A kind of bamboo slicing device

A bamboo and blade technology, applied in the direction of sugarcane machining, mechanical equipment, etc., can solve the problems of uneven bamboo slicing, large physical exertion of operators, incomplete segmentation, etc., to improve uniformity, improve efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

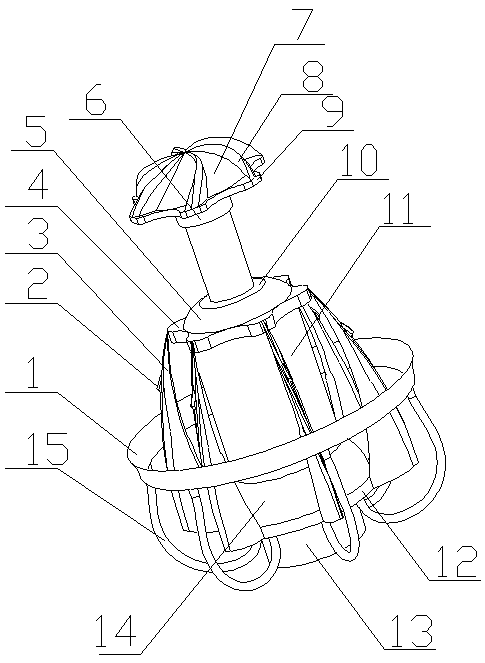

[0021] A kind of bamboo slicing device of the present invention is realized in this way, during use, when bamboo is carried out slicing, at first external extraction device is connected with connecting sleeve 13, then a plurality of cutting blades 8 are stretched in the bamboo bamboo tube, drive The motor 11 works, the motor shaft rotates, and the rotating plate 9 is driven by the fixed sleeve 6 to rotate, and the rotating plate 9 drives a plurality of cutting blades 8 to rotate. The cutting blade 2 on the splitting blade 3 is first in contact with the inner wall of the bamboo tube, and then cuts the bamboo tube, and then the splitting blade 3 splits the bamboo tube along the cutting knife mark, and then divides the bamboo tube into multiple slices , the fixed ring 1 gathers a plurality of bamboo slices to prevent dispersion, and as it continues to advance, when the cutting blade 8 moves to the bamboo joint position, the multiple cutting blades 8 rotate to chop the thin slices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com