Bamboo splitter

A slicing machine, bamboo and wood technology, applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problems of material waste, low chip output rate, low slicing accuracy, etc., to ensure the slicing accuracy, Low cost and easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

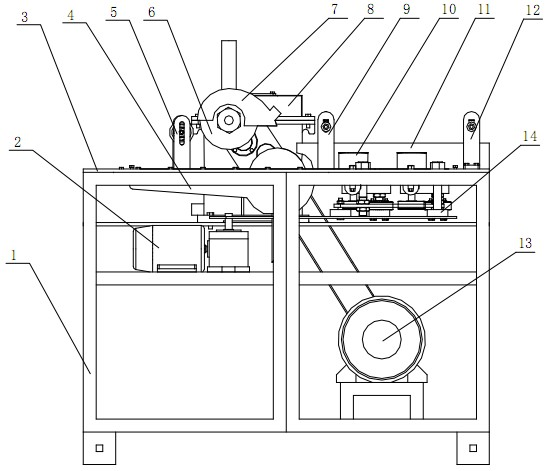

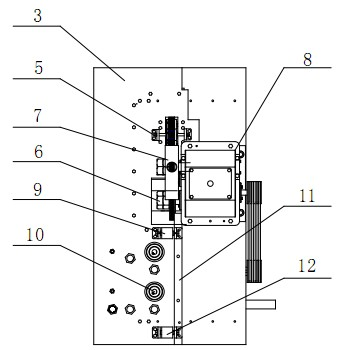

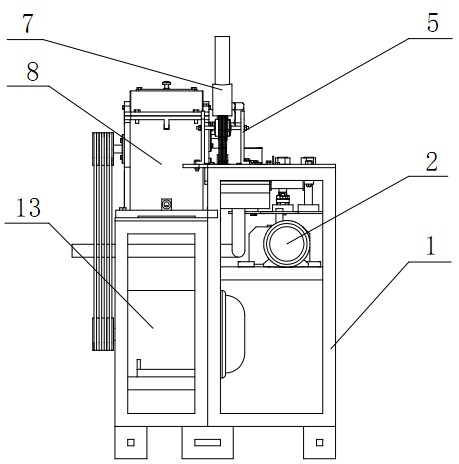

[0030] refer to Figure 1-7 , Bamboo slicer, comprising a frame 1, an upper panel 3 is installed on the frame 1, and a limited height device 12, a feeding device, a pressure-assisting device 9, a slicing device 6, Constraint device 5, described slicing device 6 is installed on the transmission case 8, comprises upper saw group device and lower saw group device, all comprises saw group shaft 61 on the described upper and lower saw group device, and described saw group shaft 61 Positioning baffles 62 , saw blades 63 and spacers are sequentially installed on the top, and the end of the saw group shaft 61 is pressed and positioned by the countertop round nut 64 ; the transmission box 8 is connected with the motor 13 .

[0031] The height limiting device 12 includes a height limiting long bracket 121 and a height limiting short bracket 126, the height limiting long bracket 121 is fixed on the upper panel 3, and the height limiting short bracket 126 is fixed on a positioning plate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com