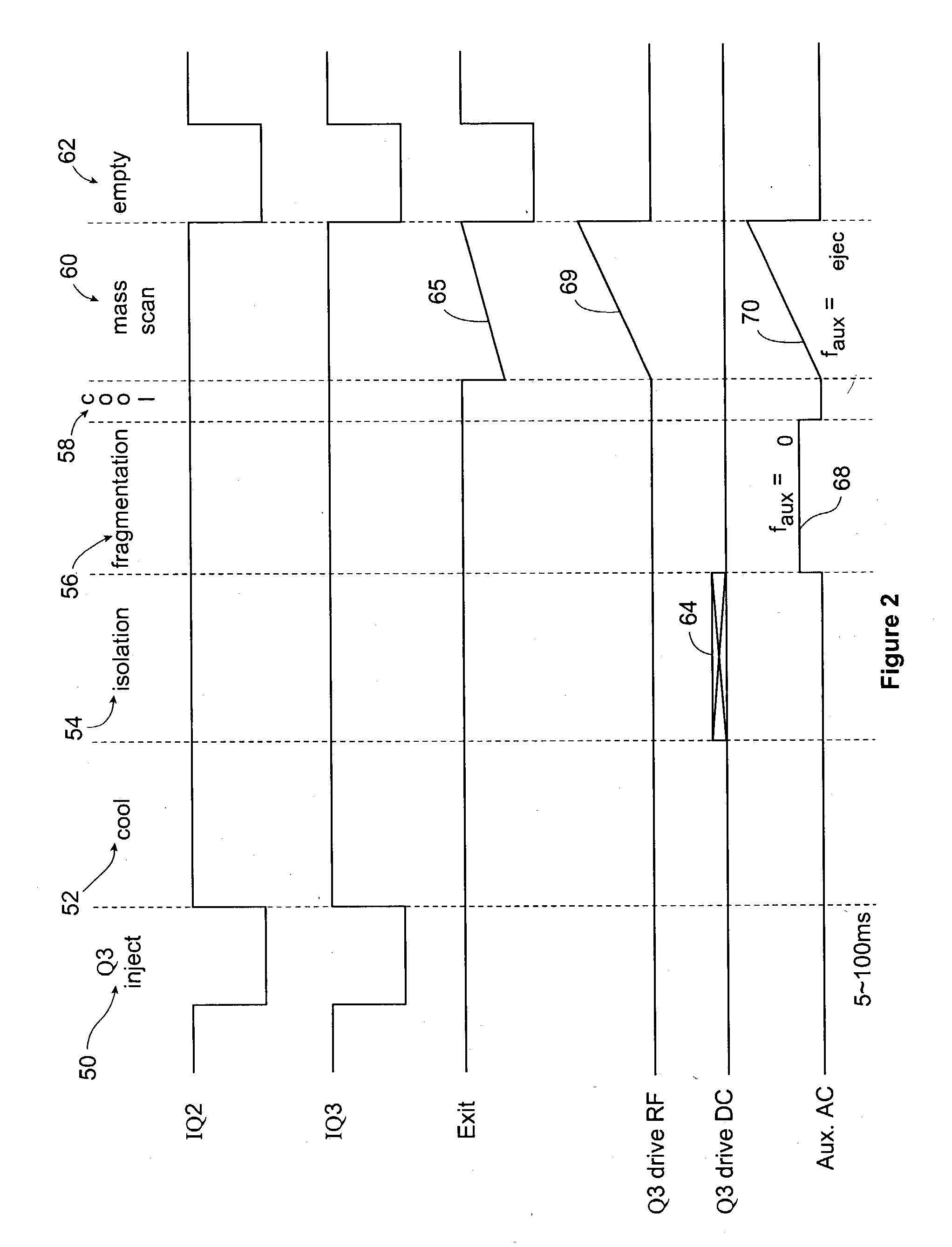

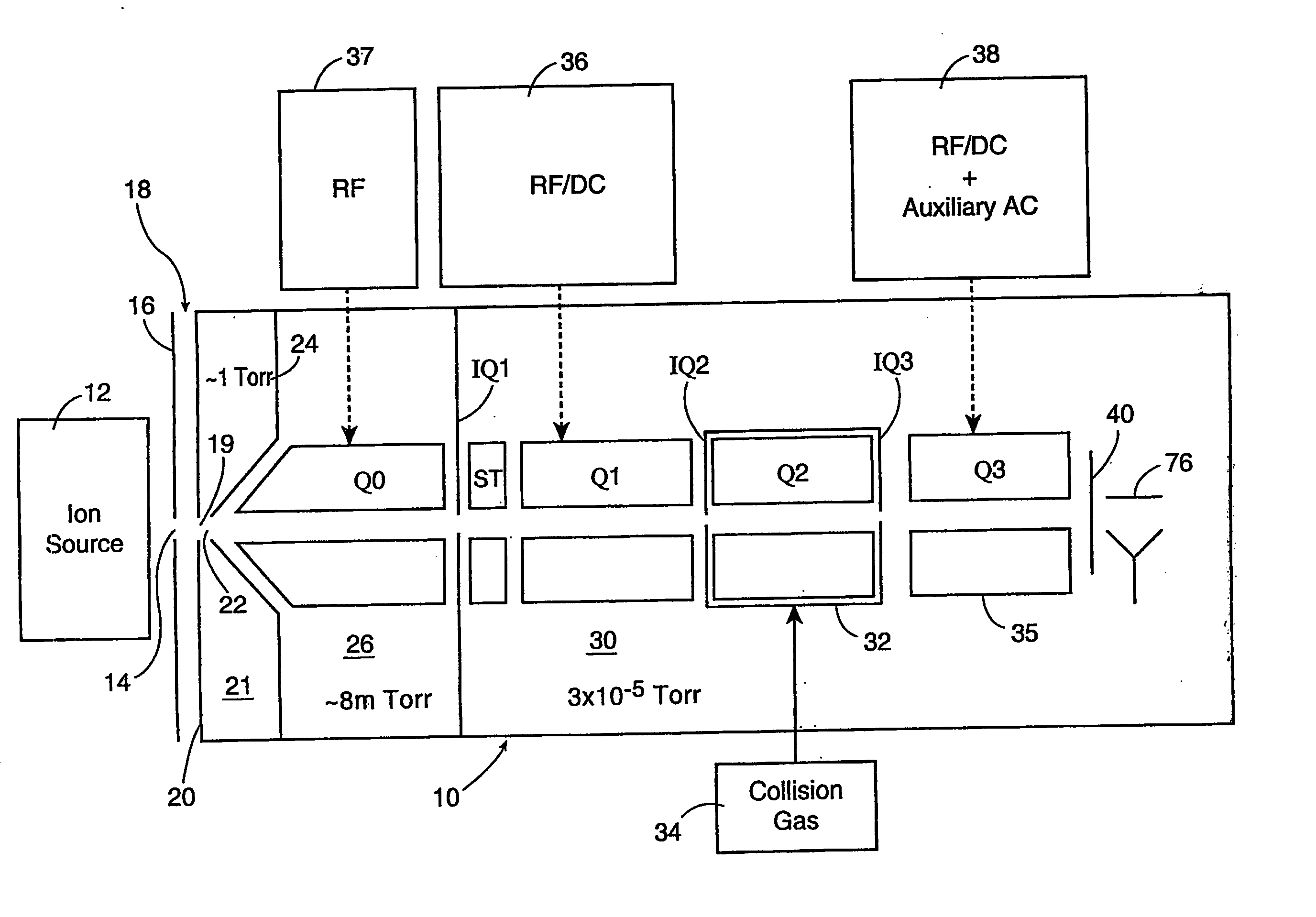

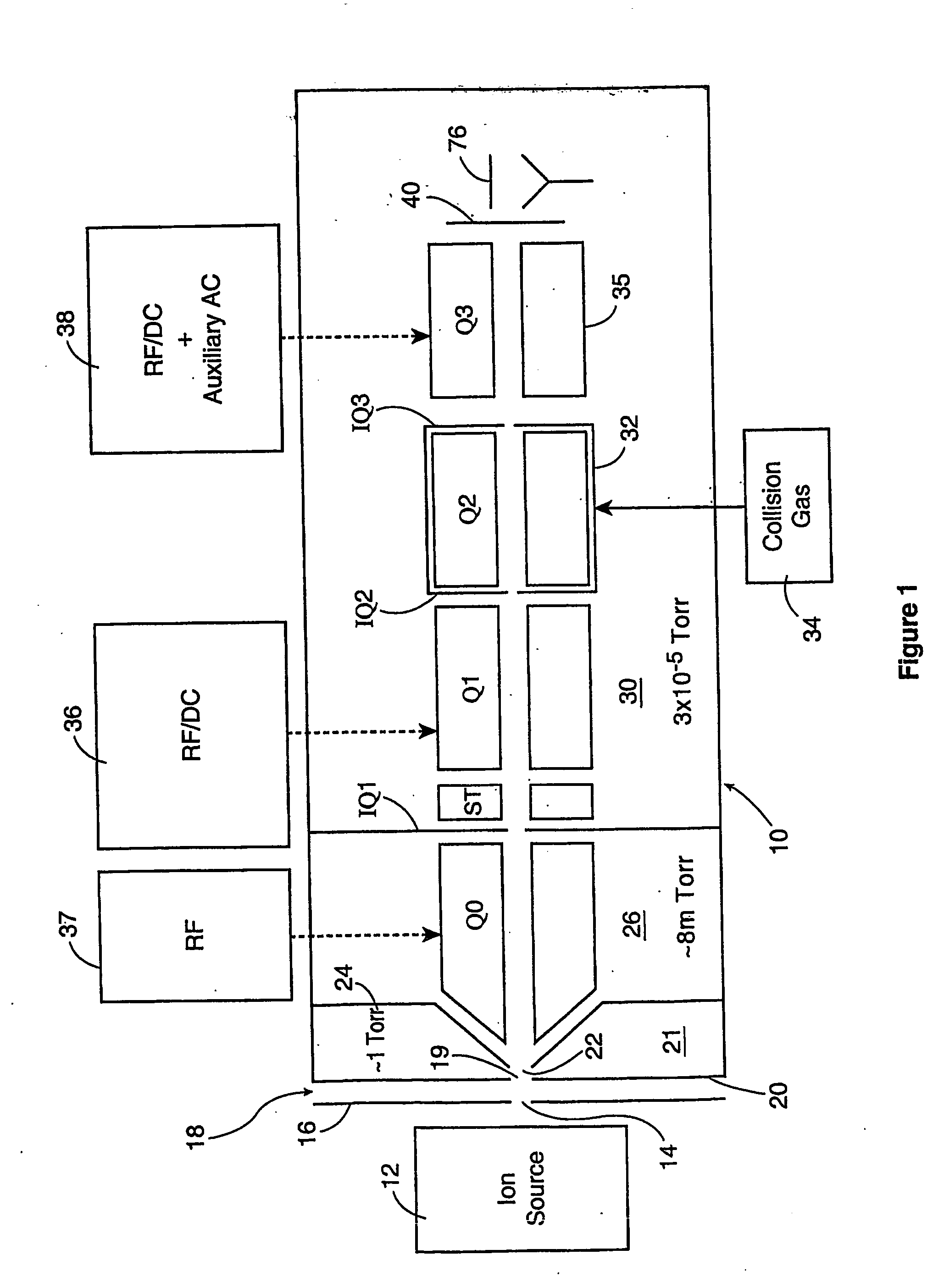

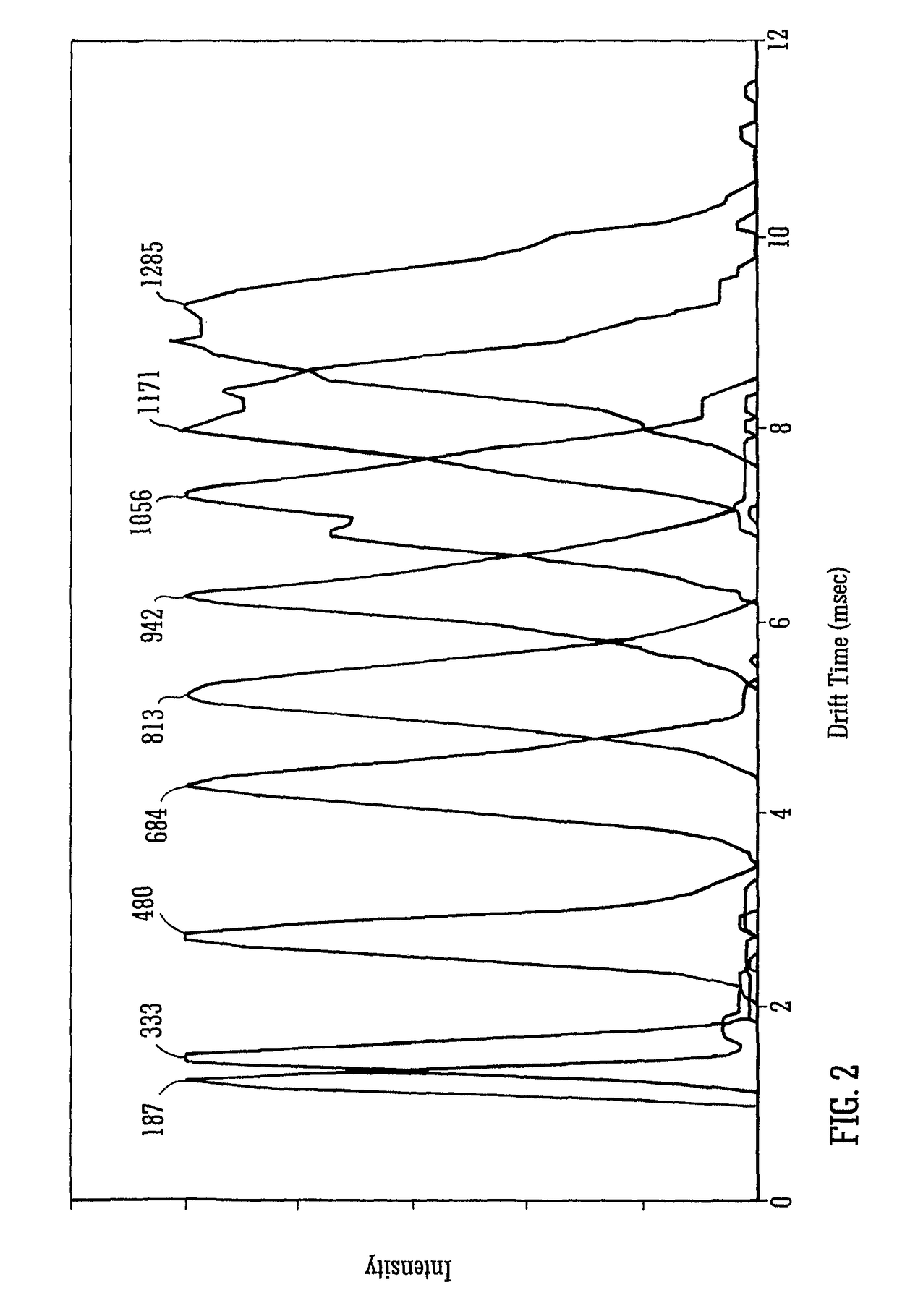

Rapid and efficient fragmentation of ions in an ion trap for MS / MS analysis is achieved by a pulsed fragmentation technique. Ions of interest are placed at an elevated value of Q and subjected to a relatively high amplitude, short-duration resonance excitation pulse to cause the ions to undergo collision-induced fragmentation. The Q value of the ions of interest is then reduced before significant numbers of ion fragments are expelled from the ion trap, thereby decreasing the low-mass cutoff and allowing retention and subsequent measurement of lower-mass ion fragments.

Owner:THERMO FINNIGAN

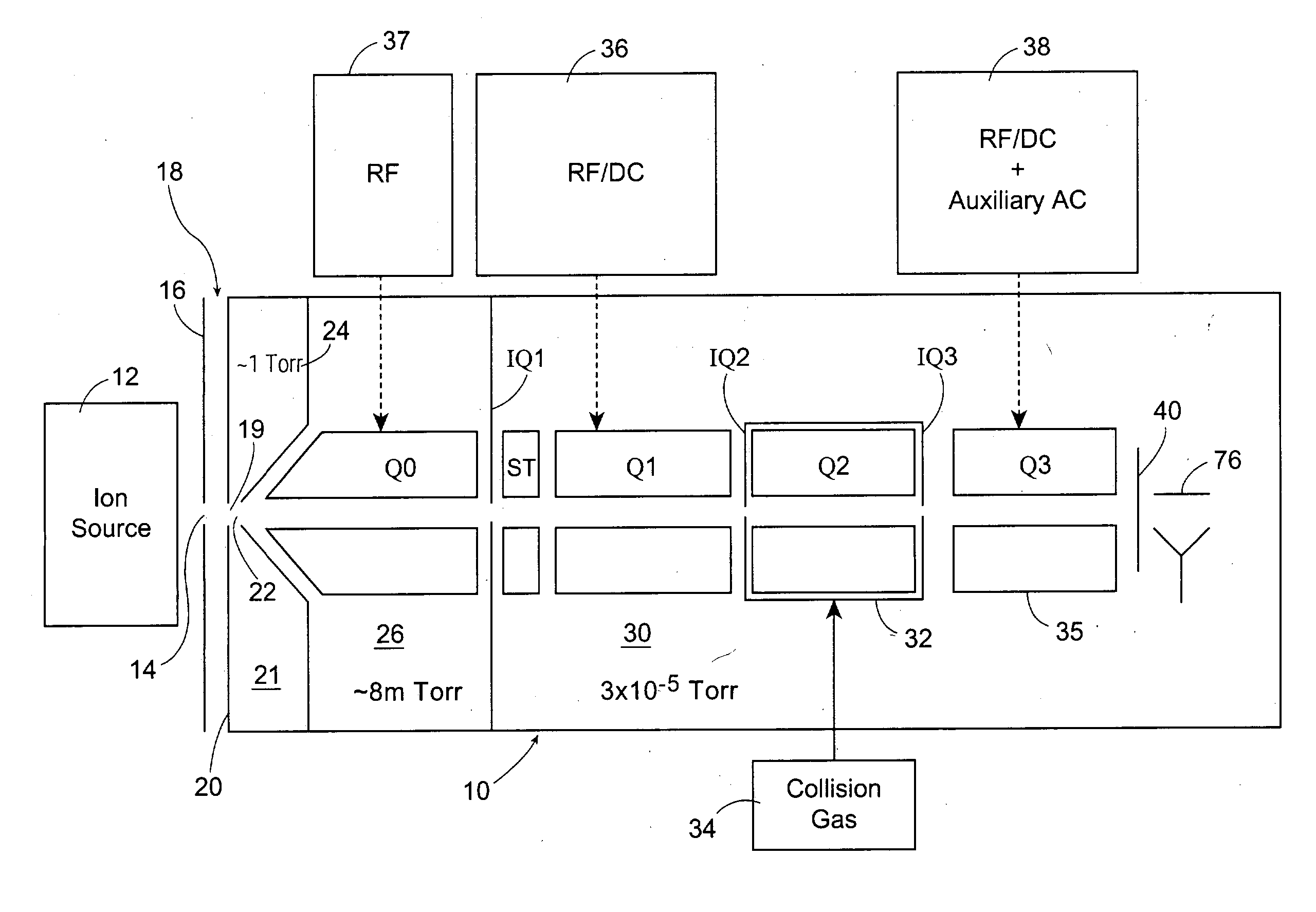

Fragmentation of ions by resonant excitation in a high order multipole field, low pressure ion trap

InactiveUS20030189171A1Promote collision-induced dissociationIncrease probabilityStability-of-path spectrometersMaterial analysis by electric/magnetic meansRf fieldIon trap mass spectrometry

In the field of mass spectrometry, a method and apparatus for fragmenting ions with a relatively high degree of resolution and efficiency. The technique includes trapping the ions in a linear ion trap, in which the background or neutral gas pressure is preferably on the order of 10<-5 >Torr. The trapped ions are resonantly excited for a relatively extended period of time, e.g., exceeding 50 ms, at relatively low excitation levels, e.g., less than 1 Volt(0-pk). The technique allows selective dissociation of ions with a high discrimination. High fragmentation efficiency may be achieved by superimposing a higher order multipole field onto the quadrupolar RF field used to trap the ions. The multipole field, preferably an octopole field, dampens the radial oscillatory motion of resonantly excited ions at the periphery of the trap. This reduces the probability that ions will eject radially from the trap thus increasing the probability of collision induced dissociation.

Owner:DH TECH DEVMENT PTE

Fragmentation of ions by resonant excitation in a high order multipole field, low pressure ion trap

InactiveUS20050178963A1Promote collision-induced dissociationIncrease probabilityStability-of-path spectrometersMaterial analysis by electric/magnetic meansIon trap mass spectrometryRf field

In the field of mass spectrometry, a method and apparatus for fragmenting ions with a relatively high degree of resolution and efficiency. The technique includes trapping the ions in a linear ion trap, in which the background or neutral gas pressure is preferably on the order of 10-5 Torr. The trapped ions are resonantly excited for a relatively extended period of time, e.g., exceeding 50 ms, at relatively low excitation levels, e.g., less than 1 Volt (0-pk). The technique allows selective dissociation of ions with a high discrimination. High fragmentation efficiency may be achieved by superimposing a higher order multipole field onto the quadrupolar RF field used to trap the ions. The multipole field, preferably an octopole field, dampens the radial oscillatory motion of resonantly excited ions at the periphery of the trap. This reduces the probability that ions will eject radially from the trap thus increasing the probability of collision induced dissociation.

Owner:MDS CO LTD +2

High-Q pulsed fragmentation in ion traps

ActiveUS7102129B2Lower LMCOPrevent and minimize lossStability-of-path spectrometersIsotope separationIon trap mass spectrometryElevated value

Rapid and efficient fragmentation of ions in an ion trap for MS / MS analysis is achieved by a pulsed fragmentation technique. Ions of interest are placed at an elevated value of Q and subjected to a relatively high amplitude, short-duration resonance excitation pulse to cause the ions to undergo collision-induced fragmentation. The Q value of the ions of interest is then rapidly reduced, thereby decreasing the low-mass cutoff and allowing retention and subsequent analysis of low-mass ion fragments.

Owner:THERMO FINNIGAN

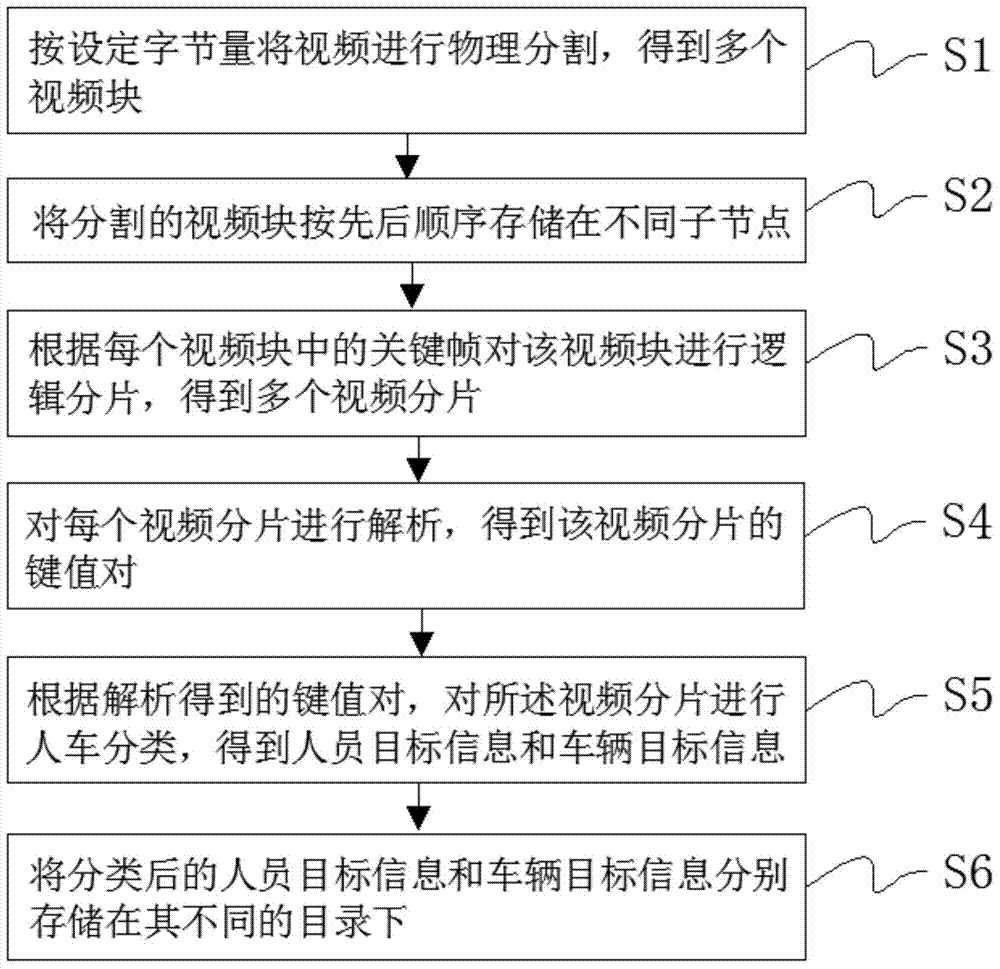

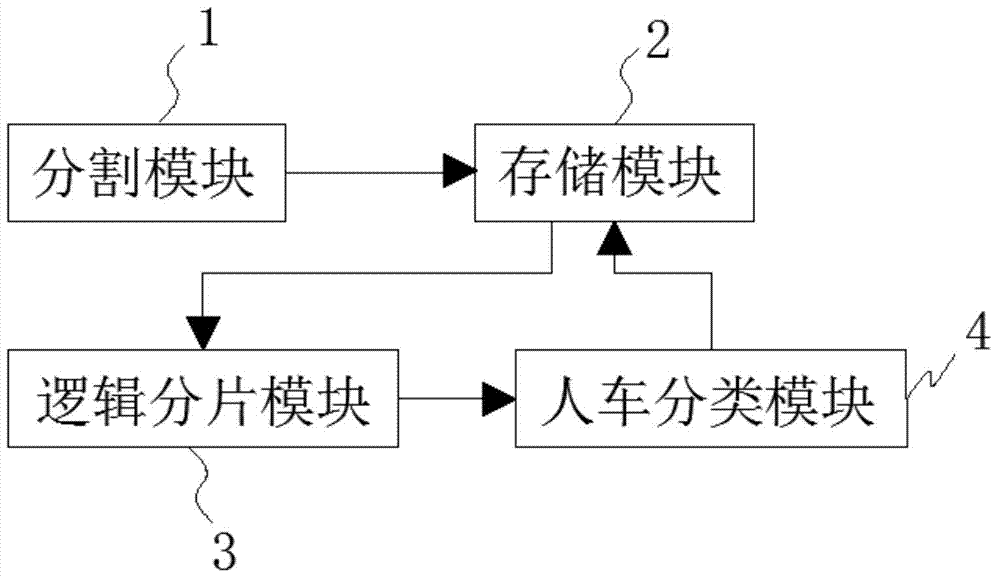

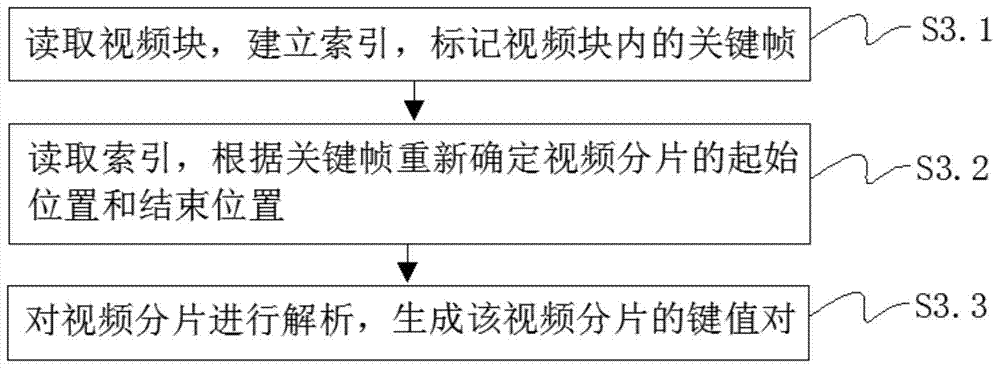

Personnel and vehicle target classification system and method

InactiveCN104519323AImprove processing efficiencyStrong relationshipClosed circuit television systemsSpecial data processing applicationsKey frameByte

The invention relates to a personnel and vehicle target classification system and method. The method comprises the following steps: (1) conducting physical partition on video according to setting byte amount to obtain a plurality of video blocks; (2) saving the partitioned video blocks at different child nodes in sequence; (3) conducting logic slicing on a video block according to the key frame of each video block to obtain a plurality of video slices; (4) analyzing each video slice to obtain a key value pair of the video slice; (5) conducting personnel and vehicle classification on the video slices according to the key value pairs obtained from analysis to obtain personnel target information and vehicle target information; (6) saving the personnel target information and the vehicle target information after classification in different catalogs respectively. Compared with the prior art, the method is easy to operate, efficient in processing, and effective in unziping.

Owner:桂林远望智能通信科技有限公司

High-Q pulsed fragmentation in ion traps

ActiveUS20060054808A1Reduce decreasePrevent and minimize lossStability-of-path spectrometersIsotope separationElevated valueIon trap mass spectrometry

Rapid and efficient fragmentation of ions in an ion trap for MS / MS analysis is achieved by a pulsed fragmentation technique. Ions of interest are placed at an elevated value of Q and subjected to a relatively high amplitude, short-duration resonance excitation pulse to cause the ions to undergo collision-induced fragmentation. The Q value of the ions of interest is then rapidly reduced, thereby decreasing the low-mass cutoff and allowing retention and subsequent analysis of low-mass ion fragments.

Owner:THERMO FINNIGAN

Ion mobility spectrometer with upstream devices at constant potential

ActiveUS9607820B2Simplifies preferred mode of operationRaise the potentialStability-of-path spectrometersMaterial analysis by electric/magnetic meansLinearityMass spectrometric

A mass spectrometer includes an ion mobility spectrometer or separator arranged upstream of a collision or fragmentation cell. Ions are separated according to their ion mobility within the ion mobility spectrometer or separator. The kinetic energy of the ions exiting the ion mobility spectrometer or separator is increased substantially linearly with time in order to optimize the fragmentation energy of ions as they enter the collision or fragmentation cell. During the time that the potential of the ion mobility spectrometer or separator is being varied, the potential of ion-optical components upstream of the ion mobility spectrometer or separator such as an ion source, ion guide, quadrupole mass filter, optional second collision or fragmentation cell and an ion trapping device are kept constant.

Owner:MICROMASS UK LTD

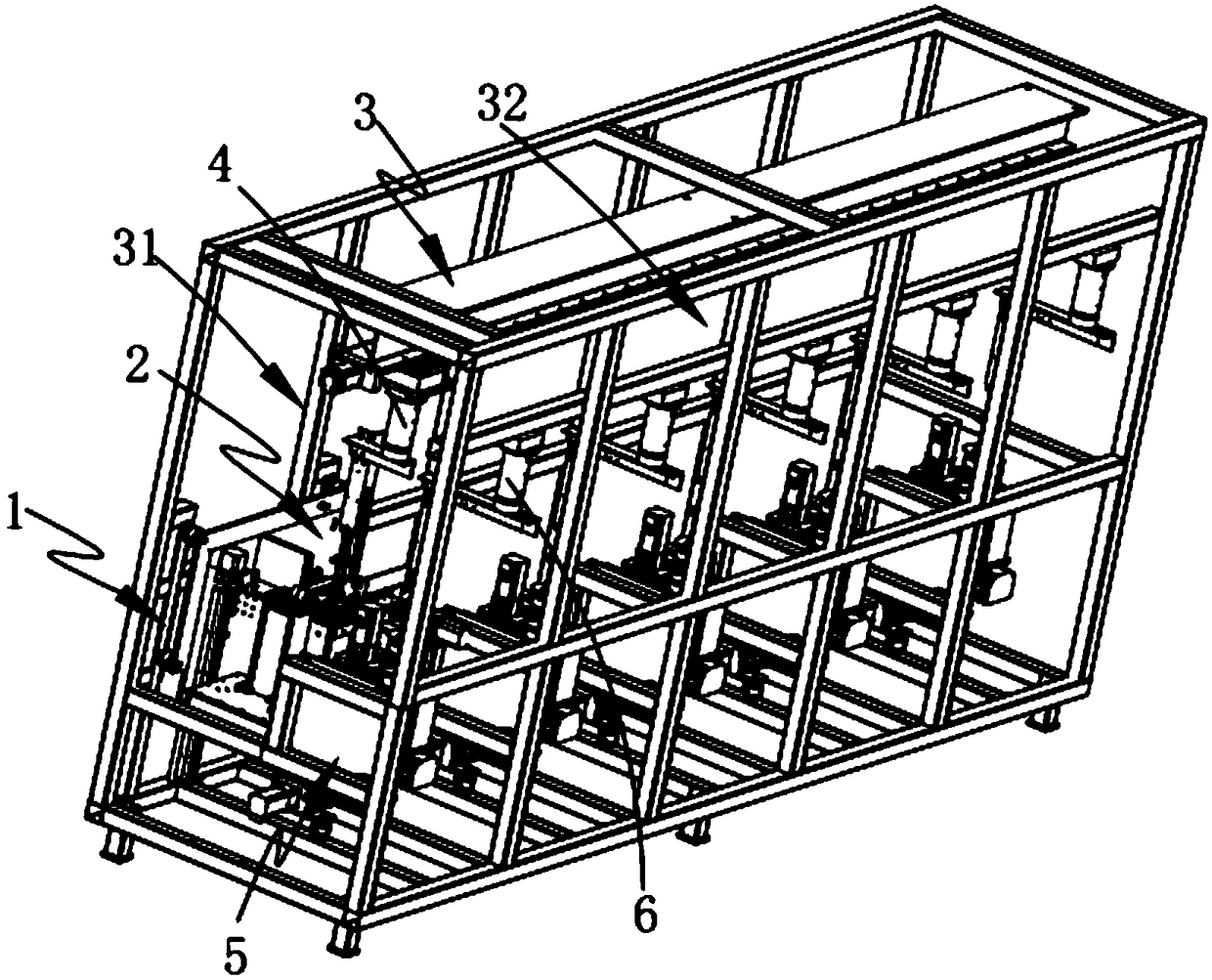

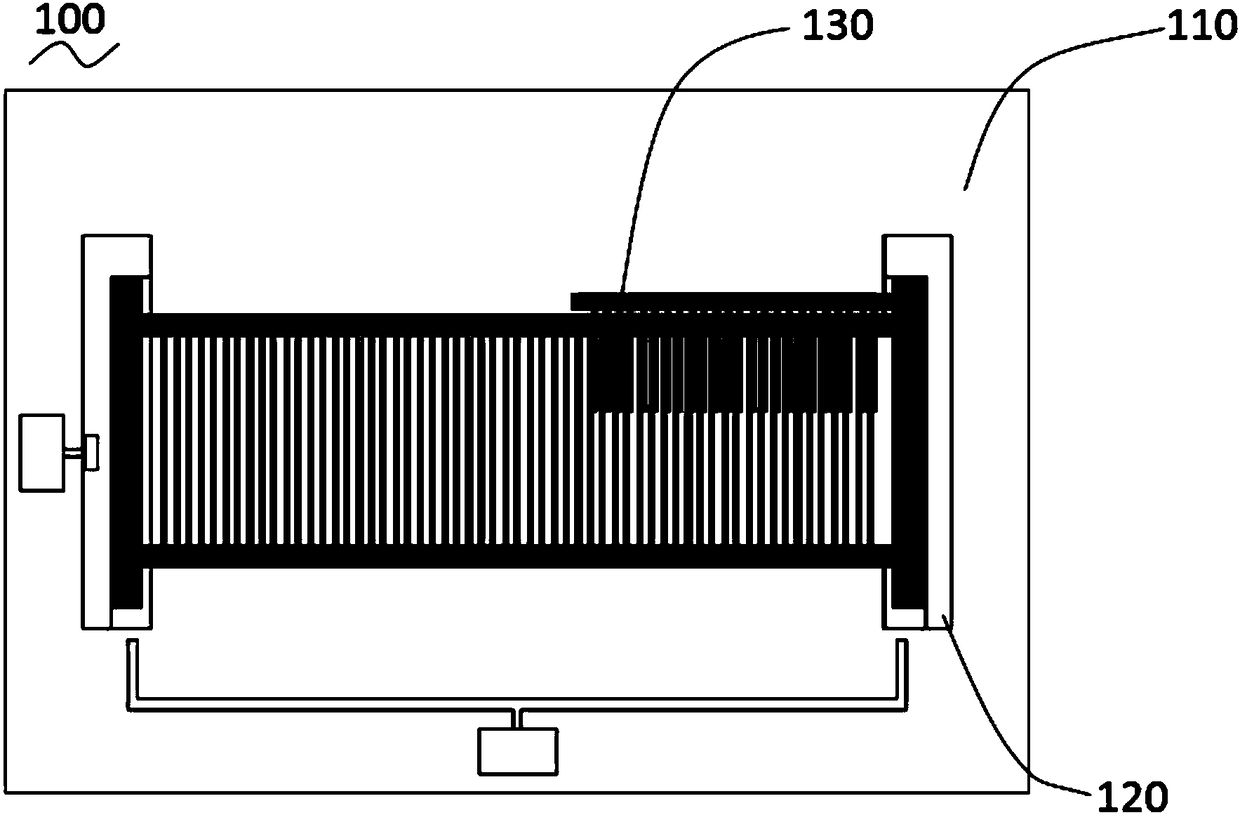

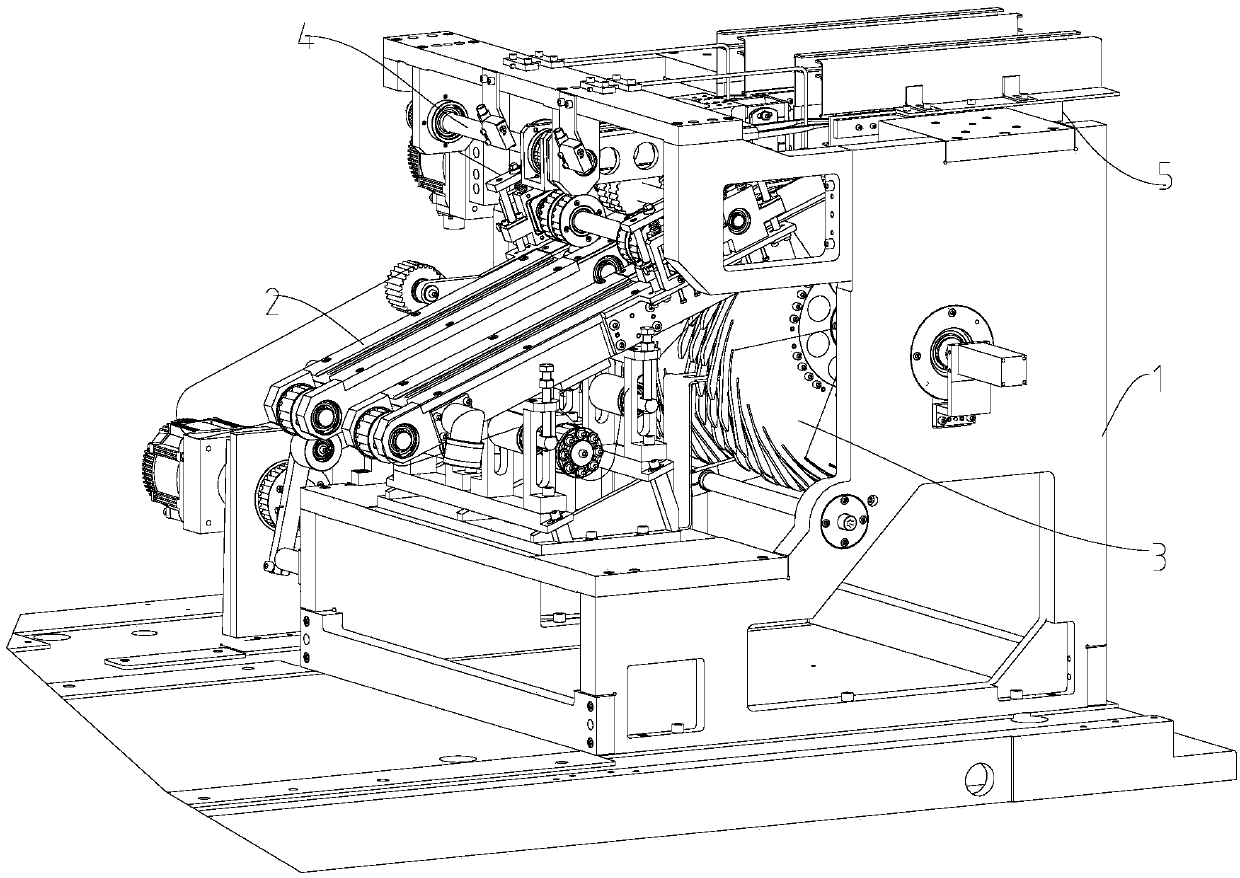

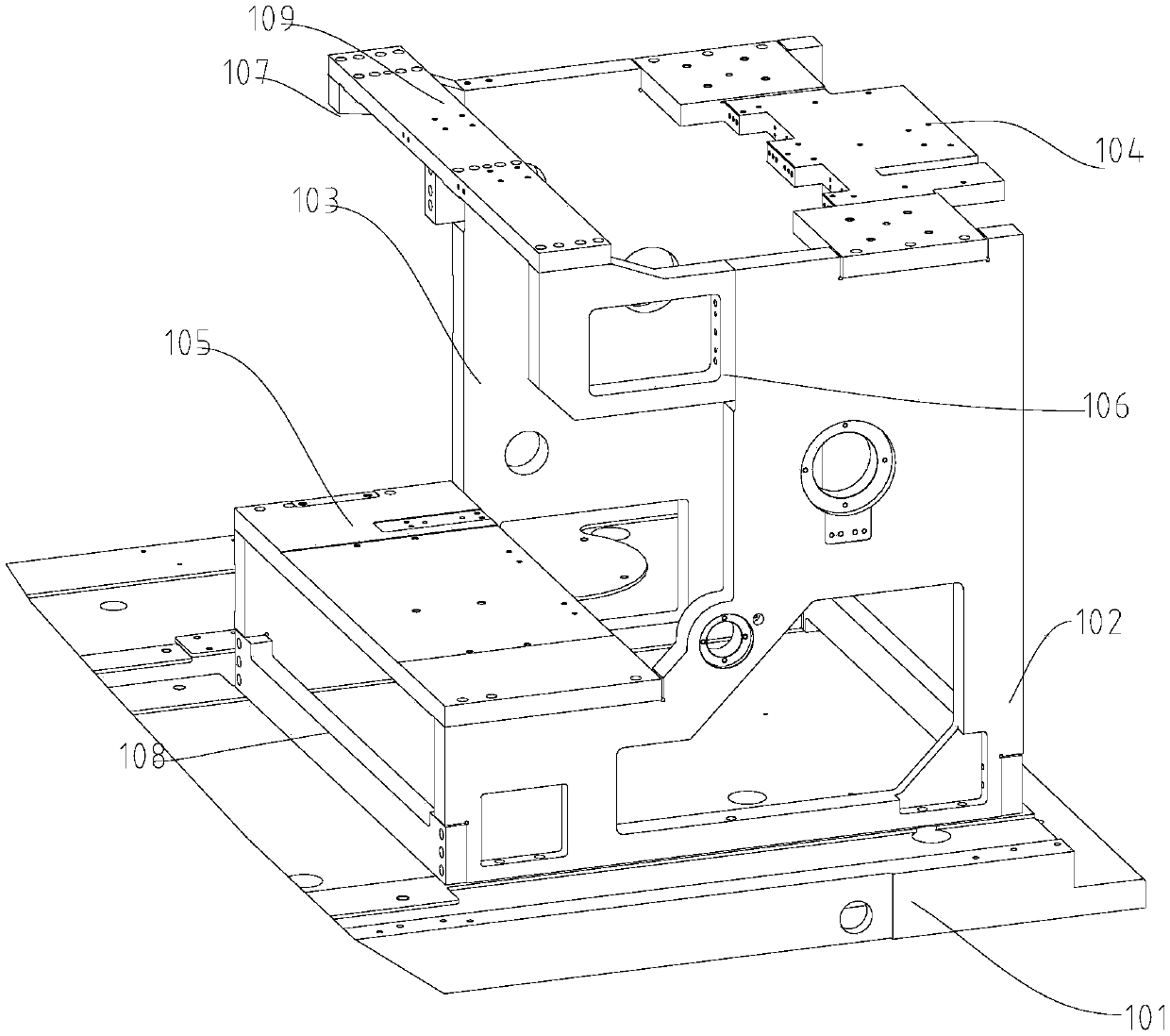

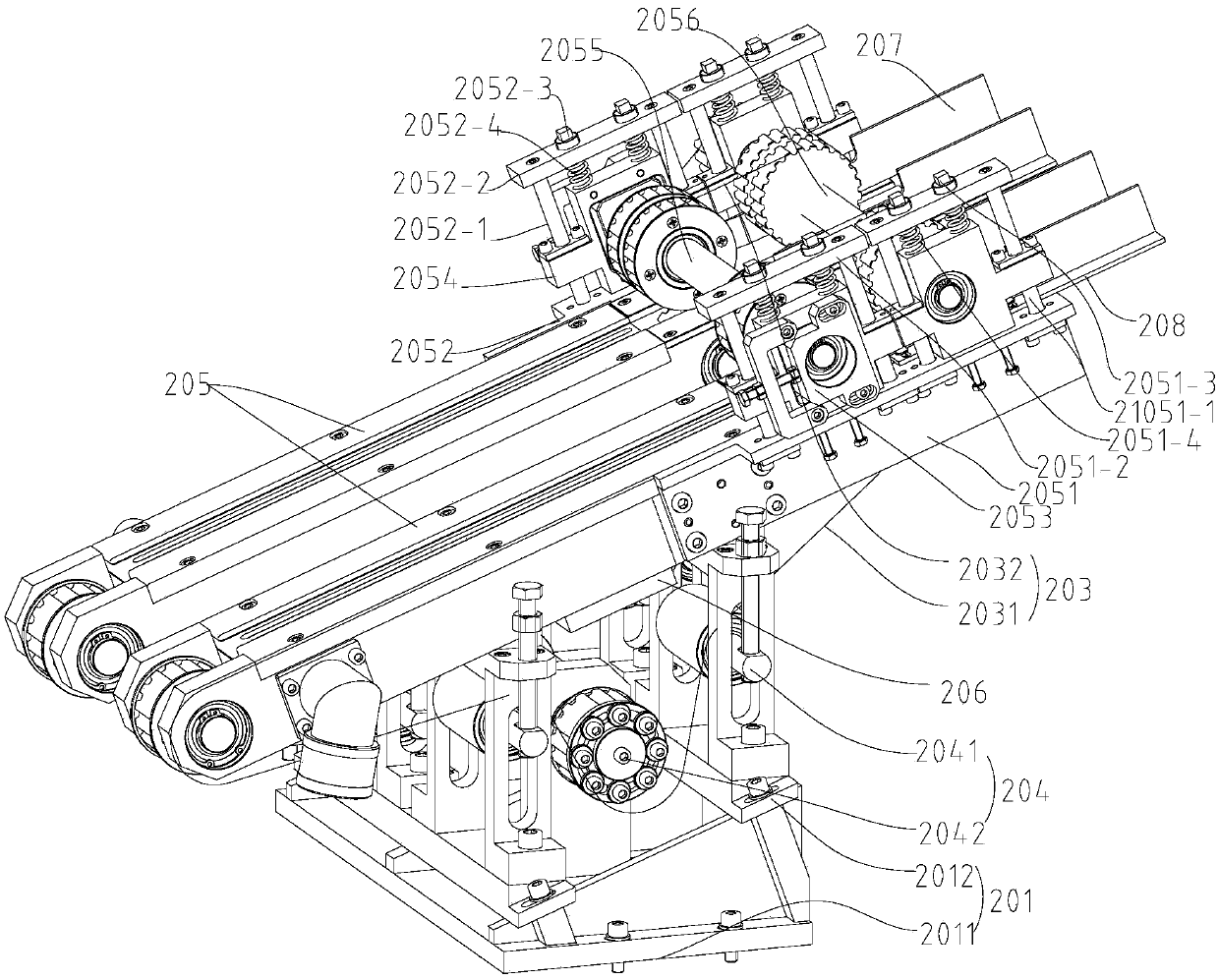

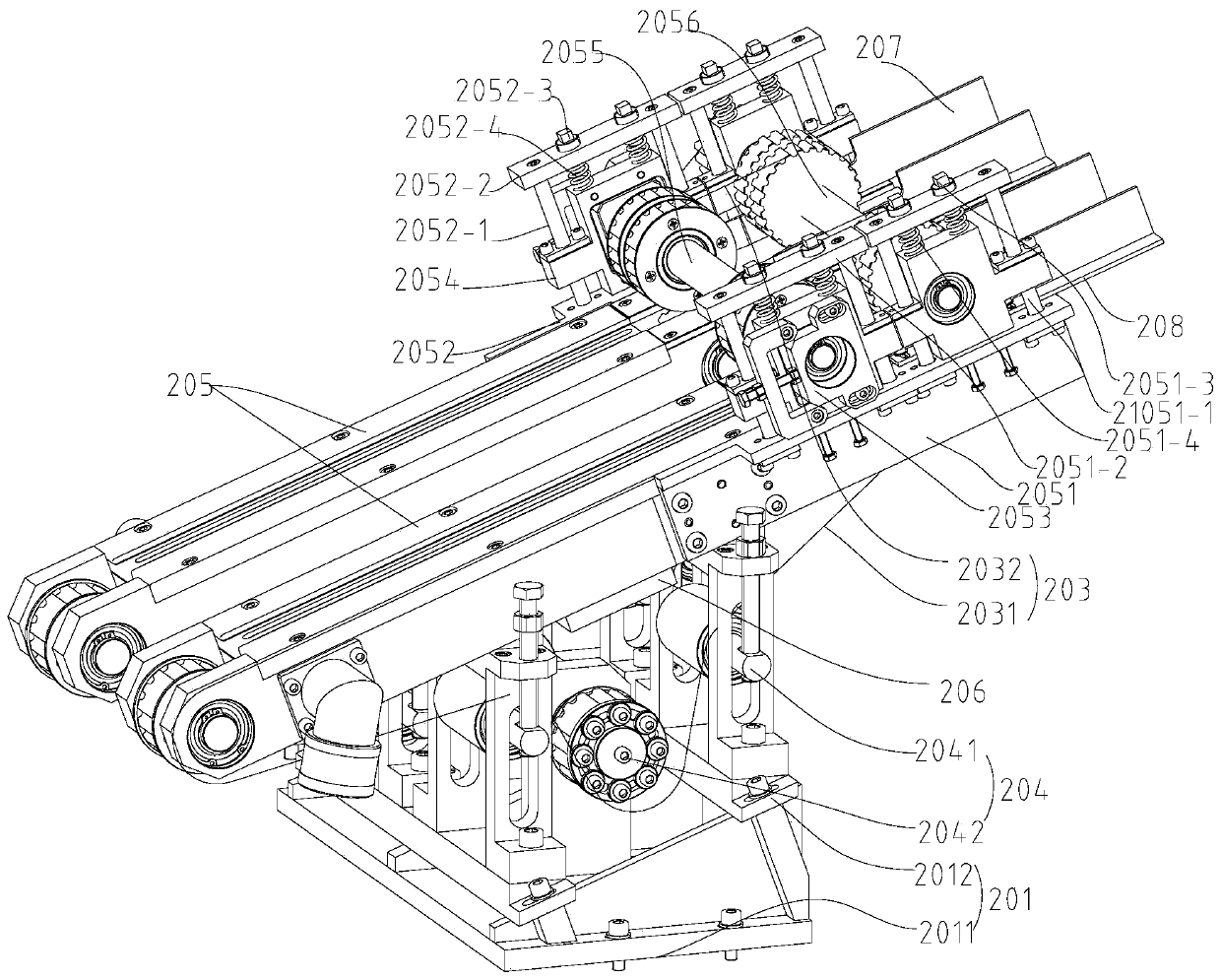

Automatic silicon wafer distributing, conveying and positioning system

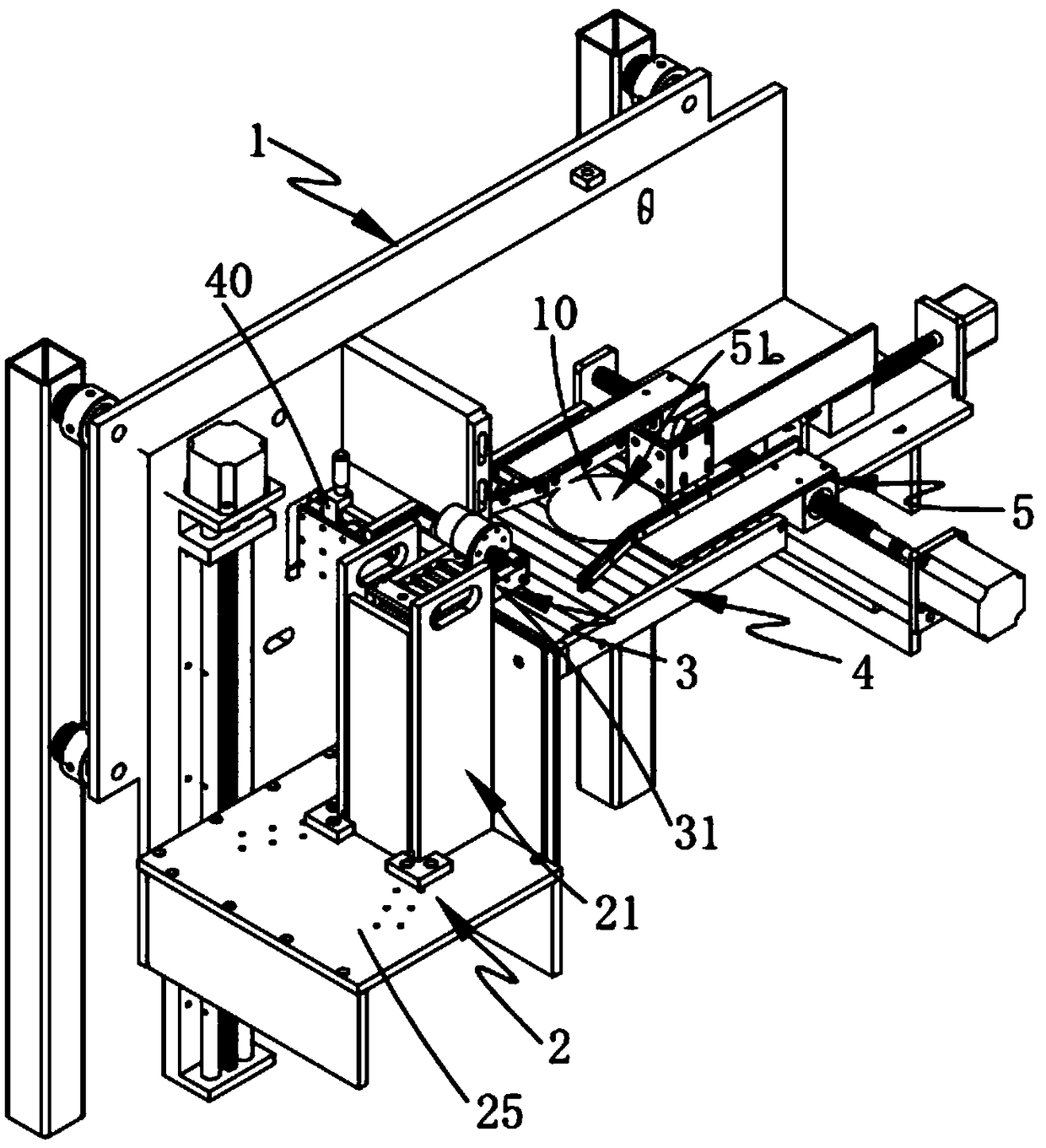

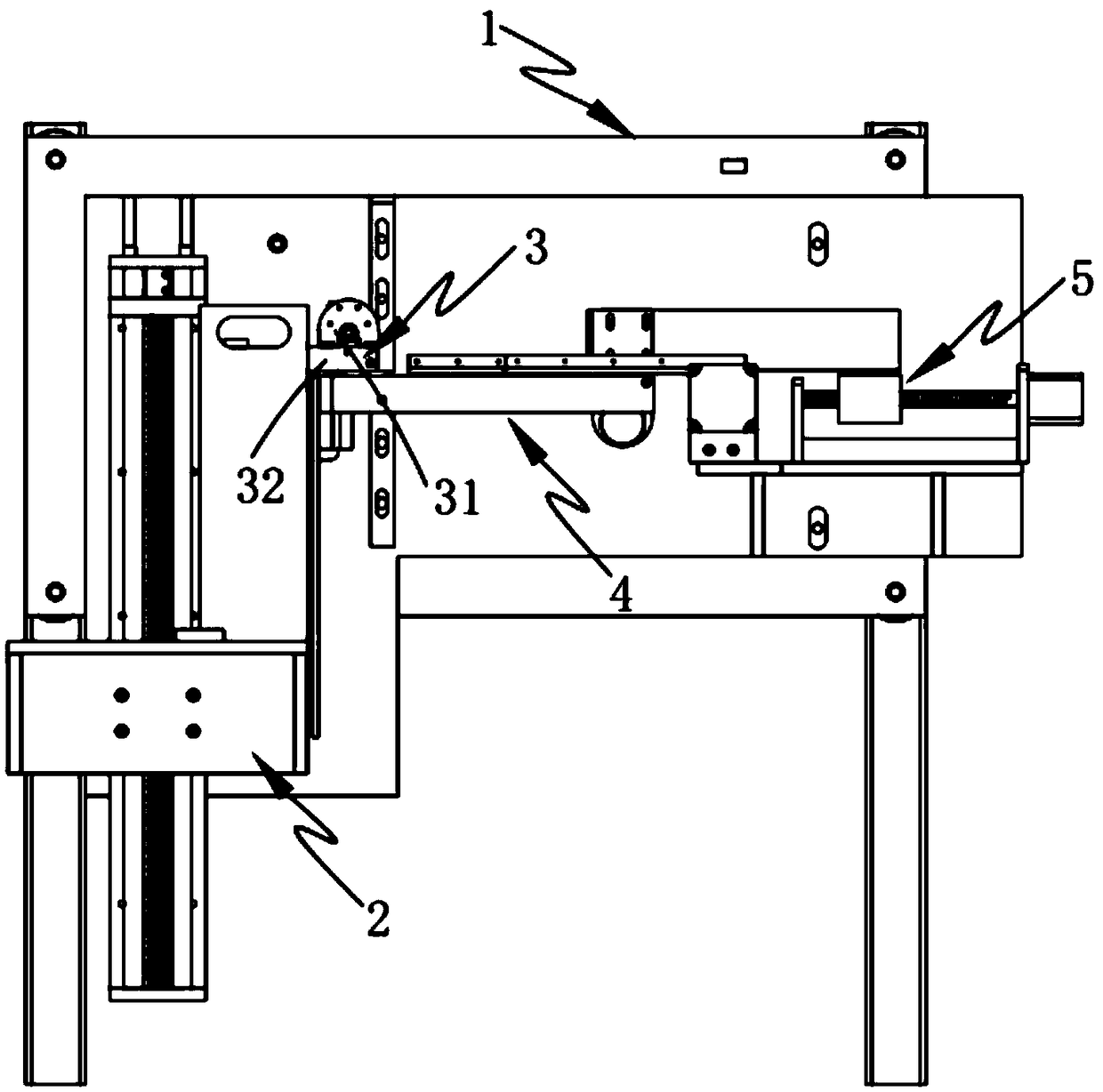

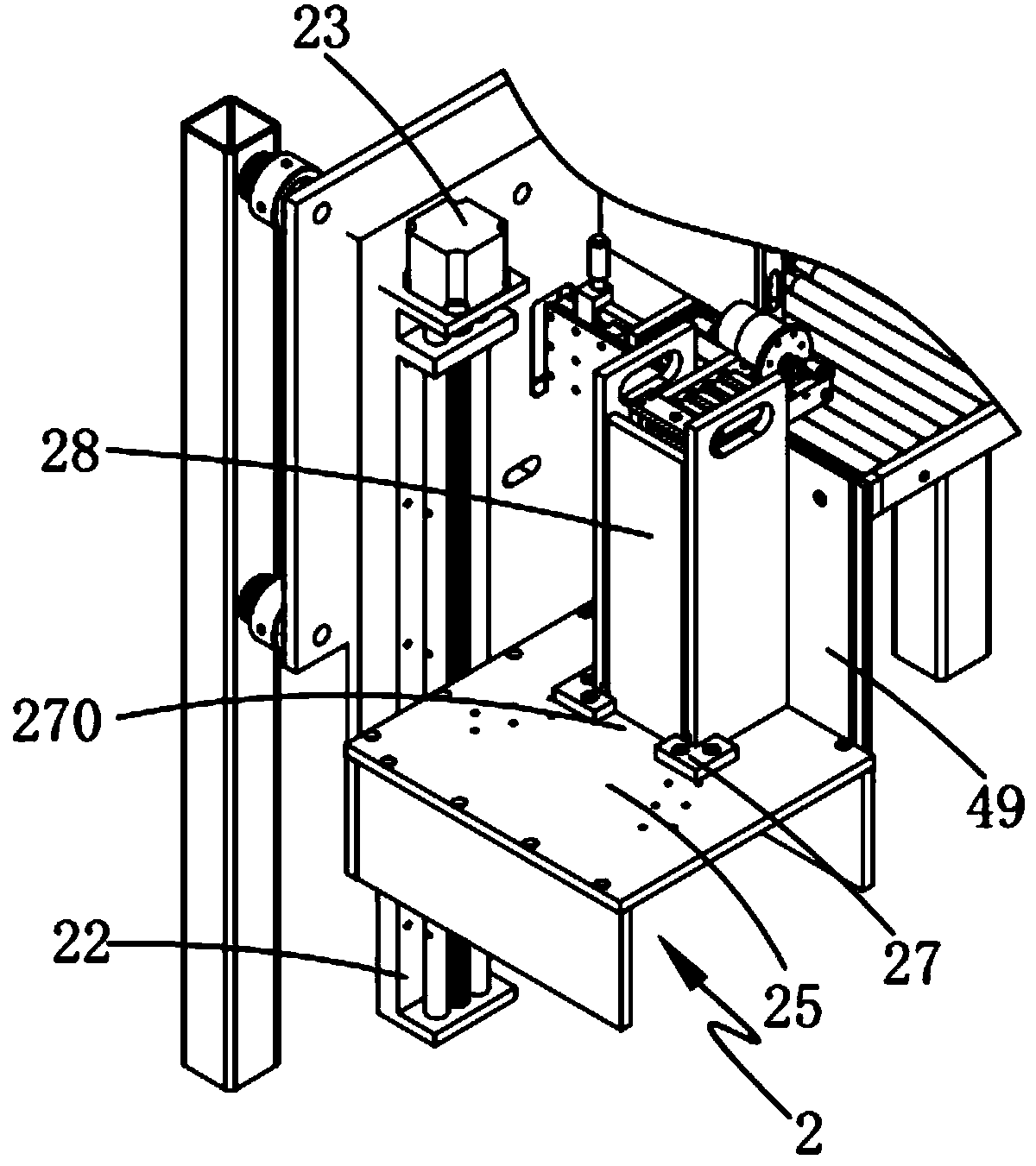

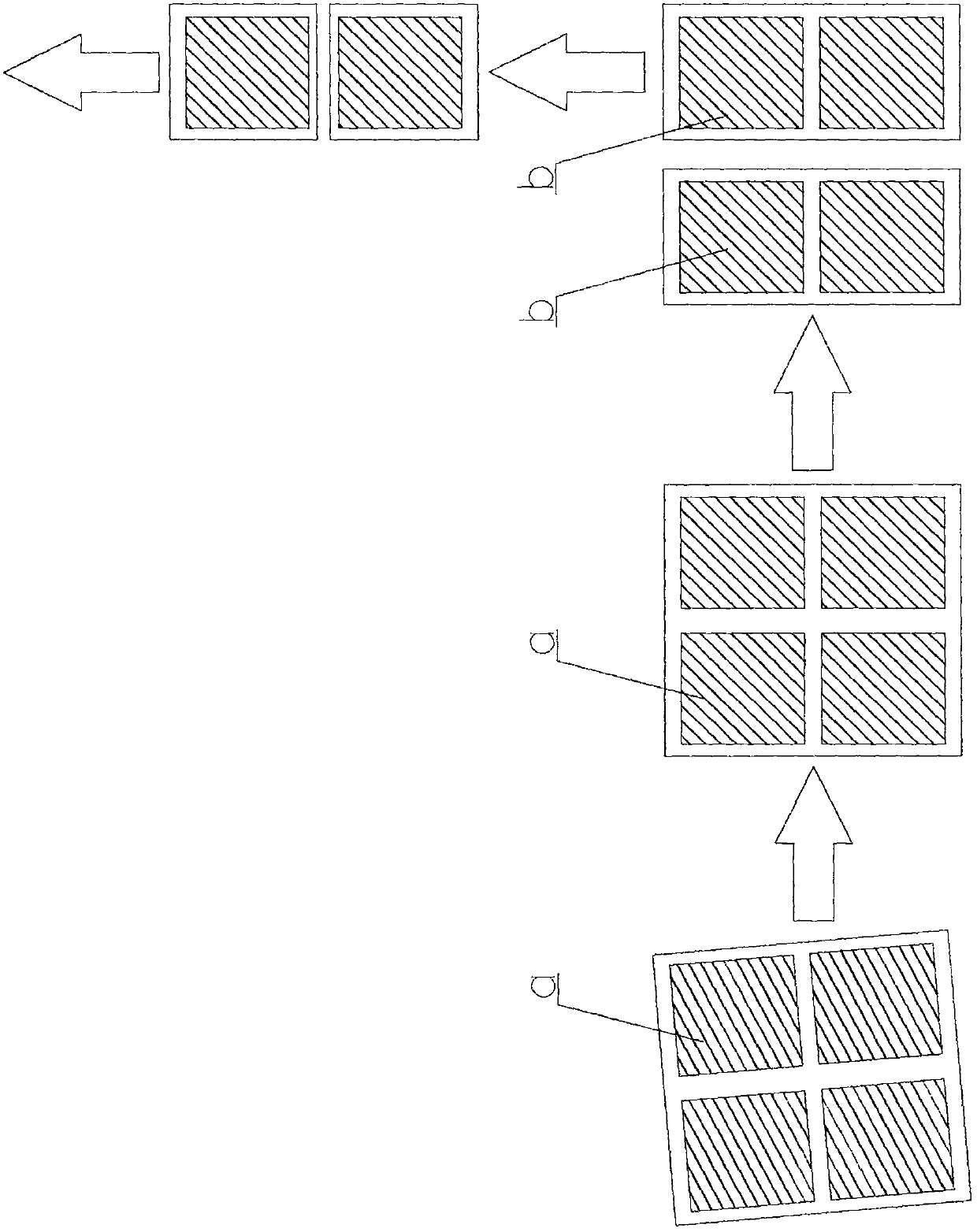

PendingCN109335707AHigh degree of automationIncrease productivityConveyorsControl devices for conveyorsPositioning systemSilicon

The invention provides an automatic silicon wafer distributing, conveying and positioning system. The system comprises a mounting rack, a feeding and lifting mechanism, a silicon wafer distributing mechanism, a conveying mechanism and a self-centering mechanism, wherein the feeding and lifting mechanism is arranged on the mounting rack and is used for driving a silicon wafer box to upwards move, and a plurality of silicon wafers are overlapped in the silicon wafer box; the silicon wafer distributing mechanism is arranged at the rear side of the feeding and lifting mechanism, and the conveyingmechanism is arranged at the back of the silicon wafer distributing mechanism; and the self-centering mechanism is arranged at the upper part of one end of the conveying mechanism. According to the system, the feeding and lifting mechanism is arranged, and a silicon wafer overlapping area is formed on a silicon wafer bearing platform; a plurality of silicon wafers can be naturally overlapped in the silicon wafer overlapping area and move to the lower part of the silicon wafer distributing mechanism from bottom to top; the silicon wafer distributing mechanism is capable of automatically distributing the silicon wafers while being in contact with the silicon wafers; and meanwhile, the silicon wafers are continuously conveyed to a self-centering part for self-centering in an one-by-one mannerthrough the conveying mechanism; and the technical problems that a mode for manually positioning the silicon wafers is carried out in the prior art, the working efficiency is low, and both labor andmaterials are wasted, can be solved.

Owner:浙江中晶新材料研究有限公司

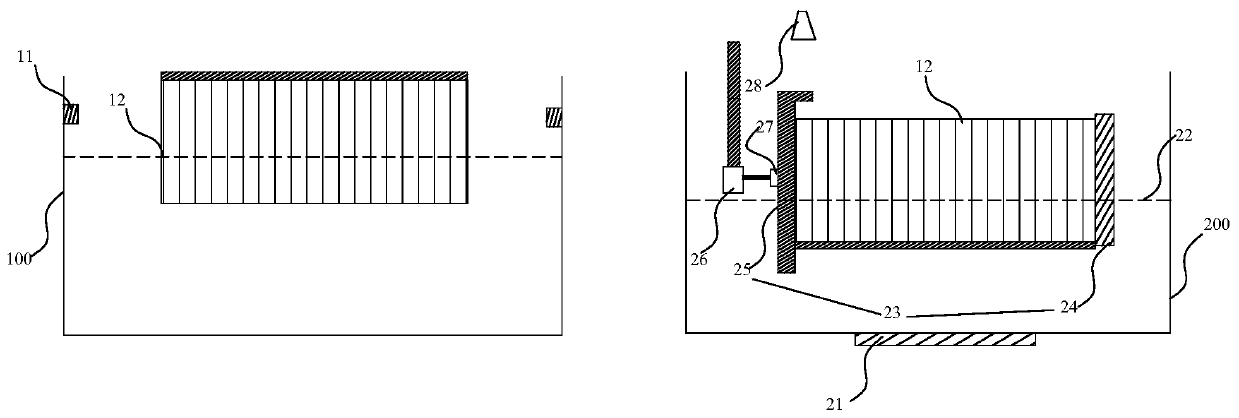

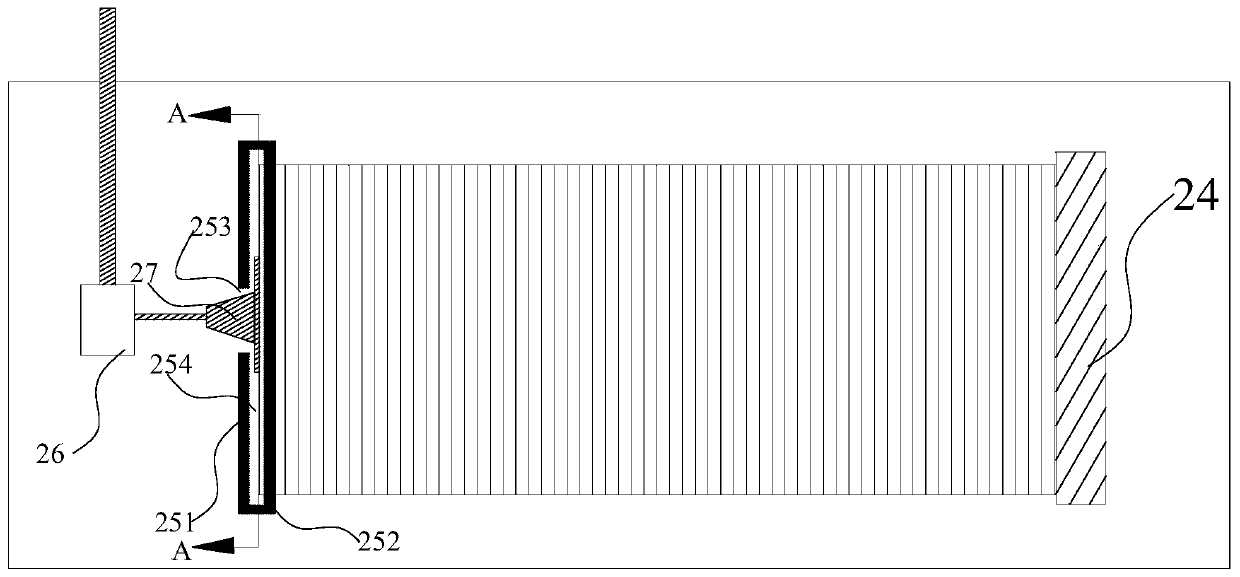

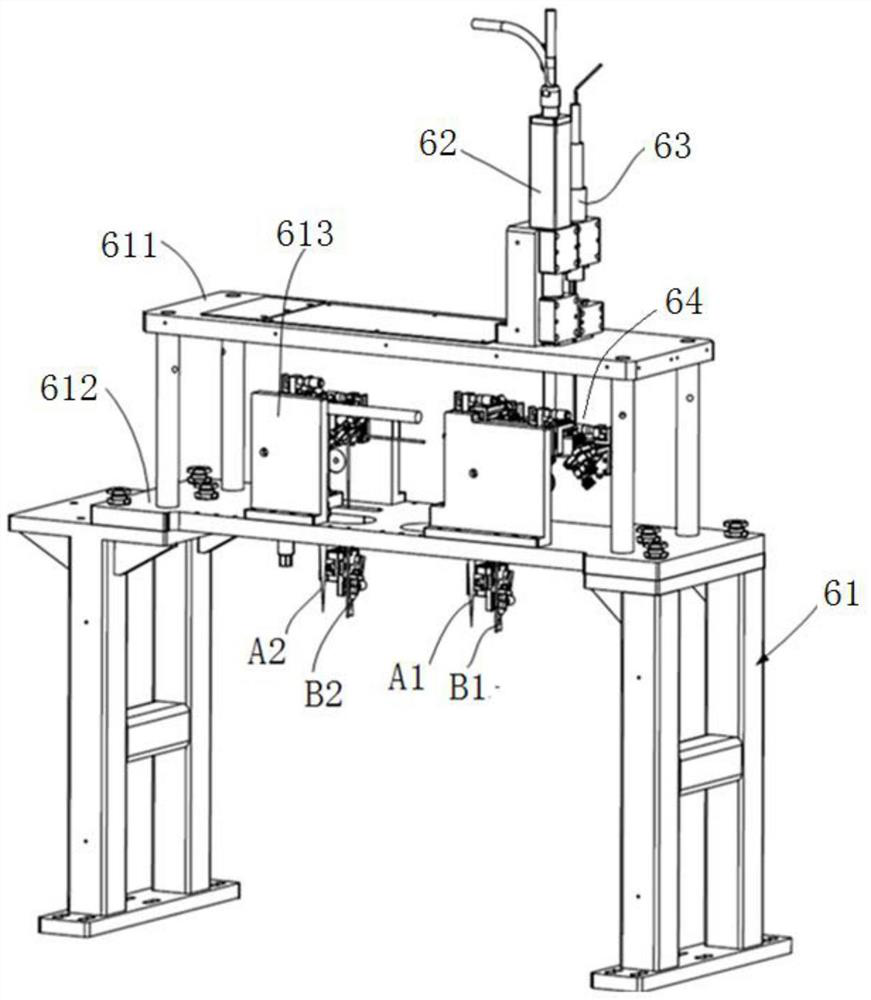

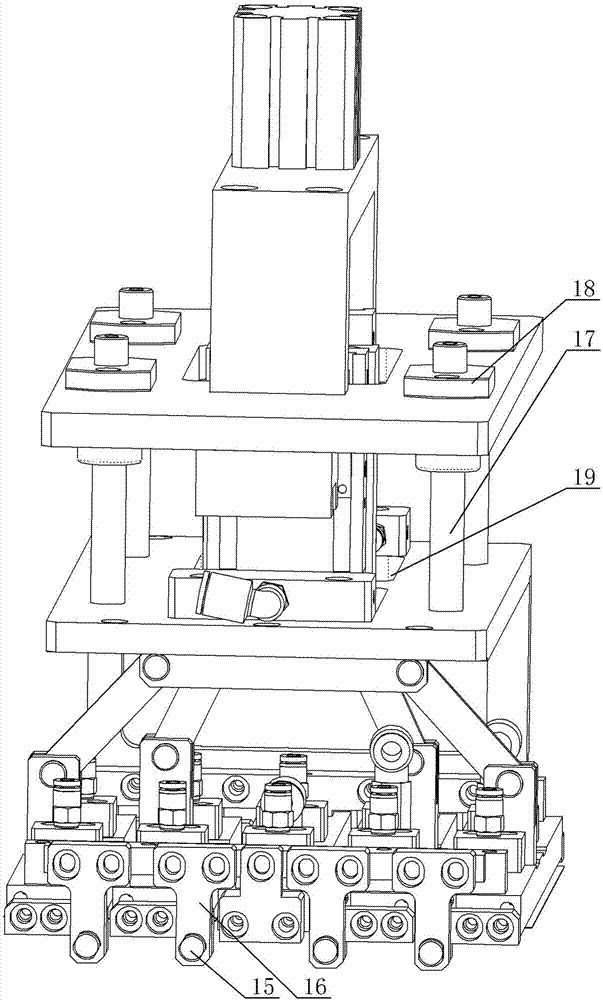

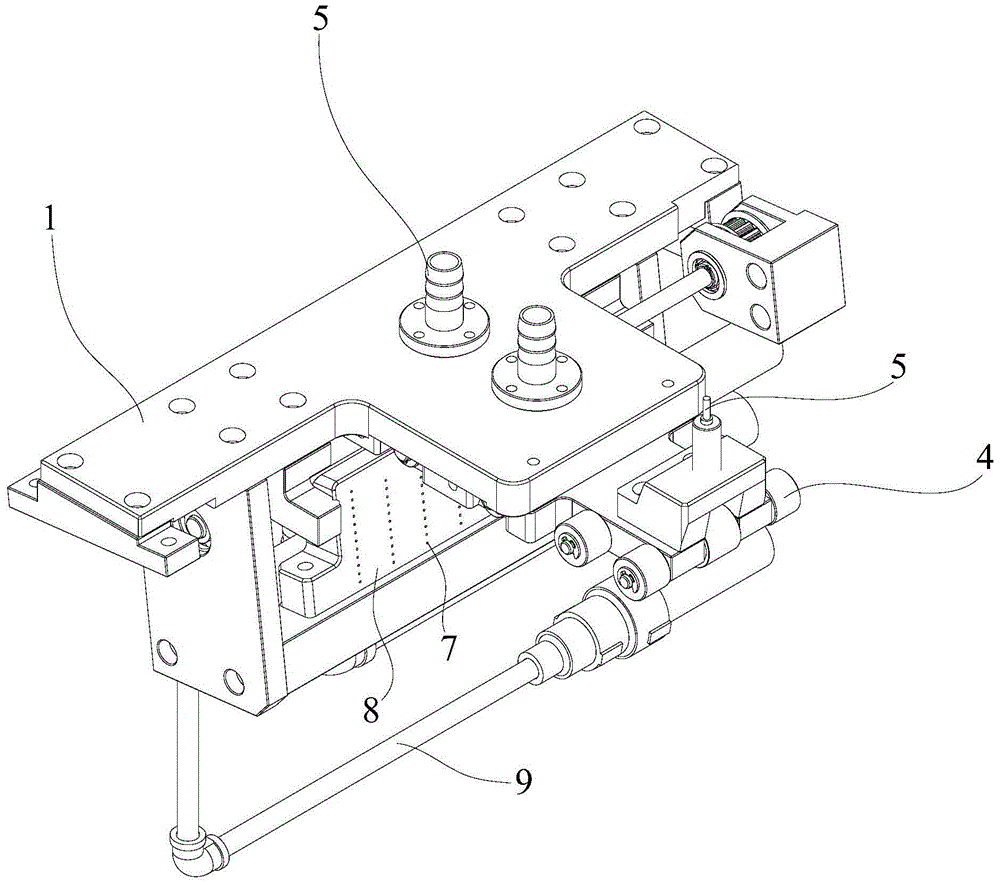

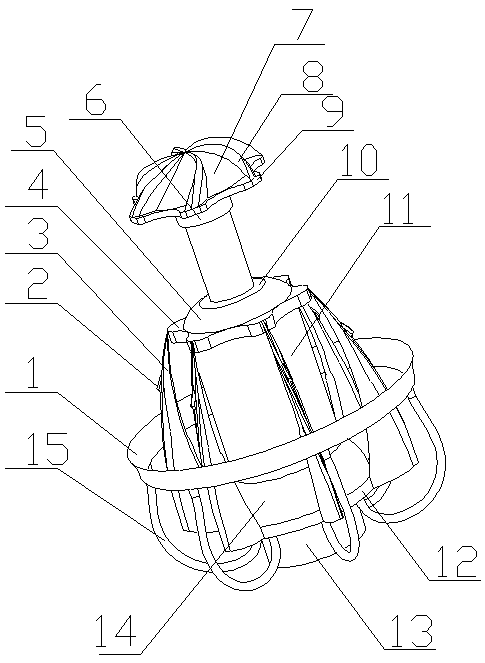

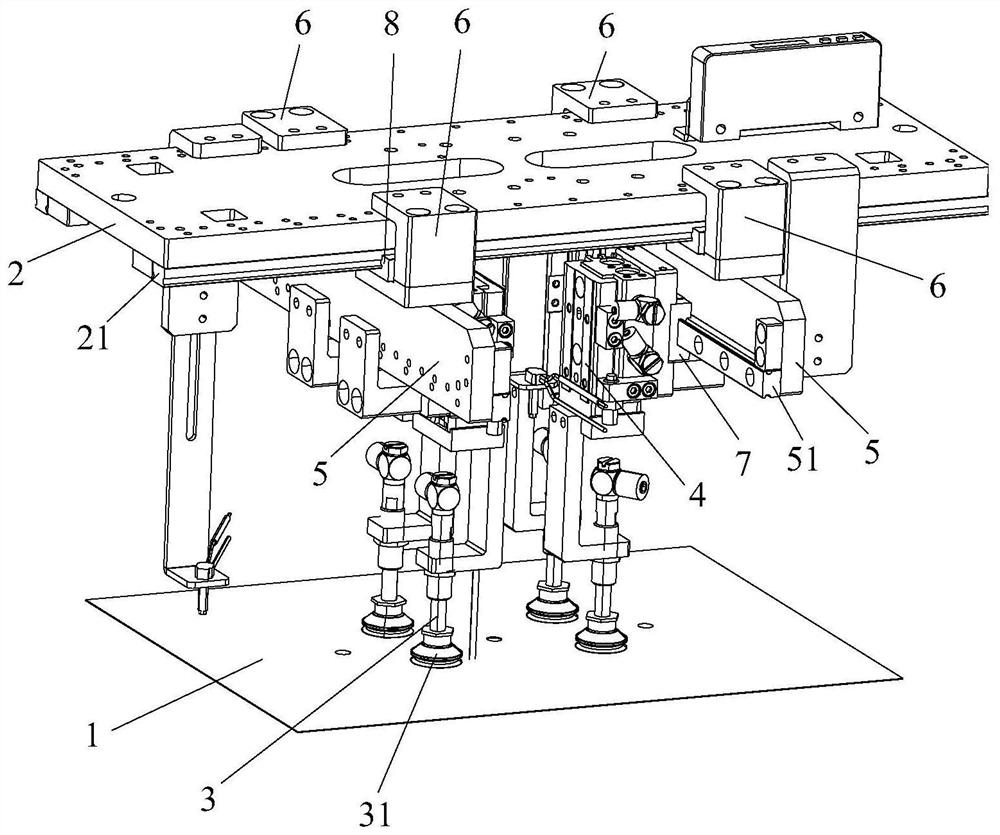

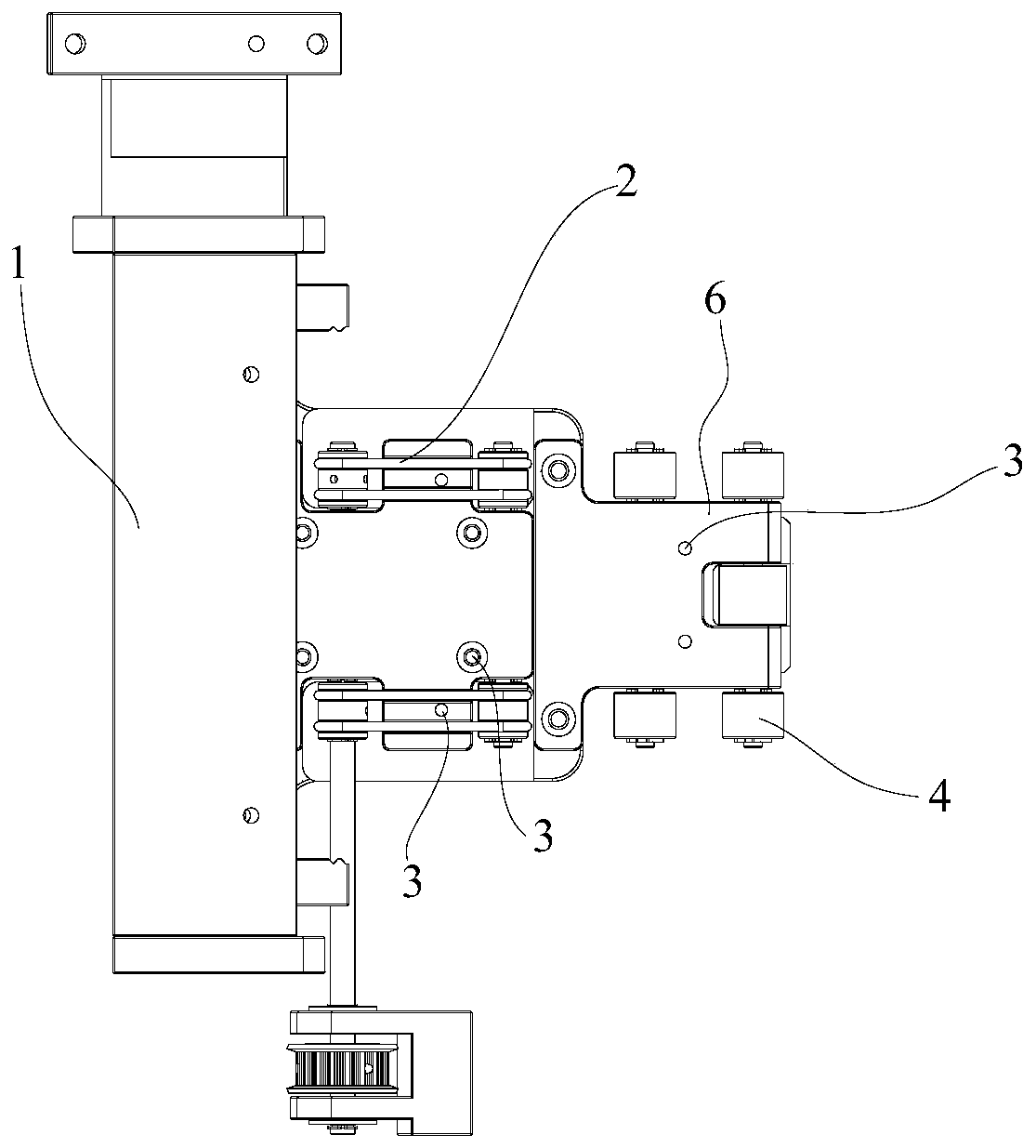

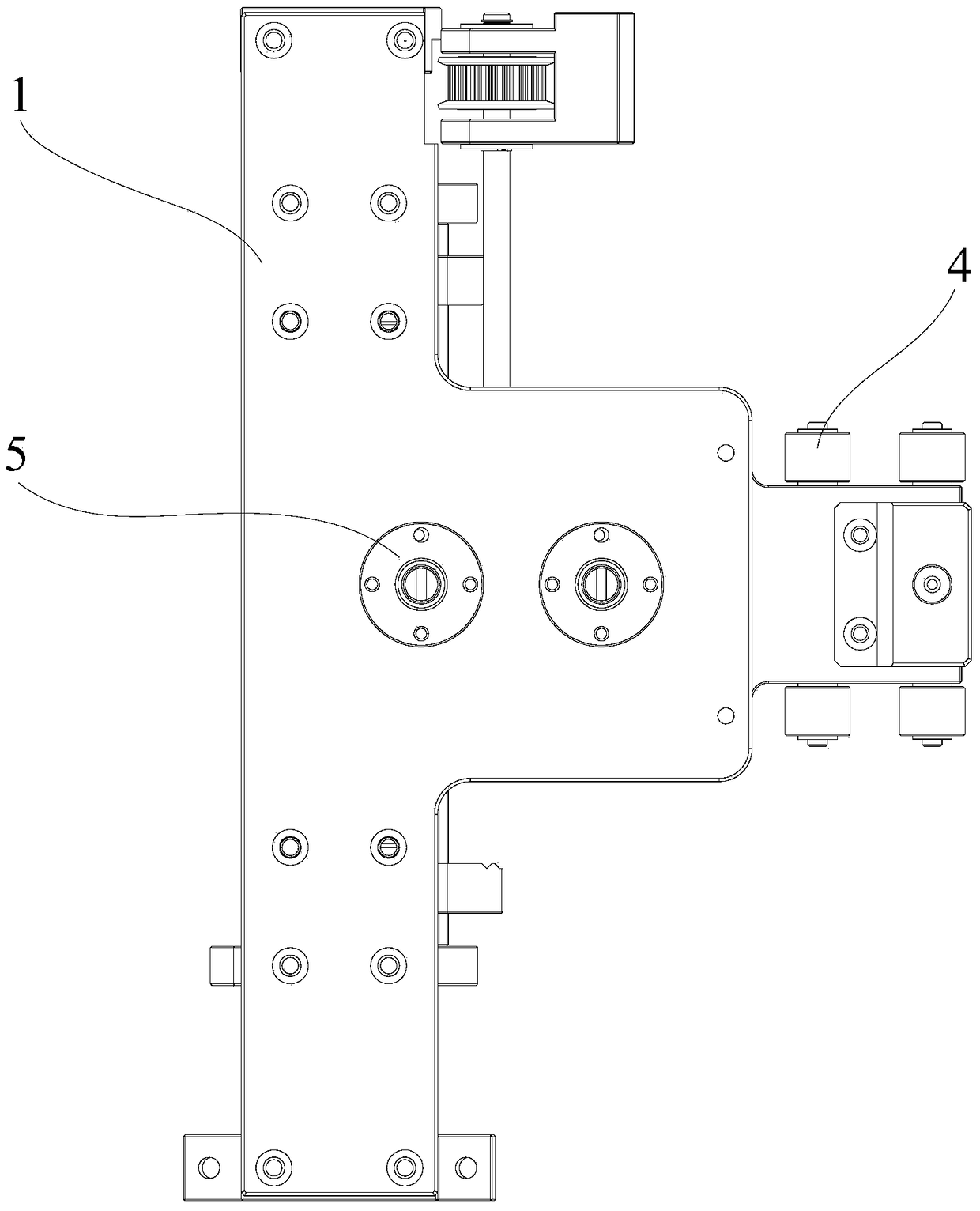

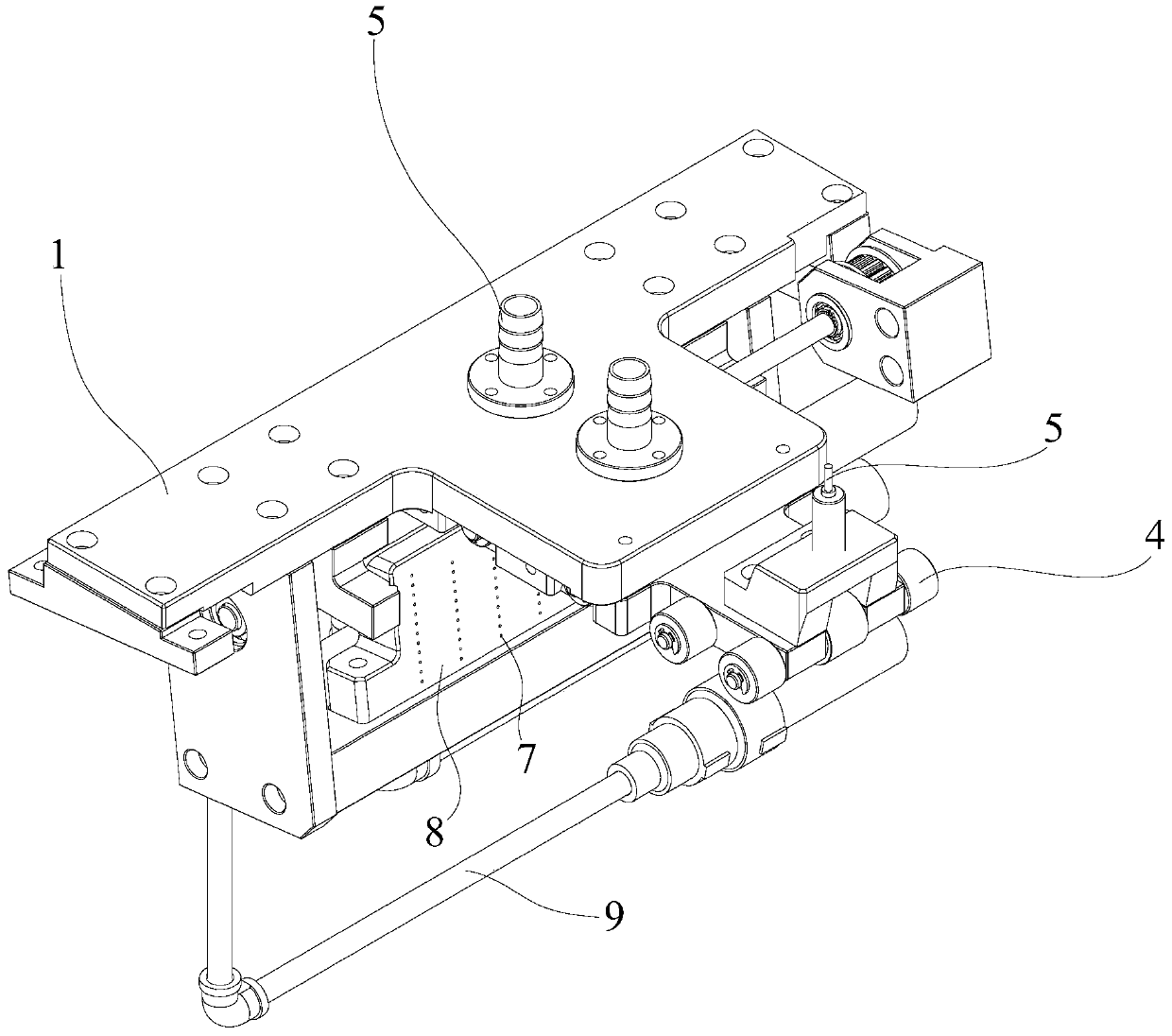

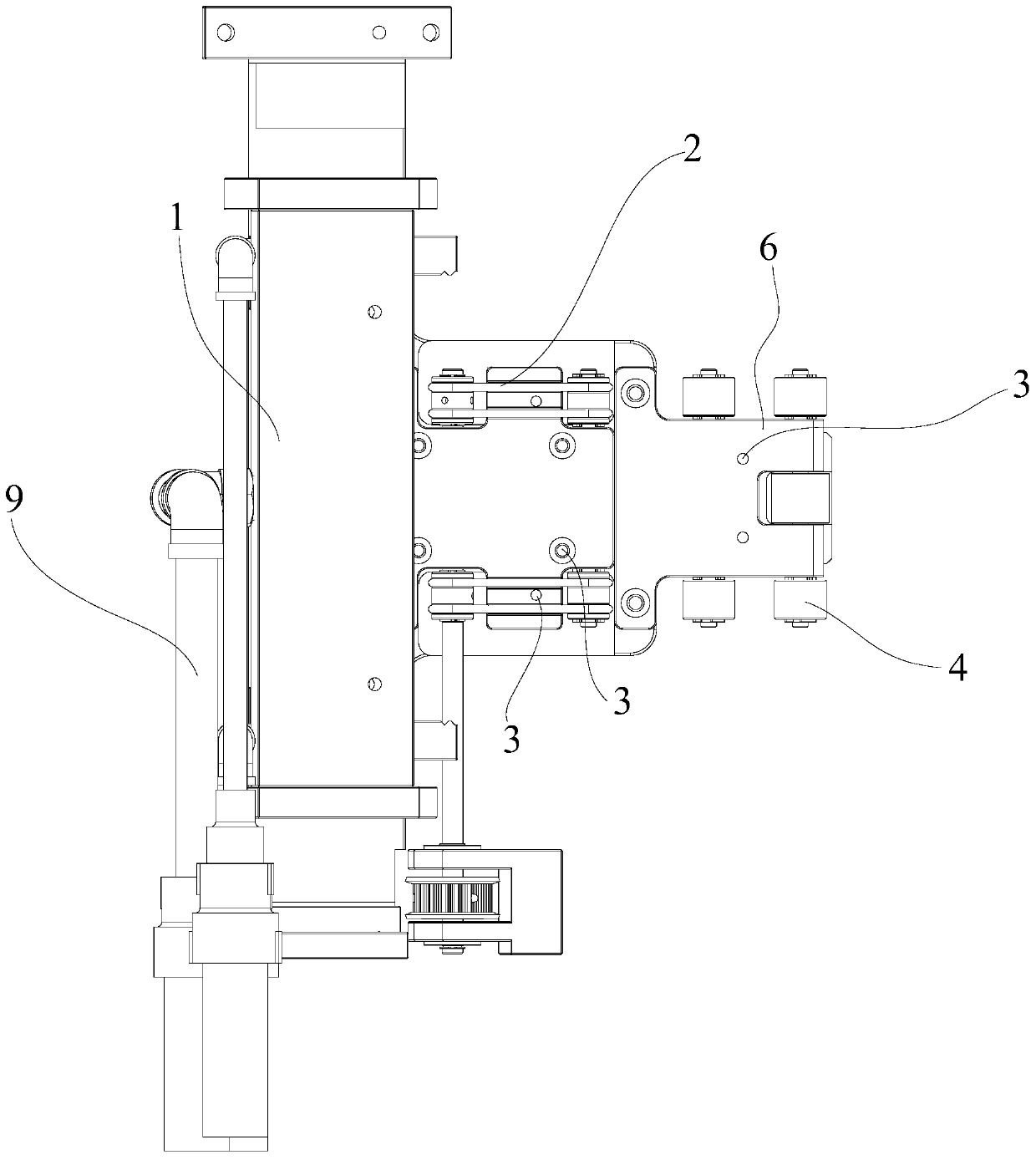

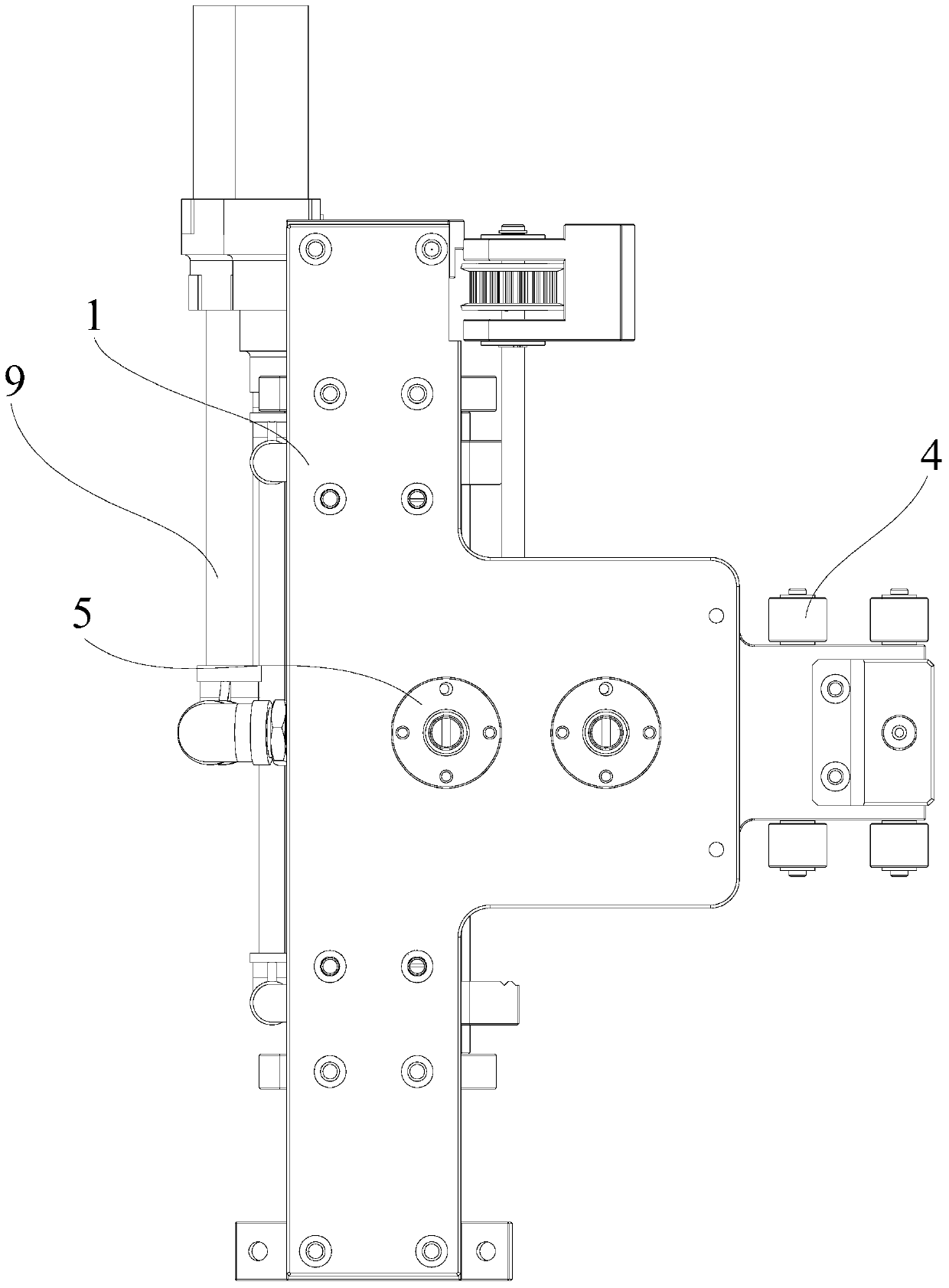

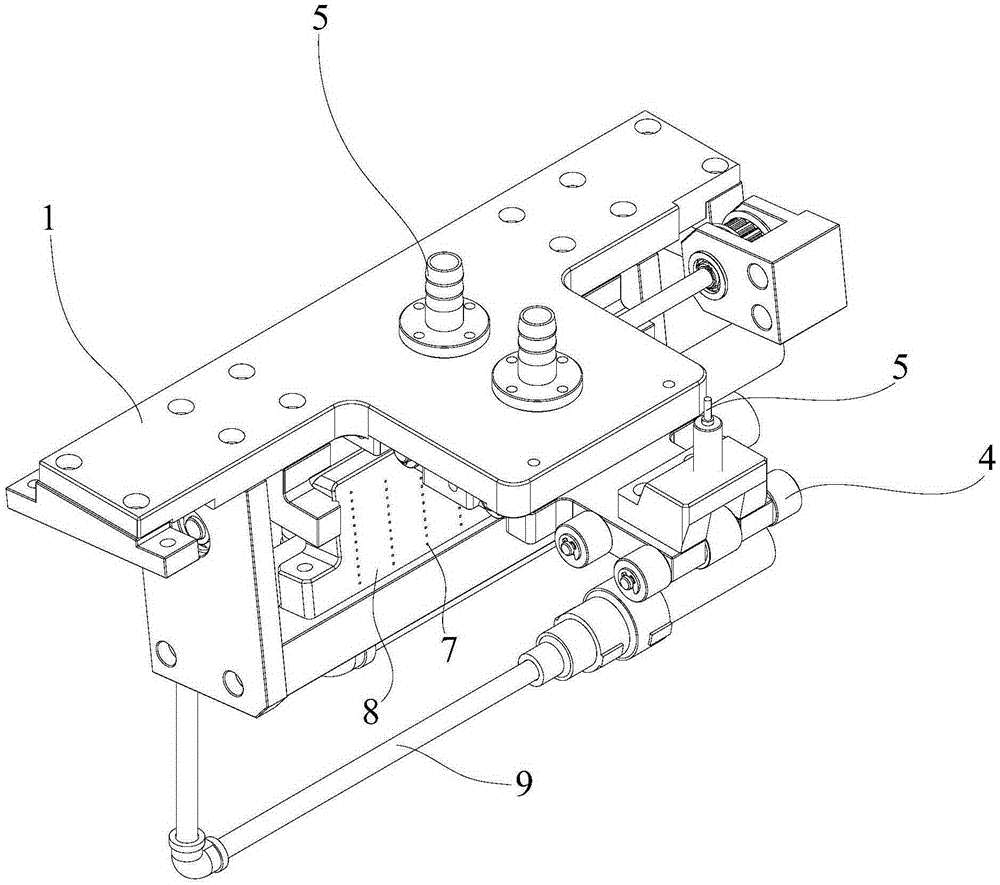

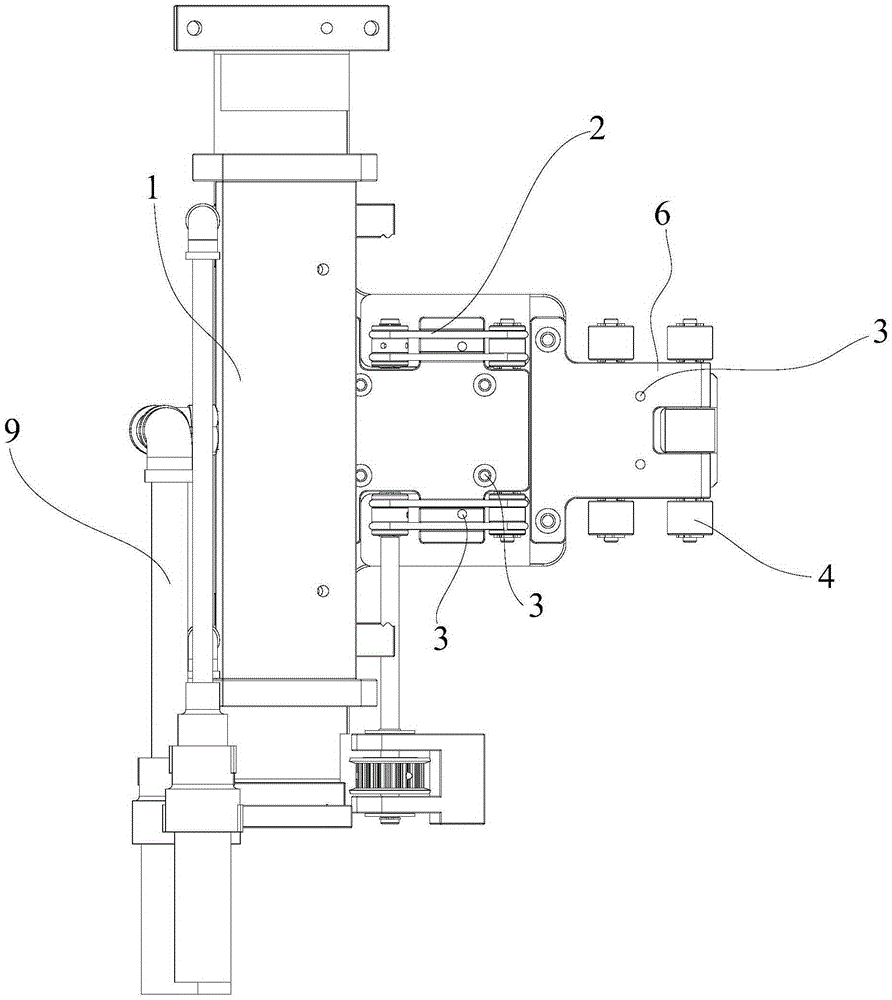

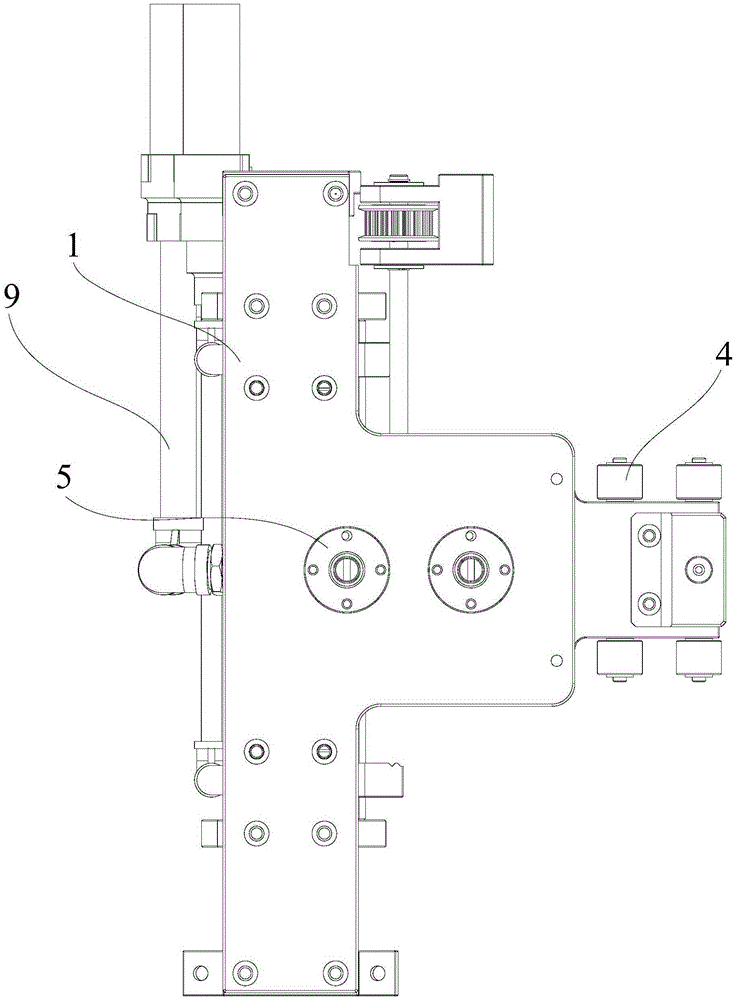

Degumming device and method of cut silicon rod

ActiveCN111318500ASolve adhesionImprove sharding efficiencyCleaning using toolsWorking accessoriesRobotic armStructural engineering

The invention discloses a degumming device and method of a cut silicon rod. The device comprises a cleaning unit and a degumming and splicing unit, wherein a spray assembly is arranged on the cleaningunit; the degumming and splicing unit is arranged downstream the cleaning unit, a heating assembly and hot water are arranged in the degumming and splicing unit, a bearing assembly is arranged abovethe degumming and splicing unit, the bearing assembly comprises a push plate and a protecting plate which are arranged at an interval, the push plate and the protecting plate are arranged on both endsof the cut silicon rod in the length direction of the cut silicon rod, the protecting plate can move in the length direction of the cut silicon rod, the protecting plate comprises a protecting platepart and a separating part which are connected, an opening which penetrates in the length direction of the cut silicon rod is formed in the protecting plate part, a sucking disc which is connected with a mechanical arm makes contact with the end of the cut silicon rod through the opening, the separating part is arranged on the upper end of one end, which is close to the push plate, of the protecting plate part, a containing clearance is formed between the separating part and the protecting plate part, the degumming and splicing unit further comprises an atomizing spray assembly, and the atomizing spray assembly is arranged above the containing clearance.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

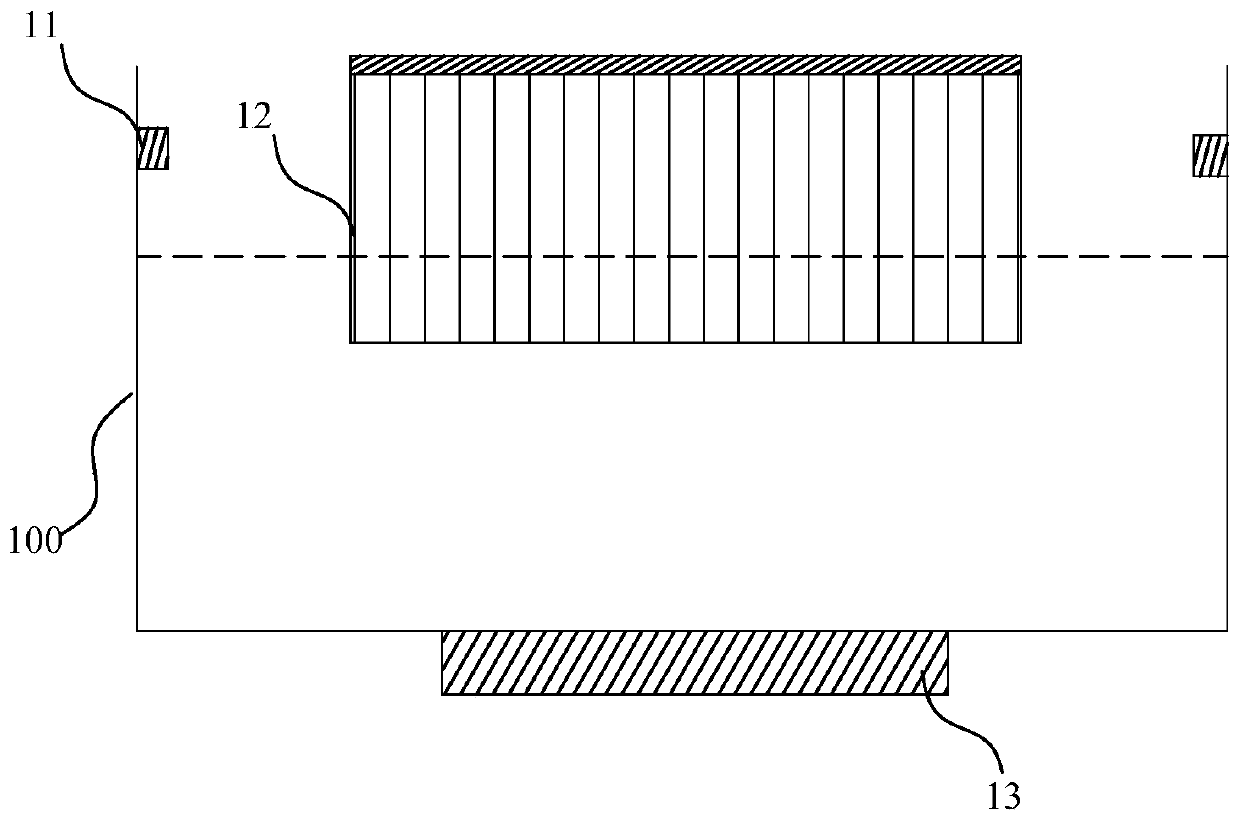

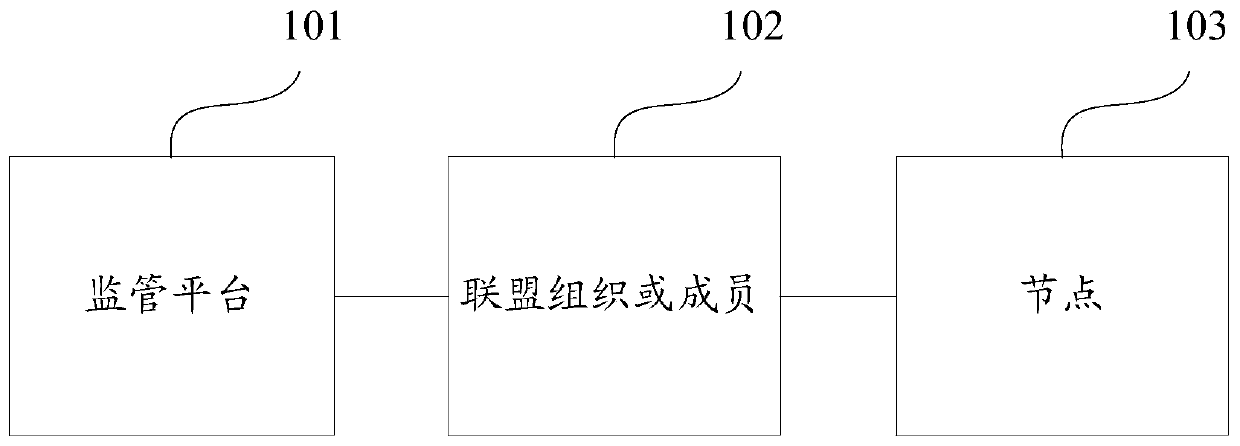

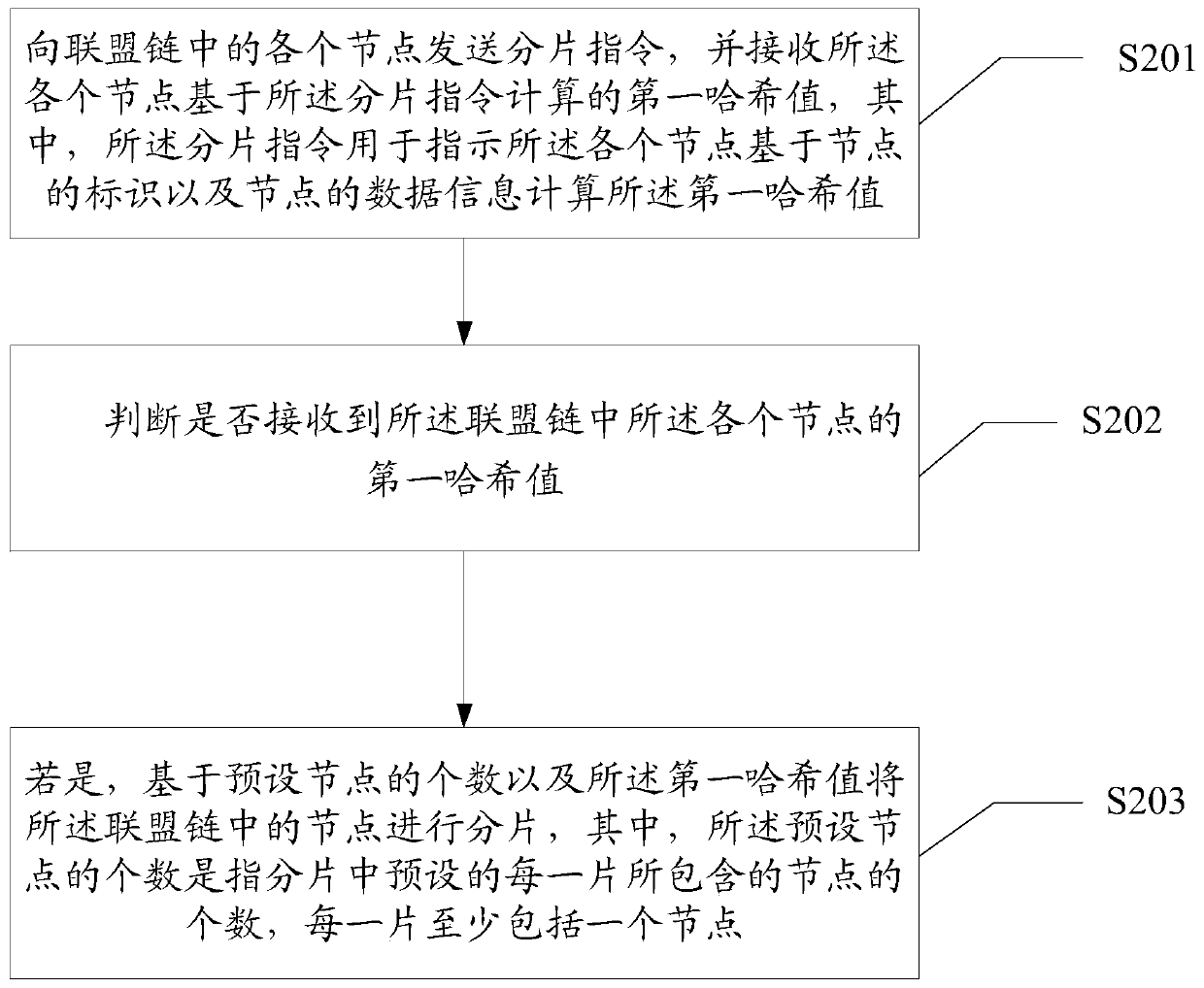

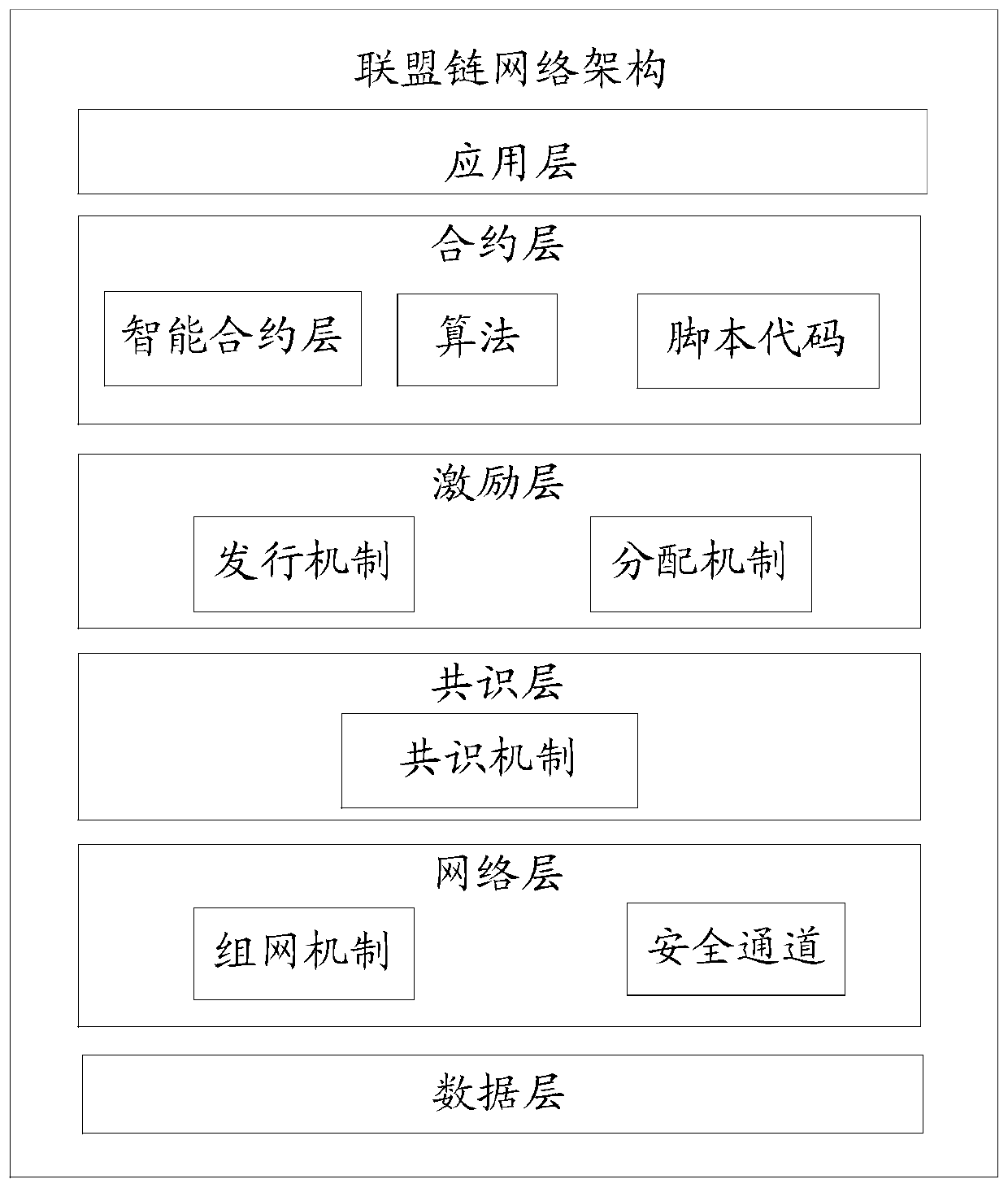

Alliance chain fragmentation method and device

PendingCN111309801AShort timeImprove sharding efficiencyDatabase distribution/replicationDatabase indexingEngineeringReal-time computing

The invention discloses an alliance chain fragmentation method and device. The method comprises the following steps: sending a fragmentation instruction to each node in the alliance chain, receiving afirst hash value calculated by each node based on the fragmentation instruction, wherein the fragmentation instruction is used for indicating each node to calculate the first hash value based on theidentifier of the node and the data information of the node; judging whether a first hash value of each node in the alliance chain is received or not; if yes, the nodes in the alliance chain are fragmented based on the number of preset nodes and the first hash value, the number of the preset nodes refers to the number of the nodes contained in each preset fragment in the fragments, and each fragment at least comprises one node. The technical problem that an alliance chain fragmentation mode in the prior art is low in efficiency is solved.

Owner:AEROSPACE INFORMATION

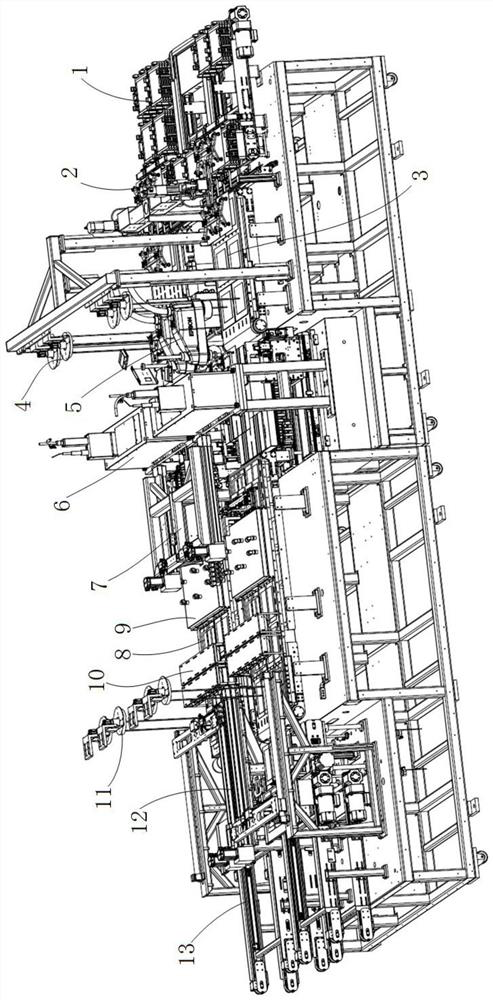

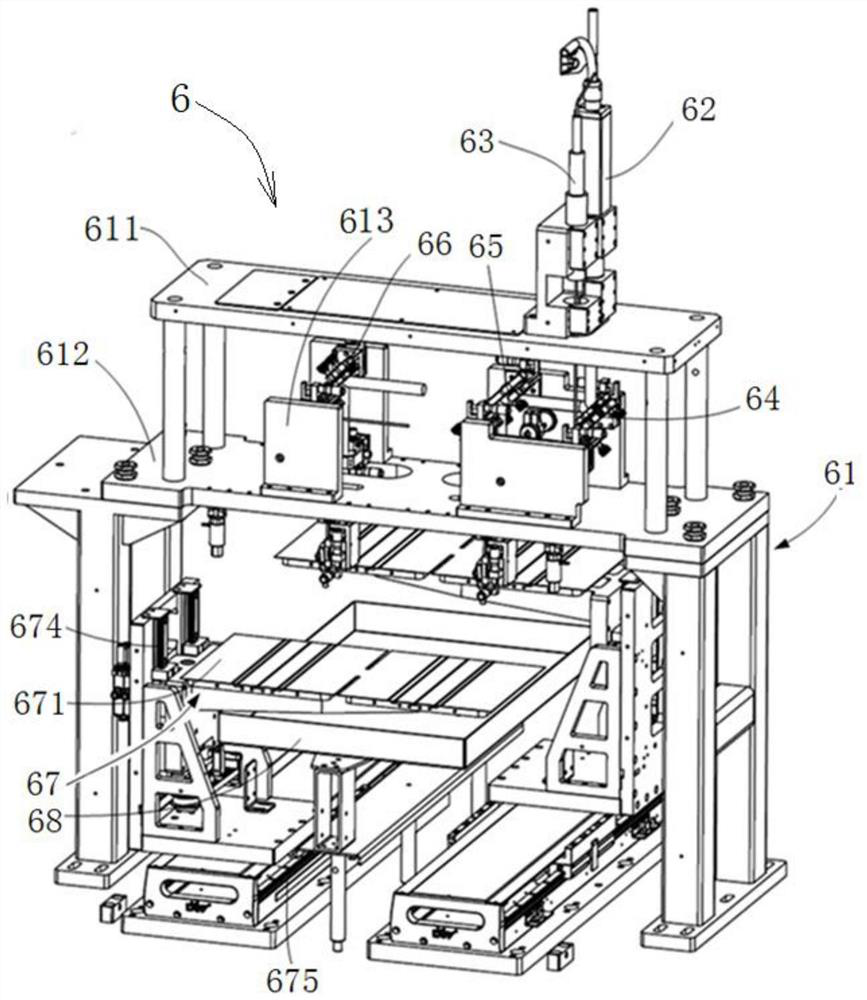

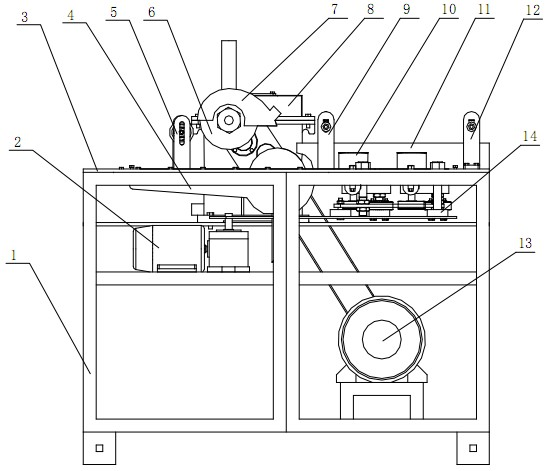

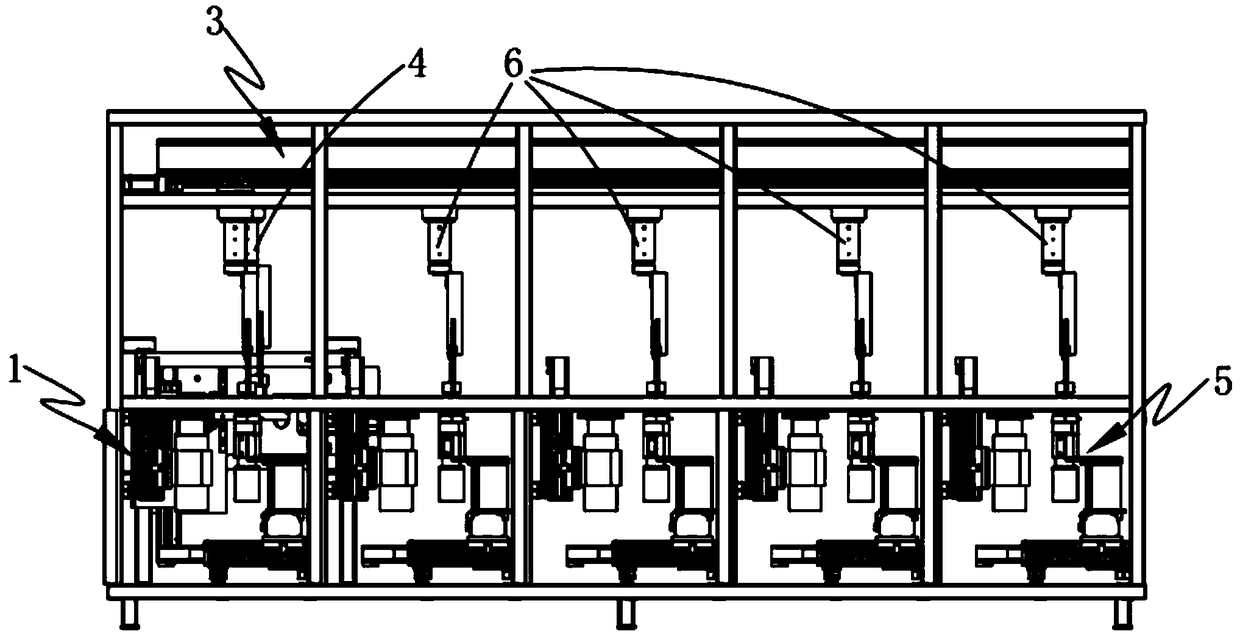

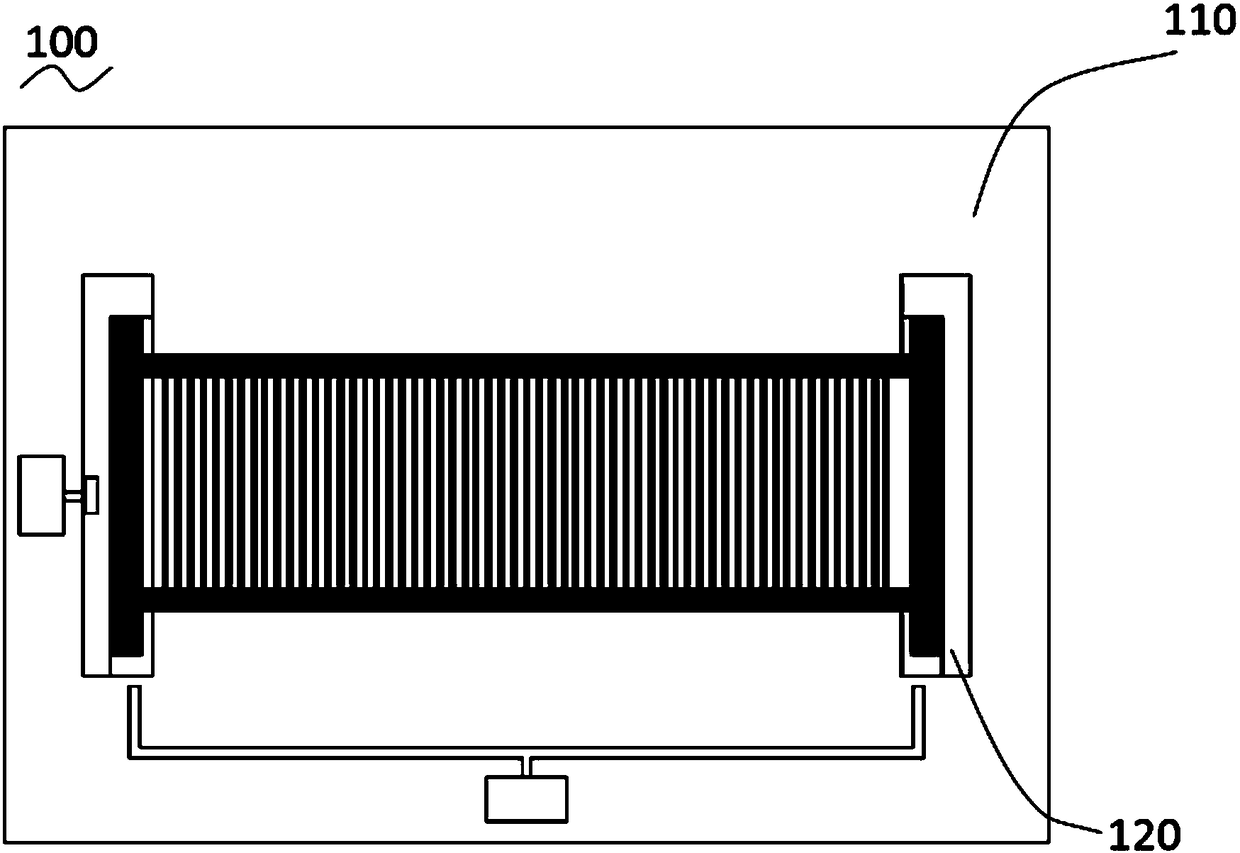

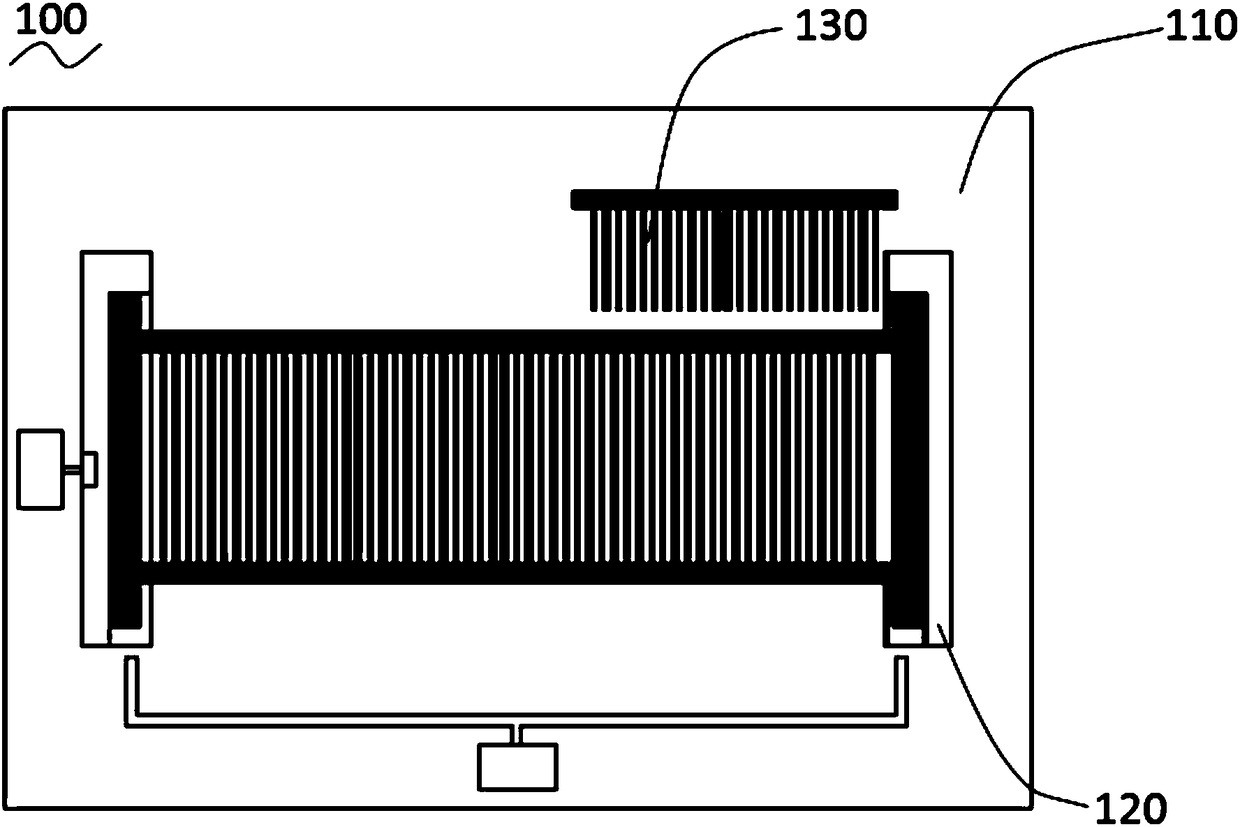

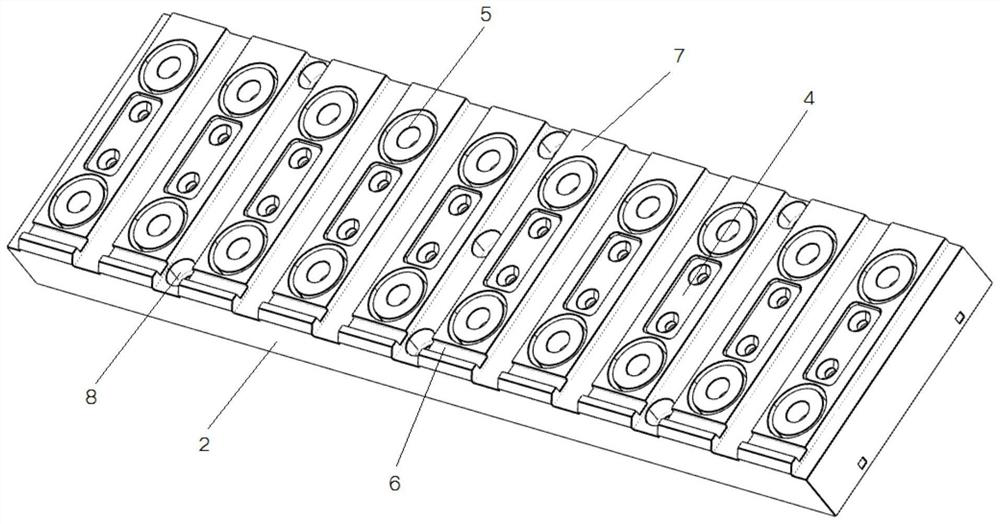

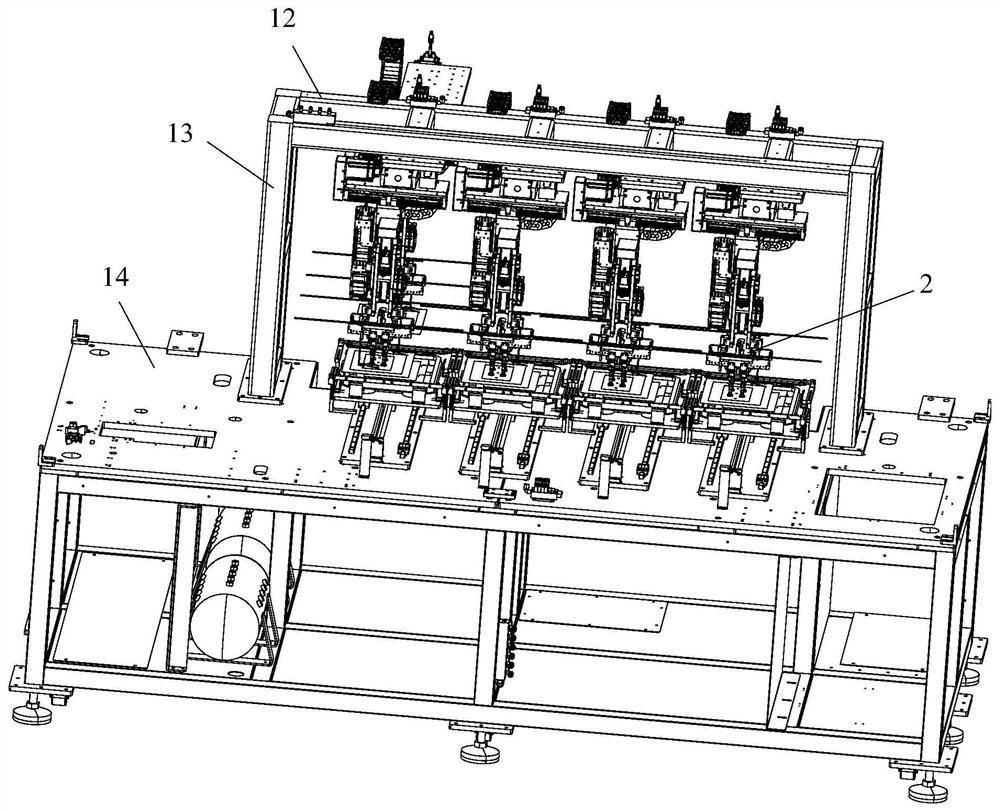

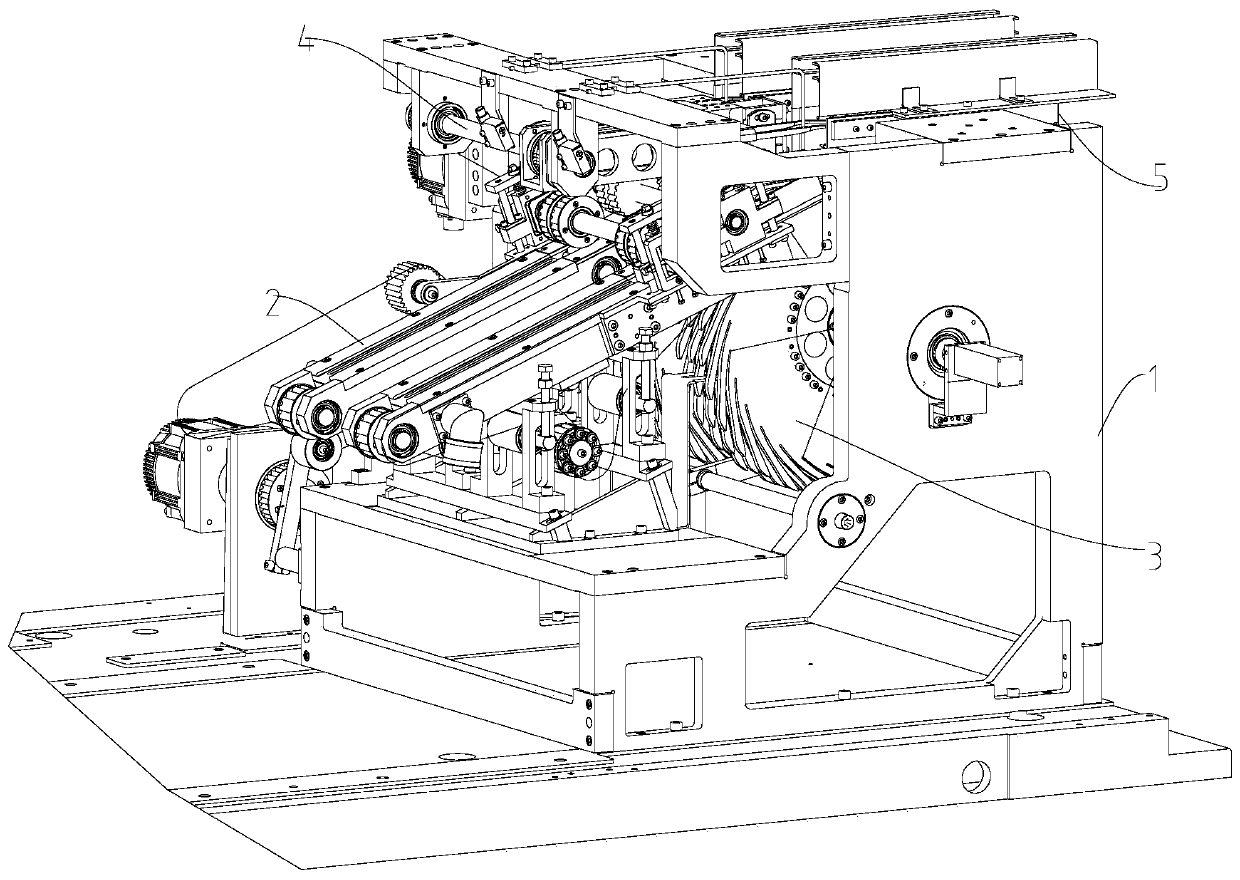

Battery piece separating equipment

PendingCN112475598AImprove sharding efficiencyFinal product manufactureLaser beam welding apparatusElectrical batteryEngineering

The invention discloses battery piece separating equipment. The battery piece separating equipment comprises a first carrying device, a piece separating device, a second carrying device, a piece separating conveying device, a detecting device, a third carrying device and a discharging device; the piece separating device comprises a scribing laser, a piece splitting laser, light splitting mechanisms and a battery piece bearing mechanism, the scribing laser and the piece splitting laser correspond to the light splitting mechanisms correspondingly, laser emitted by the scribing laser is divided into two scribing laser beams through the corresponding light splitting mechanism, and the piece splitting laser is divided into two piece splitting laser beams through the corresponding light splitting mechanism; the first carrying device carries battery pieces to the battery piece bearing mechanism; the second carrying device carries the battery pieces obtained after splitting on the battery piece bearing mechanism to the piece separating conveying device; the detecting device is used for detecting the battery pieces on the piece separating conveying device; and the third carrying device carries the battery pieces on the piece separating conveying device to the discharging device. According to the technical scheme, the battery piece separating efficiency can be effectively improved.

Owner:WUXI AUTOWELL TECH

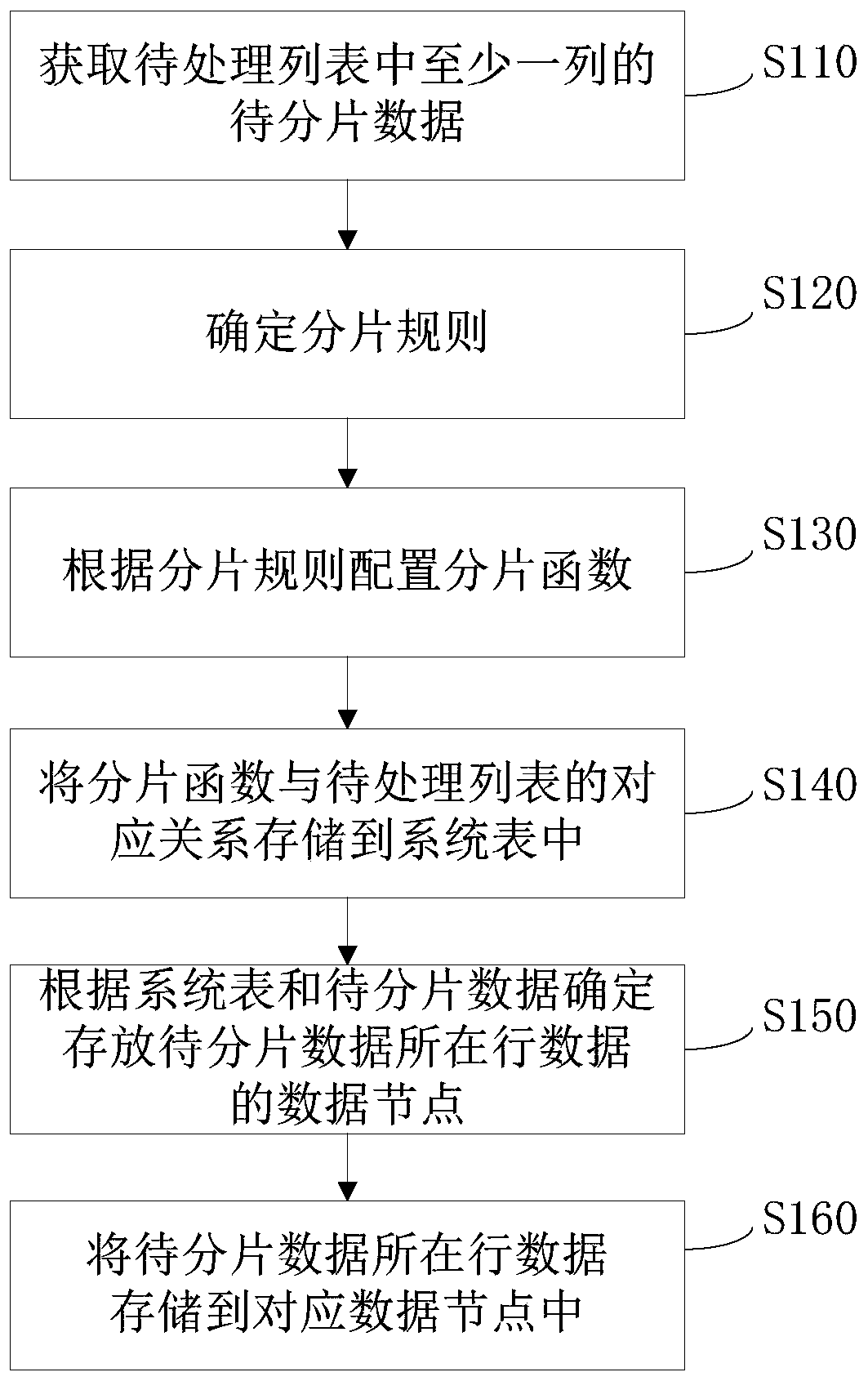

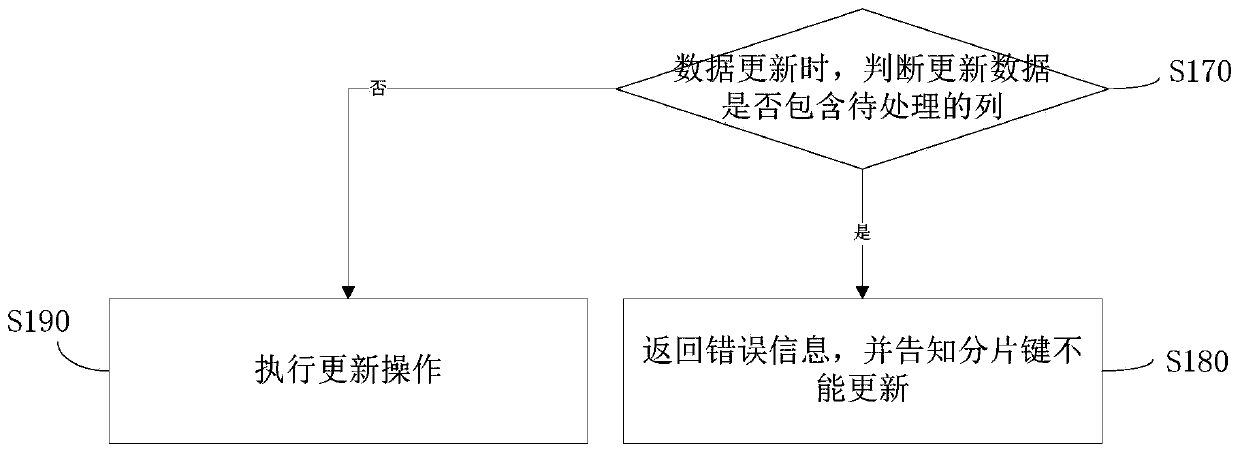

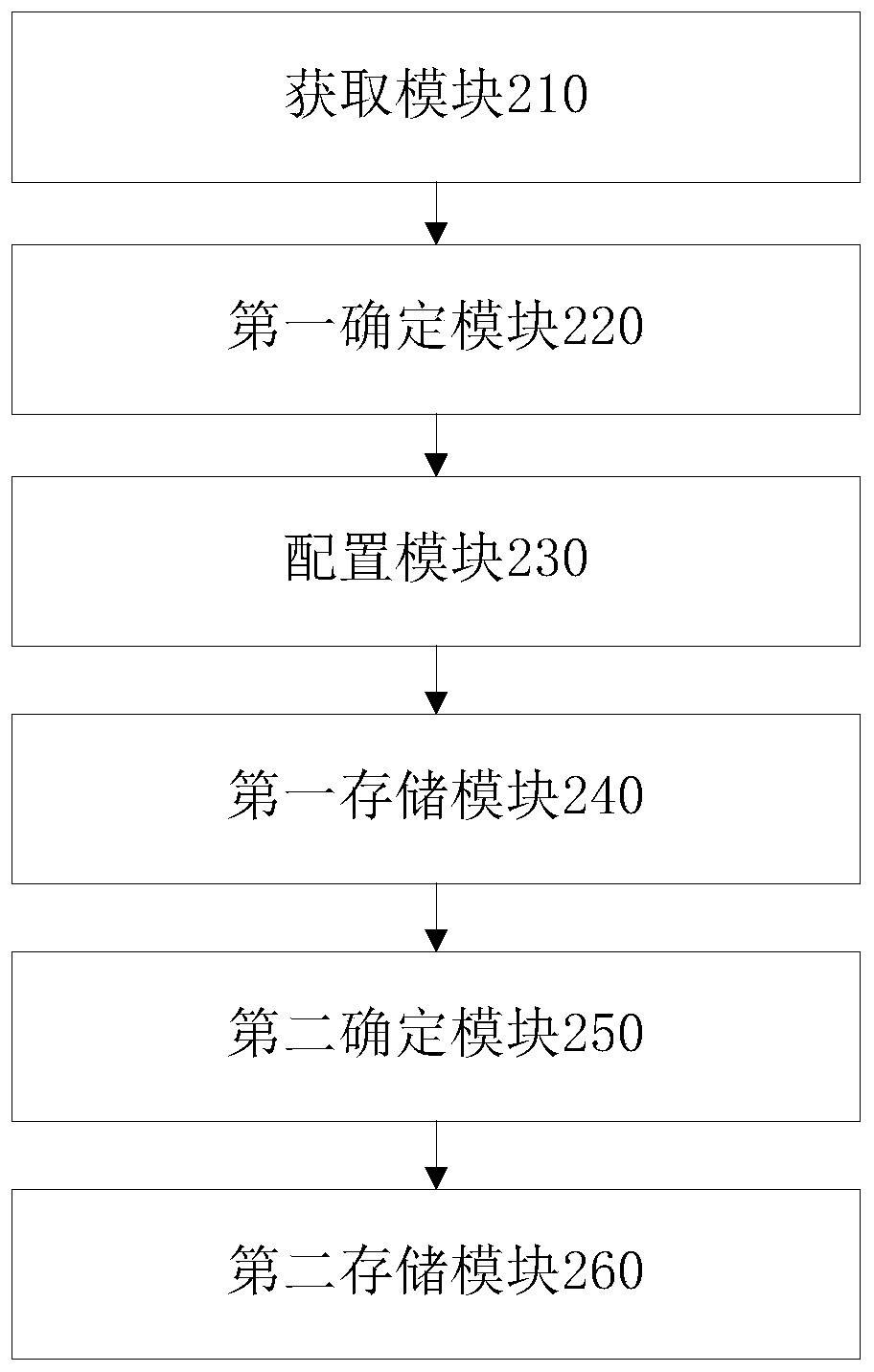

User-defined data fragmentation method, device and equipment based on distributed database

PendingCN110928949AIncrease flexibilityImprove the efficiency of shard processingDatabase updatingDatabase distribution/replicationTheoretical computer scienceEngineering

The invention provides a self-defined data fragmentation method, device and equipment based on a distributed database. The method comprises the following steps: obtaining at least one column of to-be-fragmented data in a to-be-processed list; determining a fragmentation rule; configuring a fragmentation function according to the fragmentation rule; storing the corresponding relationship between the fragmentation function and the to-be-processed list into a system table; determining a row data node for storing the to-be-fragmented data according to the system table and the to-be-fragmented data; and storing the row data of the to-be-fragmented data into the corresponding data node. According to the method, the fragmentation processing efficiency is improved, the applicability of the fragmentation algorithm is improved, and the fragmentation requirements with special rules are met.

Owner:湖南亚信安慧科技有限公司

Bamboo splitter

InactiveCN101920509AAvoid stickingEnsure processing safetyVeneer manufactureVertical planeEngineering

The invention relates to a bamboo splitter comprising a stand, a panel is arranged on the stand and sequentially provided with a height limiting device, a feeding device, a pressure assisting device, a splitting device and a restraint device, wherein the splitting device is arranged on a transmission box and comprises an upper saw group device and a lower saw group device; the upper saw group device and the lower saw group device both comprise saw group shafts; each saw group shaft is sequentially provided with a positioning baffle plate, a saw blade and a spacer; and the tail ends of the saw group shafts are compacted and positioned by double round nuts. The invention has the advantages of being capable of splitting a higher bamboo board (with the height of more than 55 mm), preventing the bamboo board from being clamped in the splitting device through the height limiting device and reducing the vibration of the bamboo board in the splitting process through the pressure assisting device, thereby ensuring the pressure assisting accuracy of the bamboo board; and in addition, the invention restrains the tail end of the bamboo board through the restraint device and prevents the vertical plane of the bamboo board from being dislocated after splitting, thereby ensuring the output rate of bamboo sheets.

Owner:ZHEJIANG UNIV OF TECH

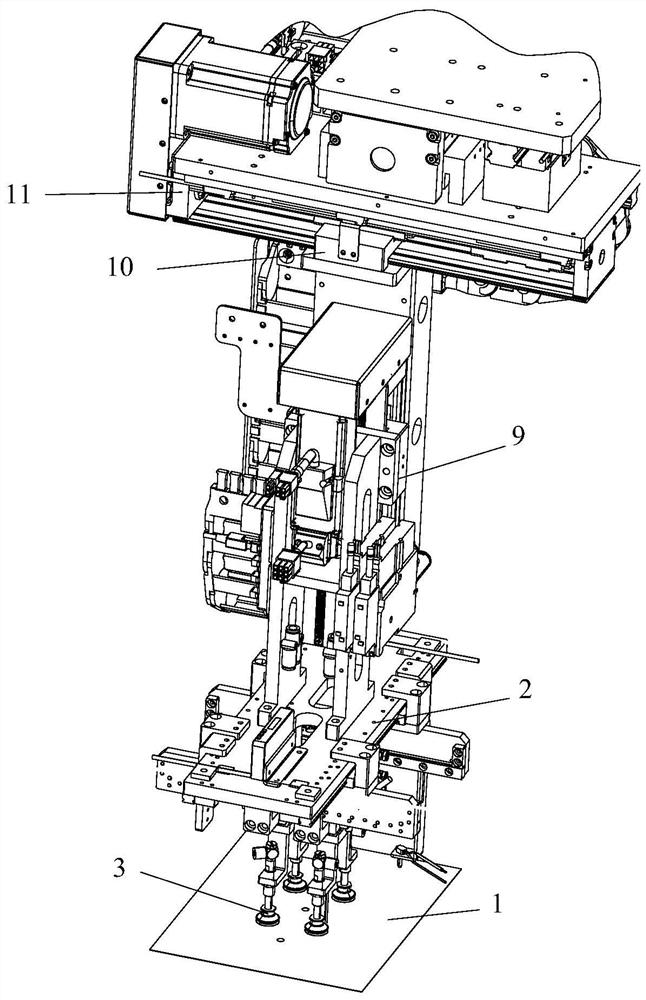

Chamfering processing equipment for full-automatic silicon wafer and processing technic thereof

PendingCN109333222ASave human resourcesImprove work efficiencyEdge grinding machinesGrinding feed controlTransfer mechanismAutomatic processing

The invention provides chamfering processing equipment for a full-automatic silicon wafer and a processing technic thereof; the full-automatic processing equipment for silicon wafer chamfering can realize single slicing and self-centering of piled silicon wafers by a slicing loading device and a transmission self-centering device; afterwards, the silicon wafers finishing the self-centering are grabbed by a grabbing device and the wafers placed on a chamfering device are realized under the movement of a silicon wafer transferring device; after the chamfering of the silicon wafer is realized onthe chamfering device, an automatic taking device can collect the silicon wafer in a silicon wafer collection box after taking the wafers; a processing method of one transferring mechanism matching with a plurality of sets of chamfering equipment is realized; human resource is saved; the technical problem that the chamfering equipment does not realize complete full automatic and has low working efficiency is solved; the processing technic for the full-automatic silicon wafer realizes quick single slicing and self-centering of the silicon wafer by using a silicon wafer slicing process and a silicon wafer locating process; and the silicon wafer can be transported to a plurality sets of chamfering equipment to conduct chamfering processing by using the silicon wafer transportation and siliconwafer placing.

Owner:浙江中晶新材料研究有限公司

Silicon wafer separator

PendingCN108538965AReduce fragmentationReduce the chance of crackingFinal product manufactureSemiconductor devicesEngineeringSilicon

The present invention relates to a silicon wafer separator. The silicon wafer separator comprises a working platform, a clamping mechanism, a side-end sucking disc and a top-end sucking disc. The working plane of the working platform is provided with a silicon wafer basket bearing area configured to bear a silicon wafer basket, the clamping mechanism is located at the upper portion of the workingplane of the working platform, the side-end sucking disc is located at one side of the silicon wafer basket bearing area on the working platform, the top-end sucking disc is located at the upper portion of the silicon wafer basket bearing area on the working platform, and the side-end sucking disc and the top-end sucking disc are inserted into the silicon wafer basket respectively through the sideend and the top end of the silicon wafer basket when being operated. The silicon wafer separator does not need to take out a silicon wafer in the silicon wafer basket in advance, can separate the silicon wafers sucked together in the silicon wafer basket and employs the cooperation sucking effect of the side-end sucking disc and the top-end sucking disc to improve the wafer separation efficiency,reduce the probability of generation of fragments and subfissure of the silicon wafers in the wafer separation process and achieve whole-process automatic operation of the wafer separation of the silicon wafers with no need for manual processing.

Owner:YANGZHOU XIEXIN PHOTOVOLTAIC TECH

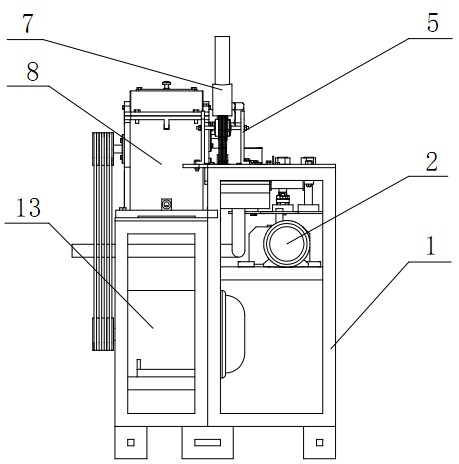

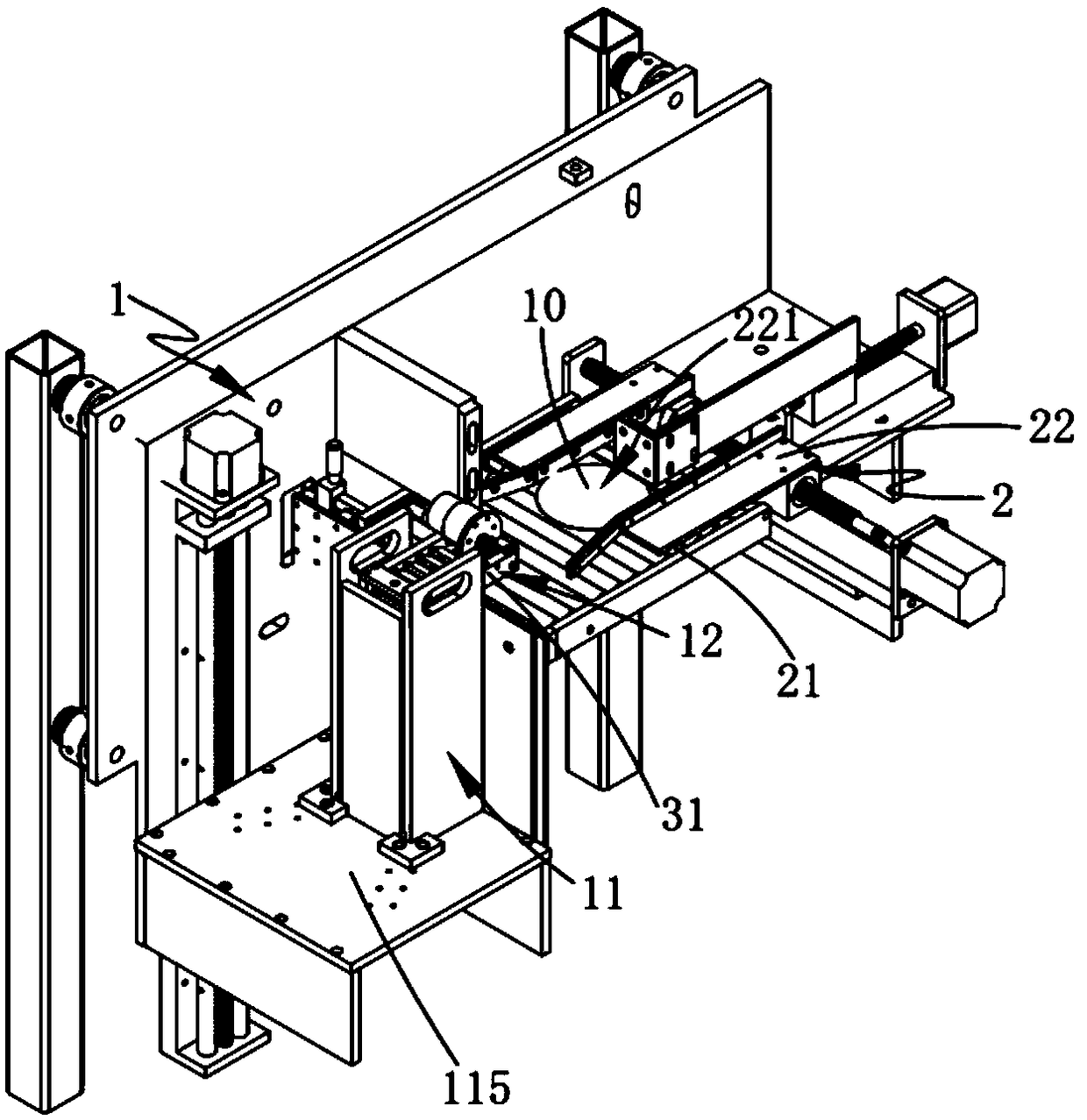

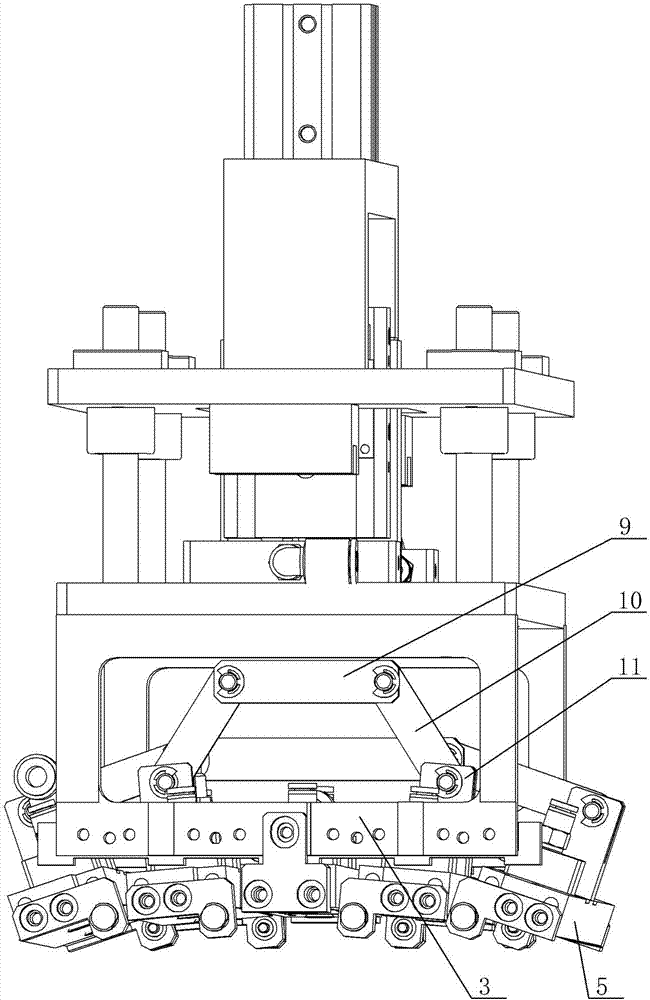

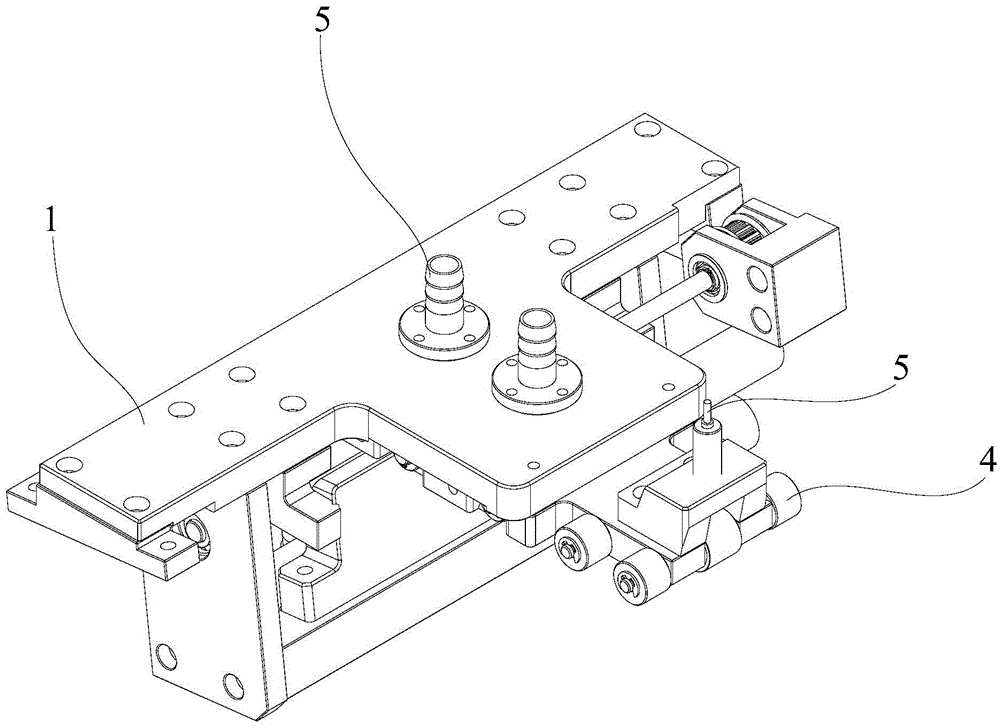

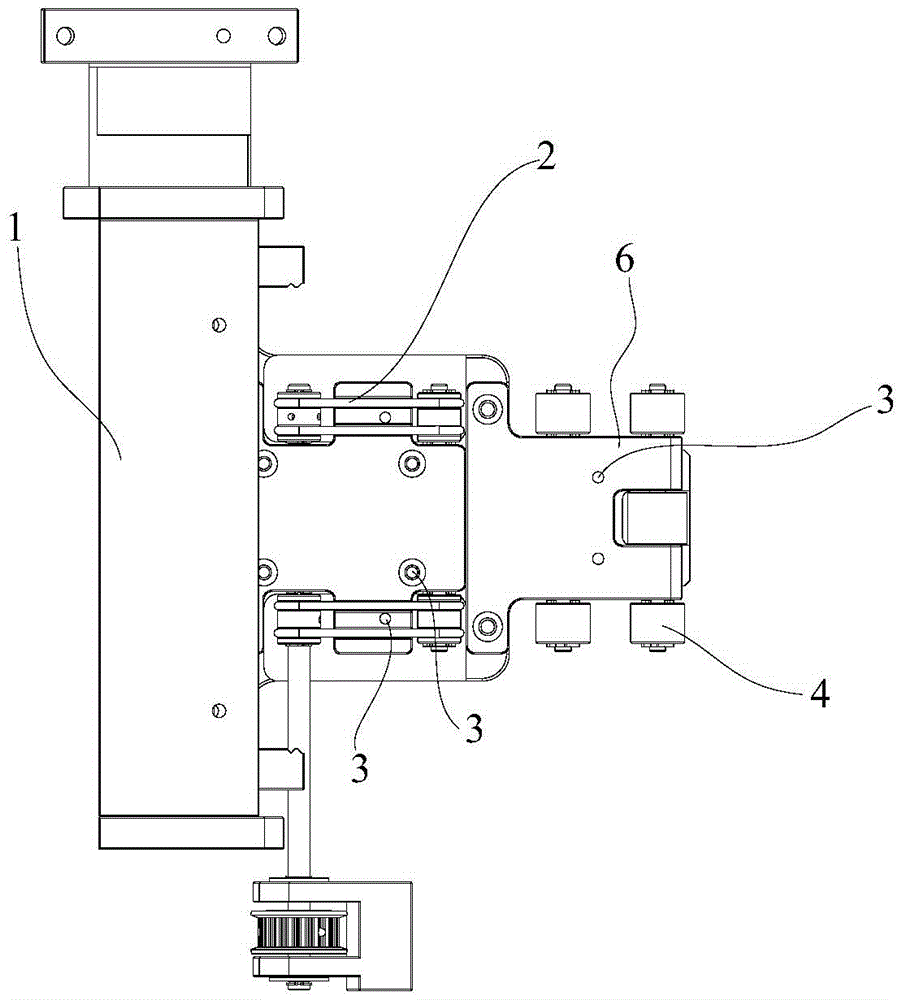

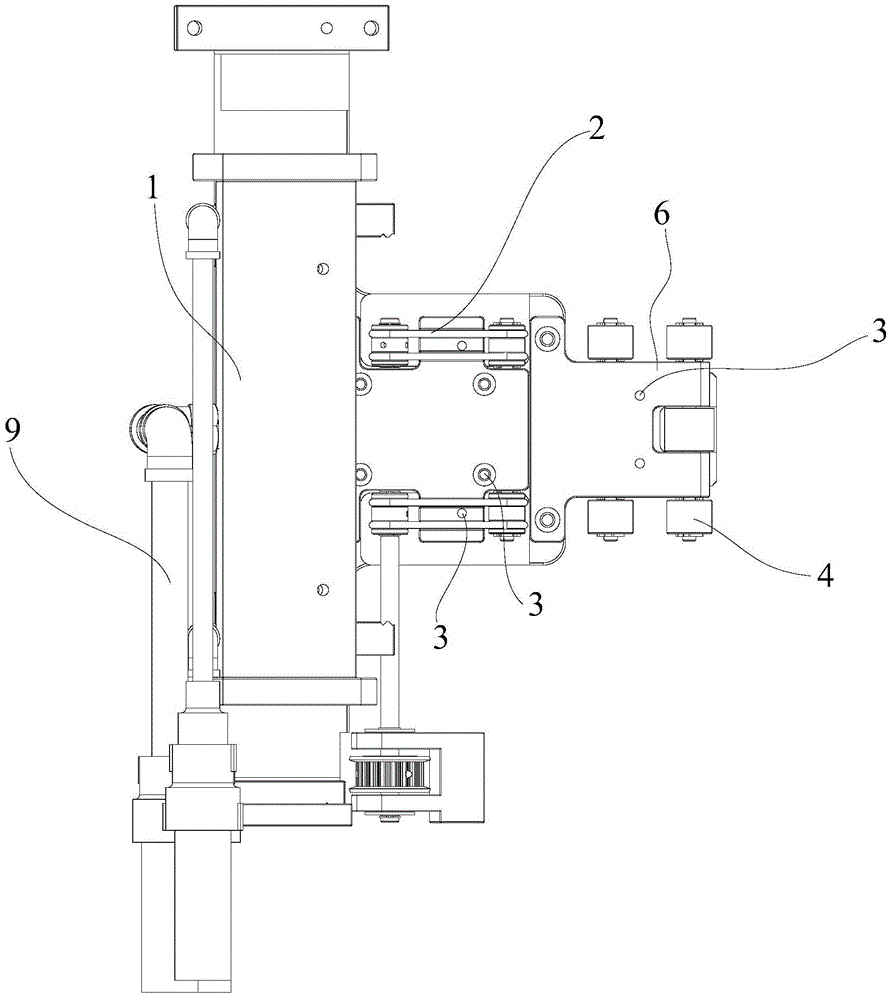

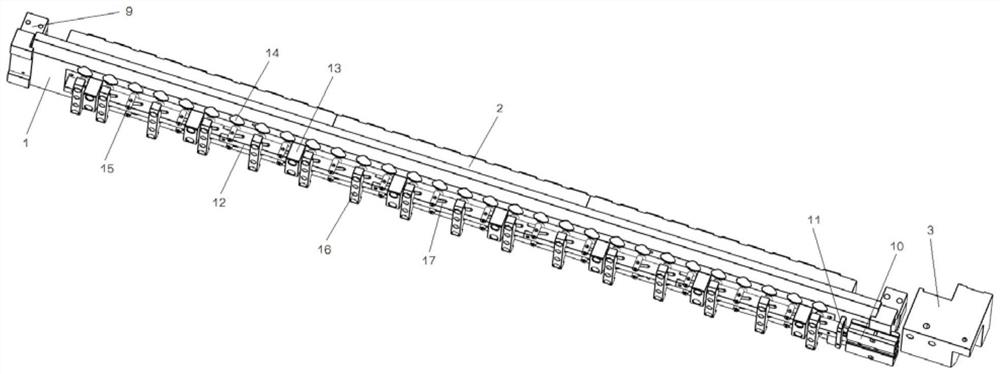

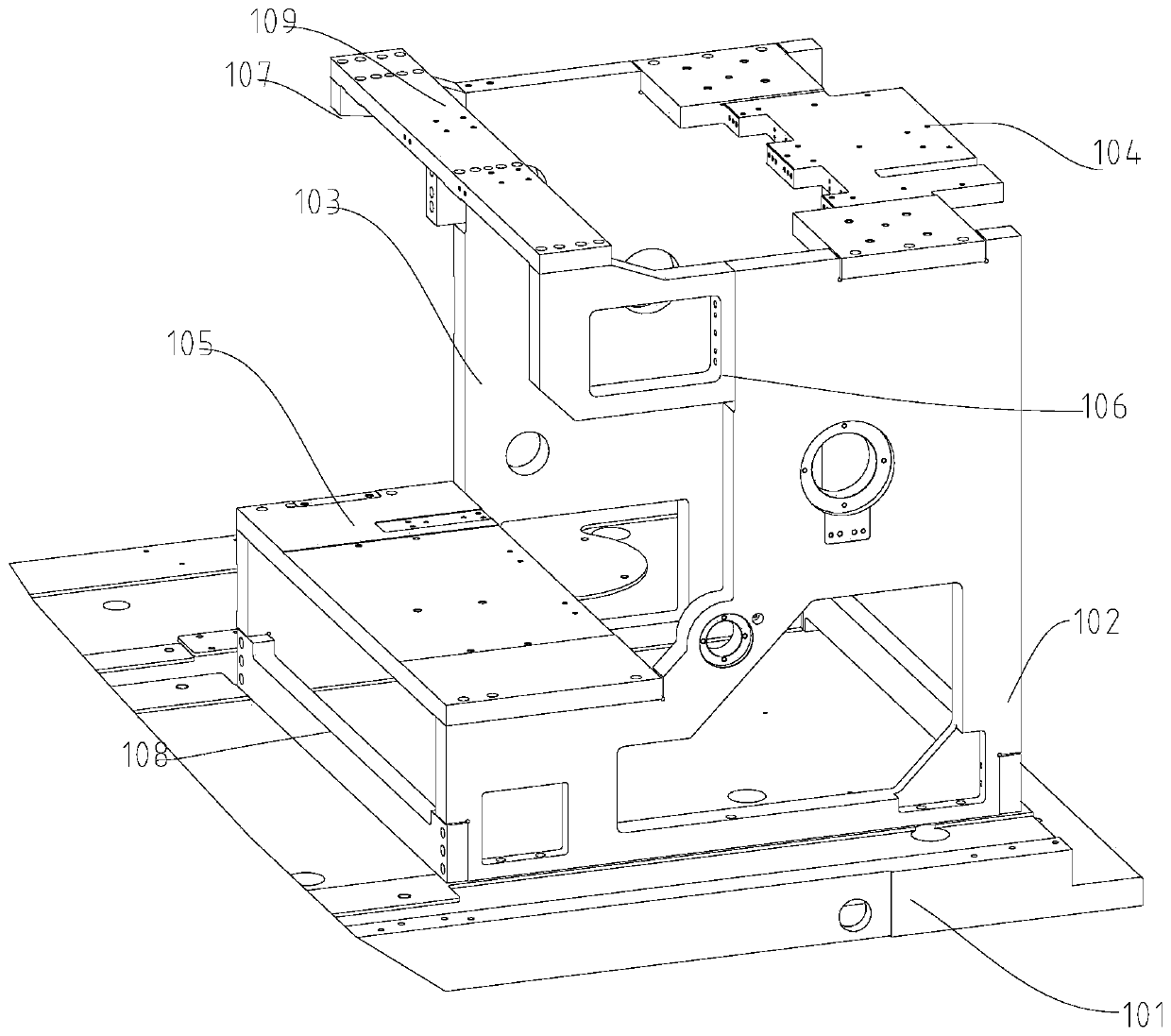

Midair piece breaking-off mechanism and corresponding piece separation material-collecting station

PendingCN107986019ABreaking apart the space is safe enoughImprove sharding efficiencyConveyorsFinal product manufactureEngineeringMechanical engineering

The invention provides a midair piece breaking-off mechanism. The midair piece breaking-off mechanism automatically separates a plurality of cut cell pieces from the two sides towards a center piece area, so that the piece separation efficiency is high, and the pipe separation yield is high. The midair piece breaking-off mechanism comprises a piece breaking-off upper plate. A piece breaking-off frame is arranged under the piece breaking-off upper plate. The piece breaking-off frame comprises two side plates. A lifting air cylinder is fixedly installed on the piece breaking-off upper plate. A lower piston rod of the lifting air cylinder is fixedly connected with the piece breaking-off frame. N breaking-off plates are arranged between the lower ends of the two side plates of the piece breaking-off frame, wherein N is a natural number larger than 1. The number of the breaking-off plates and the number of cell pieces needing to be separated are identical. The N breaking-off plates in the non-work state are spliced into a combined plane in the width direction. The two ends, in the length direction, of each breaking-off plate are connected to the corresponding side plate positions through rotating shaft mechanisms correspondingly. The piece breaking-off frame is fixedly provided with M piece breaking-off air cylinders, wherein M is a natural number. A lower piston rod of each piece breaking-off cylinder is connected with a corresponding horizontal connection rod.

Owner:SUZHOU AUTOWAY SYST

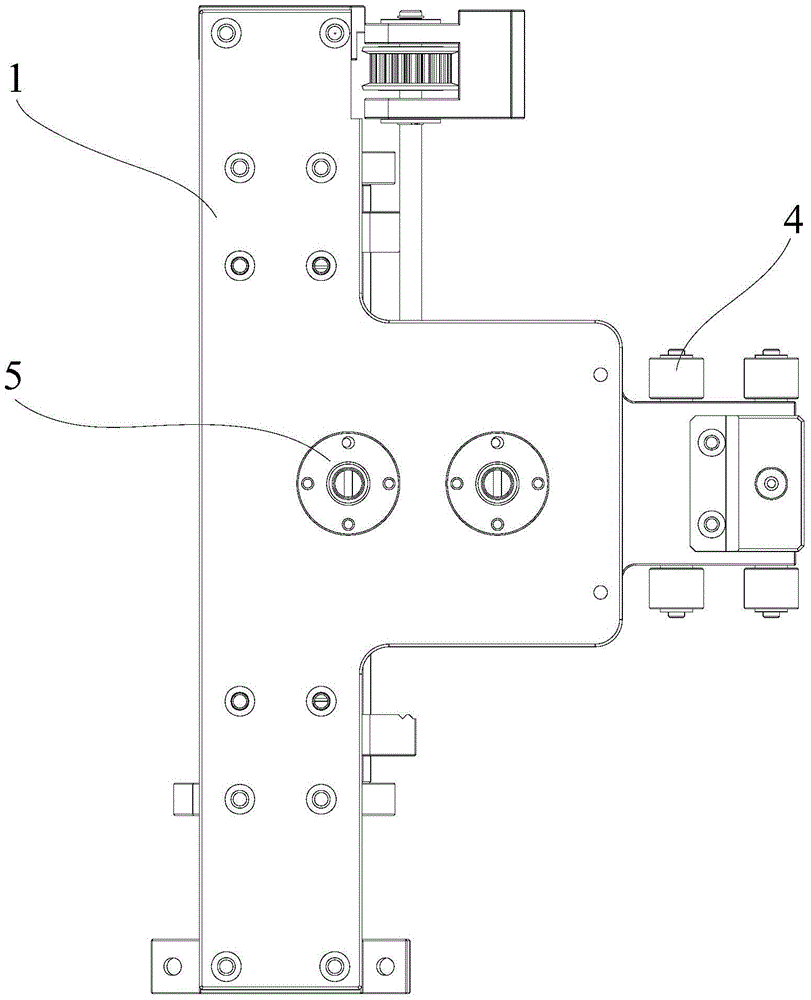

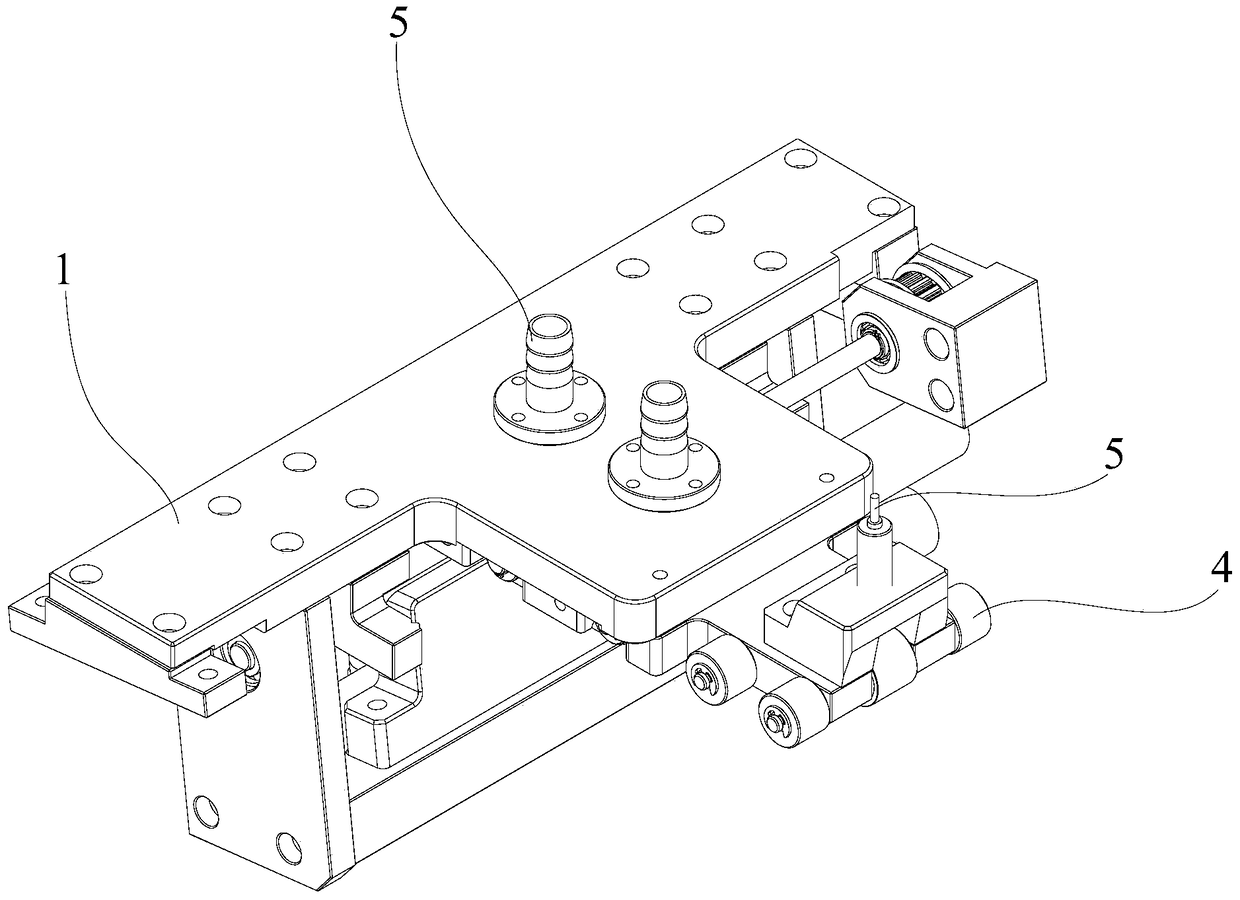

Silicon wafer separation mechanism

InactiveCN105460612AImprove sharding efficiencyFinal product manufactureConveyor partsEngineeringConveyor belt

A silicon wafer separation mechanism comprises a silicon wafer separation mechanism body. Two parallel conveyor belts arranged in a spaced manner are arranged on the silicon wafer separation mechanism body downwards. Air holes are formed in the silicon wafer separation mechanism body towards the conveyor belts and communicated with air suction devices through pipelines. Idler wheels are arranged at the front ends of the conveyor belts in the conveying direction. The air suction devices and the conveyor belts are adopted for combined action, so that stacked silicon wafers are separated, and the silicon wafer separation mechanism has the advantage of being high in wafer separation efficiency.

Owner:SUZHOU BOYANG ENERGY EQUIP

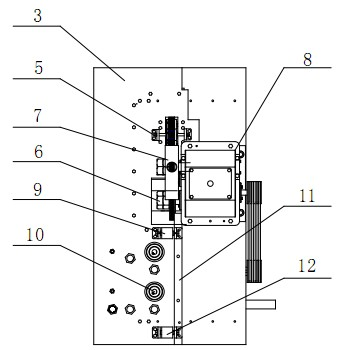

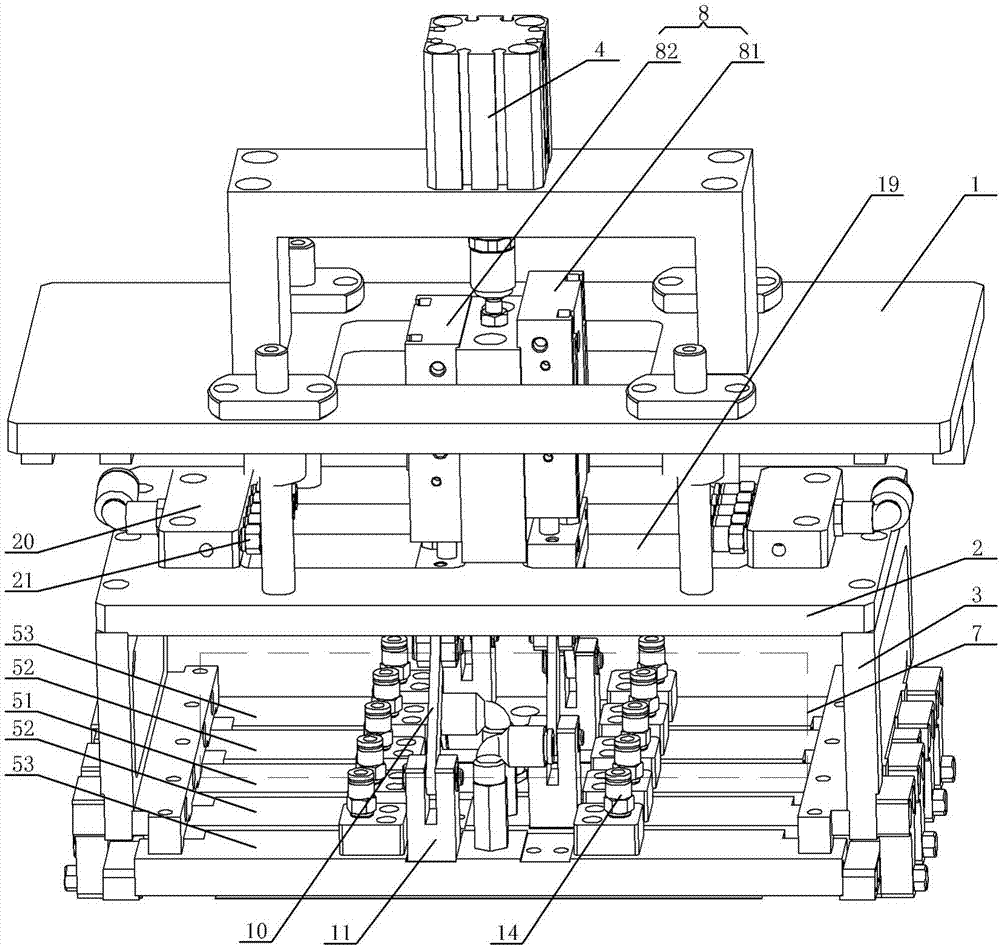

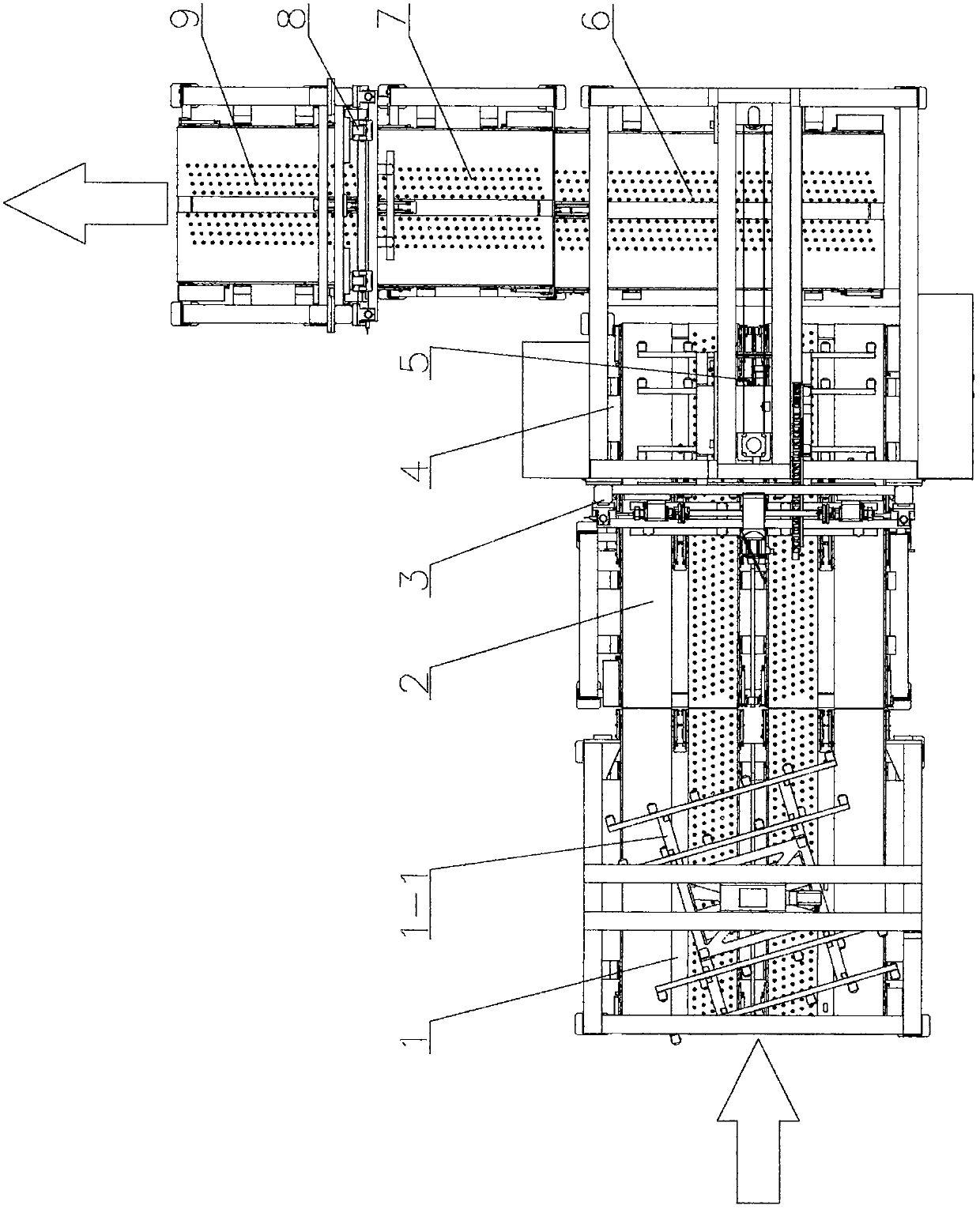

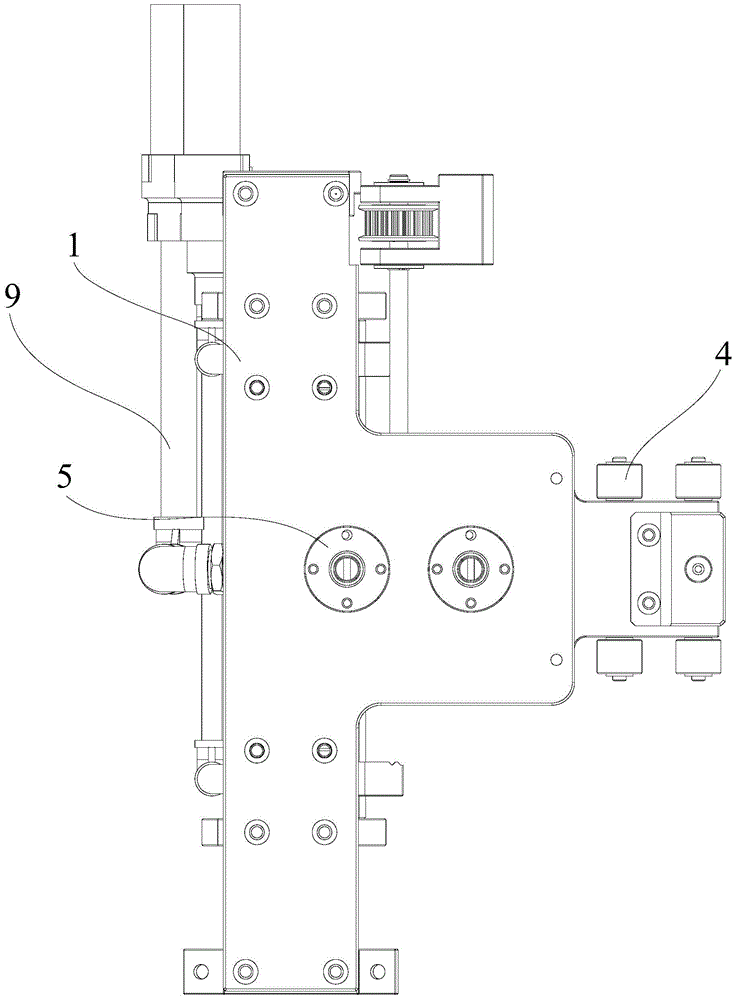

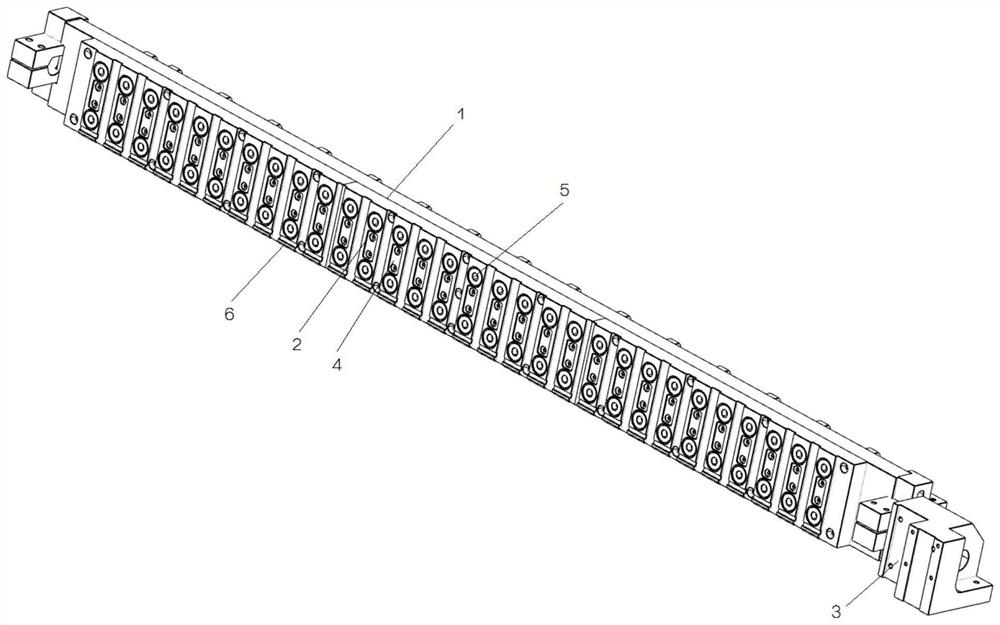

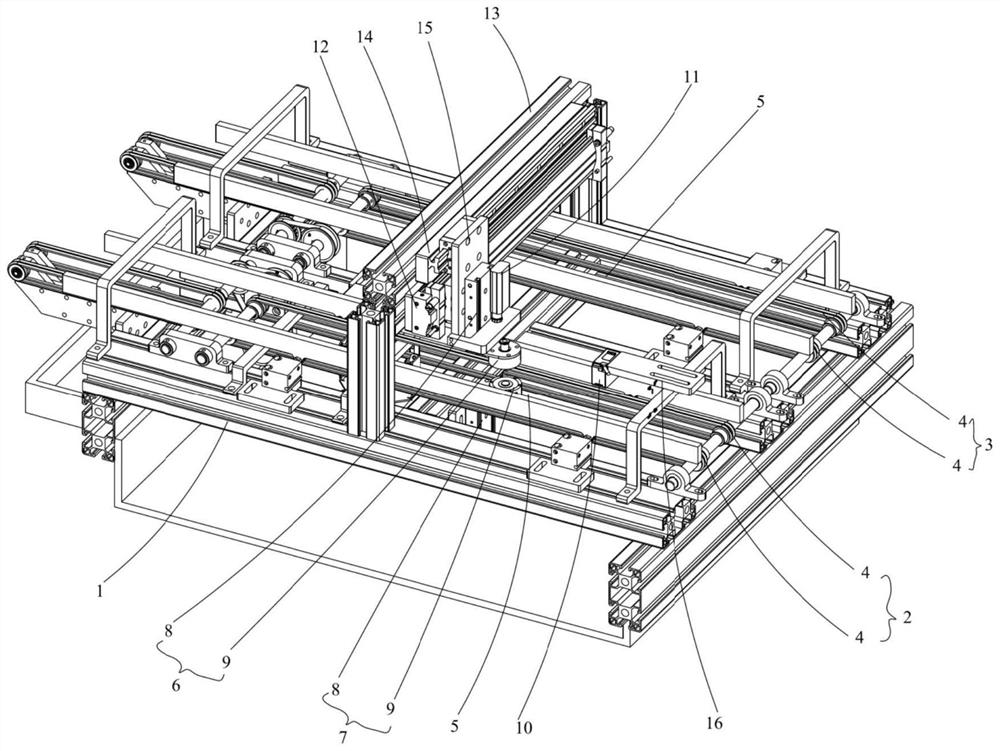

Fragmenting system for laminated PCB and segmenting method of fragmenting system

InactiveCN107756515AImprove sharding efficiencyMeet fragmentation requirementsMetal working apparatusAutomationLateral positioning

The invention relates to a fragmenting system for a laminated PCB and a segmenting method of the fragmenting system. The fragmenting system is provided with a conveying correction device, a transversecutting positioning device, a transverse cutting device, a transverse cutting discharge device and a cutting suction plate transplanting device which are sequentially arranged in the transverse direction, as well as a transplanting discharge device, a longitudinal cutting positioning device, a longitudinal cutting device and a longitudinal cutting discharge device which are sequentially arrangedin the longitudinal direction, wherein the cutting suction plate transplanting device and the transplanting discharge device are perpendicular and mutually spliced. The segmenting system with high degree of automation is adopted to perform positioning correction, transverse positioning cutting, transplanting and longitudinal positioning cutting on the laminated PCB, and manual processing is not needed, so that the segmenting efficiency is higher, and the segmenting requirement of the laminated PCB is completely satisfied.

Owner:捷惠机械(惠州)有限公司

Silicon Wafer Slicing Device

InactiveCN105428465BAvoid damageImprove sharding efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingAir blowerSilicon chip

A silicon chip separating device comprises a silicon chip separating mechanism and a feeding trough. The silicon chip separating mechanism comprises a silicon chip separating mechanism body. Two separated silicon chip conveyor belts which are parallelly and separately arranged are configured below the silicon chip separating mechanism body. The silicon chip separating mechanism body is provided with an exhausting holes which face the separated silicon chip conveyor belts. The air exhausting holes are communicated with an air exhausting device through pipeline. The silicon chip separating mechanism body is provided with rollers at positions which correspond with the front end of the conveying direction of the separated silicon chip conveyor belts. The silicon chip separating mechanism body is provided with air blowing holes of which the air blowing direction face the separated silicon chip conveyor belts. The air blowing holes are communicated with an air blower through pipeline. The feeding trough comprises a feeding trough body and a water pump. The feeding trough body is provided with an overflow opening. The overflow opening is communicated with a liquid storage trough through pipeline. The feeding trough body is internally provided with a supporting platform for placing stacked silicon chips. The supporting platform is transmissibly connected with the driving part of a vertical movement driving device. The silicon chip separating device has advantages of high silicon chip separating efficiency and small silicon chip damage in silicon chip separation.

Owner:SUZHOU BOYANG ENERGY EQUIP

A kind of bamboo slicing device

ActiveCN107696193BAchieve the purpose of shardingImprove uniformityCane mechanical workingElectric machineryEngineering

The invention discloses a bamboo slicing device. According to the bamboo slicing device, in the internal of a bamboo pipe, thin sheets at a bamboo joint are cut up through rotating of a plurality of cutting blades first, and a plurality of dividing blades are cooperated to slice the bamboo into equal-sections. The device is characterized in that a connecting sleeve is arranged on the middle of oneside of a motor fixing plate, the motor fixing plate is of a circular plate-shaped structure, and a plurality of through holes are formed in the motor fixing plate; a plurality of through holes are formed in the connecting sleeve and communicates with the through holes in the motor fixing plate in a one-to-one correspondence mode, and the through holes in the connecting sleeve are provided with wider inlets and narrower outlets; a fixing ring is connected with the motor fixing plate through a plurality of connecting rods, each connecting rod is of a fishhook shape, and the distances between every two adjacent connecting rods are equal; a grinding piece is arranged on the inner side of the fixing ring, and a driving motor is arranged on the other side of the motor fixing plate; and a guideplate is arranged on the motor fixing plate, the guide plate is annular, the inner side of the guide plate is attached to the outer side of the driving motor, and the thickness of the guide plate isgradually increased from one end to the other end.

Owner:湖南通达竹业科技有限公司

Glass slide separating device for glass stacking

PendingCN113086642AImprove sharding efficiencyEasy to pull inCharge manipulationConveyor partsSeparation technologyEngineering

The invention discloses a glass slide separating device for glass stacking, which comprises a mounting base; cushion blocks are adjacently mounted on the mounting base at equal intervals; a fixed seat is arranged on one side of the mounting base and a limiting seat is arranged on the other side of the mounting base; a pushing cylinder is mounted on one side, far away from the limiting seat, of the mounting base; and a guide rail plate is transversely arranged below the mounting base. The cushion blocks are close to one side of a glass material groove after overturning; a suction cup head is attached to glass sheets, and the suction cup head tightly sucks the glass sheets after vacuumizing, a certain gap is formed between a first glass sheet and the next glass sheet which are arranged, so that the suction cup head can pull the glass sheets into a glass placing clamping groove conveniently, the sheet separation function is achieved conveniently after glass stacking, manual sheet separation is not needed, the automatic glass sheet separation technology is adopted, the glass sheet separation efficiency is improved, safety and efficiency are higher, and scratches caused by adhesion of the glass sheets after cleaning and friction generated during relative movement are solved.

Owner:东莞市科靖自动化设备有限公司

Full-automatic square paper towel receiving and separating device

ActiveCN109626045ARealize automatic crawlingReduce manual interventionArticle feedersPaper towelPulp and paper industry

The invention discloses a full-automatic square paper towel receiving and separating device, comprising: a frame for supporting the entire full-automatic square paper towel receiving and separating device; a vacuum feed suction belt assembly mounted at a front end of the frame for conveying paper; a pickup roller assembly for receiving paper mounted on the frame; and a separating assembly for separating disposed at a top end of the frame and corresponding to the pickup roller assembly. The full-automatic square paper towel receiving and separating device according to the present invention transfers the paper to the pickup roller assembly through the vacuum feed suction belt assembly, and the pickup roller assembly receives the paper and performs the separating operation under the action ofthe separating assembly. The full-automatic square paper towel receiving and separating device in the invention realizes automatic grasping, does not need manual grasping, and reduces manual intervention, thereby improving the efficiency of separating.

Owner:CHANGDE TOBACCO MACHINERY

Conductive film separating device

PendingCN113493128AAutomatically achieve single chip separationImprove sharding efficiencyArticle separationStructural engineeringMaterials science

The invention relates to a conducting film separating device. The conducting film separating device comprises a suction nozzle frame and a plurality of suction nozzles, the suction nozzle frame is connected with a plurality of first lifting driving devices, the first lifting driving devices correspond to the suction nozzles in a one-to-one mode, each suction nozzle is driven by the corresponding first lifting driving device to ascend and descend, a quadrilateral frame is defined by the multiple suction nozzles, and the suction nozzle frame is also connected with an air blowing device. According to the invention, the single-piece separation of the conductive film can be automatically realized, and the piece separation efficiency is improved.

Owner:苏州菱麦自动化设备科技有限公司

Silicon wafer separating device

PendingCN114093801ASharding is fastIncrease the level of automationSemiconductor/solid-state device manufacturingConveyor partsSilicon chipMechanical engineering

The invention discloses a silicon wafer separating device. The device comprises a rack, a first conveying device and a second conveying device are arranged on the rack, the first conveying device comprises a pair of conveying belts, a first suction cup device and a second suction cup device are arranged above and below the first conveying device respectively, the first suction cup device comprises a lifting air cylinder and a suction cup, an image sensor and a thickness sensor are arranged above the first conveying device, and a translation air cylinder for driving the lifting air cylinder to move back and forth between the first conveying device and the second conveying device is arranged above the first conveying device. According to the silicon wafer separating device, an n surface and a p surface are distinguished through the image sensor, whether wafers are adhered or not is detected through the thickness sensor, the adhered wafers are separated through the suction cup devices arranged along a vertical direction, so that the silicon wafers with the p surface facing upwards and the silicon wafers with the n surface facing upwards are conveyed along the two conveying devices, wafer separation is fast, the automation level is high, wafer separation efficiency is improved, labor is saved, and the wafer rejection rate is reduced.

Owner:ZHANGJIAGANG DECHANG AUTOMATIC CO LTD

A device for slicing silicon wafers

ActiveCN105489534BAvoid damageImprove sharding efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMaterial supply

A silicon wafer slicing apparatus is disclosed. The silicon wafer slicing apparatus comprises a slicing mechanism and a material supply slot, wherein the slicing mechanism comprises a silicon wafer slicing mechanism body; the silicon wafer slicing mechanism body is provided with two parallel and spaced slicing conveying belts downwardly; air holes are formed, facing to the slicing conveying belts, of the silicon wafer slicing mechanism body; the air holes are communicated with an air extractor through pipelines; rolling wheels are arranged at the front ends of the slicing conveying belts in the conveying directions; the material supply slot comprises a material supply slot body and a water pump; an overflow opening is formed in the material supply slot body; the overflow opening is communicated with a liquid storage slot through a pipeline; a bearing and supporting platform for bearing stacked silicon wafers is arranged in the material supply slot body; and the bearing and supporting platform is arranged corresponding to the slicing conveying belts. When the silicon wafer slicing apparatus is used for slicing, the silicon wafer slicing apparatus has the advantages of high slicing efficiency and low damage to the silicon wafers.

Owner:江苏博阳智能装备有限公司

Silicon Wafer Slicing Mechanism

ActiveCN105448784BImprove sharding efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSilicon chipElectrical and Electronics engineering

A silicon chip separating mechanism comprises a silicon chip separating mechanism body, wherein two parallel conveying belts are arranged below the silicon chip separating mechanism body at an interval; air extraction holes facing the conveying belts are formed in the silicon chip separating mechanism body, and are communicated with an air extraction device through pipelines; rollers are arranged on the silicon chip separating mechanism body and correspond to the front ends of the conveying directions of the conveying belts; and an air blowing hole facing the conveying belts is formed in the silicon chip separating mechanism body, and is communicated with an air blowing device. According to the invention, the air extraction device, the air blowing device and the conveying belts work together to separate stacked silicon chips, so that the silicon chip separating mechanism is high in chip separating efficiency.

Owner:江苏博阳智能装备有限公司

Lens separation method for separately placing bonded optical lenses

InactiveCN105016082AImprove sharding efficiencyIncrease production capacityConveyor partsCell separationPhysics

The invention discloses a lens separation method for separately placing bonded optical lenses. The method comprises the following steps: (1) a clip is prepared, and is provided with a groove; (2) the optical lenses are dipped; and the clip with the optical lenses is put in a dipping tank for dipping; (3) lens separation: the clip is put on a lens separator for separating; and (4) covering: an upper cover covers a lower tray to finish the lens separation operation. As multiple overlapped and bonded optical lenses are put in the clip, the clip and the optical lenses are dipped for separating, and the optical lenses are positioned and sucked by the lens separator, and are separated and placed in placing holes of the lower tray, so that the traditional manual lens separation is replaced, the separation efficiency of the optical lenses is greatly improved, the yield of enterprises is improved, the production cost of the enterprises is reduced, and the social competitive force of the enterprises is enhanced.

Owner:KAIPING YINGGUANG ELECTROMECHANICAL TECH

A fully automatic splicing and splitting device for tissue paper

ActiveCN109626045BRealize automatic crawlingReduce manual interventionArticle feedersPaper towelEngineering

The invention discloses a full-automatic square paper towel receiving and separating device, comprising: a frame for supporting the entire full-automatic square paper towel receiving and separating device; a vacuum feed suction belt assembly mounted at a front end of the frame for conveying paper; a pickup roller assembly for receiving paper mounted on the frame; and a separating assembly for separating disposed at a top end of the frame and corresponding to the pickup roller assembly. The full-automatic square paper towel receiving and separating device according to the present invention transfers the paper to the pickup roller assembly through the vacuum feed suction belt assembly, and the pickup roller assembly receives the paper and performs the separating operation under the action ofthe separating assembly. The full-automatic square paper towel receiving and separating device in the invention realizes automatic grasping, does not need manual grasping, and reduces manual intervention, thereby improving the efficiency of separating.

Owner:CHANGDE TOBACCO MACHINERY

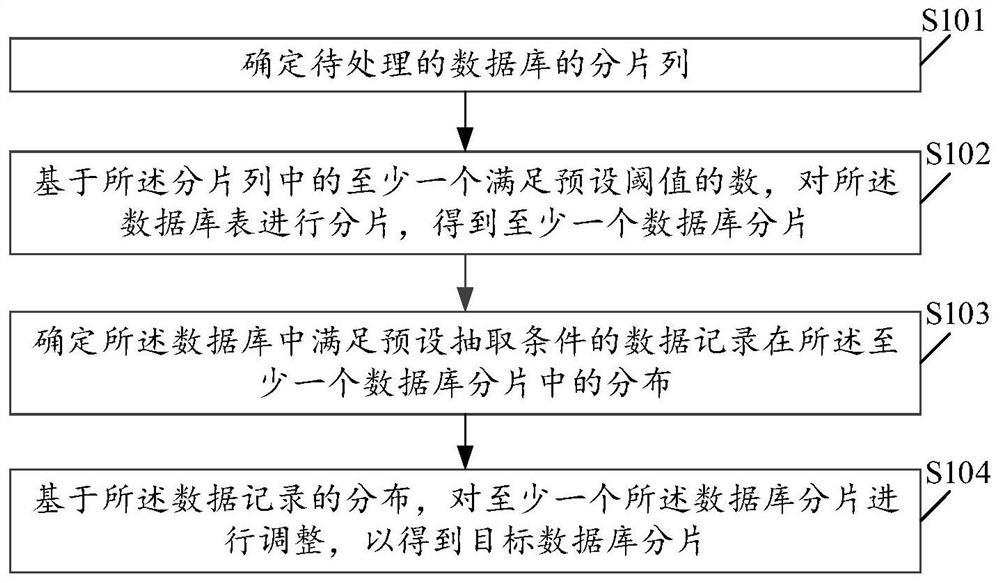

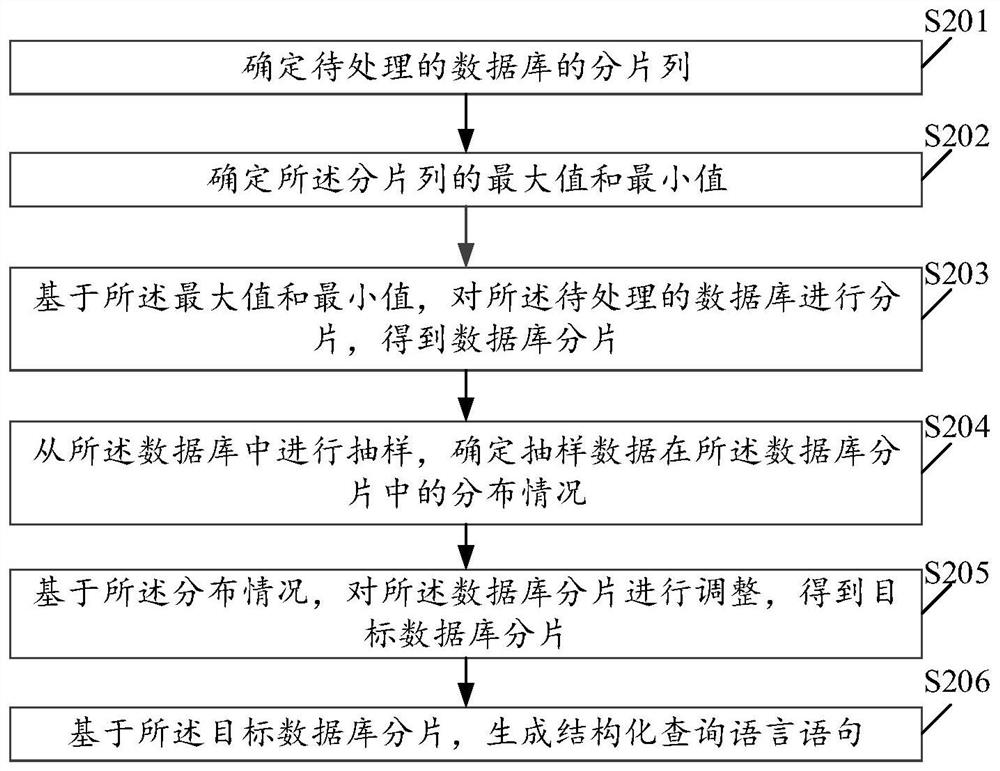

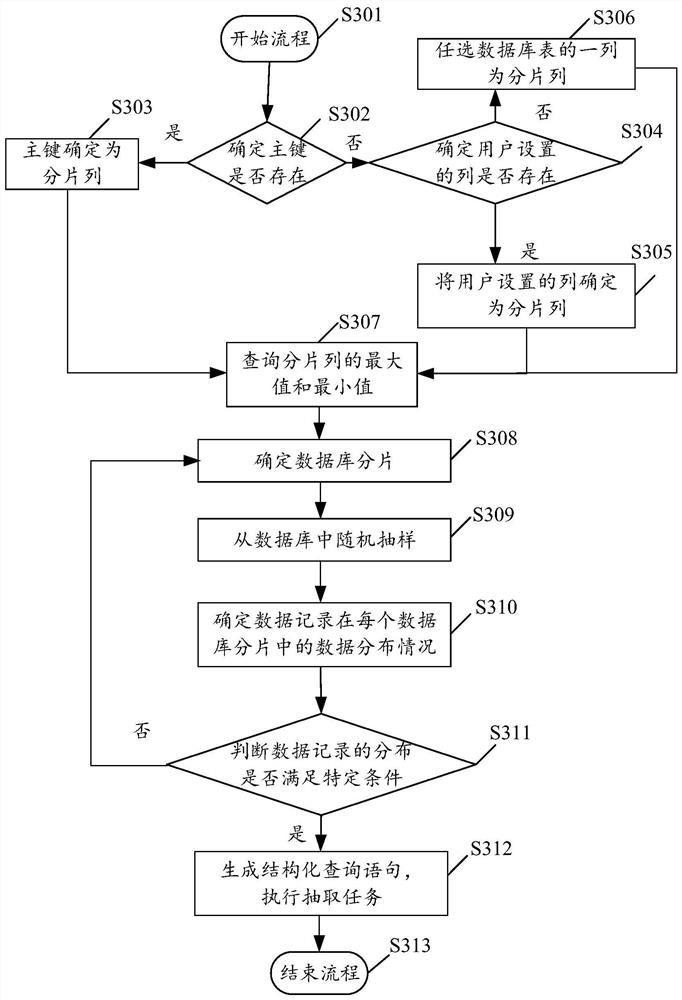

Data processing method and device, terminal and storage medium

PendingCN113934703AImprove sharding efficiencySpecial data processing applicationsDatabase design/maintainanceData miningData records

The invention provides a data processing method and device, a terminal and a storage medium. The method comprises the steps of determining a fragment column of a to-be-processed database; based on at least one number meeting a preset threshold value in the fragment column, fragmenting the database to obtain at least one database fragment; determining the distribution of data records meeting a preset extraction condition in the database in the at least one database fragment; and based on the distribution of the data records, adjusting the at least one database fragment to obtain a target database fragment. Therefore, the database fragmentation efficiency can be improved, and the database fragment with uniform data distribution is obtained.

Owner:CHINA MOBILE SUZHOU SOFTWARE TECH CO LTD +1

Silicon chip separating device

InactiveCN105428465AAvoid damageImprove sharding efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingAir blowerSilicon chip

A silicon chip separating device comprises a silicon chip separating mechanism and a feeding trough. The silicon chip separating mechanism comprises a silicon chip separating mechanism body. Two separated silicon chip conveyor belts which are parallelly and separately arranged are configured below the silicon chip separating mechanism body. The silicon chip separating mechanism body is provided with an exhausting holes which face the separated silicon chip conveyor belts. The air exhausting holes are communicated with an air exhausting device through pipeline. The silicon chip separating mechanism body is provided with rollers at positions which correspond with the front end of the conveying direction of the separated silicon chip conveyor belts. The silicon chip separating mechanism body is provided with air blowing holes of which the air blowing direction face the separated silicon chip conveyor belts. The air blowing holes are communicated with an air blower through pipeline. The feeding trough comprises a feeding trough body and a water pump. The feeding trough body is provided with an overflow opening. The overflow opening is communicated with a liquid storage trough through pipeline. The feeding trough body is internally provided with a supporting platform for placing stacked silicon chips. The supporting platform is transmissibly connected with the driving part of a vertical movement driving device. The silicon chip separating device has advantages of high silicon chip separating efficiency and small silicon chip damage in silicon chip separation.

Owner:SUZHOU BOYANG ENERGY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com