Patents

Literature

43results about How to "Ensure processing safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

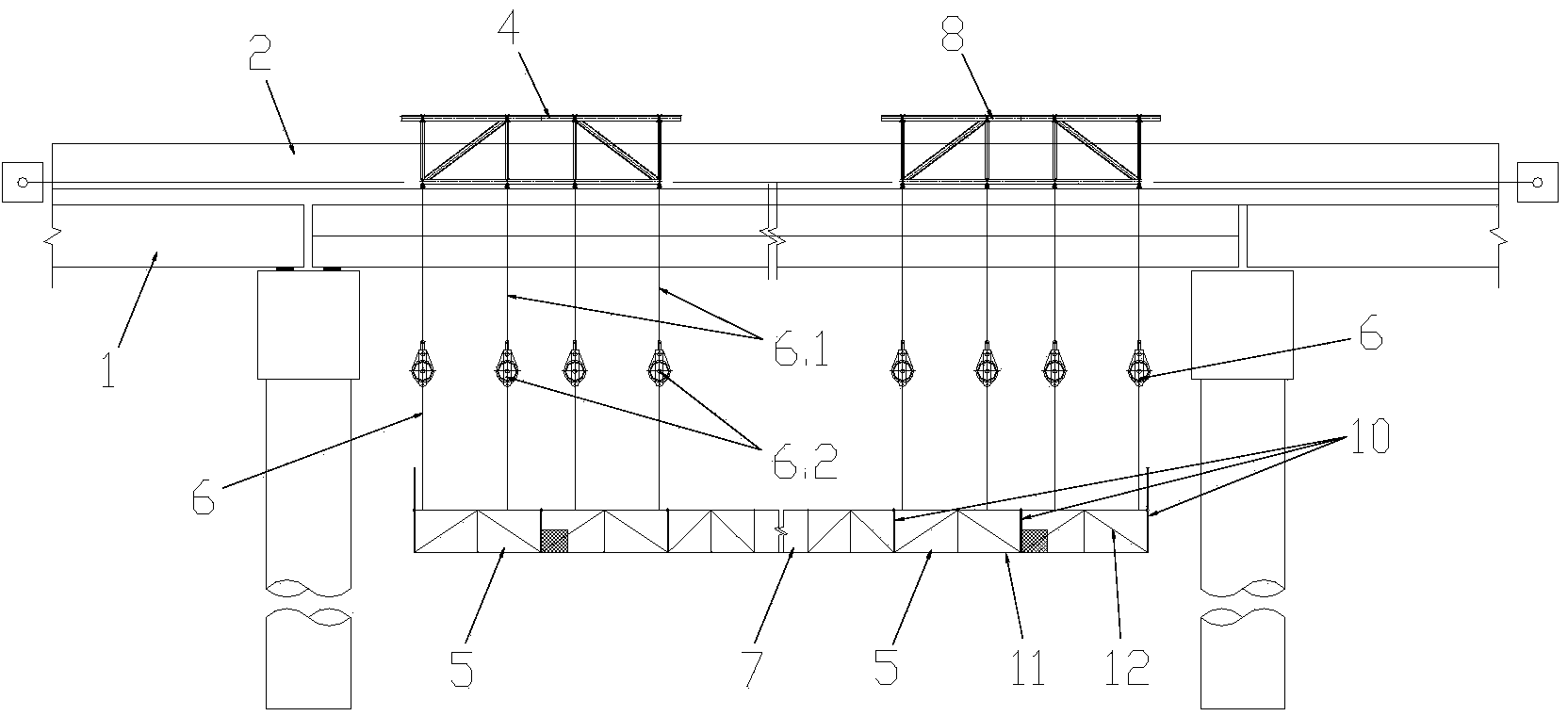

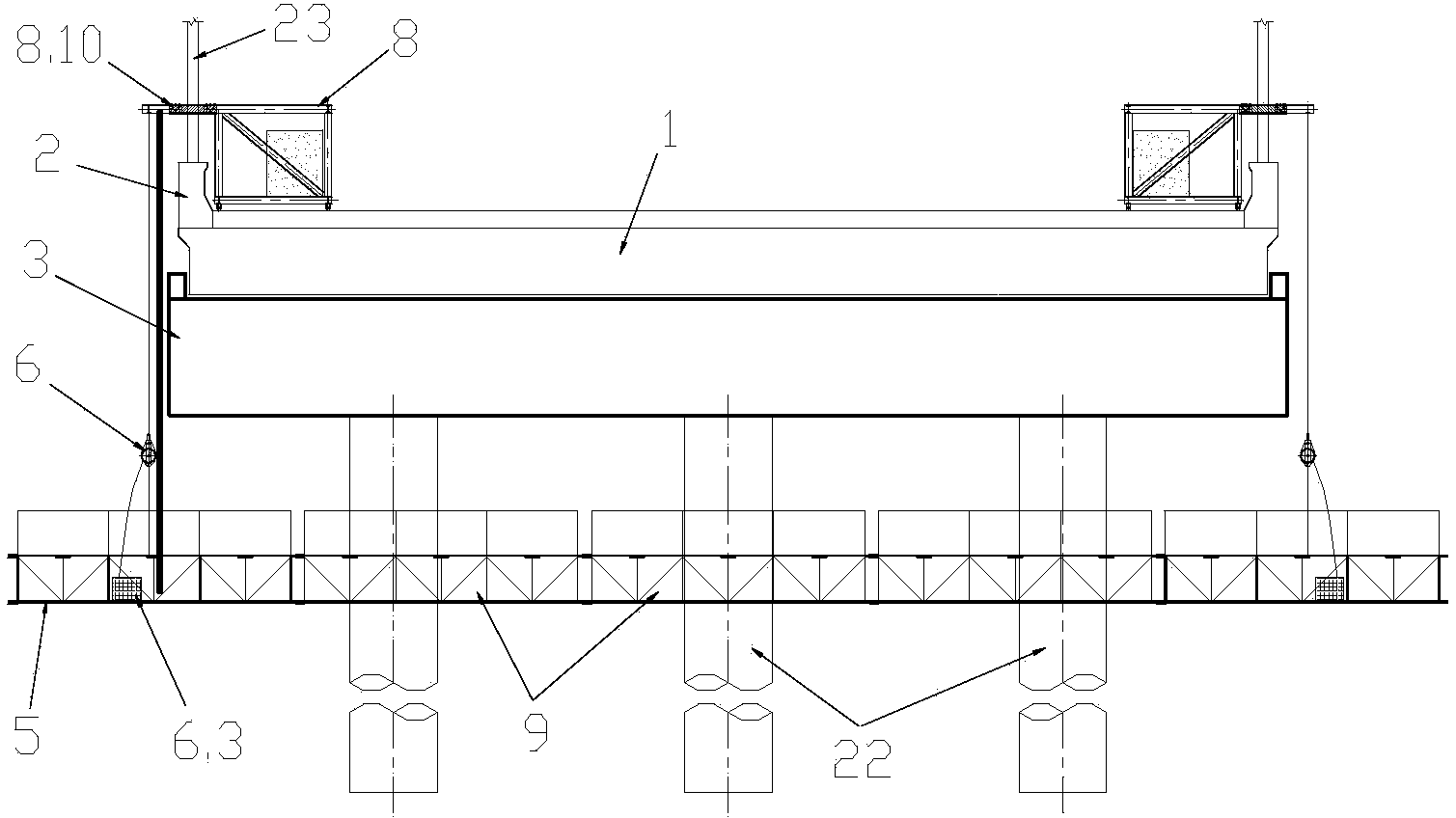

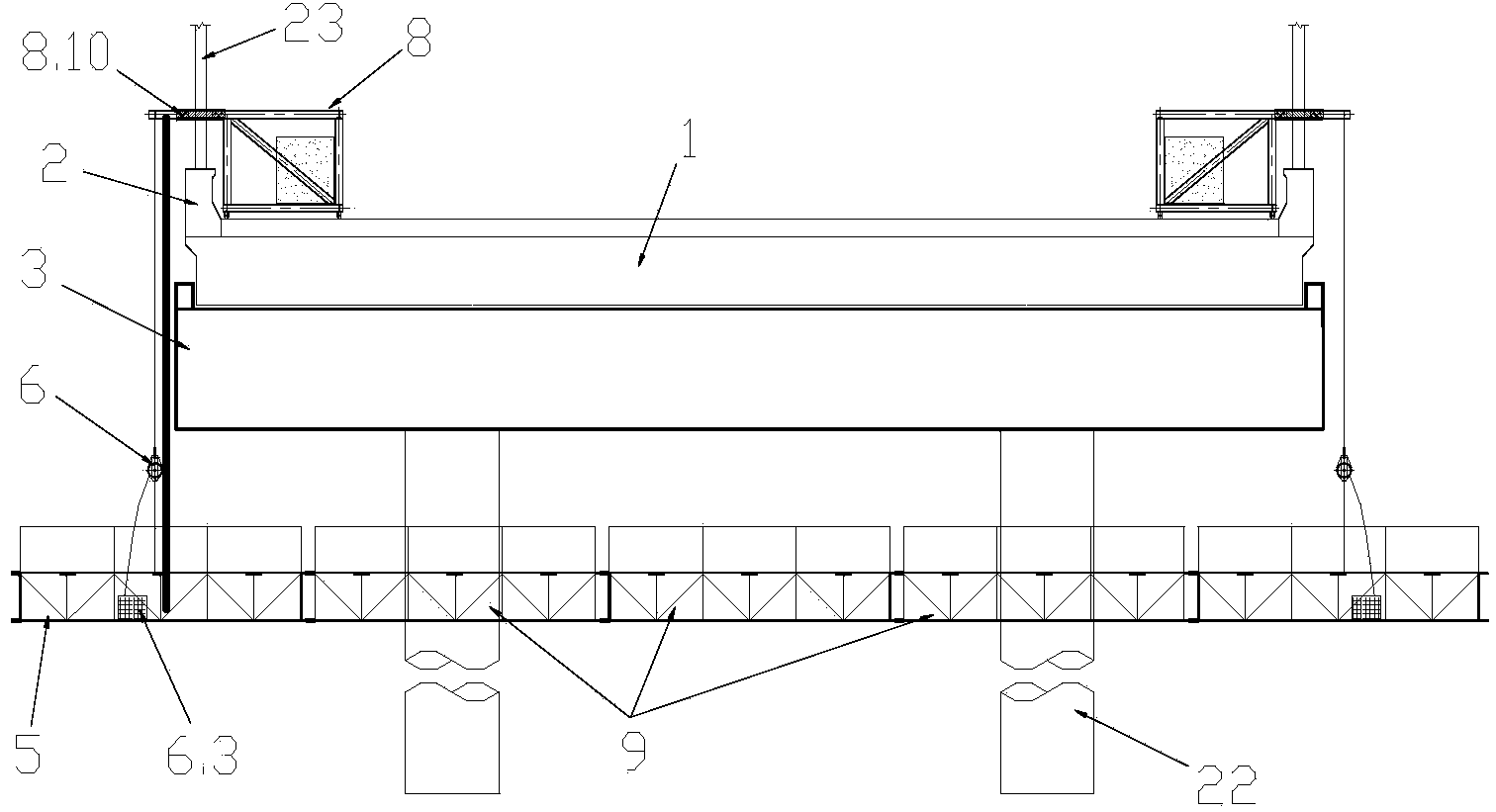

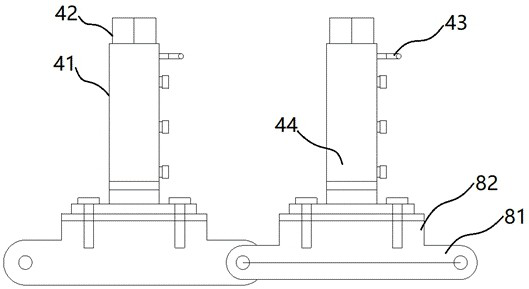

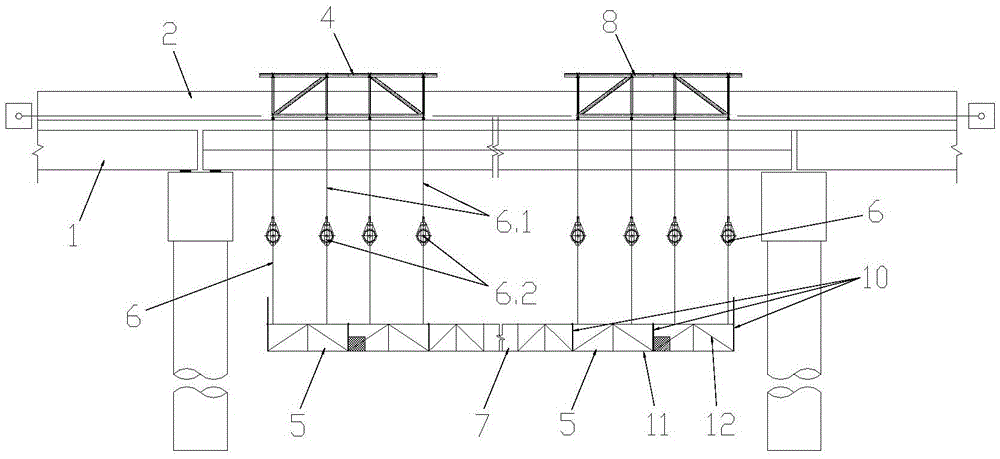

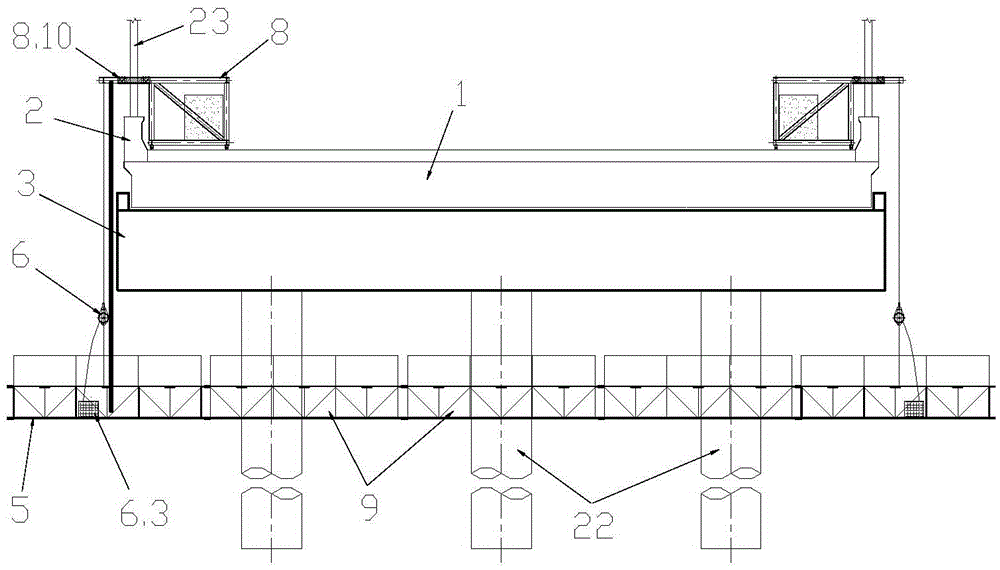

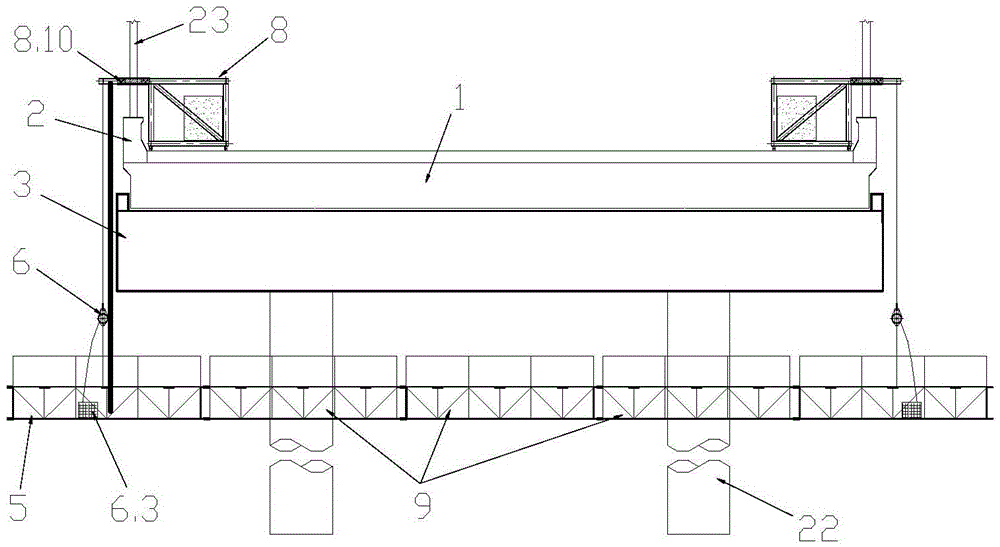

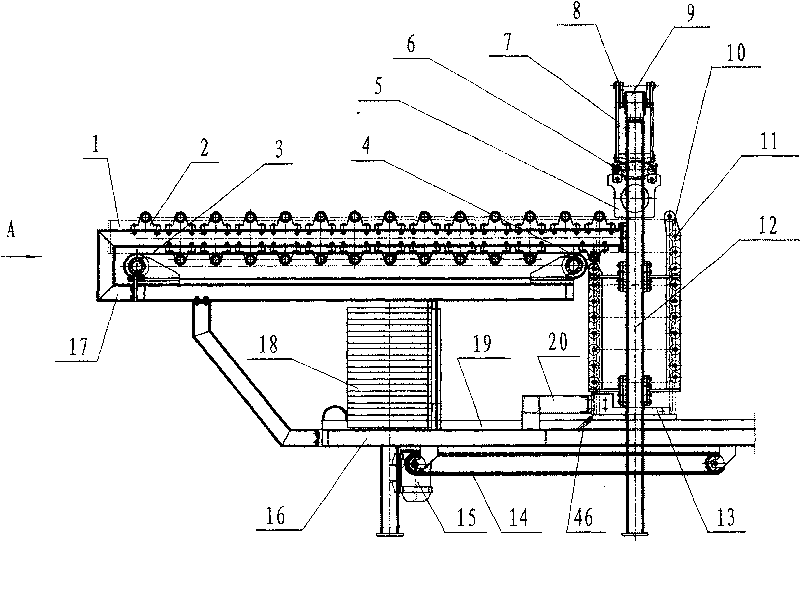

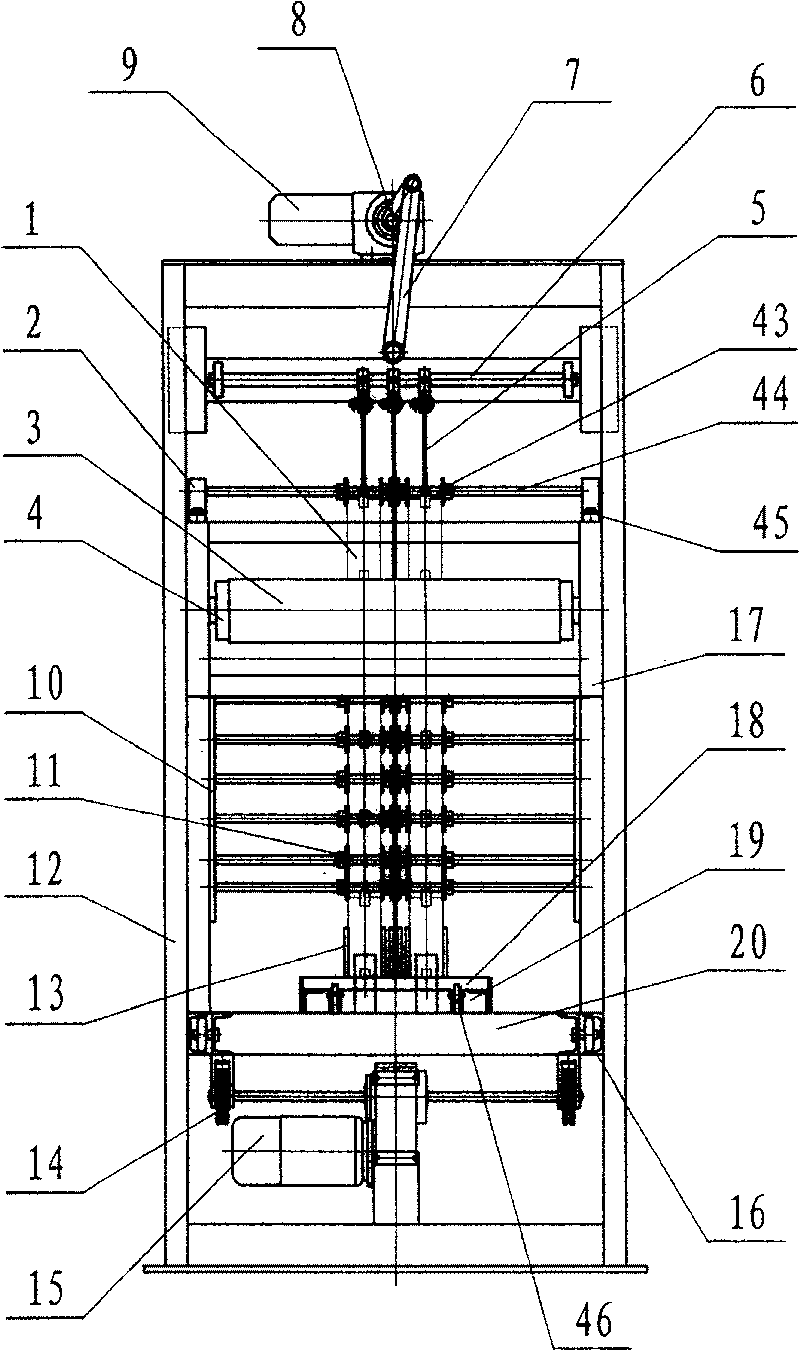

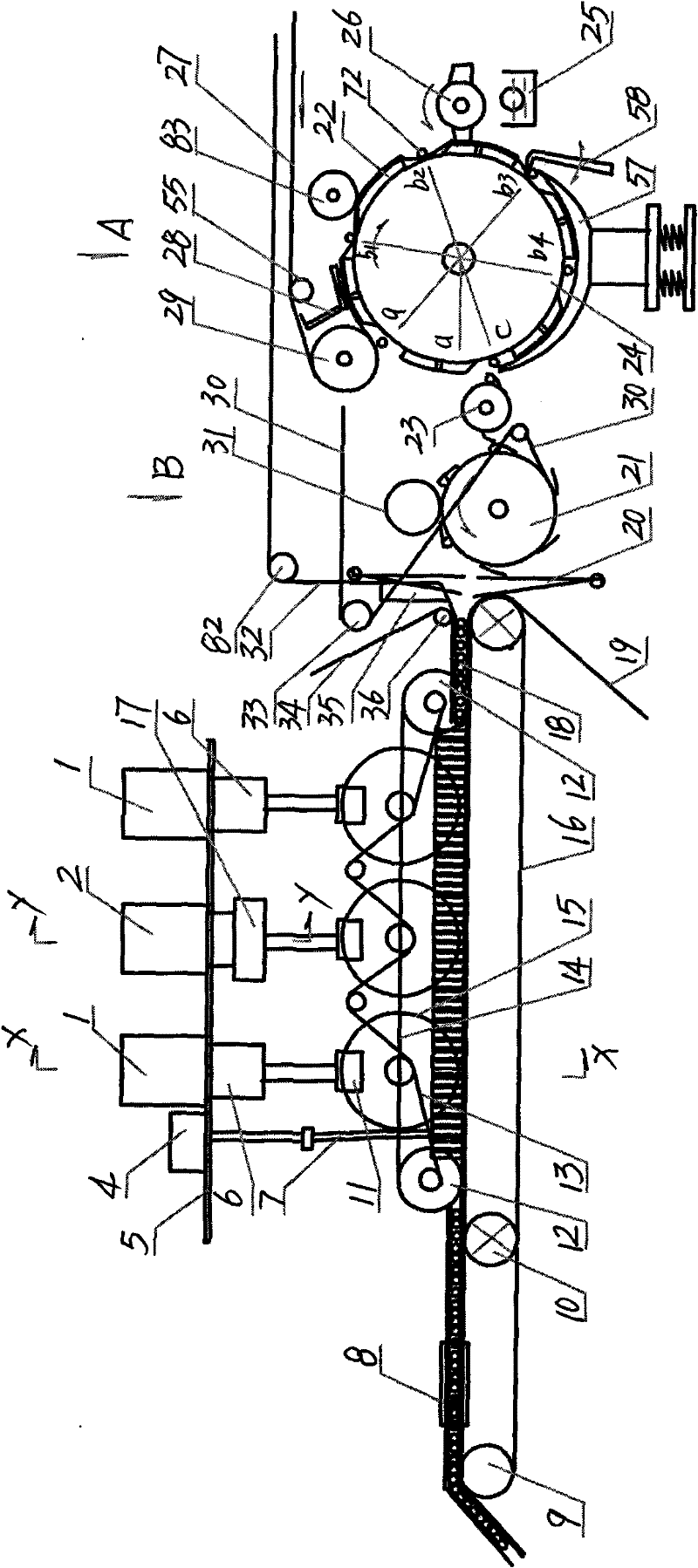

Beam bottom overhaul platform capable of spanning bridge piers and obstacle pillars and use method of beam bottom overhaul platform

ActiveCN104358211AImprove applicabilityEasy to operateBridge structural detailsBridge strengtheningBridge engineeringCantilever

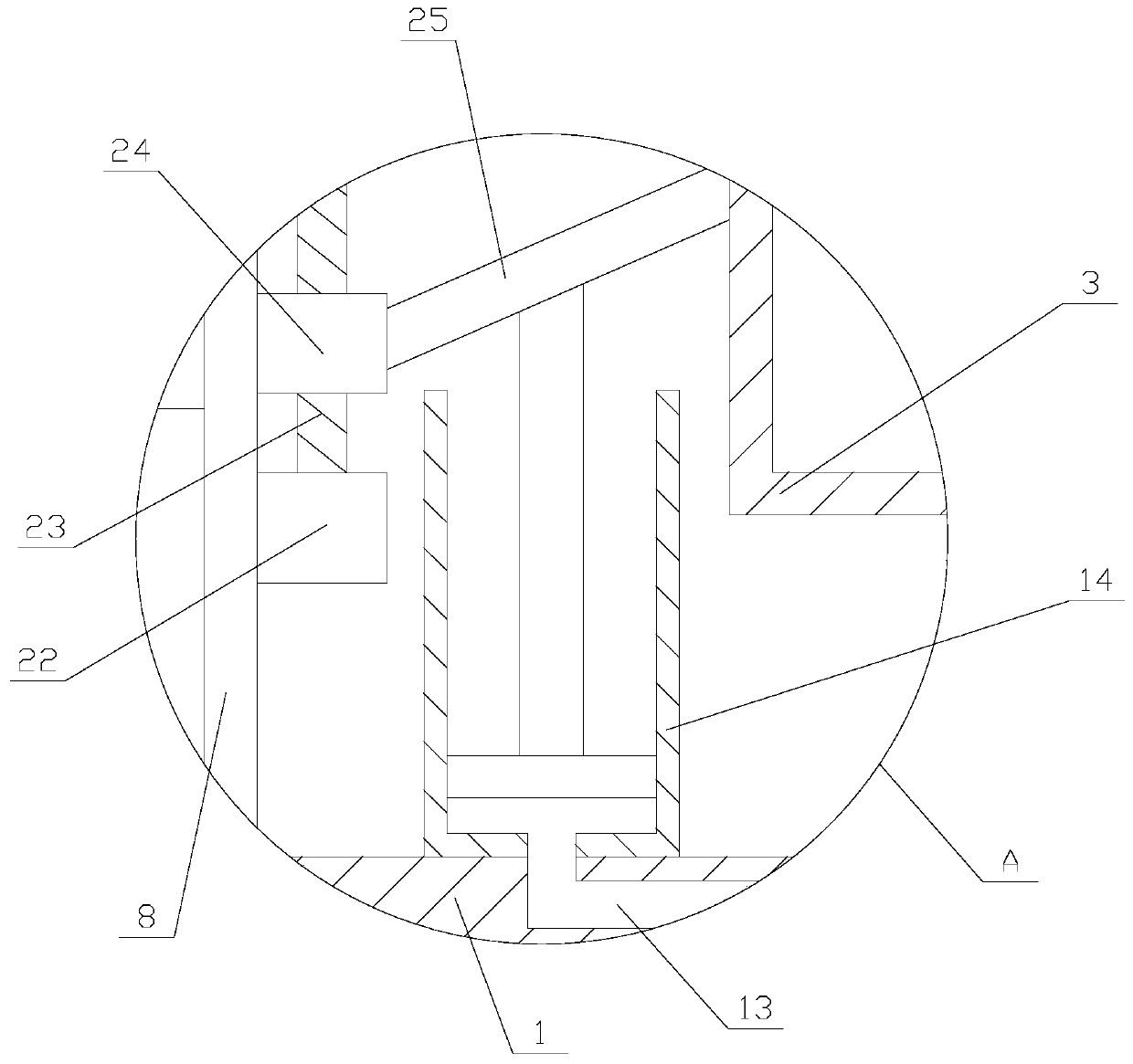

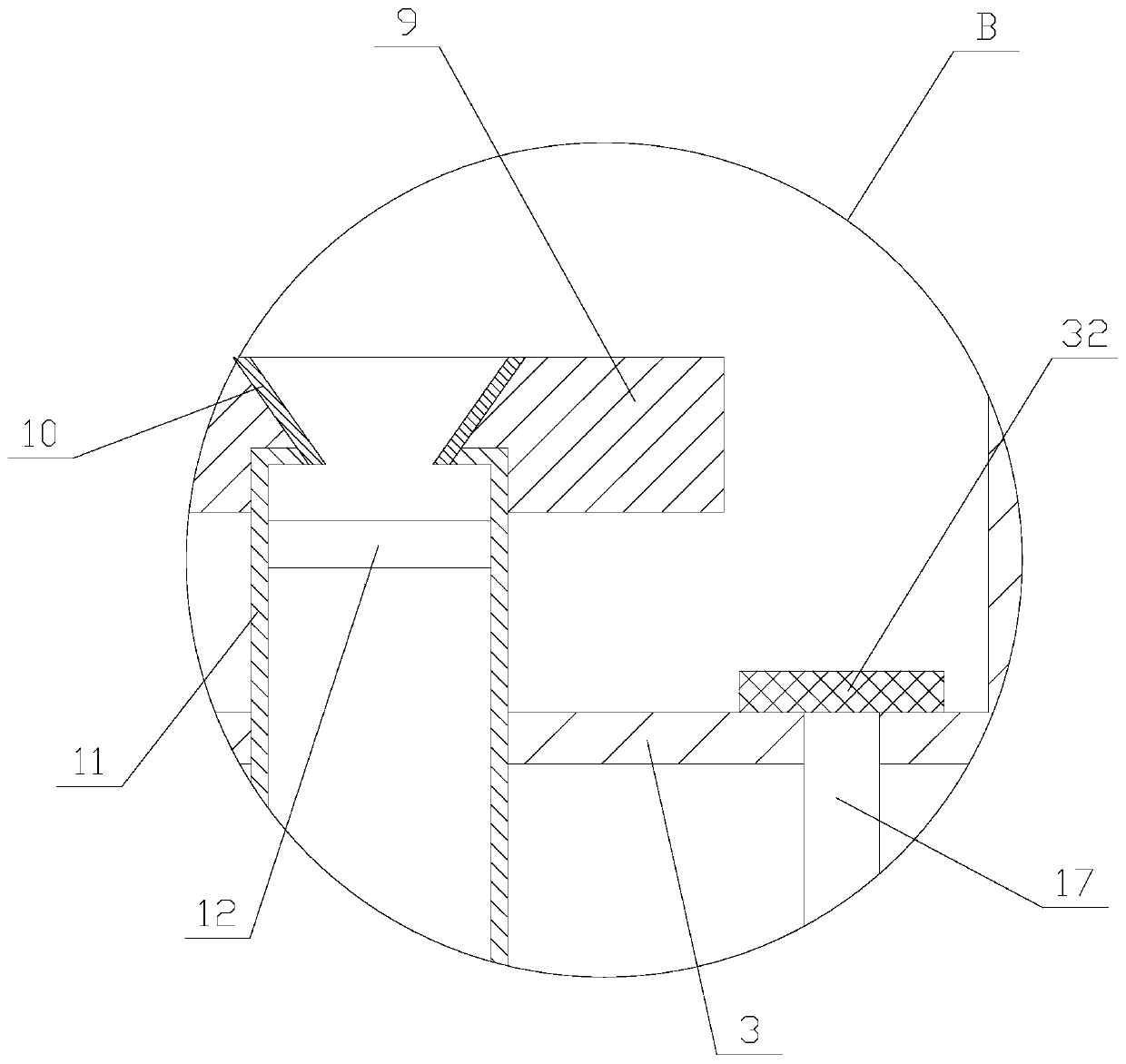

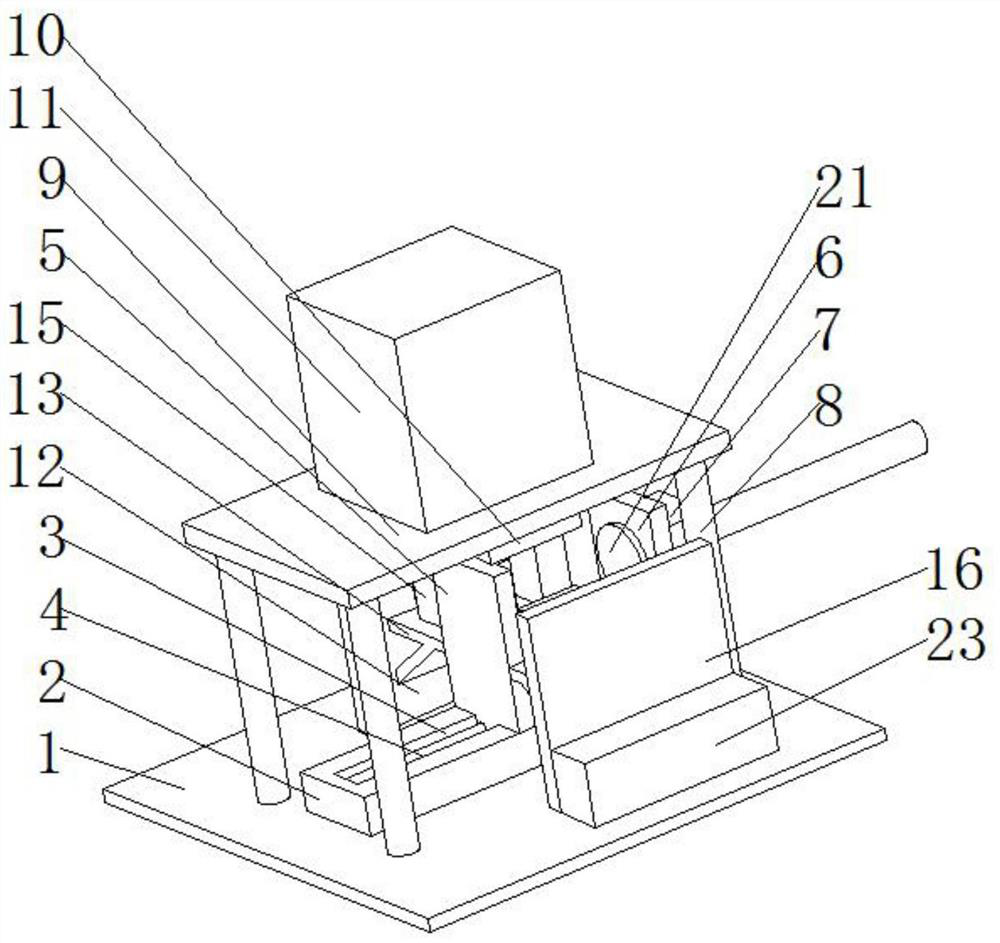

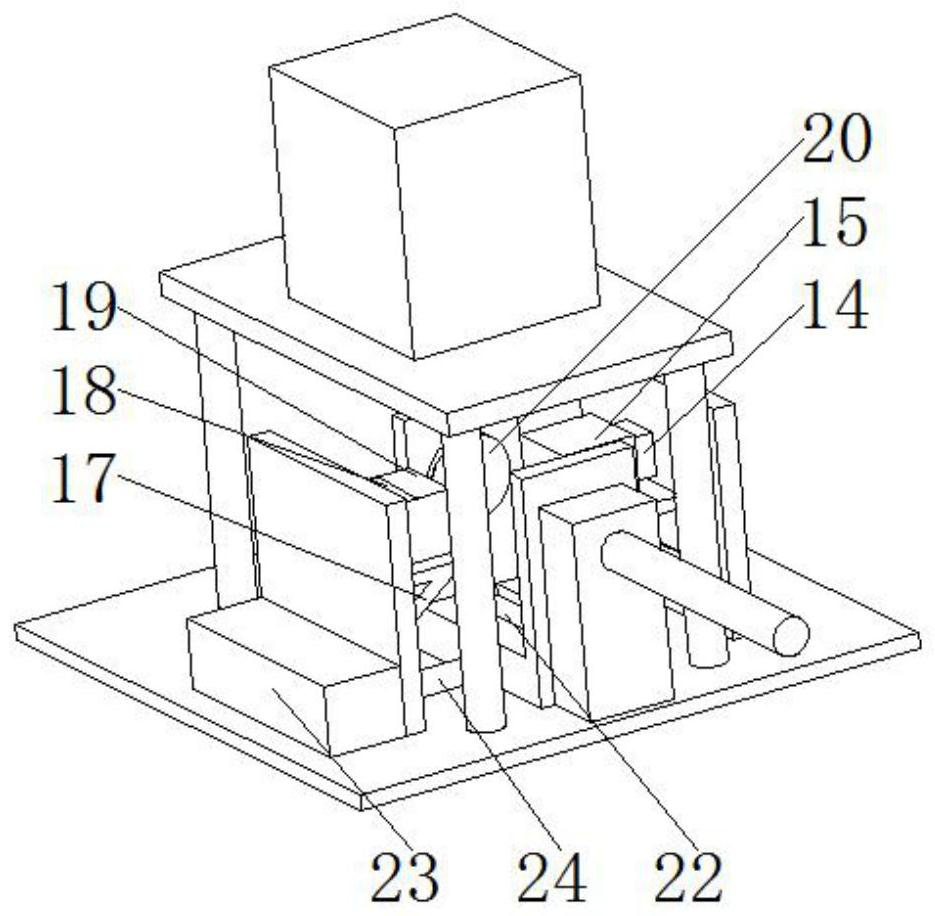

The invention belongs to the technical field of bridge engineering, and in particular relates to a beam bottom overhaul platform capable of spanning bridge piers and obstacle pillars and a use method of the beam bottom overhaul platform. The beam bottom overhaul platform comprises pillar spanning truss trolleys, pier pillar spanning hanging racks, hoisting systems and connecting units, wherein the pillar spanning truss trolleys comprise two pairs of truss trolleys which are positioned on the inner sides of guardrails on two sides of a bridge, are capable of moving in the direction of the bridge and are arranged in symmetry; a plurality of detachable cantilever rods stretch outwards from one side adhering to the guardrails, of each truss trolley; the pier pillar spanning hanging racks are suspended on the cantilever rods on each pair of the truss trolleys through the hoisting systems; adjacent pier pillar spanning hanging racks are connected through the connecting units; the pier pillar spanning hanging racks comprise a plurality of truss units which are arranged in the direction of the bridge; adjacent truss units are in detachable fixed connection. The beam bottom overhaul platform has the advantages of high applicability, simple operation, good security, good economic property, good application prospect and the like.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

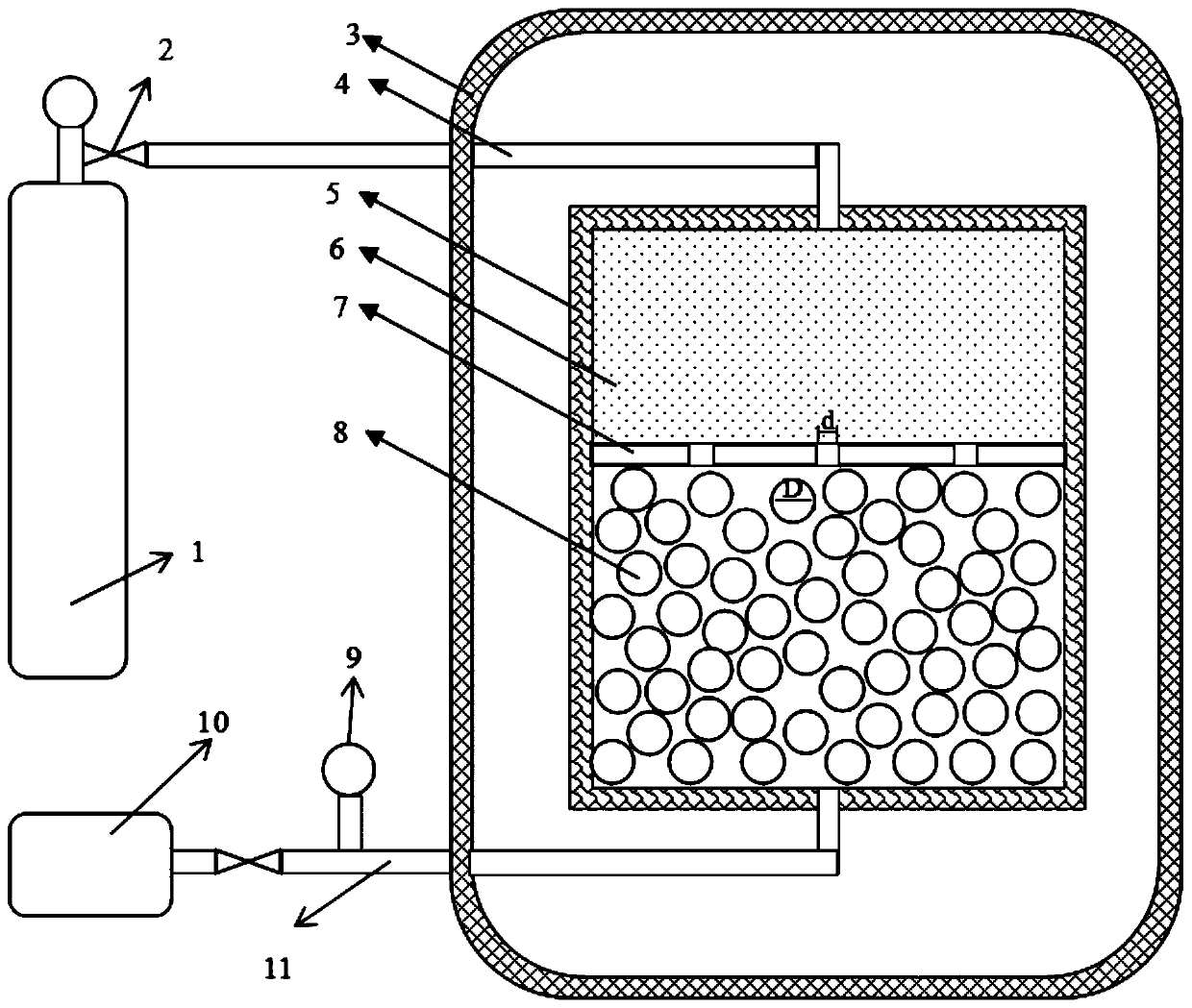

Preparation method of nanoparticle/hollow sphere composite reinforced metal-based composite material

InactiveCN110791673AFree from external pollution such as oxidationAvoid burnsNanoparticleMetal matrix composite

The invention relates to a preparation method of a nanoparticle / hollow sphere composite reinforced metal-based composite material. The preparation method comprises the steps that firstly, a nanoparticle-reinforced metal-based composite material blank and hollow spheres are sealed in a steel capsule and isolated with a perforated plate in the middle, a first air guiding pipe is connected with the blank end, and a second air guiding pipe is connected with the hollow sphere end; secondly, the steel capsule is put into a box-type resistance furnace to be heated, vacuumizing is conducted through avacuum unit in the heating process to keep the vacuum degree in the steel capsule, melt is formed after the nanoparticle-reinforced metal-based composite material blank is molten, and the melt is loaded through the first air guiding pipe and enters spaces among the ceramic hollow spheres through the perforated plate; and lastly, the steel capsule is taken out from the box-type resistance furnace and cooled to room temperature, the steel capsule is removed in a machining mode, and finally the nanoparticle / hollow sphere composite reinforced metal-based composite material is prepared. Therefore,a way is provided for efficient, low-cost and high-performance preparation of the nanoparticle / hollow sphere composite reinforced metal-based composite material.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

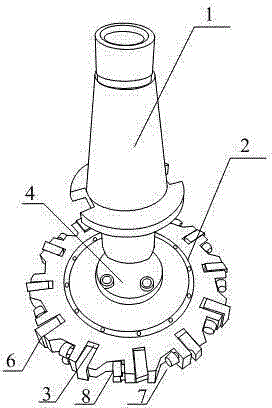

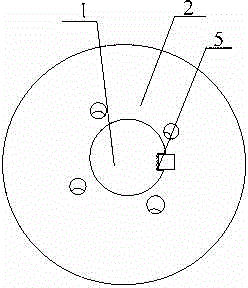

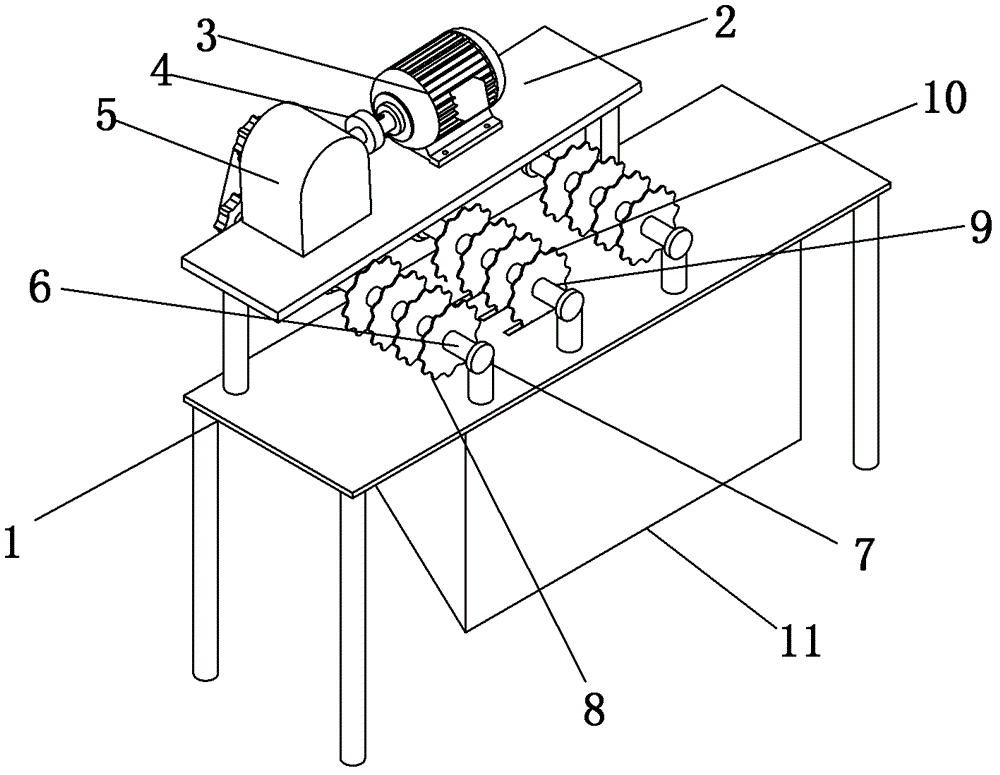

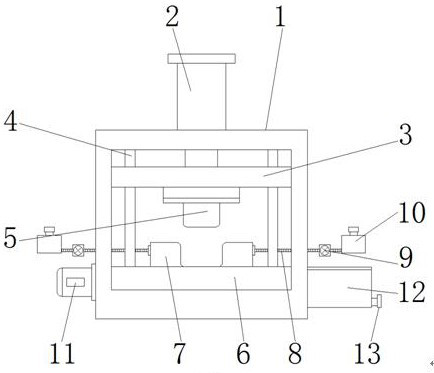

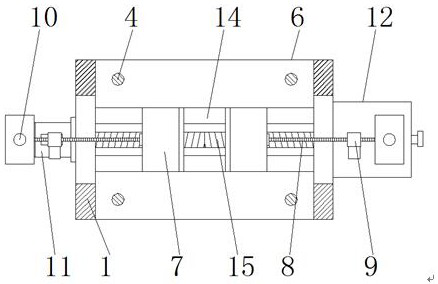

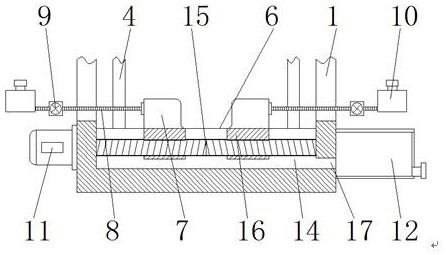

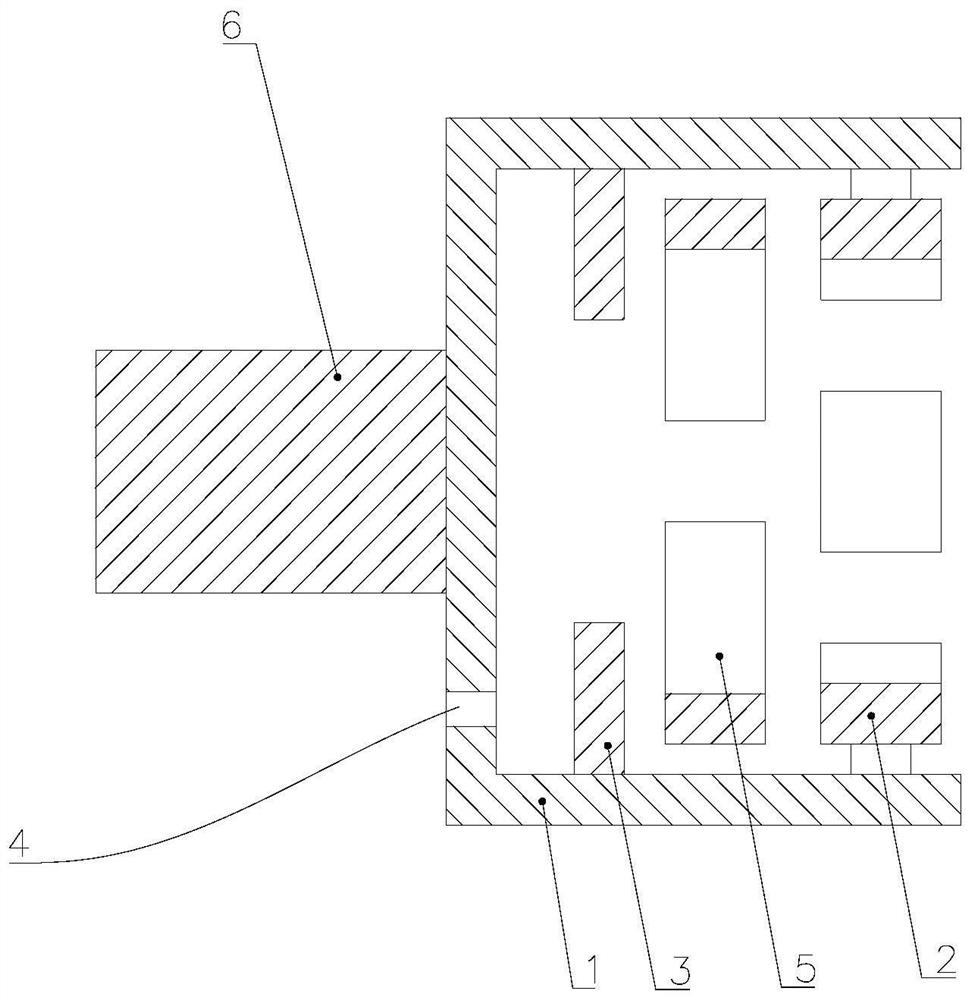

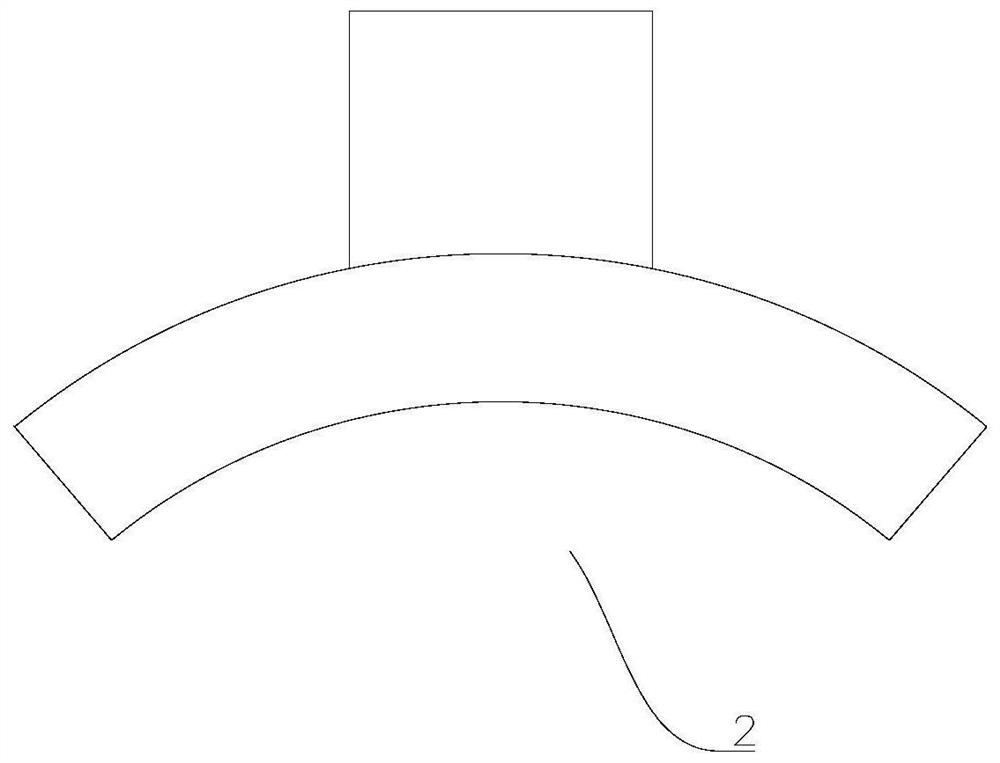

Adjustable multi-mount lathe tool rack

The invention discloses an adjustable multi-mount lathe tool rack; when different lathe tools are replaced in the prior art, the mounted lath tool needs to be removed, then a lathe tool is replaced, so operation is complex, and thus reducing processing efficiency; the adjustable multi-mount lathe tool rack can solve the said problems, and mainly comprises a main shaft (1) connected with a machine tool, and a lathe tool disc (2) tightly connected with the end portion of the main shaft (1) and used for mounting lathe tools; a bolt mount slot (7) is arranged between adjacent lathe tool mount slots (3); bolts or screws used for fixing the lathe tool are arranged in parallel in the bolt mount slot (7), wherein one ends of the bolts / screws penetrate the side wall of the lathe tool mount slot (3) and extend into the lathe tool mount slot (3). The adjustable multi-mount lathe tool rack is simple in structure, convenient to realize, and the lathe tool needs not to be dismounted in replacement, only the lathe tool disc is adjusted, thus improving processing efficiency; the adjustable multi-mount lathe tool rack is suitable for promotion application.

Owner:CHANGZHOU LONGPENG METAL PROD CO LTD

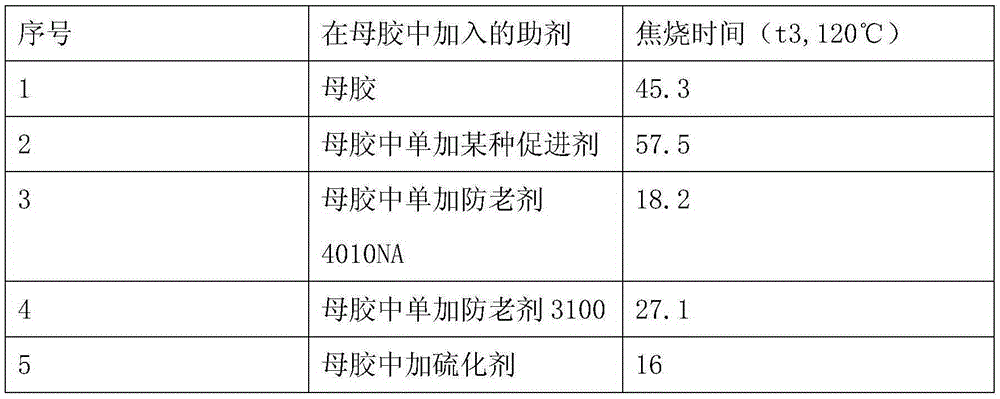

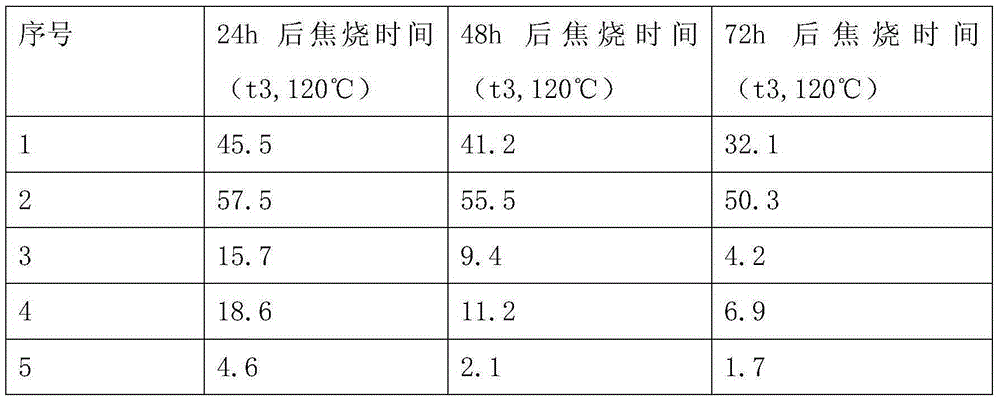

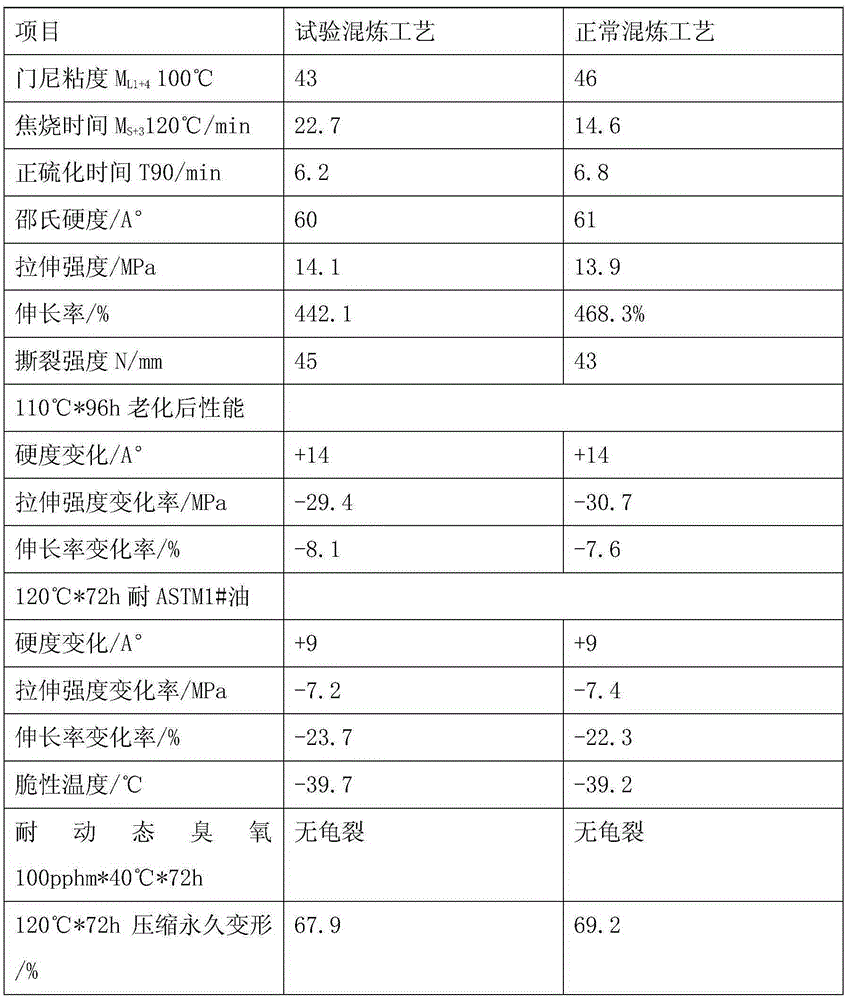

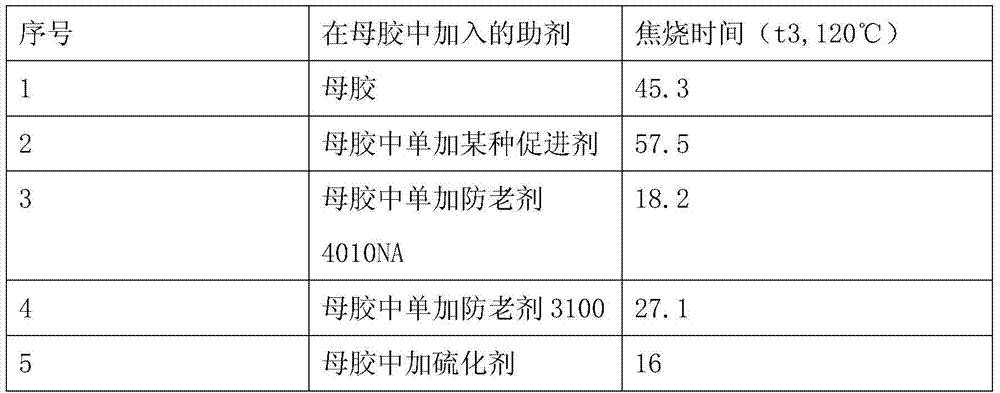

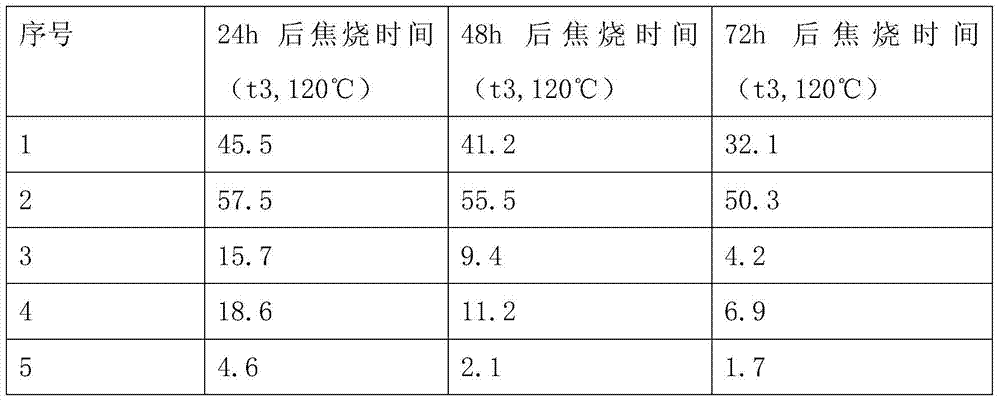

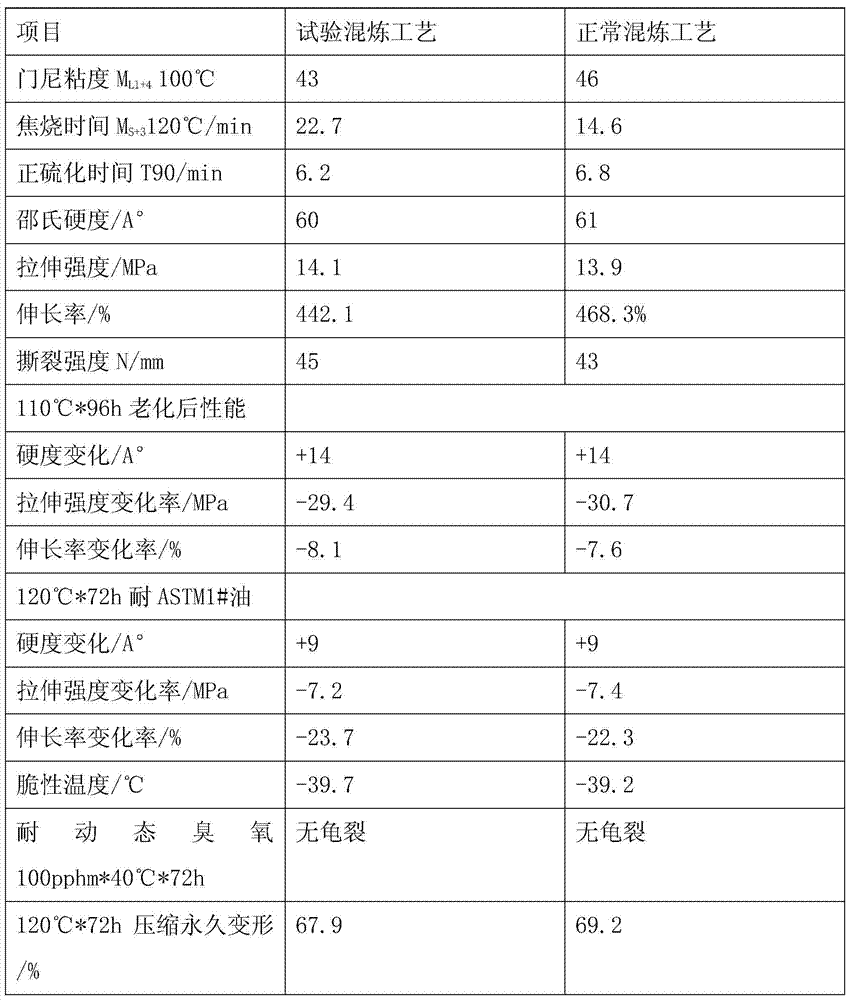

Process for improving chloroprene mixed rubber scorching performances

The invention discloses a process for improving chloroprene mixed rubber scorching performances. The mixed rubber comprises, by weight, a masterbatch ingredient comprising 70-100 parts of chloroprene rubber, 1-3 parts of a promoter, 0.5-2 parts of stearic acid, 1-3 parts of protection wax, 1-3.5 parts of an antiager OCT, 20-80 parts of fast extruding furnace black N550, 20-70 parts of semi-reinforcing furnace black N774 and 10-50 parts of dioctyl sebacate, and an auxiliary material ingredient comprising 1-3 parts of an antiager 3100, 1-2.5 parts of an antiager 4010NA and 2-10 parts of a vulcanizing agent. The mixing process comprises 1, initial stage mixing and 2, tail stage auxiliary material addition and mixing. Compared with the existing mixing process, the process provided by the invention improves mixing processes, changes a material use order by prior use of a part of the promoter and later use of all vulcanizing agent and a part of antiagers in masterbatch preparation to improve mixed rubber scorching time, and guarantees a mixed rubber transport and storage period and processing safety.

Owner:NANJING ORIENTLEADER TECH CO LTD

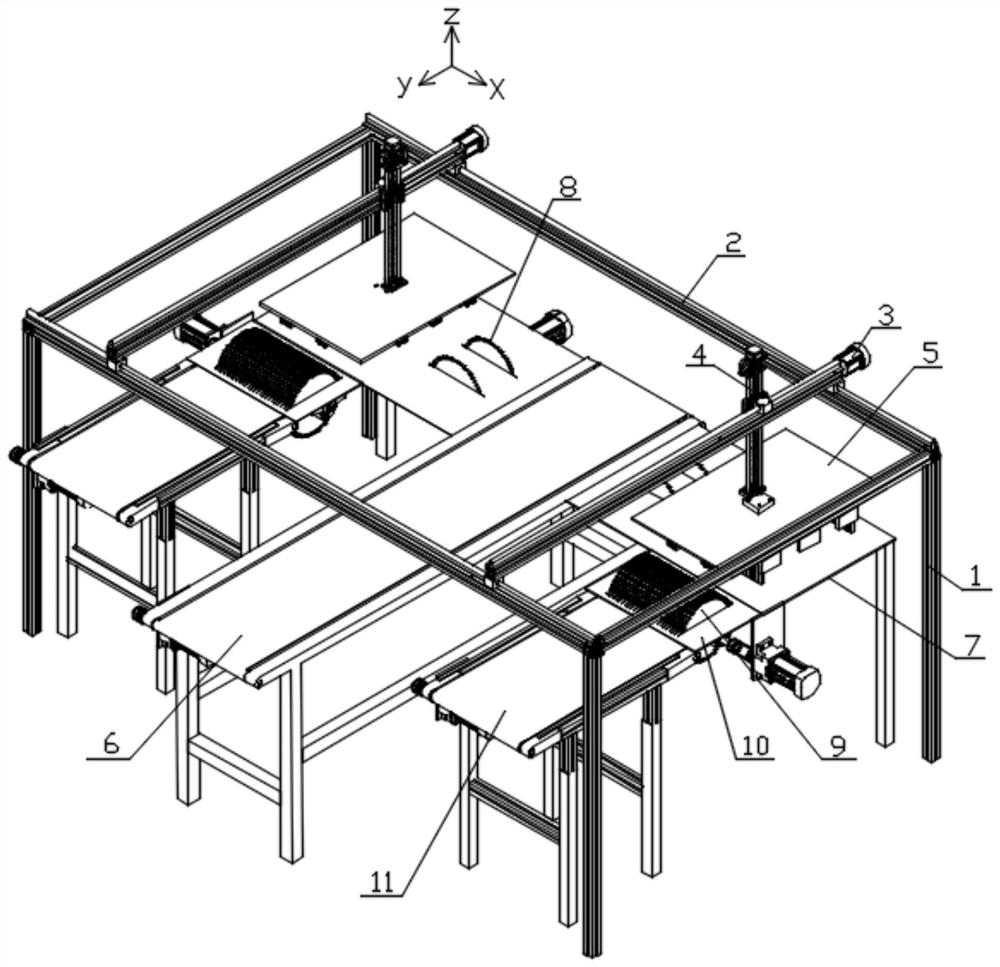

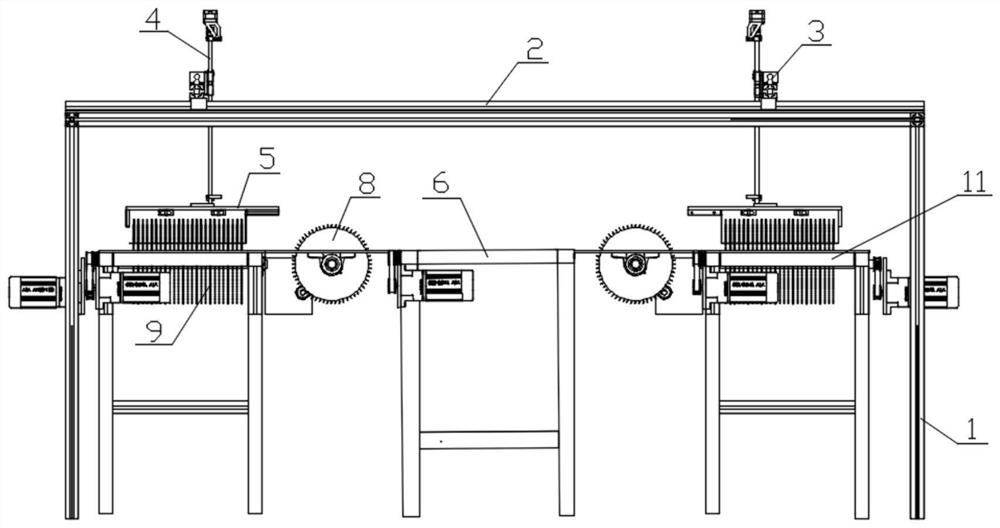

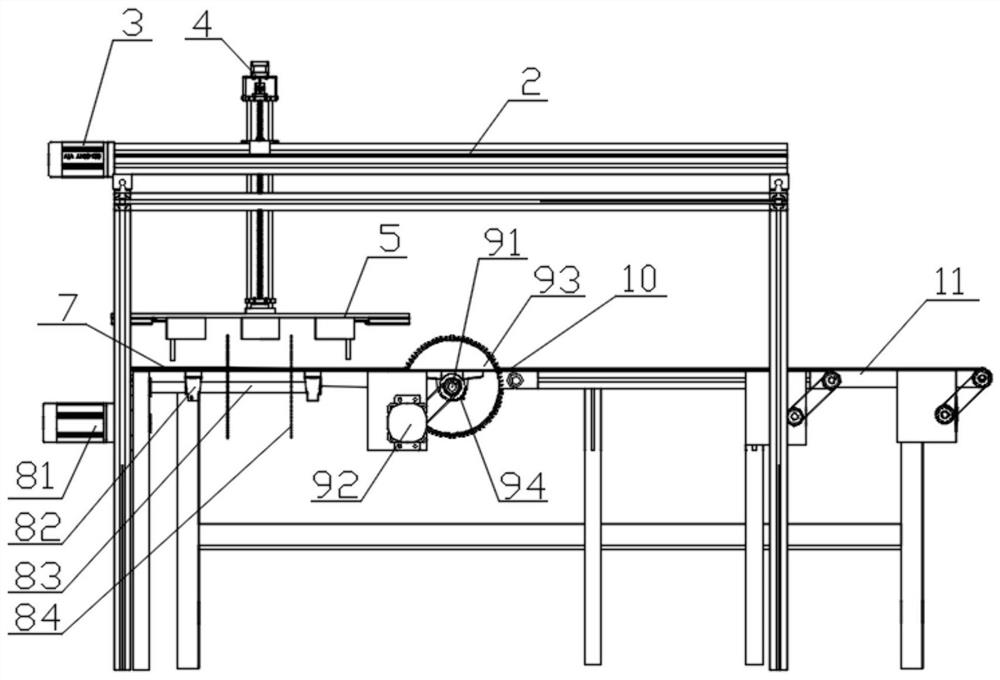

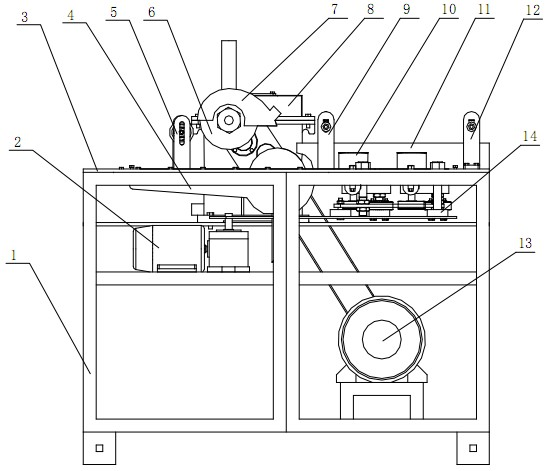

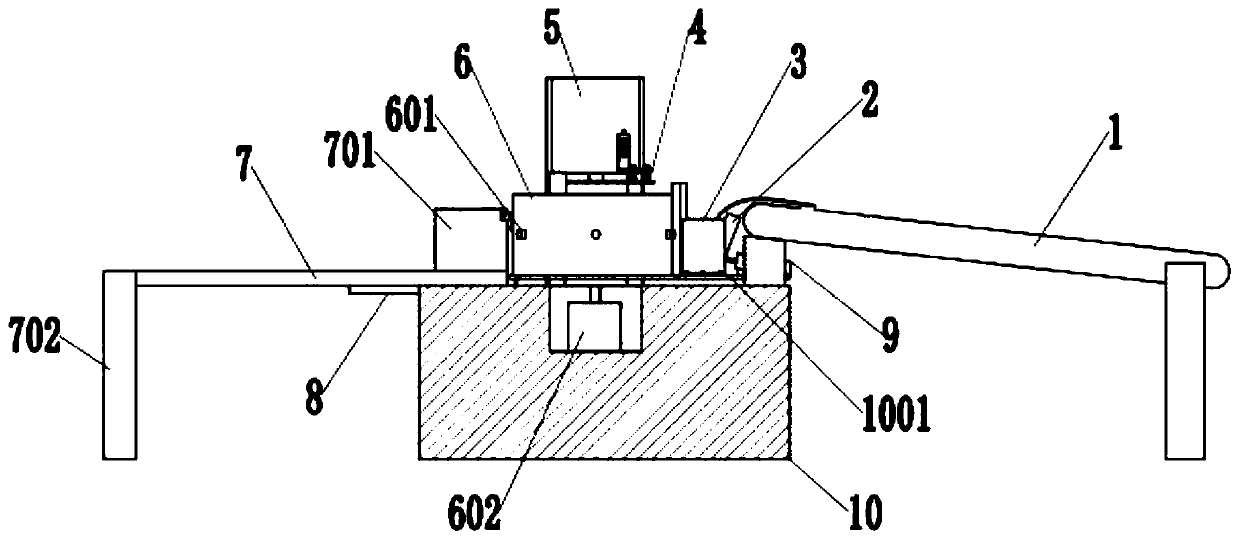

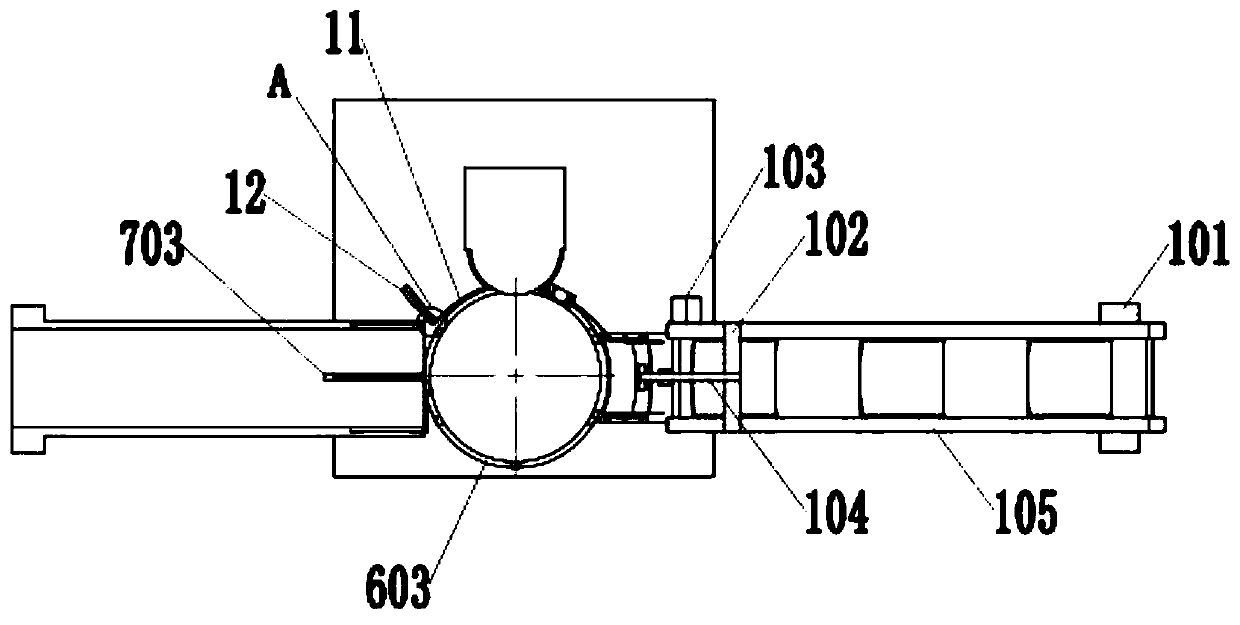

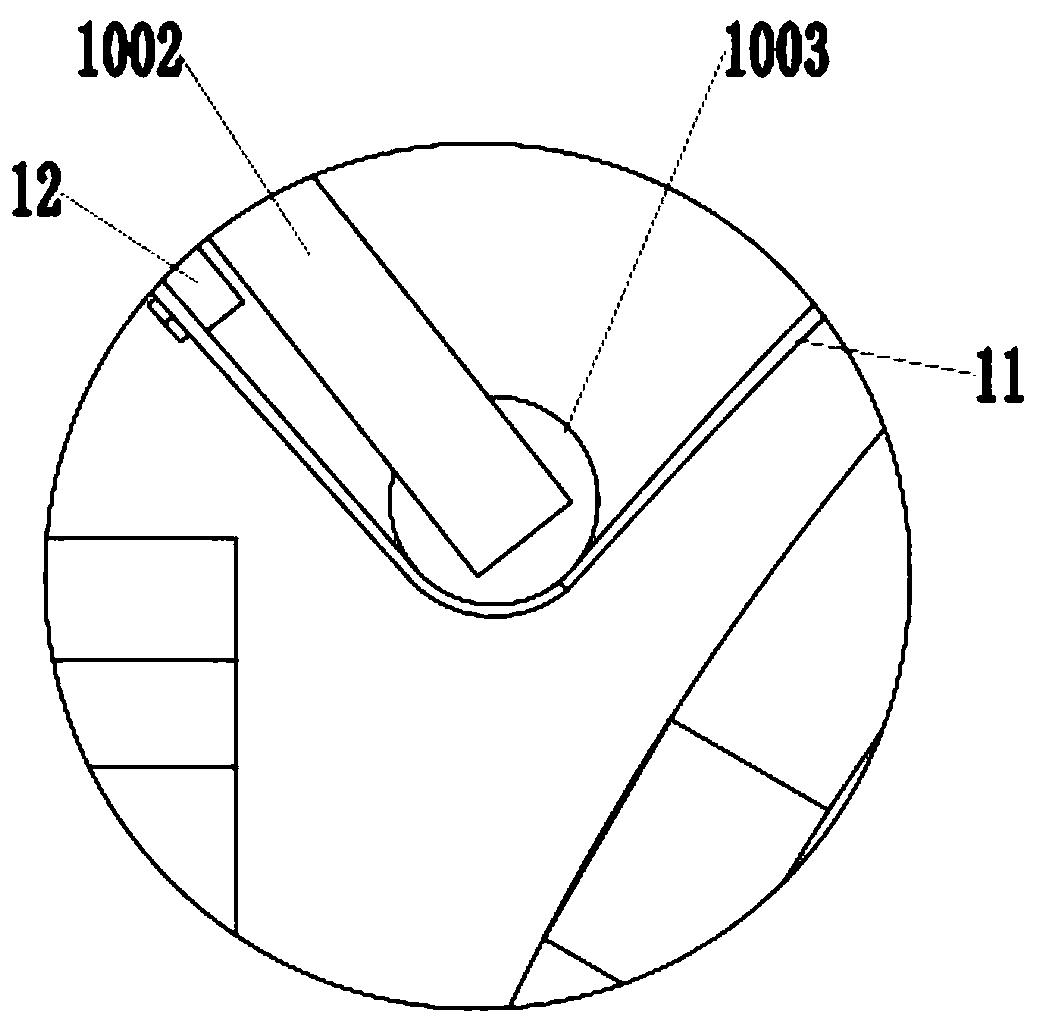

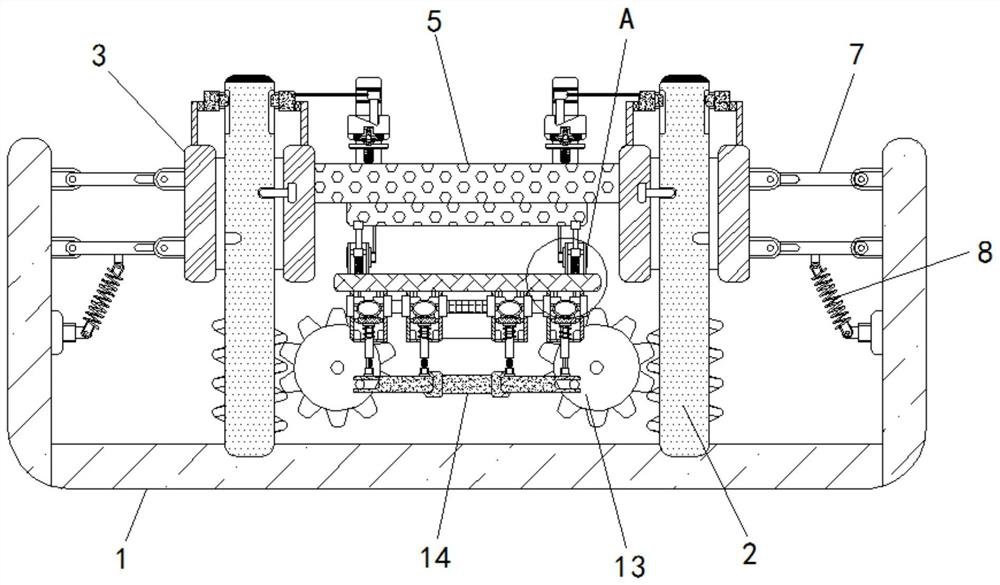

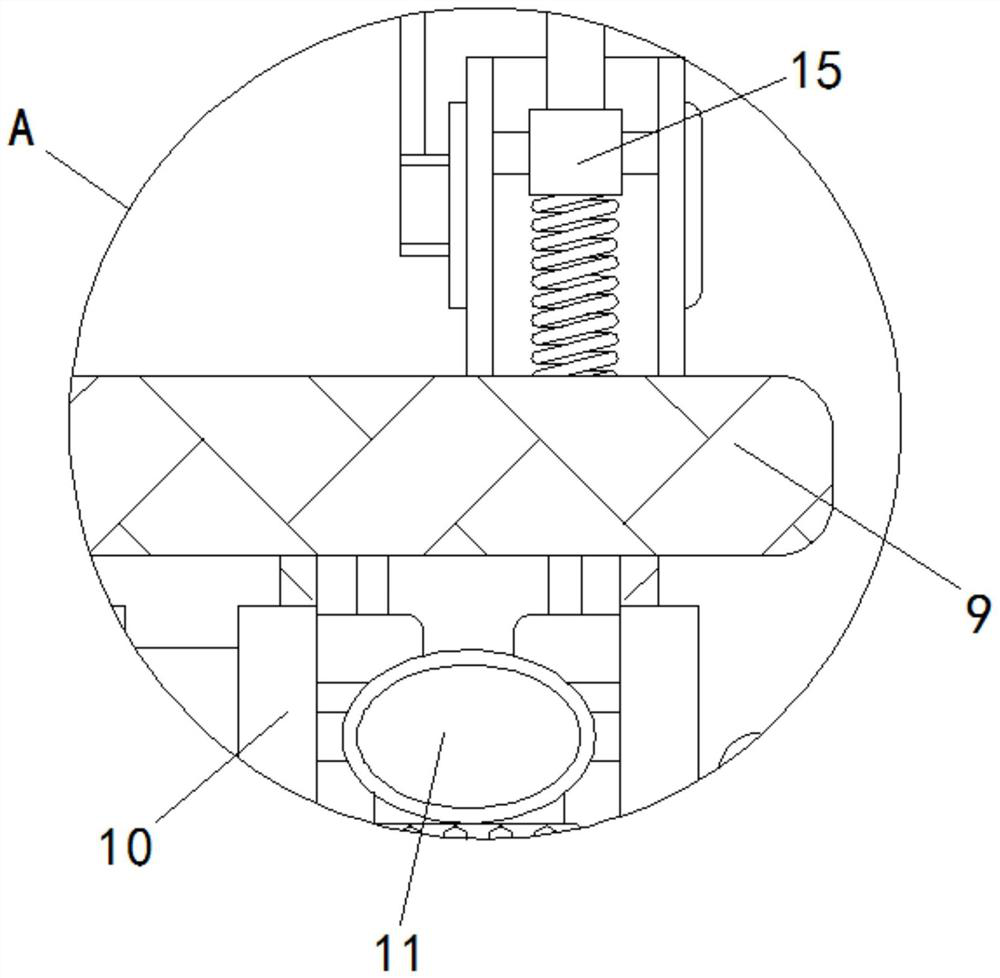

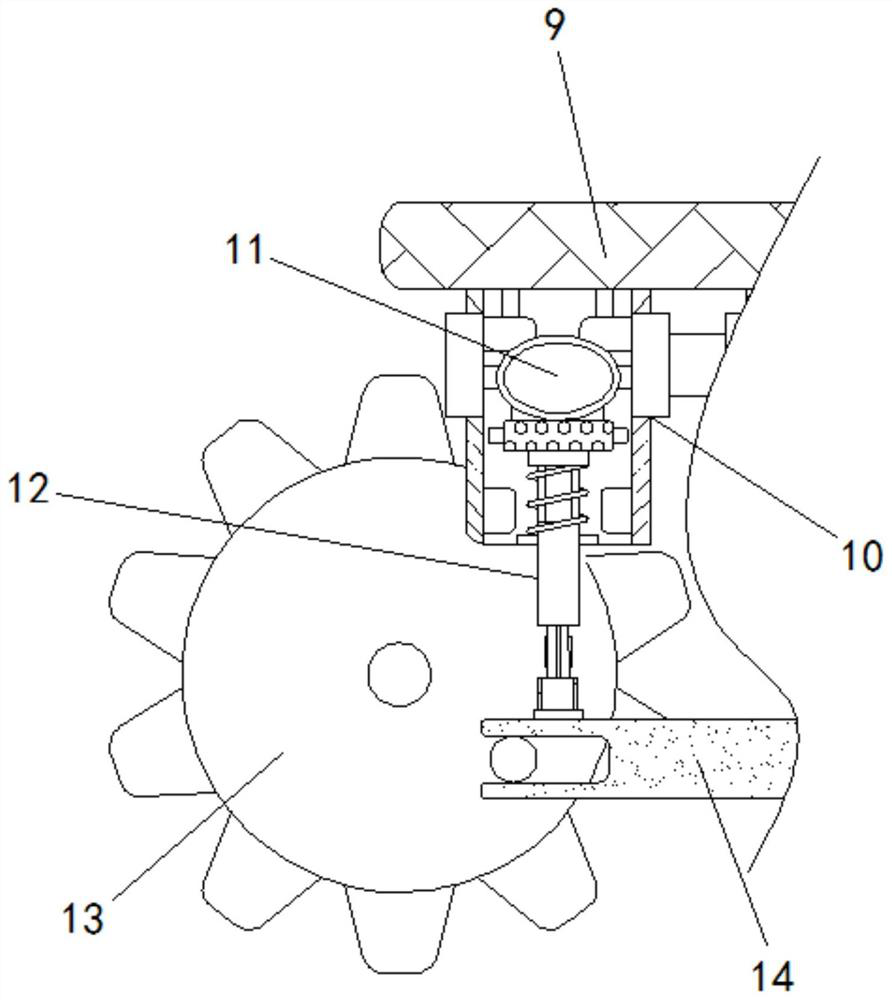

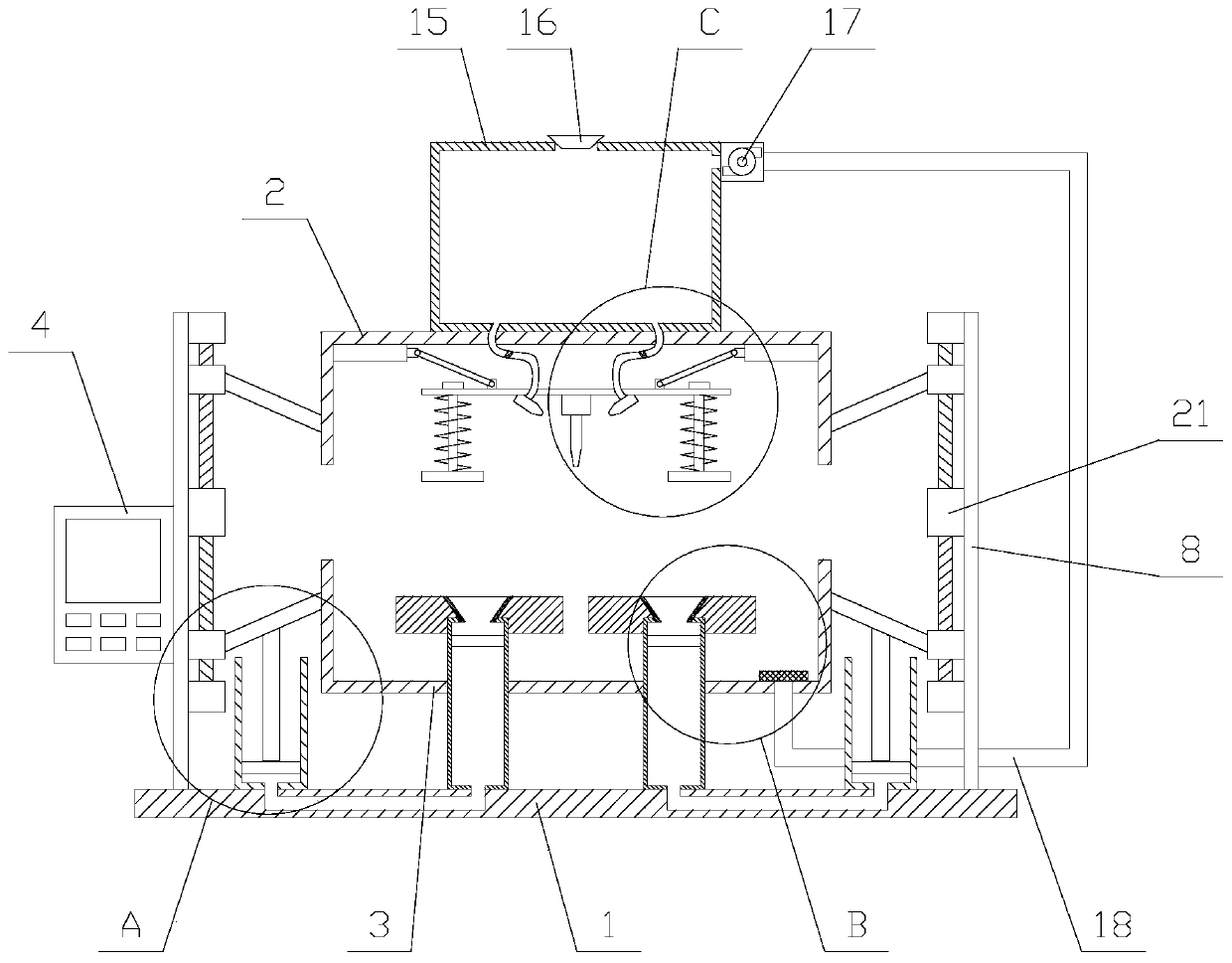

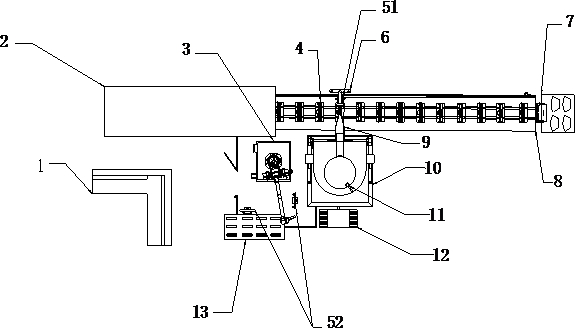

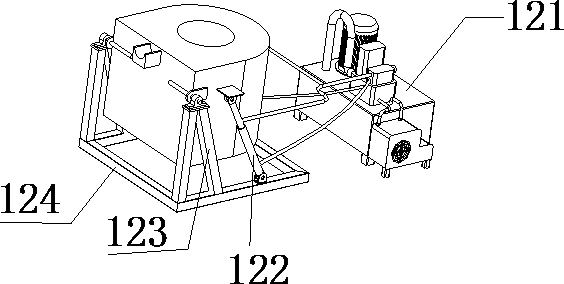

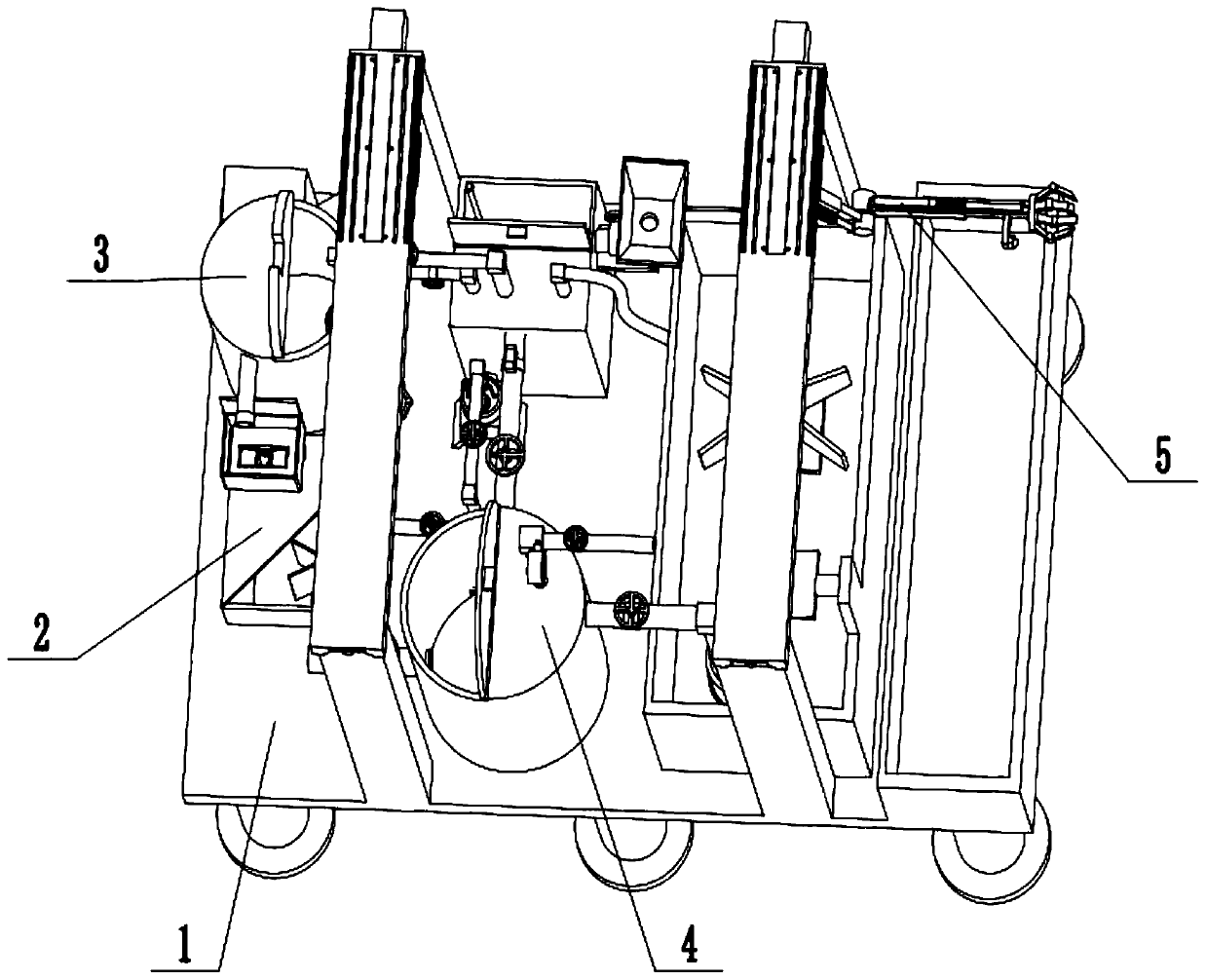

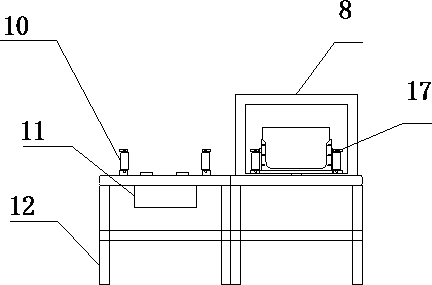

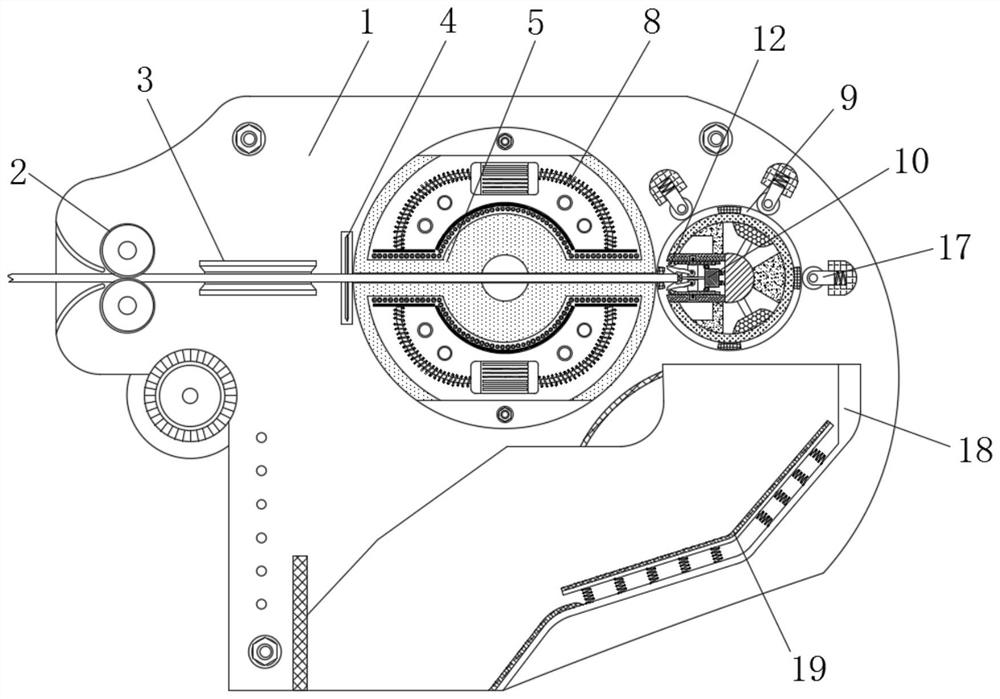

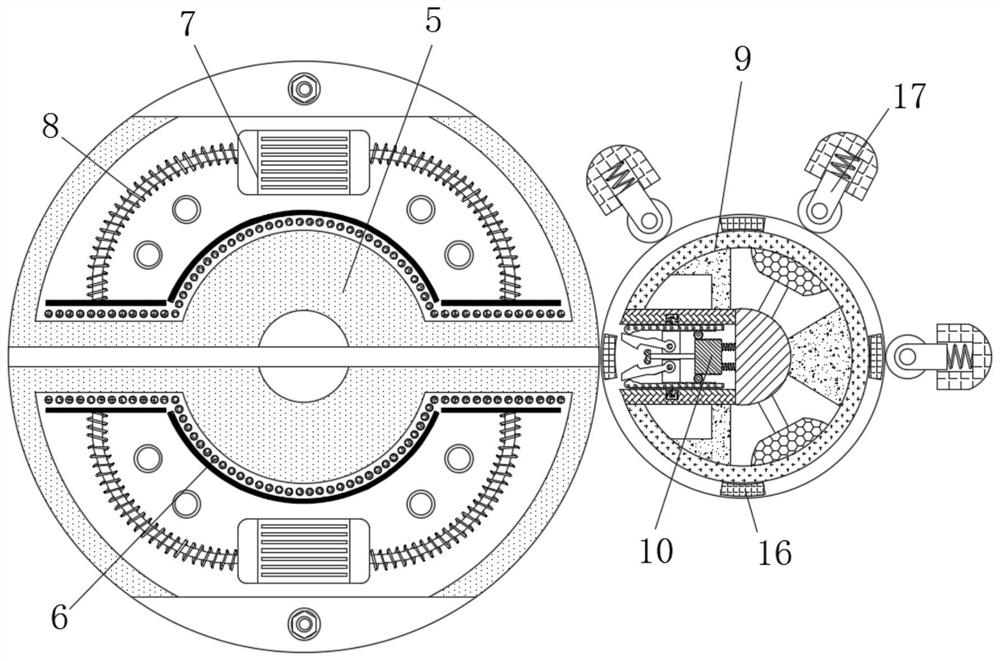

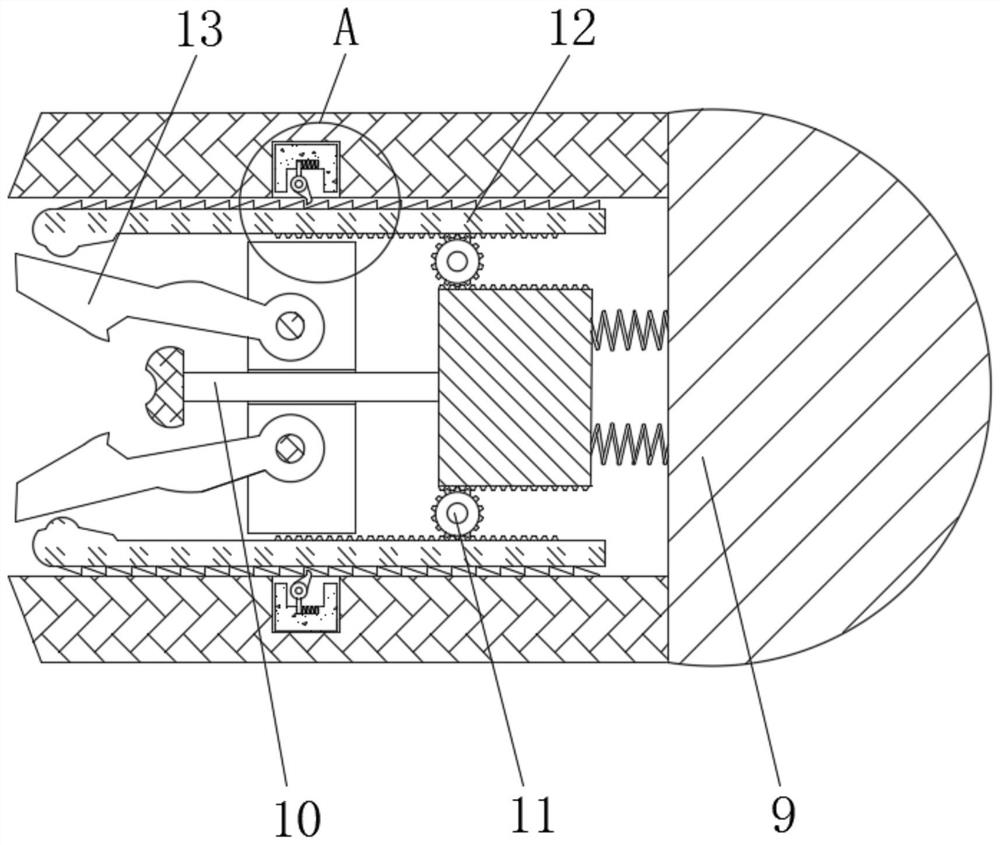

Fully-automatic safe bone sawing machine adopting double knives and multiple knives to perform successive cutting and control method thereof

InactiveCN112544671AEnsure processing safetySave manpower and material resourcesMeat holding apparatusMeat shaping/cuttingAutomatic processingBiomedical engineering

The invention relates to the technical field of meat processing, and specifically relates to a fully-automatic safe bone sawing machine adopting double knives and multiple knives to perform successivecutting and a control method thereof. The bone sawing machine includes a frame; two sets of x-axis lateral movement mechanisms are horizontally installed on the top of the frame; each set of the x-axis lateral movement mechanisms is provided with two sets of movable sliding tables; y-axis longitudinal movement mechanisms are installed between the corresponding movable sliding tables on the two sets of the x-axis lateral movement mechanisms; z-axis vertical movement mechanisms are installed on the sliding tables of the y-axis longitudinal movement mechanisms; compound clamping tools are fixedly installed on the bottom ends of the z-axis vertical movement mechanisms; the lower part of the frame is provided with a feeding conveyor; and the discharging end of the feeding conveyor is providedwith an infrared transducer used for detecting materils. The provided bone sawing machine can realize the automatic processing of frozen meat (bones), so the required manpower costs can be reduced; and therefore, the bone sawing machine is suitable for further promotion and application.

Owner:FUJIAN UNIV OF TECH

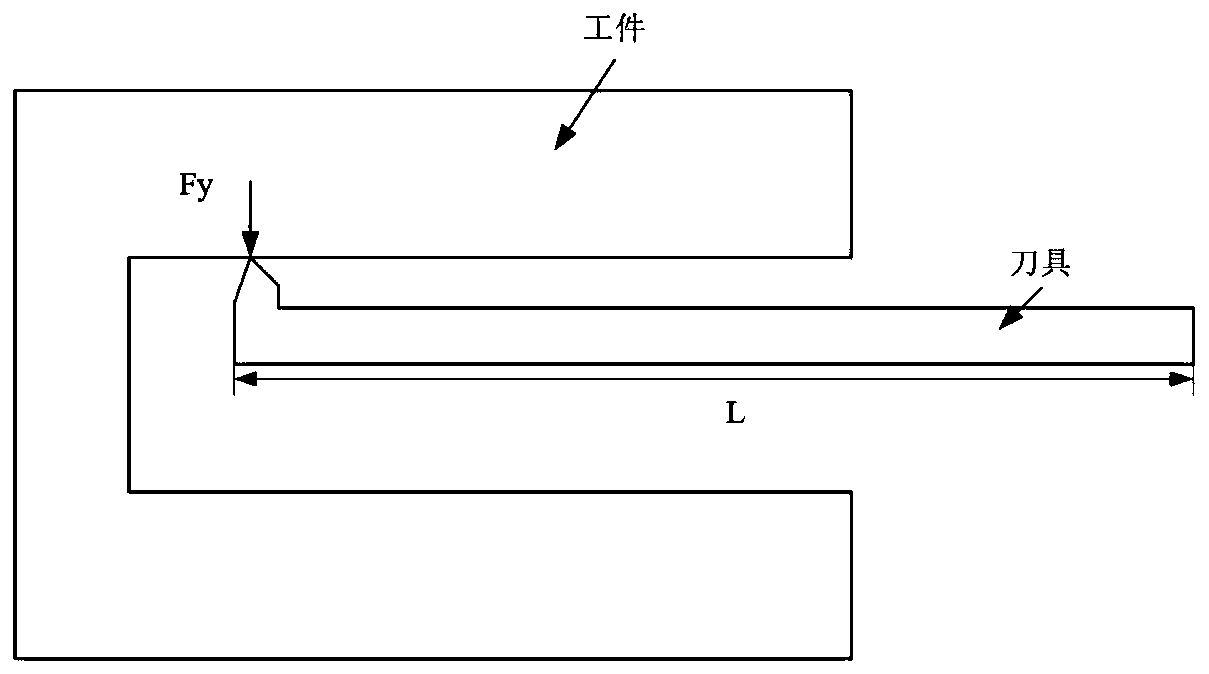

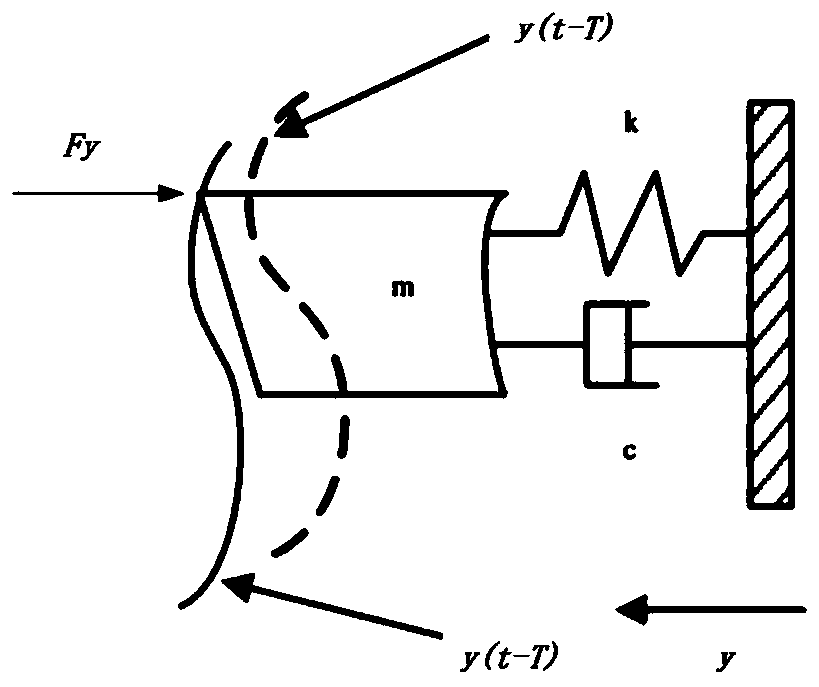

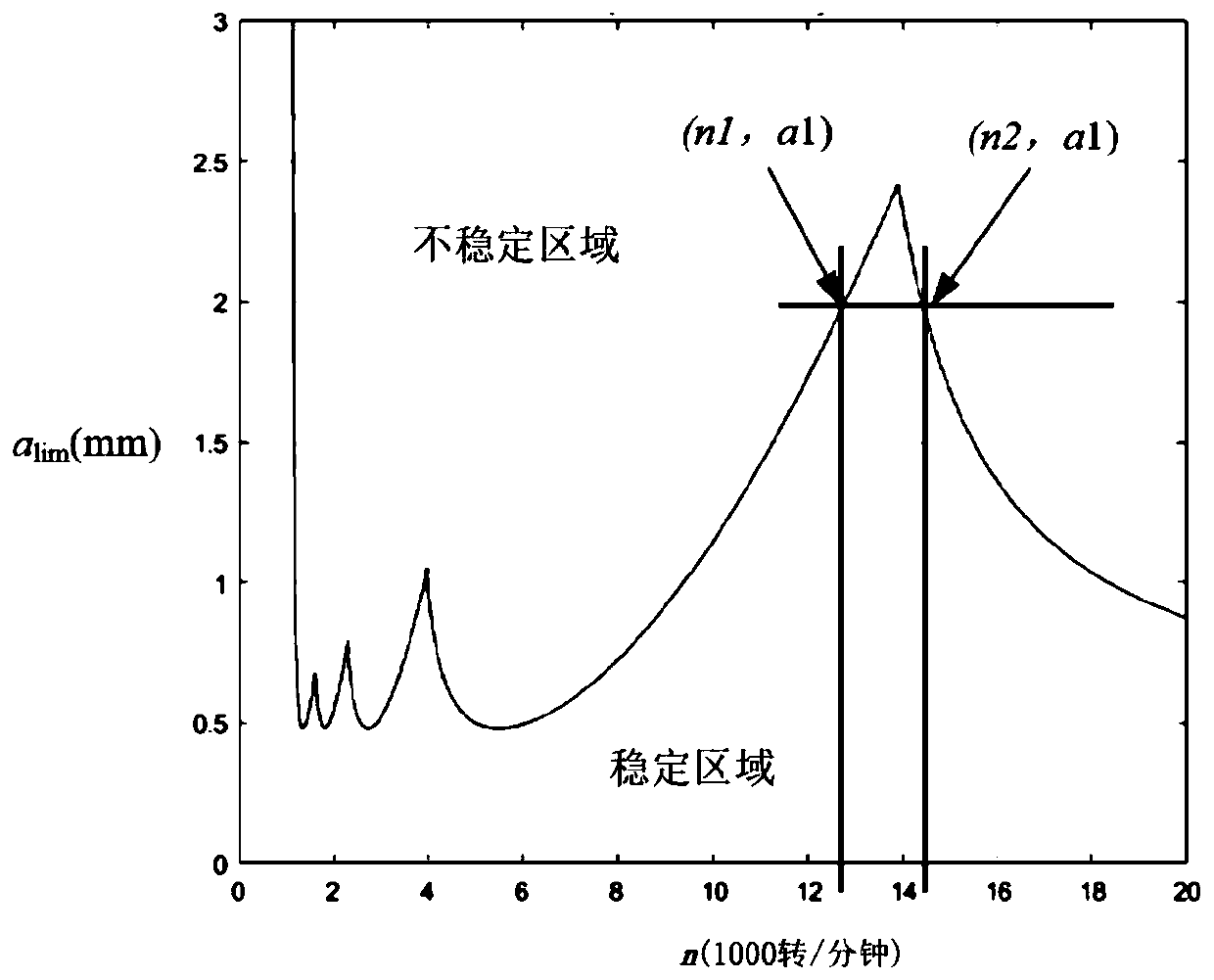

Monitoring method of tool state in deep hole inner thread machining

InactiveCN110712066AEasy to modify the processing methodImprove machining accuracyThread cutting machinesMeasurement/indication equipmentsMonitoring methodsIndustrial engineering

The invention discloses a monitoring method of a tool state in deep hole inner thread machining. On the basis of a kinetic model and a stable area thereof in the cutting process, the relation betweenvibration energy in a special frequency band and tool wear is built. The method can be used for monitoring the tool wear state in the deep space inner thread, a machining method can be conveniently modified, machining precision is improved, and machining safety is ensured.

Owner:HUNAN INST OF TECH

Bamboo splitter

InactiveCN101920509AAvoid stickingEnsure processing safetyVeneer manufactureVertical planeEngineering

The invention relates to a bamboo splitter comprising a stand, a panel is arranged on the stand and sequentially provided with a height limiting device, a feeding device, a pressure assisting device, a splitting device and a restraint device, wherein the splitting device is arranged on a transmission box and comprises an upper saw group device and a lower saw group device; the upper saw group device and the lower saw group device both comprise saw group shafts; each saw group shaft is sequentially provided with a positioning baffle plate, a saw blade and a spacer; and the tail ends of the saw group shafts are compacted and positioned by double round nuts. The invention has the advantages of being capable of splitting a higher bamboo board (with the height of more than 55 mm), preventing the bamboo board from being clamped in the splitting device through the height limiting device and reducing the vibration of the bamboo board in the splitting process through the pressure assisting device, thereby ensuring the pressure assisting accuracy of the bamboo board; and in addition, the invention restrains the tail end of the bamboo board through the restraint device and prevents the vertical plane of the bamboo board from being dislocated after splitting, thereby ensuring the output rate of bamboo sheets.

Owner:ZHEJIANG UNIV OF TECH

A bamboo cutting machine with fixed length for lantern production is disclosed

InactiveCN108890785APrevent the phenomenon of detaching from the third fixing memberTimely transportGripping devicesCane mechanical workingFixed frameEngineering

The invention discloses a fixed-length bamboo cutting machine for lantern production, which comprises a base, a first work table, a second work table, a cutting device, a first fixing part and a second fixing part. The cutting device comprises a frame, a moving member, a third fixing member, a fixing member, a first driving mechanism, a second driving mechanism, a pressing member and a knife assembly. The first worktable is inclined on the base, the second worktable is horizontally arranged on the base, and the first worktable and the second worktable are connected and arranged; The cutting device is arranged on the first workbench, and the moving part is slidably arranged on the first workbench. The third fixing part is arranged on the moving part, and the third fixing part is provided with a cutting groove; The machine frame is arranged on the movable part, and the fixing frame is arranged on the top of the machine frame. A first driving mechanism and a second driving mechanism are arranged at the bottom of the fixture. The invention only needs one positioning, can obtain the fixed length cutting of the bamboo, does not need repeated measurement, saves labor, is simple in operation and convenient in use.

Owner:望江县红和木业灯饰有限公司

Drum brake pad abrasion line processing equipment

PendingCN110293472ALabor savingFast processingGrinding machinesGrinding feedersSlide plateEngineering

The invention discloses drum brake pad abrasion line processing equipment which comprises a feeding conveyor belt, a tableting device, a grinding machine, a rotating table, a discharging sliding plateand a workbench, wherein the grinding machine and the rotating table are arranged on the workbench; the rotating table is arranged close to the grinding machine; dialing bulges are uniformly arrangedon the side wall of the rotating table; a rotating motor connected with the rotating table is arranged in the workbench; the feeding conveyor belt and the discharging sliding plate are correspondingly arranged on two sides of the rotating table; a bracket is arranged between the feeding conveyor belt and the rotating table; first baffle plates are arranged on two sides of the bracket; a second air cylinder used for pushing brake pads is arranged below the feeding conveyor belt; second baffle plates are arranged on two sides of the end, close to the rotating table, of the discharging sliding plate; pulling pieces are arranged between the first baffle plates and the second baffle plates, and positioned between the rotating table and the grinding machine; a dialing hole is formed in the discharging sliding plate; a first air cylinder is arranged below the discharging sliding plate; and a pulling block is arranged at the end part of the first air cylinder and matched with the dialing hole.

Owner:山东梁山耐驰汽车零部件有限公司

Intelligent manufacturing and machining table for precision part trepanning

ActiveCN112692335AAvoid high temperature deformationGuarantee processing qualityPositioning apparatusBoring/drilling componentsRubber sheetMachining process

The invention relates to the technical field of hardware machinery, and discloses an intelligent manufacturing and machining table for precision part trepanning. The intelligent manufacturing and machining table comprises a shell, a rotating screw is connected to each of the left part and the right part of an inner cavity of the shell in a rotating mode, the upper parts of the rotating screws are sleeved with sleeves in a sliding mode, closed curved grooves are formed in inner cavities of the sleeves on the surfaces of the upper parts of the rotating screws, a bearing plate is fixedly connected between the sleeves, rotating rings are connected to the top ends of the sleeves in a rotating mode, and symmetrical movable strips are movably connected between the sleeves and the side wall of the inner cavity of the shell. According to the intelligent manufacturing and machining table for precision part trepanning, parts are fixed between a rubber plate and a placement plate, in the machining process, the rotating screws are made to rotate automatically by utilizing downward force applied to the placement plate by a user, an air pressure bag are extruded by utilizing an abutting column to cool the parts, and therefore the machining quality of the corresponding parts is effectively guaranteed, and the machining safety of the parts is effectively guaranteed.

Owner:上海冈匠精密五金制品有限公司

Method and device for slitting plank

InactiveCN103056928AEnsure processing safetyQuality assuranceCircular sawsGear driveEnvironmental quality

The inventing discloses a method and a device for slitting plank. A transmission gear drives a pinch roller assembly to rotate, and the transmission gear presses the plank tightly and drives the plank to rotate through the pinch roller assembly, and then the plank is cut into strips by a cutting disk assembly. The method and the device for slitting the plank need not pressing through manpower, thus processing safety of workers is ensured and labor intensity of the workers is reduced. The pinch roller drives the plank to move at constant speed so that slitting quality is improved. A plurality of cutting disks slit one plank simultaneously and can cut the plank into a plurality of strips one time, and thus processing efficiency is improved greatly. A collecting cover is used for recycling the bits of wood, thus not only is environmental quality improved, but also energy is saved.

Owner:董金奎

A process for improving the scorch performance of neoprene rubber compound

The invention discloses a process for improving chloroprene mixed rubber scorching performances. The mixed rubber comprises, by weight, a masterbatch ingredient comprising 70-100 parts of chloroprene rubber, 1-3 parts of a promoter, 0.5-2 parts of stearic acid, 1-3 parts of protection wax, 1-3.5 parts of an antiager OCT, 20-80 parts of fast extruding furnace black N550, 20-70 parts of semi-reinforcing furnace black N774 and 10-50 parts of dioctyl sebacate, and an auxiliary material ingredient comprising 1-3 parts of an antiager 3100, 1-2.5 parts of an antiager 4010NA and 2-10 parts of a vulcanizing agent. The mixing process comprises 1, initial stage mixing and 2, tail stage auxiliary material addition and mixing. Compared with the existing mixing process, the process provided by the invention improves mixing processes, changes a material use order by prior use of a part of the promoter and later use of all vulcanizing agent and a part of antiagers in masterbatch preparation to improve mixed rubber scorching time, and guarantees a mixed rubber transport and storage period and processing safety.

Owner:NANJING ORIENTLEADER TECH CO LTD

Punching device having protection function

The invention relates to a punching device having a protection function. The punching device having the protection function comprises a bottom seat, a lower case, an upper case, a placing mechanism, atemperature reducing mechanism, a lifting mechanism, a lifting plate, an electromotor, a drill rod and two vertical plates, wherein the placing mechanism comprises a platform and two support assemblies, the temperature reducing mechanism comprises a water tank, a sealing plug, a backflow pipe, a water pump and a plurality of temperature reducing assemblies, and each temperature reducing assemblycomprises a spray head and a temperature reducing pipe. The punching device having the protection function can drive the upper case and the lower case to move close to each other through a drive mechanism so as to form a sealed processing environment, prevents that chippings spatter and harm surrounding personnel, guarantees processing safety, drives the placing mechanism to fix a workpiece, prevents the workpiece from shaking and offsetting, uses the temperature reducing mechanism to spray out water stream for absorbing heat of the workpiece and the drill rod so as to realize temperature reduction, prolongs life of the drill rod, improves processing accuracy, prevents the water stream from spattering to the exterior due to the fact that the water stream is sprayed in sealed environment, facilitates recycle of the water stream for repeatedly absorbing heat and reducing temperature, and improves practicability of the device.

Owner:南京江宁区上峰国银标准件厂

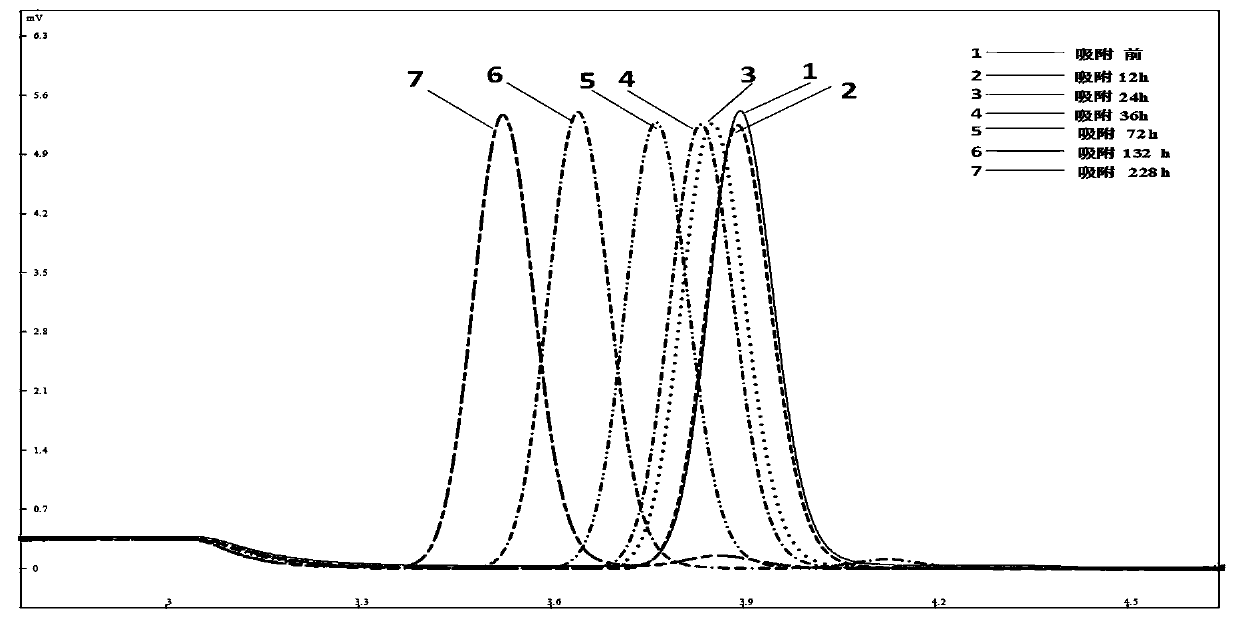

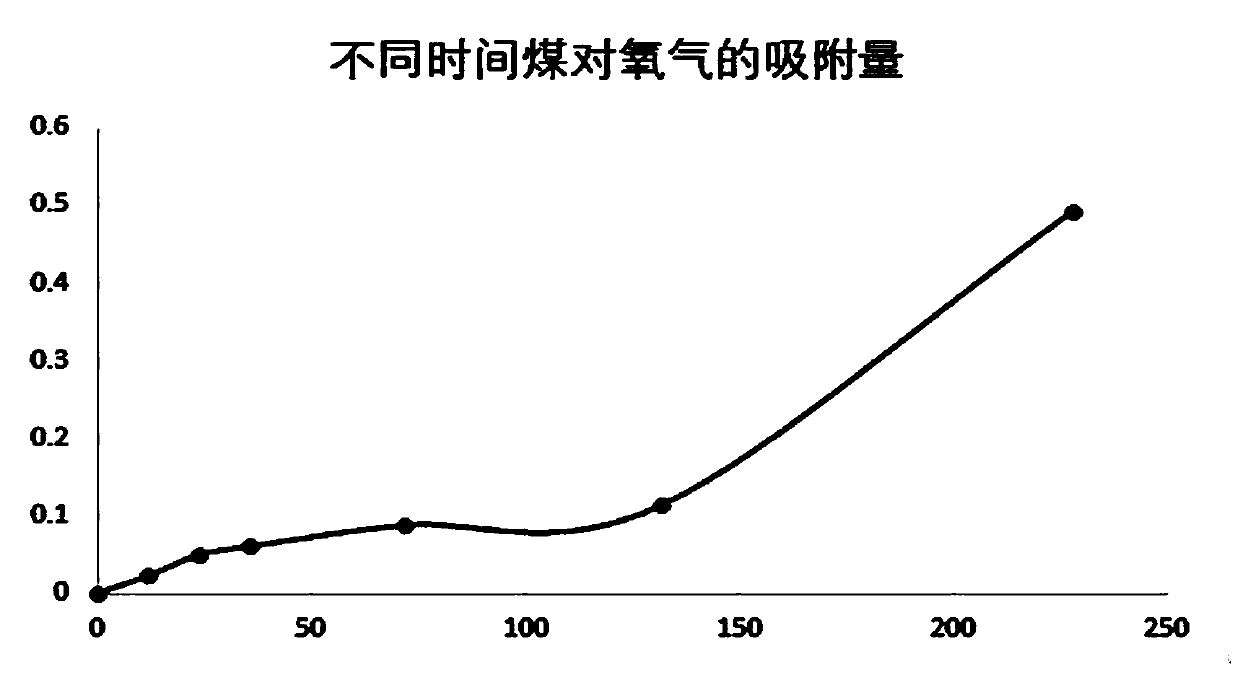

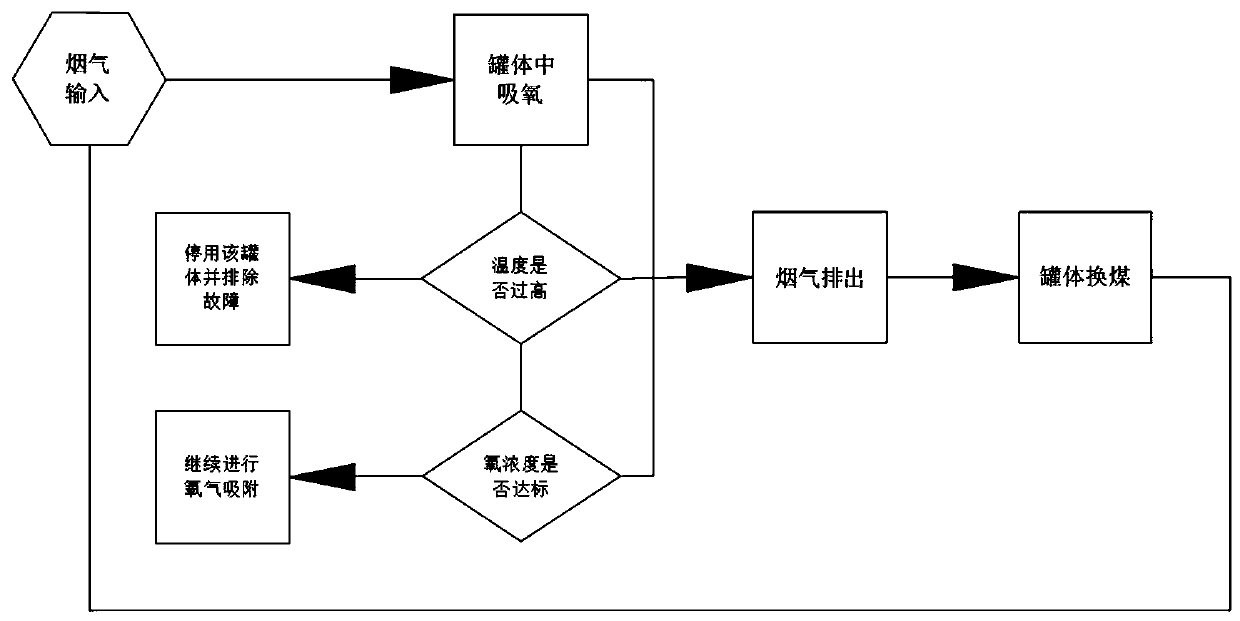

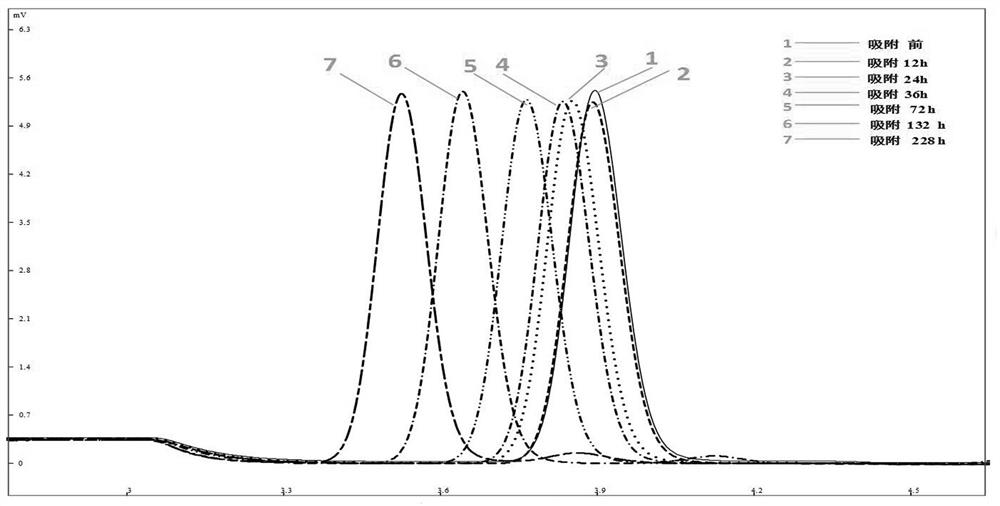

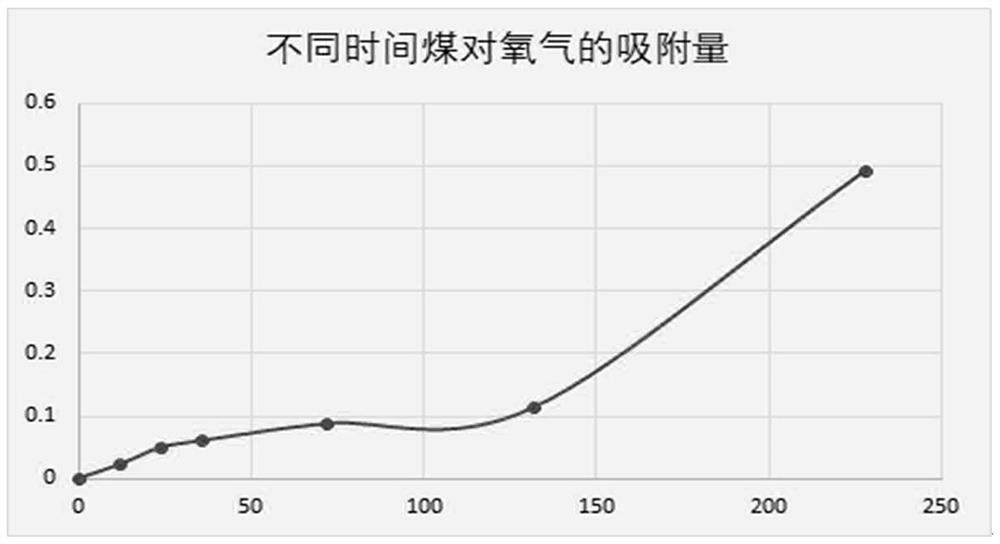

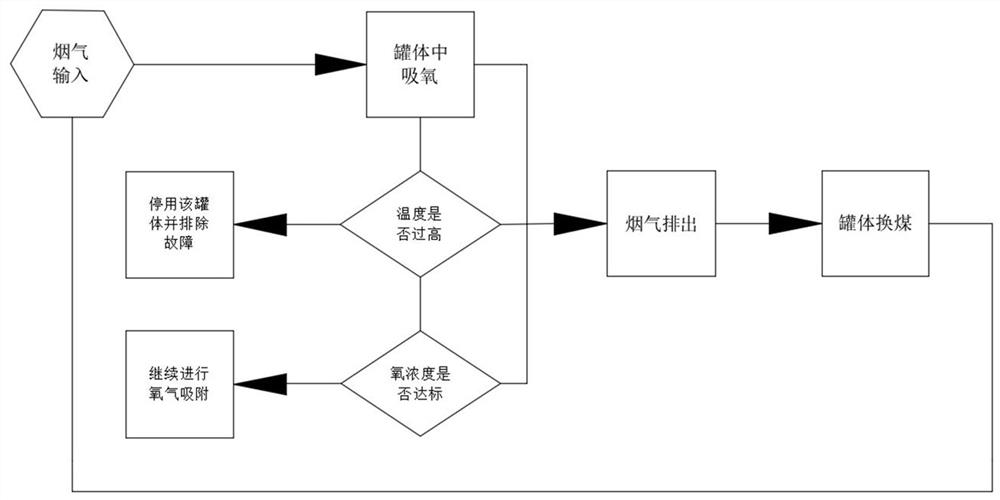

Method for preventing fire and reducing oxygen content in exhaust gas through injecting exhaust gas of power plant in well

ActiveCN110735659ARich in coal resourcesLow costMining devicesDust removalProcess engineeringEnvironmental engineering

The invention discloses a method for preventing fire and reducing oxygen content in exhaust gas through injecting exhaust gas of a power plant in a well. Coal can adsorb oxygen to reduce oxygen content in exhaust gas. Oxygen concentration reduction mainly utilizes 11 coal storage tanks to be cooperated for recycling; according to the normal pressure volumetric method, the coal quantity in one coalstorage tank is obtained through the comprehensively fed exhaust gas quantity, the oxygen content when the exhaust gas is fed and the oxygen content when the exhaust gas is discharged; the tanks carry out four procedures including exhaust gas feeding, oxygen removal, exhaust gas discharging and coal changing sequentially; 11 tanks take turns to carry out the four procedures and are alternately recycled to ensure that exhaust gas is continuously provided for a goaf; the coal storage tanks can conveniently carry out coal loading and unloading operation; as oxygen adsorption by coal does not change the coal nature, the loaded coal is new coal produced by a coal yard, and the unloaded coal can be transported to the power plant as fuel; and coal is adopted to adsorb oxygen to avoid spontaneouscombustion of coal; fire prevention of an underground goaf is carried out on a coal mine, and the coal resource is rich, so that the cost is greatly reduced.

Owner:TAIYUAN UNIV OF TECH

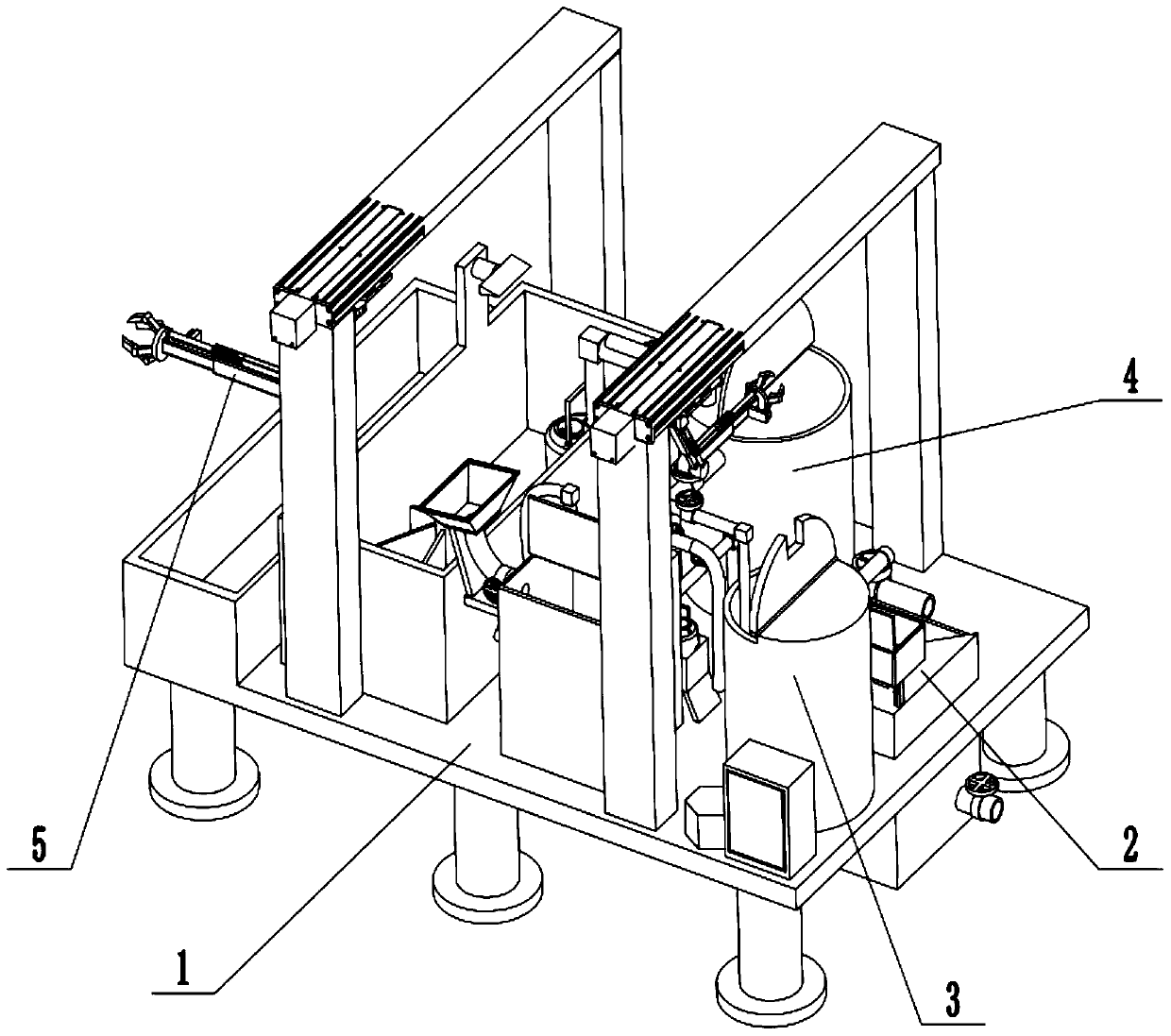

Liquid level interlocking automatic casting system

PendingCN114559021ASimple processEasy to operateMolten metal supplying equipmentsCasting safety devicesProcess engineeringManufacturing engineering

The invention belongs to the field of metal casting, and discloses a liquid level interlocking automatic casting system which comprises a smelting furnace feeding device, a smelting furnace casting device, a mold preheating conveying device and a control unit. The smelting furnace feeding device is used for conveying metal materials to the smelting furnace casting device; the smelting furnace casting device comprises a dumping furnace, a first driving assembly and a liquid level measuring assembly. The first driving assembly is used for driving the dumping furnace to conduct casting into the mold assembly. The liquid level measuring assembly is used for measuring the liquid level in the dumping furnace and the liquid level in the mold assembly. The mold preheating and conveying device is used for preheating the mold assembly, conveying the preheated mold assembly to the casting side of the dumping furnace for casting, and then conveying the mold assembly reaching the casting liquid level to the next procedure. The liquid level linkage automatic casting system is high in treatment efficiency, more flexible and convenient to operate, capable of automatically and continuously operating and treating and simple in later maintenance.

Owner:广东长信精密设备有限公司

A beam bottom maintenance platform capable of spanning bridge piers and obstacle columns and its application method

ActiveCN104358211BAddress limitationsAdaptableBridge structural detailsBridge strengtheningBridge engineeringEngineering

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

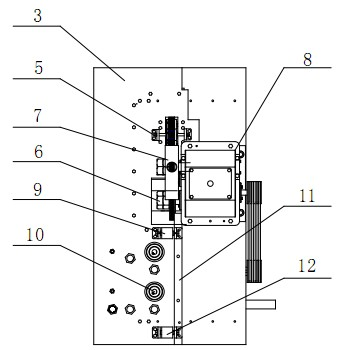

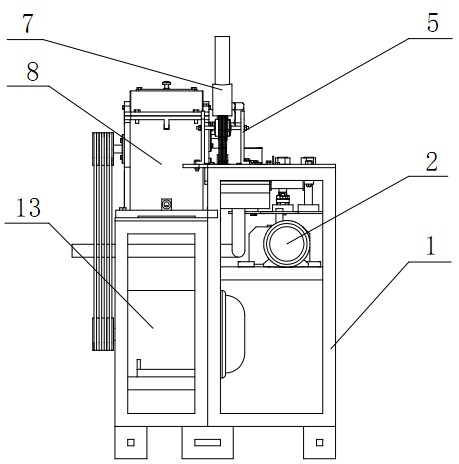

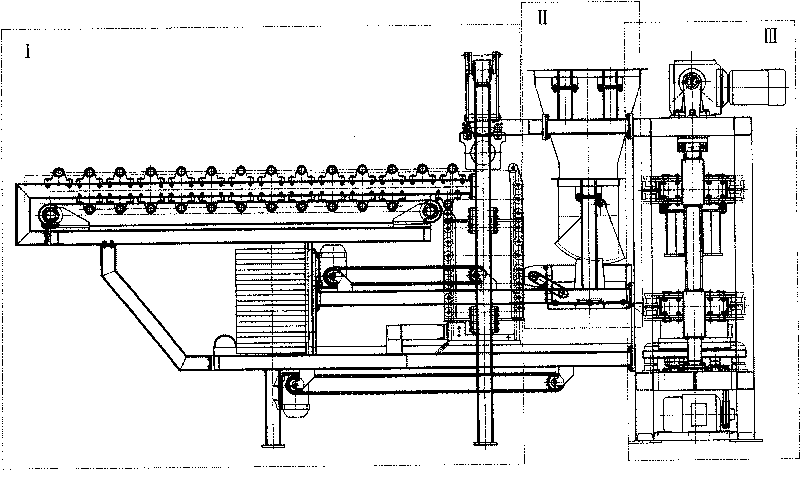

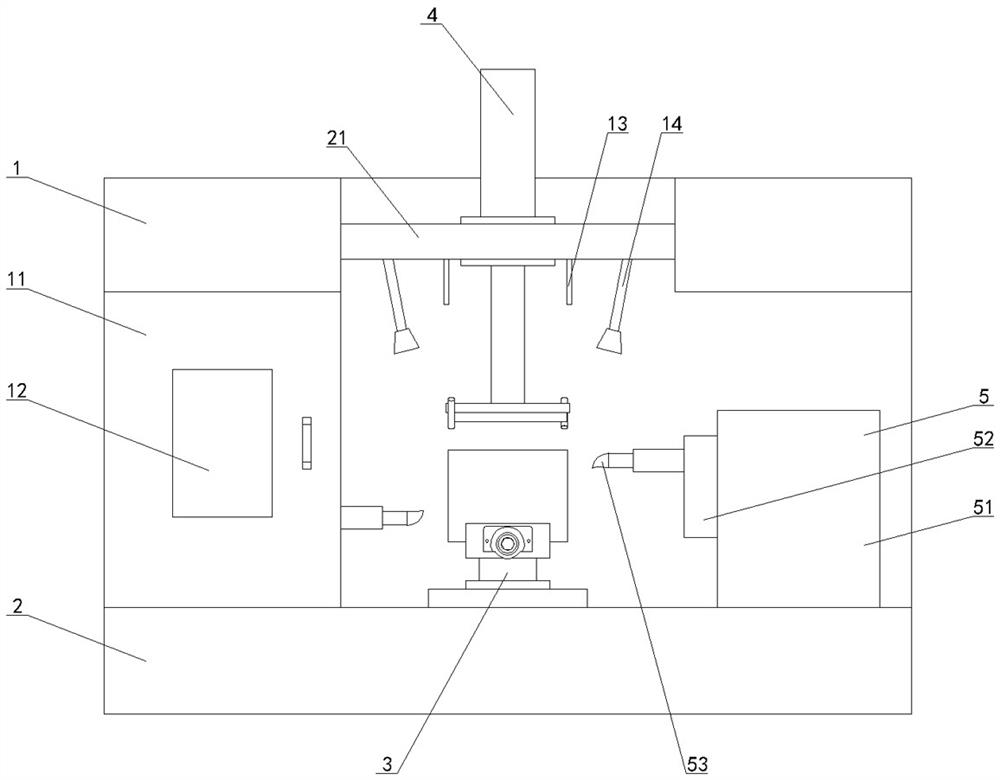

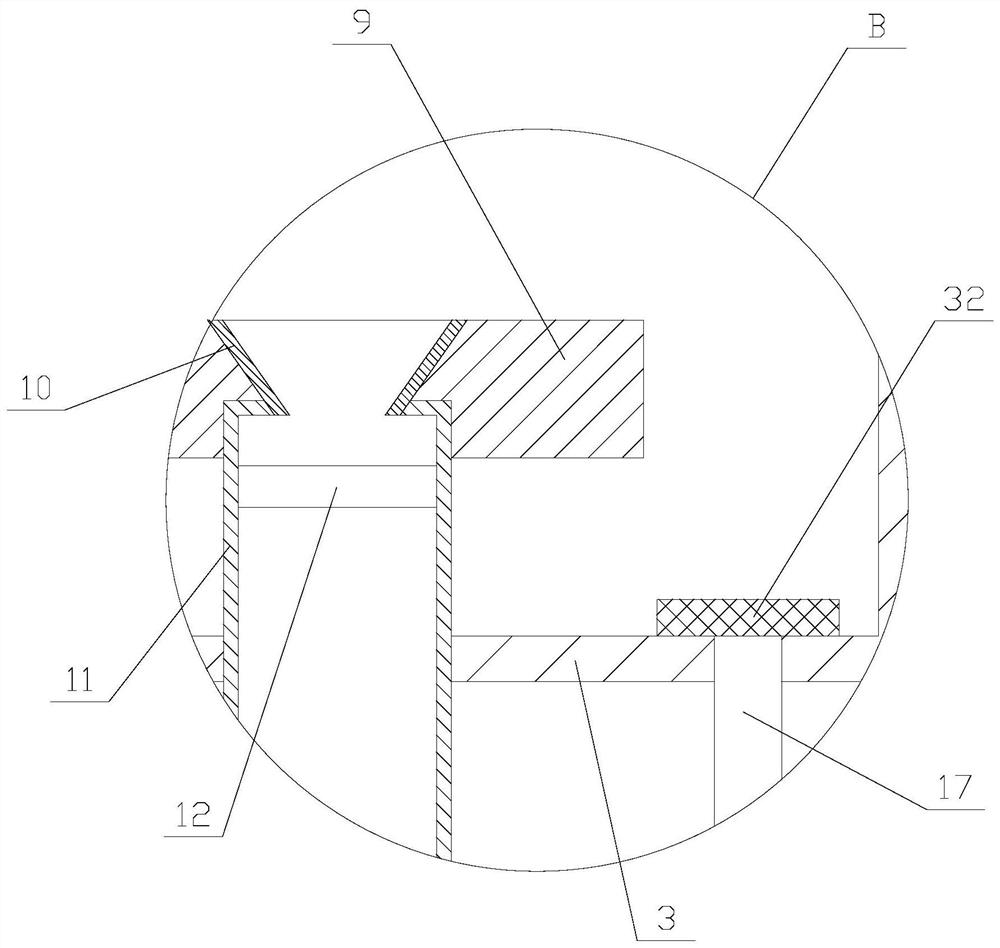

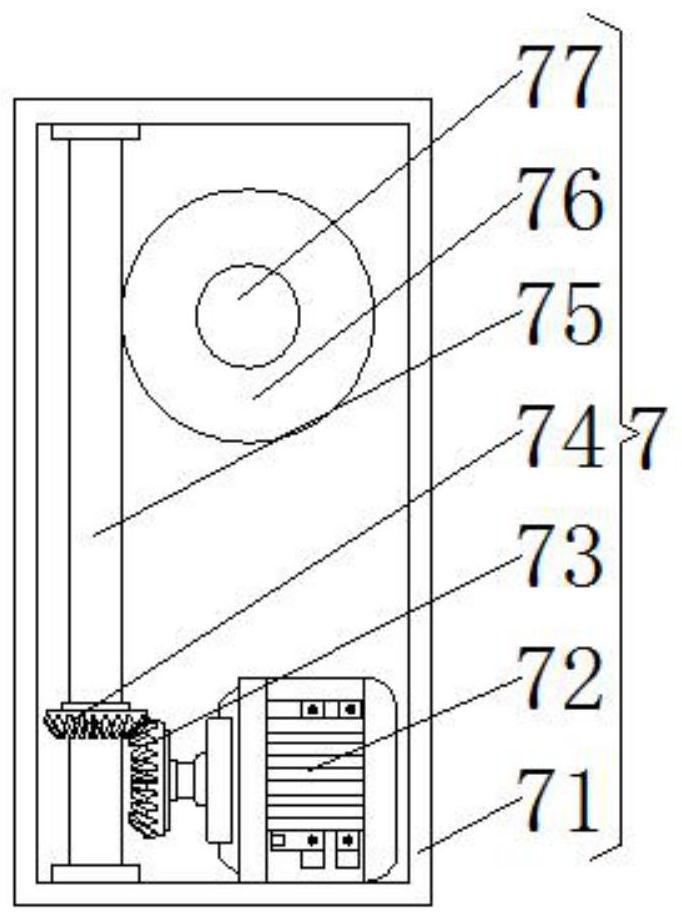

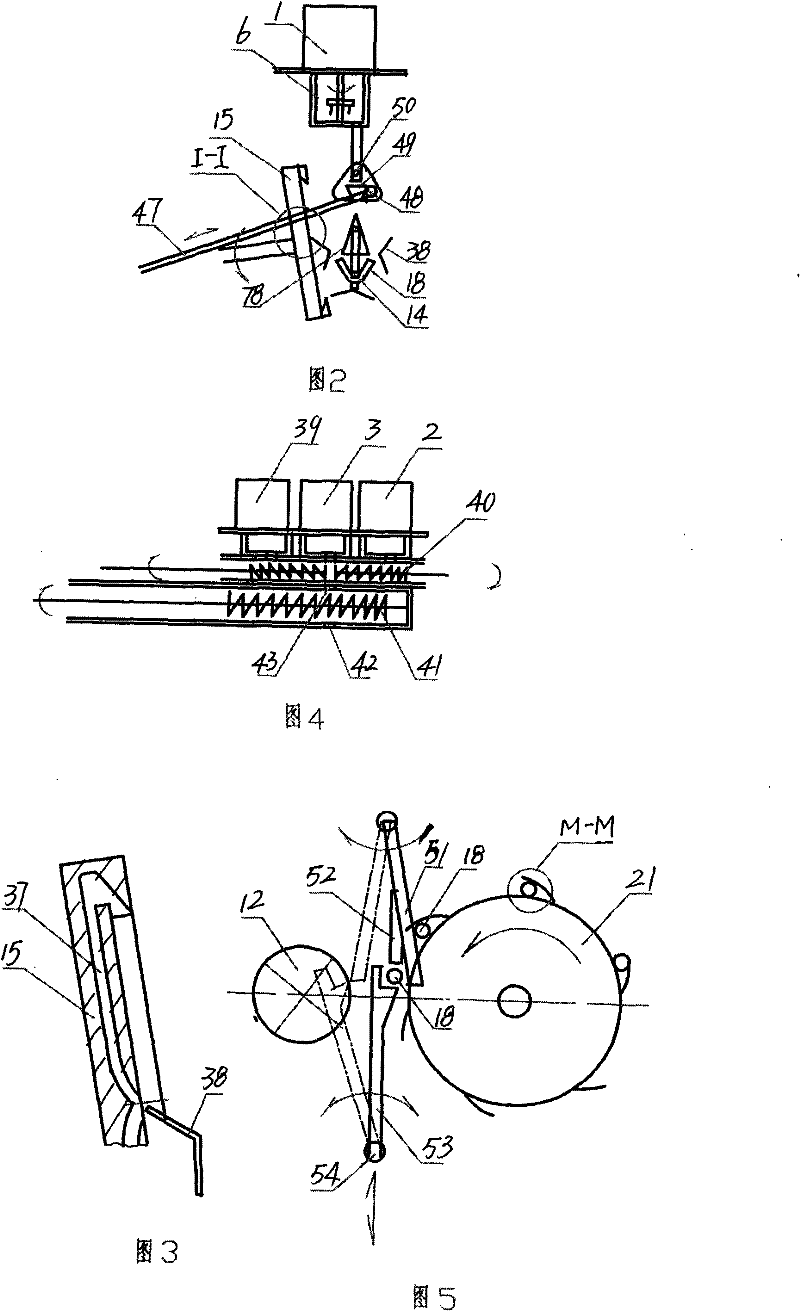

Composite wire-lacing block-building shaping machine

InactiveCN101186079BGuarantee product qualityEnsure processing safetyCeramic shaping plantsFeeding arrangmentsSlagPolystyrene

The invention belongs to the mechanical technical field where mixtures such as sinter, cement, slag, etc. are processed, and formed and removed out of a forming die, in particular to a composite tie bar masonry forming machine of the heat preservation masonry with tie bars suitable for automatic production on a polystyrene board. The invention comprises an automatic plate supply system I, a material supply system II, and a forming host machine III; wherein, the automatic plate supply system I is the creation core of the invention and is horizontally and fixedly provided with a slab transmission frame; the upper part of the slab transmission frame is horizontally provided with a horizontal guide mechanism and an adhesive tape slab conveyor; the front end of the slab transmission frame is vertically and fixedly provided with a vertical guide trough and a vertical guide idler wheel frame; the upper part of the vertical guide trough is provided with a vertical plate press which can only vertically move up and down according to times; the front end of a plate supply vehicle is fixedly provided with a plate clamp which is horizontally positioned. The invention has the advantages of filling up the blank of the technical process in China, effectively and actively prompting the technical conversion of the masonry with tie bars composite into a whole, ensuring the quality of the product,ensuring the safety of the process, and improving production efficiency.

Owner:怀方林

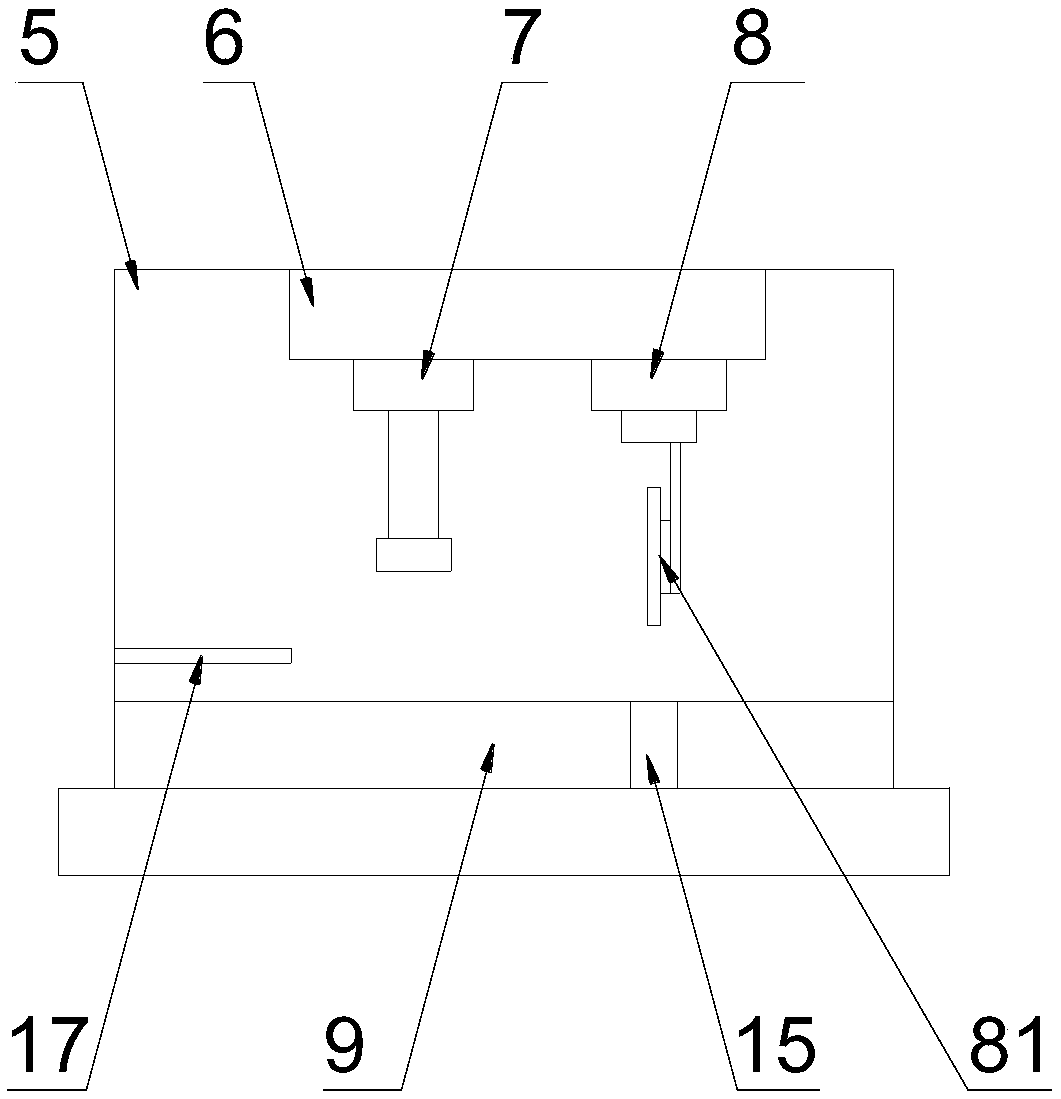

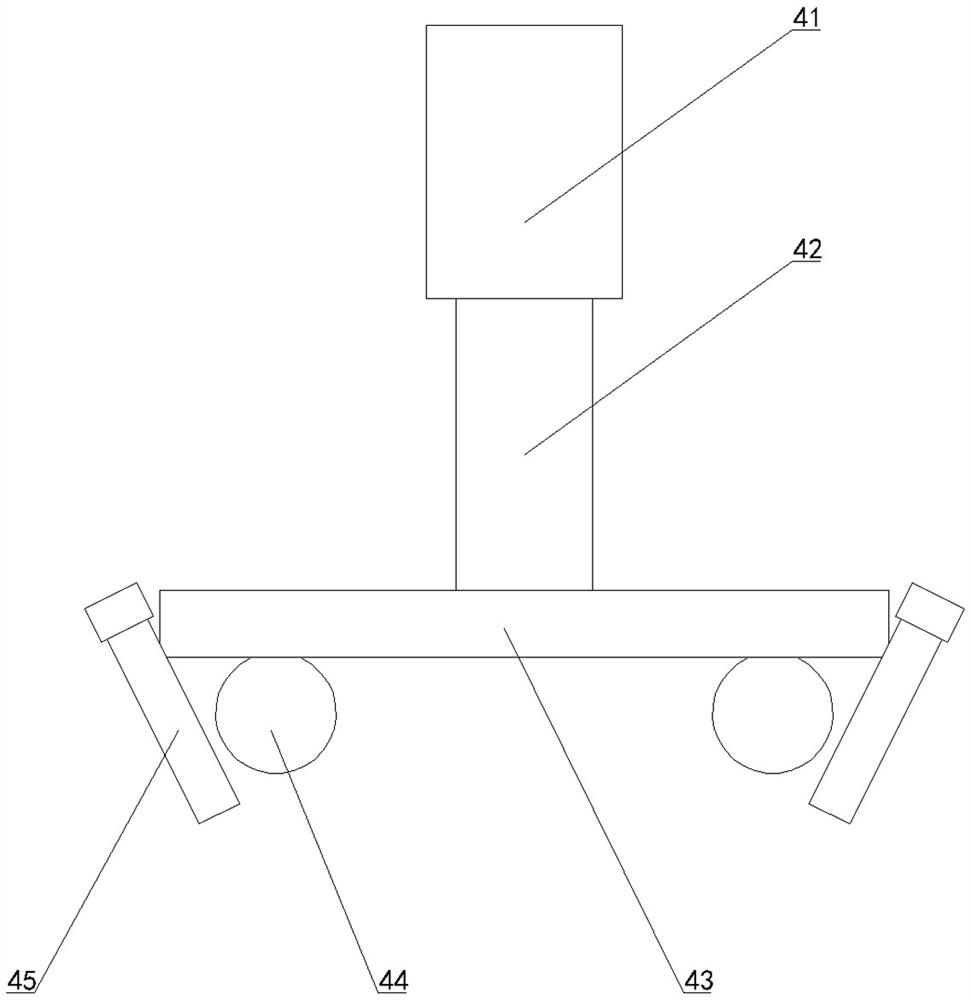

Spring machining tool

PendingCN112059260ASimple structureEasy to useLighting elementsMilling equipment detailsEngineeringMachine tool

A spring machining tool comprises a shell, a frame, a clamping device, a limiting device and machining devices. The shell is arranged outside the frame, a base is arranged below the frame, a first guide rail is arranged above the base, and a crossbeam is arranged above the frame. The clamping device is used for clamping a spring and is arranged in the middle of the first guide rail. The limiting device is used for positioning the spring and is arranged in the middle of the crossbeam. The two machining devices are used for milling the spring and arranged at the two ends of the first guide rail.The limiting device is located over the clamping device. The spring machining tool has the advantages of being simple in structure, convenient to use and capable of milling the two ends of the springsimultaneously and improving the milling efficiency. The spring is fixed through the clamping device and the limiting device, then the two ends of the spring are milled at the same time through the machining devices arranged at the two ends, time is greatly saved, and efficiency is improved.

Owner:JINING XINGFA SPRING

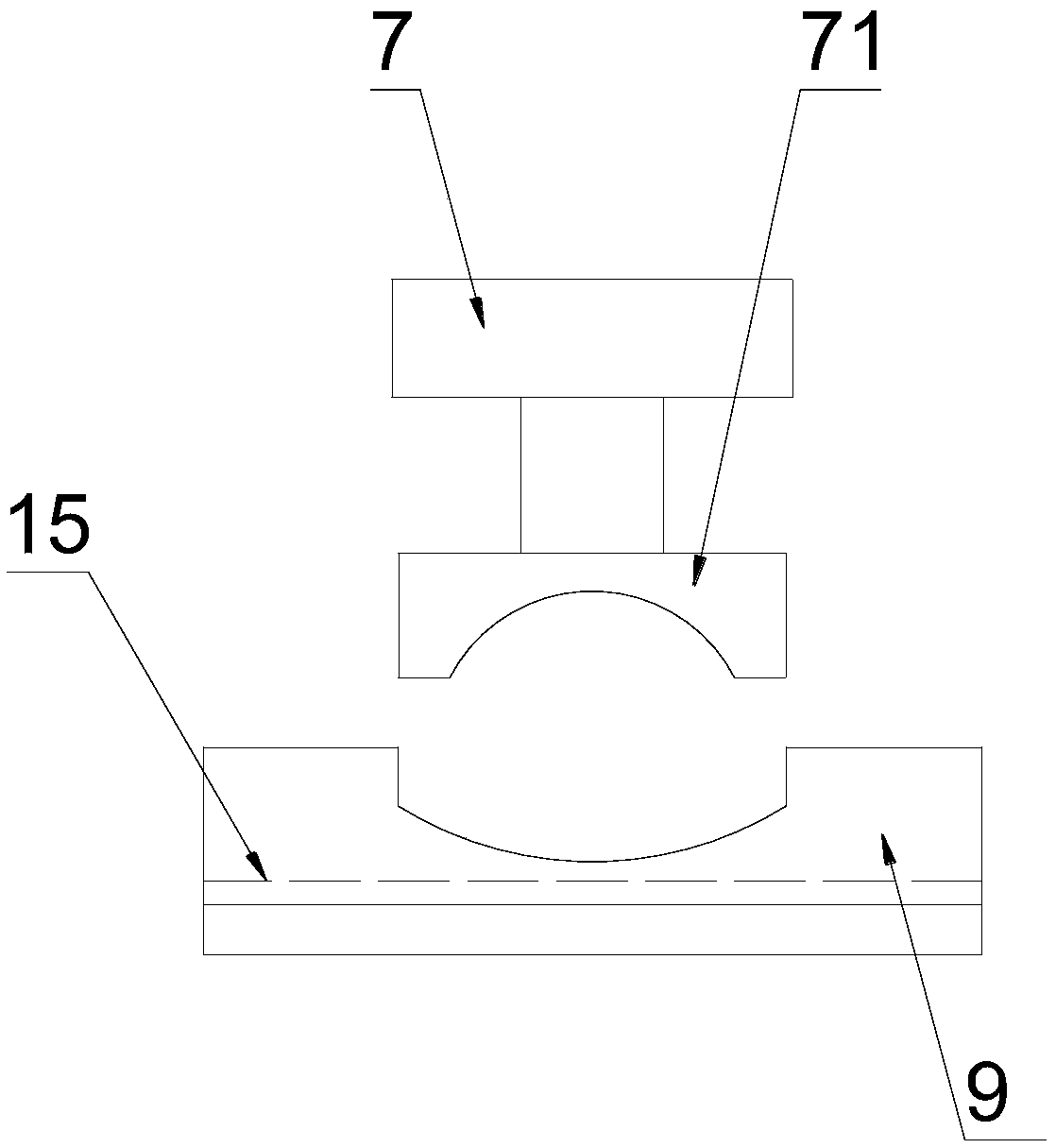

A forging punch die that can reduce workpiece wear

ActiveCN110788211BReduce wearEnsure processing safetyShaping toolsHydraulic cylinderElectric machinery

Owner:QINGDAO HENGLI PACKAGE CO LTD

Device and process for adsorbing precious metal in acid wastewater in gold purifying process

PendingCN110629029AEnsure process safetyReduce drug costsWater contaminantsMultistage water/sewage treatmentChemistryActivated carbon

The invention discloses a device and process for adsorbing precious metal in acid wastewater in the gold purifying process. The device comprises a base, a depositing mechanism, a wastewater purifyingmechanism, an activated carbon purifying mechanism and a mechanical arm. In use, gold-containing acid wastewater is pumped by a second anti-corrosion fluorine magnetic pump into an activated carbon adsorbing tank, the wastewater adsorbed by activated carbon returns into a wastewater storage tank through a pipeline G3, a closed-loop circulating system is formed, the gold in the wastewater is sufficiently adsorbed by the activated carbon, the activated carbon can be converted from acid to alkali so as to meet the requirements of the electrolysis process and ensure the process safety when the grade of the gold contained in the activated carbon in the activated carbon adsorbing tank reaches 4500 g / t or above, the loss of the precious metal in the acid wastewater in a gold purifying workshop iseffectively avoided, work efficiency is improved, labor cost is reduced, workers are prevented from making direct contact with the activated carbon, the operation safety and environment safety are ensured for the workers, and the discharge water of the adsorbed acid wastewater reaches the national sewage discharge standard.

Owner:TIANJIN HUAKAN GRP CO LTD

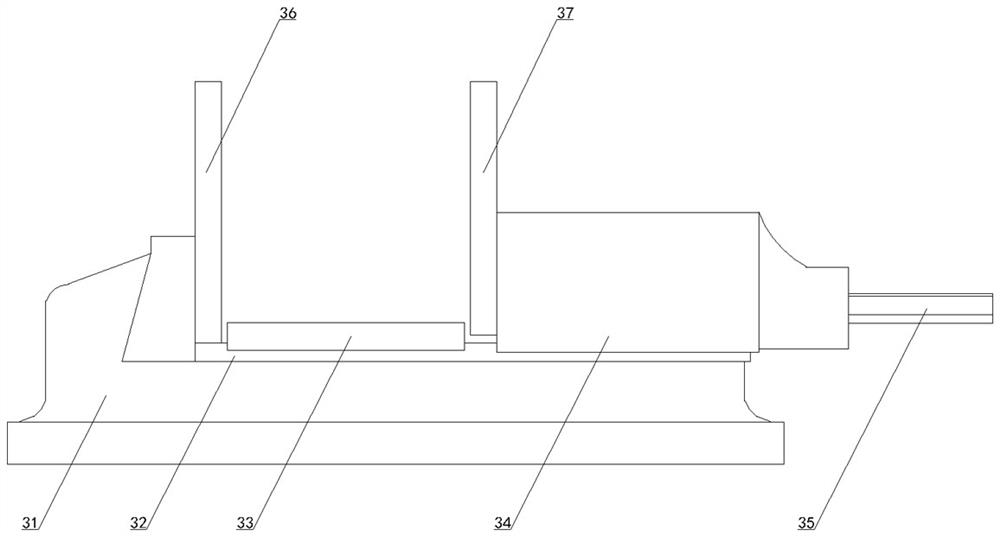

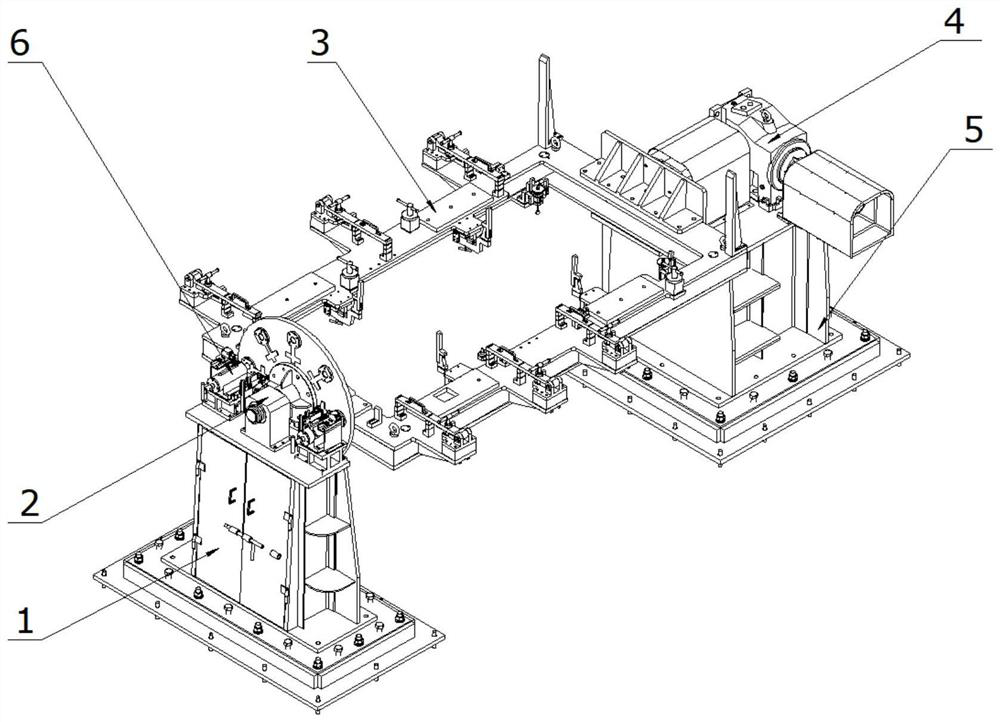

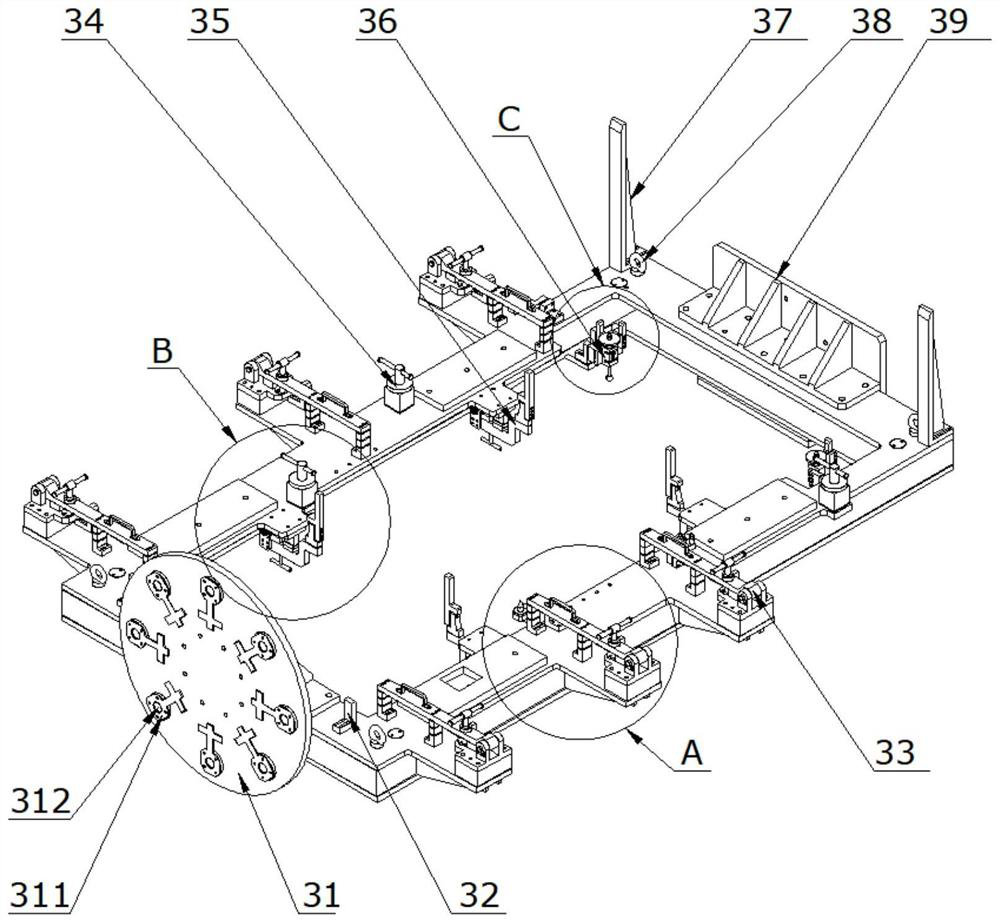

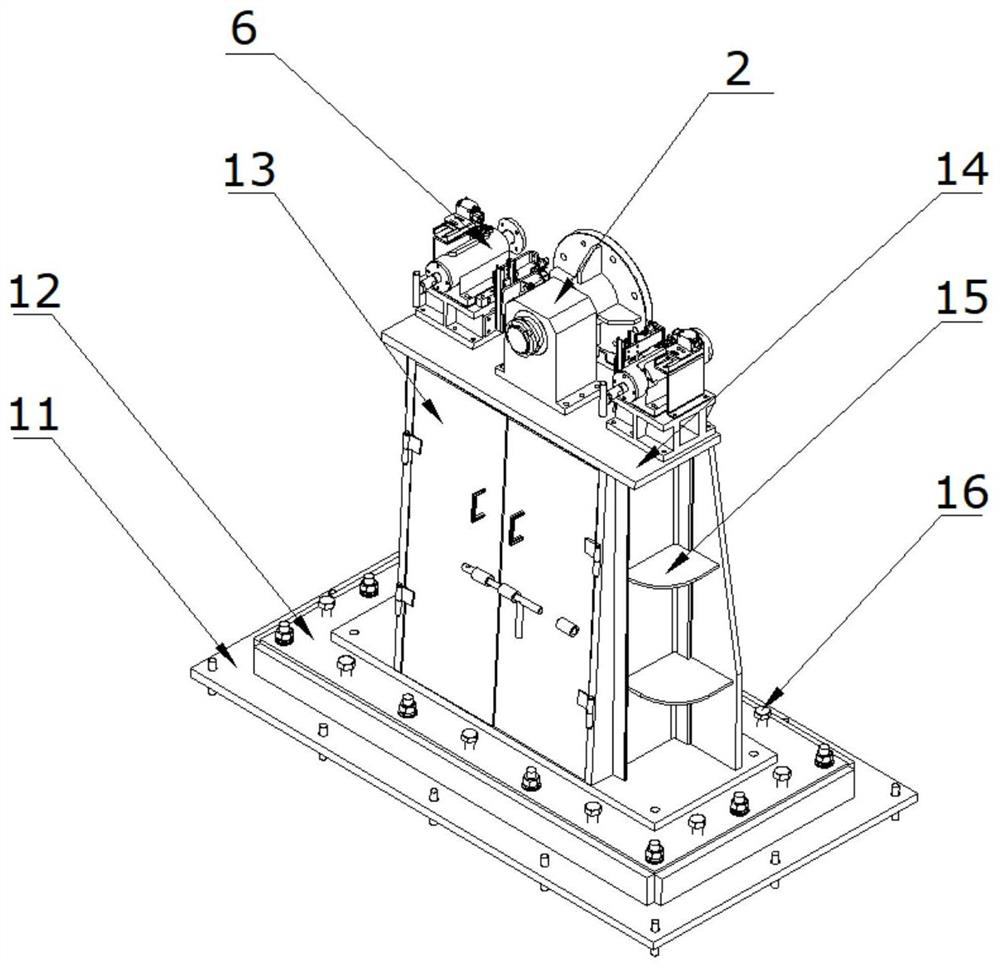

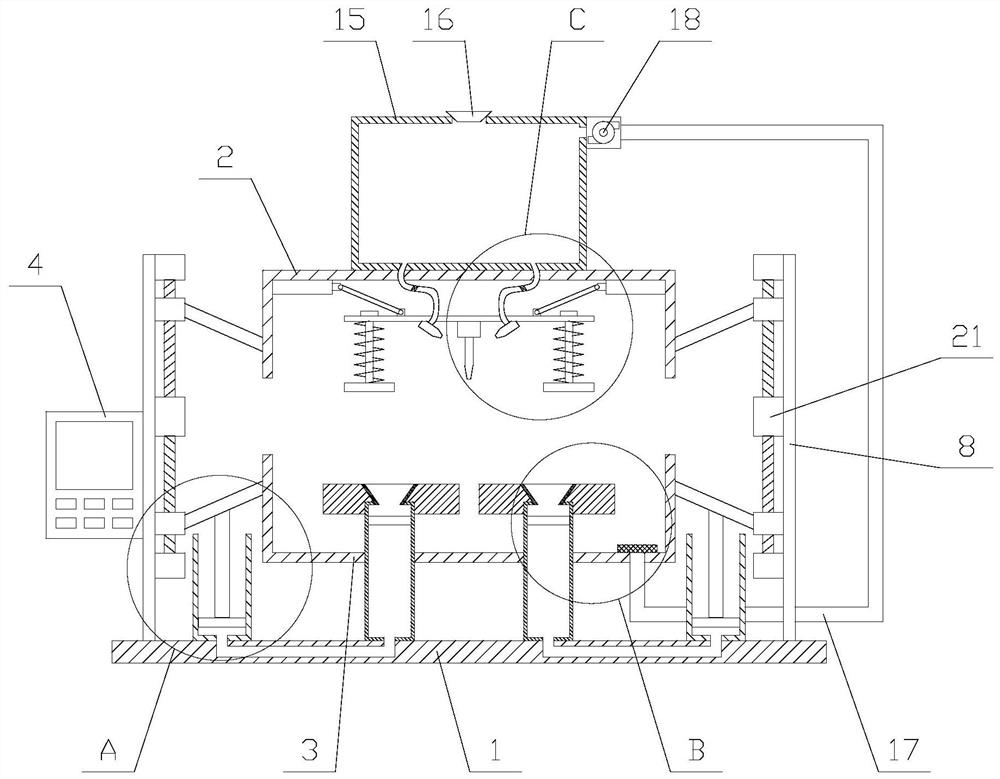

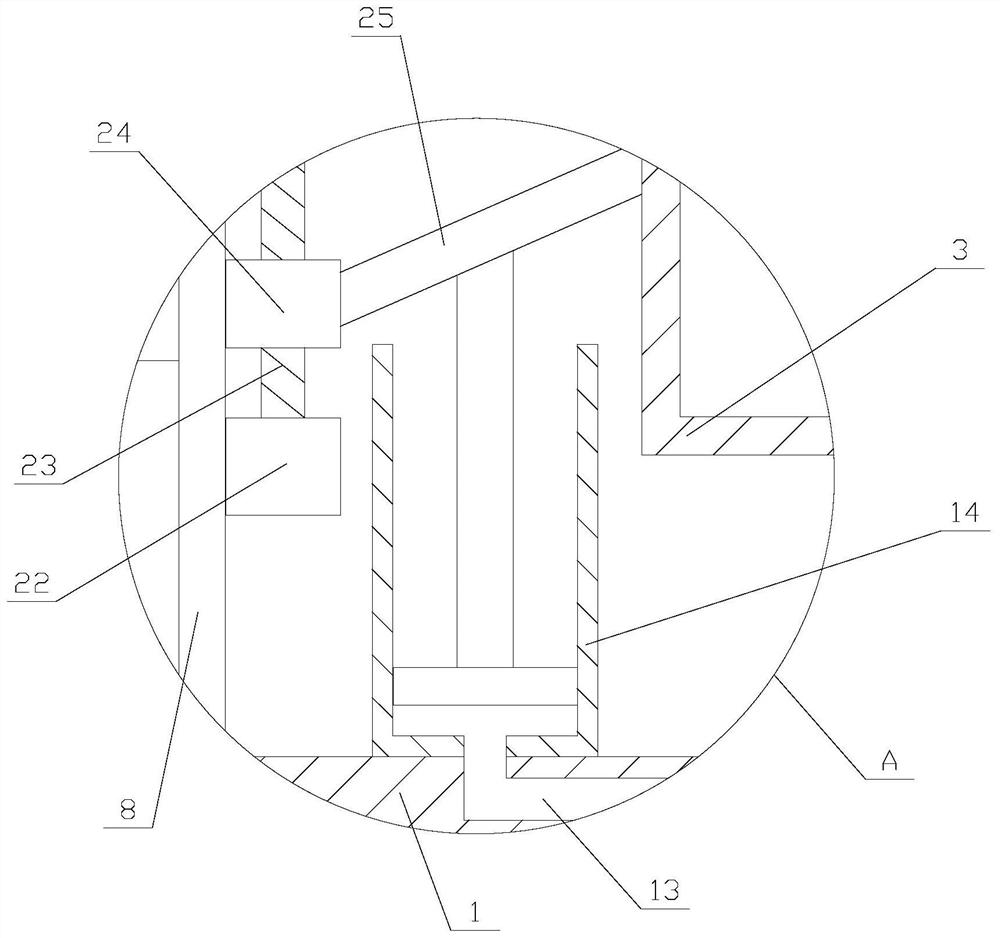

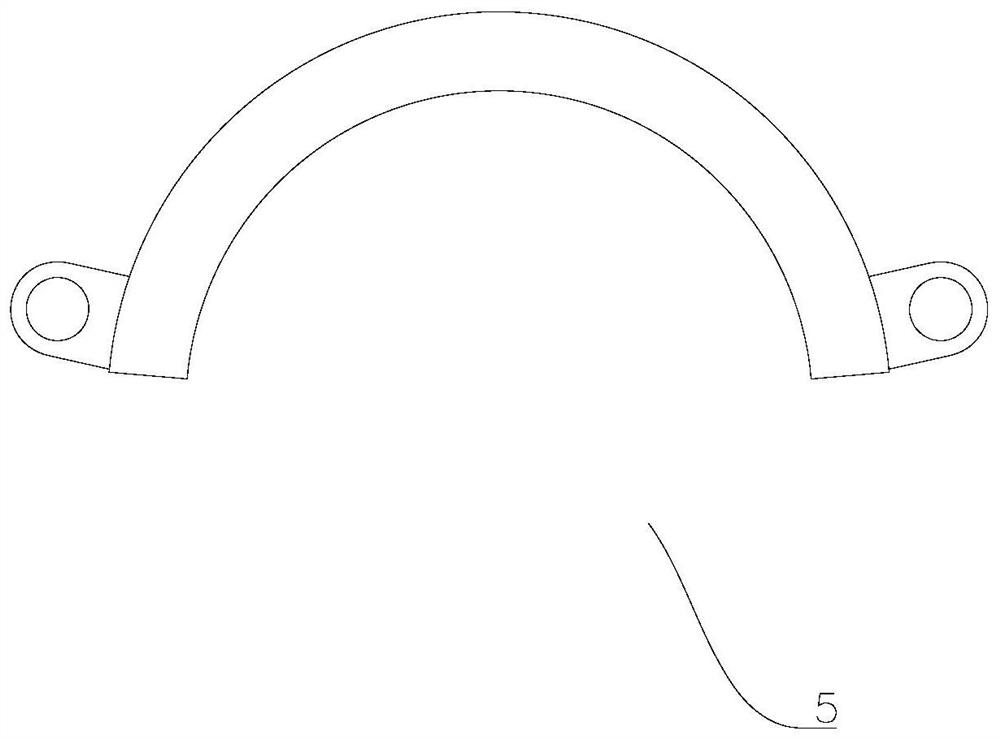

Clamp device and method for welding of front floor of special vehicle

PendingCN112719739AReduce labor intensityEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPower apparatus

The invention discloses a clamp device and method for welding of a front floor of a special vehicle. The clamp device comprises a plate seat main body (3), wherein one end of the plate seat main body (3) is fixedly connected with a power device (4), the other end of the plate seat main body (3) is provided with a wheel disc (31), and the wheel disc (31) is fixedly connected with a wheel disc fixing seat (2); the wheel disc fixing seat (2) is fixed to a first supporting base (1), the power device (4) is fixed to a second supporting base (5), and the first supporting base (1) and the second supporting base (5) are in direct contact with the ground; locking devices (6) are further arranged on the first supporting base (1), and locking pins (64) are arranged on the locking devices (6); and the wheel disc (31) is further provided with locking holes (312). According to the device, the plate seat main body (3) can be locked at any angle, overhead welding is changed into flat welding, and the labor intensity of operators is reduced.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

A punching device with protective function

Owner:南京江宁区上峰国银标准件厂

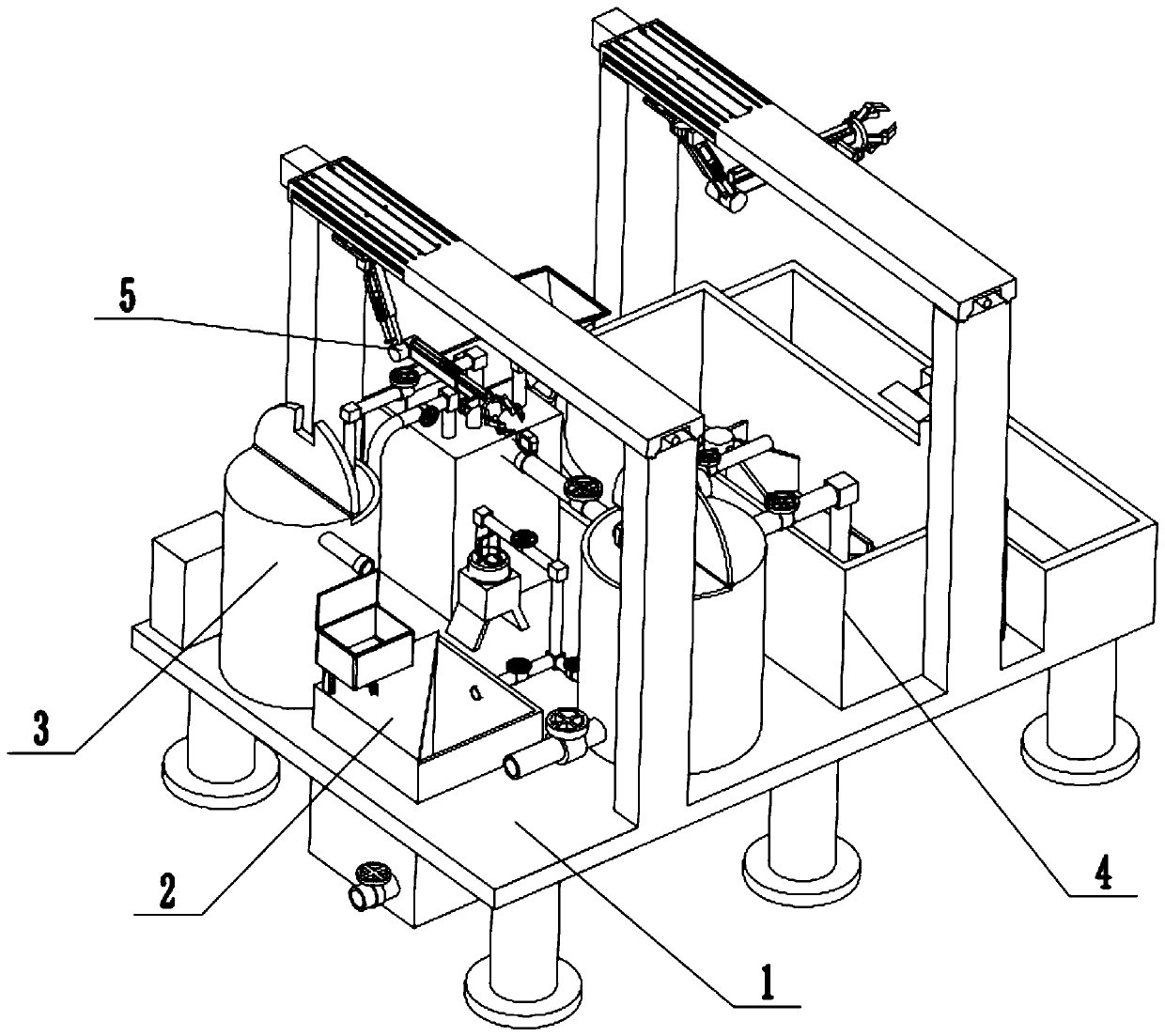

Weighing interlocking automatic casting system and casting method

PendingCN114559023ASimple processEasy to operateMolten metal supplying equipmentsCasting safety devicesCasting moldMolten metal

The invention belongs to the field of metal casting, and discloses a weighing interlocking automatic casting system and a casting method.The weighing interlocking automatic casting system comprises a smelting furnace feeding device, a smelting furnace casting device, a mold assembly, a mold preheating device and a control unit; the smelting furnace feeding device is used for conveying metal materials to the smelting furnace casting device; the mold preheating device is used for preheating a to-be-cast mold assembly; the smelting furnace casting device is used for melting metal materials and casting molten metal into the mold assembly located on the weighing platform. And the smelting furnace feeding device, the smelting furnace casting device and the mold preheating device are electrically connected with the control unit. According to the automatic casting system and the casting method, the production efficiency is high, the product quality is good, excessive control by personnel is not needed, the labor intensity of the personnel is reduced, the treatment efficiency is high, operation is more flexible and convenient, automatic continuous operation treatment can be achieved, the treatment efficiency and safety are greatly improved, and later maintenance is simple.

Owner:广东长信精密设备有限公司

An automatic feeding, drilling, hair planting and flying hair all-in-one machine

InactiveCN111012034BUnified processingAvoid human errorBrush bodiesControl engineeringStructural engineering

The invention discloses an automatic feeding, drilling, hair-planting and flying hair all-in-one machine, which includes a support base plate, the end of the return spring far away from the left inner wall of the inner cavity of the track groove is fixedly connected with a sliding splint, and the middle of the top of the support base plate is located on the track block The left side is fixedly connected with a fixed splint, the middle of the top of the support bottom plate is located on the side of the fixed splint away from the track block and is fixedly connected with a mobile device, and the bottom of the support top plate is fixedly connected with a tufting machine directly above the sliding splint, and the first reciprocating The side of the device close to the sliding splint is fixedly connected with a drilling machine, and the side of the second reciprocating device close to the sliding splint is fixedly connected with a fly machine. The invention relates to the technical field of brush manufacture. The device unifies each processing procedure and combines them in an orderly manner to avoid human error and ensure processing quality. Through mutual cooperation, processing is performed simultaneously to save processing time, improve processing efficiency, and remove dust and impurities in time to ensure processing safety.

Owner:深圳市双永科技有限公司

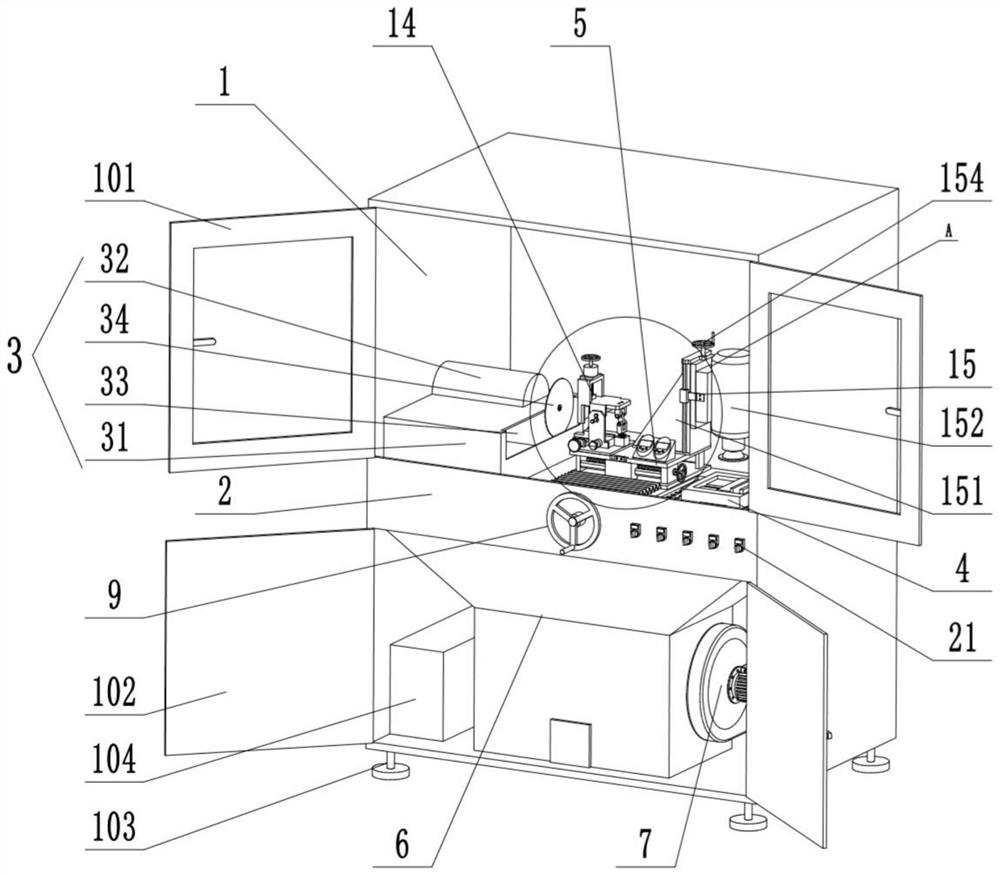

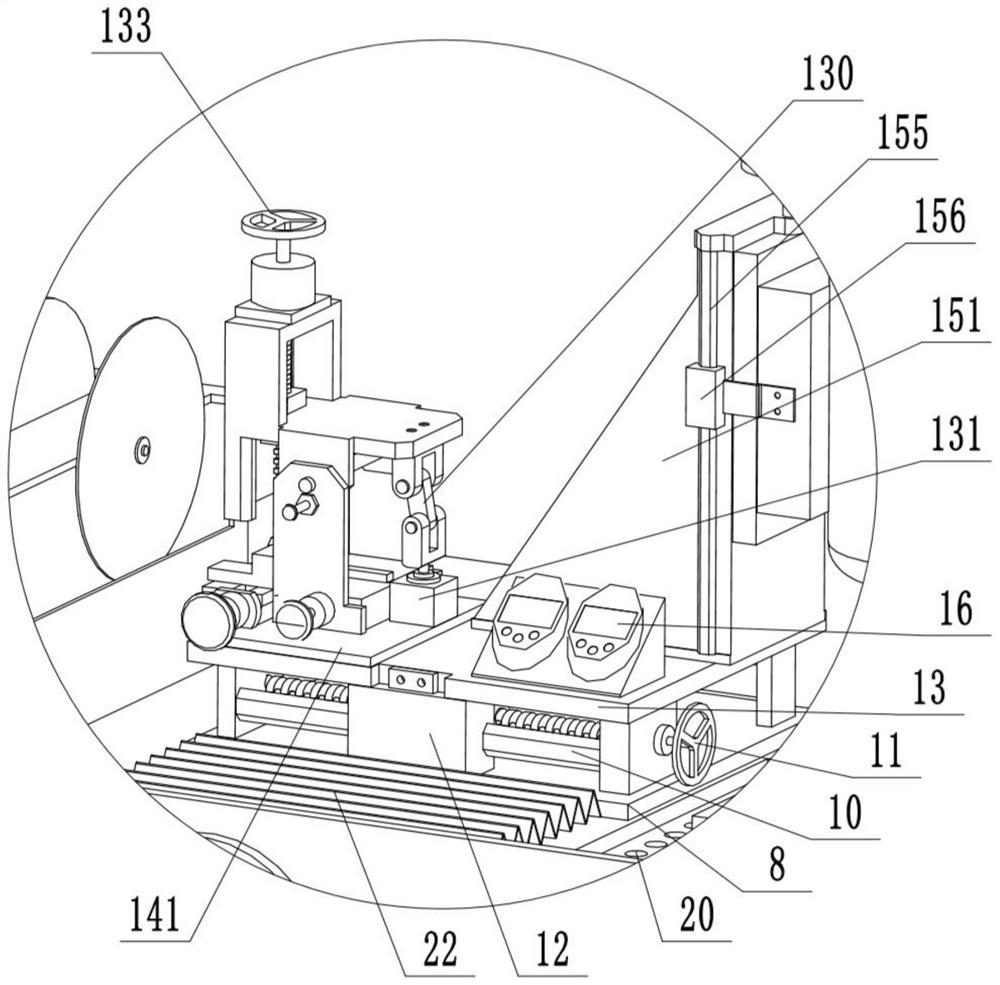

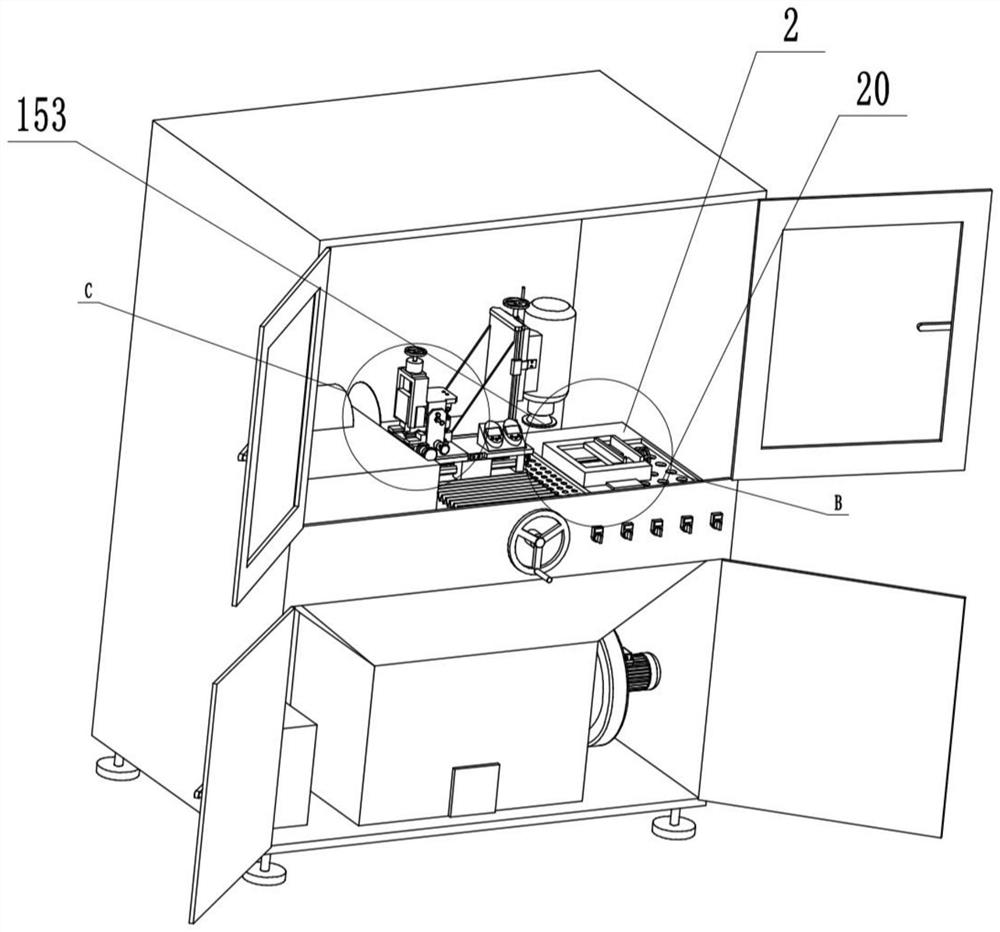

Dust-free universal digital display sample preparation equipment for friction materials

PendingCN112207692AGuaranteed cutting accuracyEnsure processing safetyPreparing sample for investigationGrinding machinesMaterials processingWorkbench

The invention provides dust-free universal digital display sample preparation equipment for friction materials, and mainly relates to the field of friction material processing. The dust-free universaldigital display sample preparation equipment for the friction materials comprises a box body, wherein a workbench is arranged in the middle of the box body in a sliding mode, a cutting device, a grinding fixture and a moving platform are arranged on the workbench, a scrap recycling box is arranged at the bottom of the workbench, the moving platform comprises a lower sliding plate, a feeding handwheel is connected to the bottom of the lower sliding plate, a translation sliding rail is arranged on the lower sliding plate, a translation sliding block is connected to the translation sliding railin the sliding mode and is fixedly connected with an upper sliding plate, a cutting fixture is arranged on the left side of the upper sliding plate, and a grinding device is arranged on the right side of the upper sliding plate. The dust-free universal digital display sample preparation equipment has the beneficial effects that the friction materials can be cut and ground, and the friction materials can be stably clamped by the fixture; displacement data of the friction materials or displacement data of the equipment are displayed through a digital display screen during machining, so that themachining efficiency is improved, and the machining precision is guaranteed; and no pollution is caused during machining.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

A method for preventing and extinguishing fire and reducing oxygen content in flue gas by injecting flue gas from a power plant downhole

ActiveCN110735659BRich in coal resourcesLow costMining devicesDust removalFlue gasEnvironmental engineering

The invention discloses a method for preventing fire and reducing oxygen content in exhaust gas through injecting exhaust gas of a power plant in a well. Coal can adsorb oxygen to reduce oxygen content in exhaust gas. Oxygen concentration reduction mainly utilizes 11 coal storage tanks to be cooperated for recycling; according to the normal pressure volumetric method, the coal quantity in one coalstorage tank is obtained through the comprehensively fed exhaust gas quantity, the oxygen content when the exhaust gas is fed and the oxygen content when the exhaust gas is discharged; the tanks carry out four procedures including exhaust gas feeding, oxygen removal, exhaust gas discharging and coal changing sequentially; 11 tanks take turns to carry out the four procedures and are alternately recycled to ensure that exhaust gas is continuously provided for a goaf; the coal storage tanks can conveniently carry out coal loading and unloading operation; as oxygen adsorption by coal does not change the coal nature, the loaded coal is new coal produced by a coal yard, and the unloaded coal can be transported to the power plant as fuel; and coal is adopted to adsorb oxygen to avoid spontaneouscombustion of coal; fire prevention of an underground goaf is carried out on a coal mine, and the coal resource is rich, so that the cost is greatly reduced.

Owner:TAIYUAN UNIV OF TECH

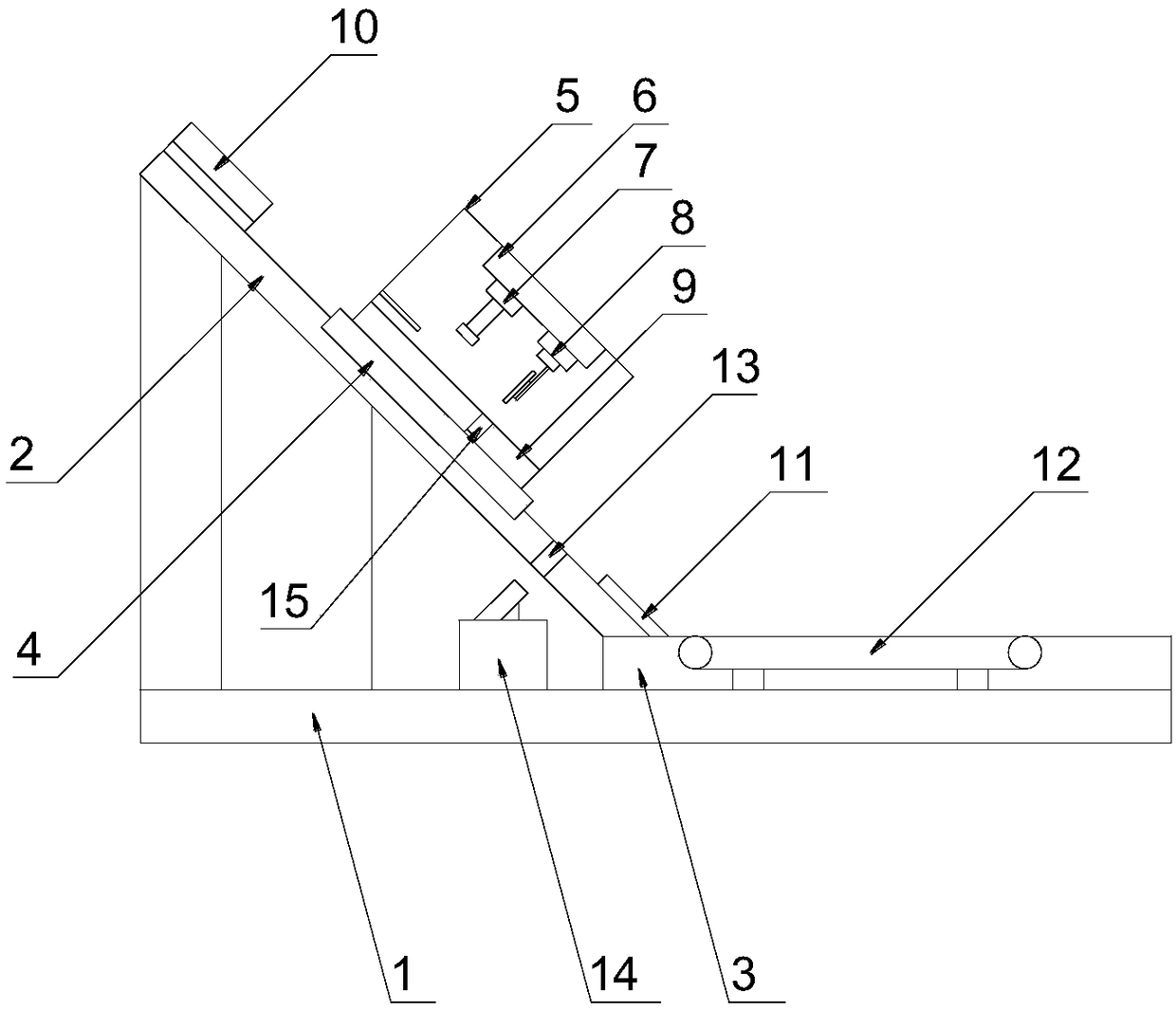

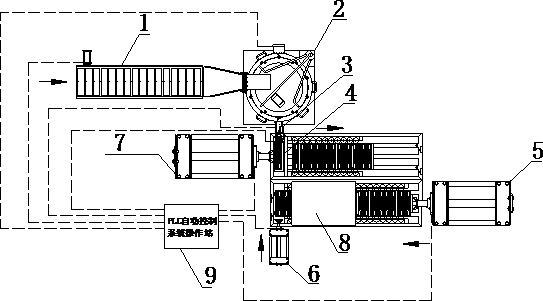

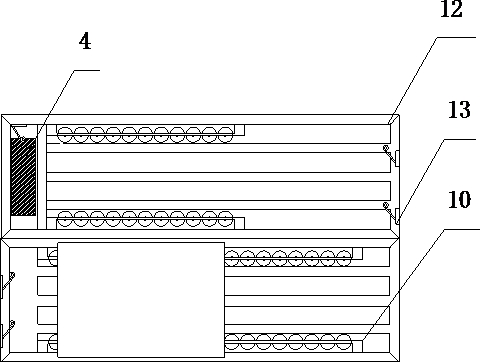

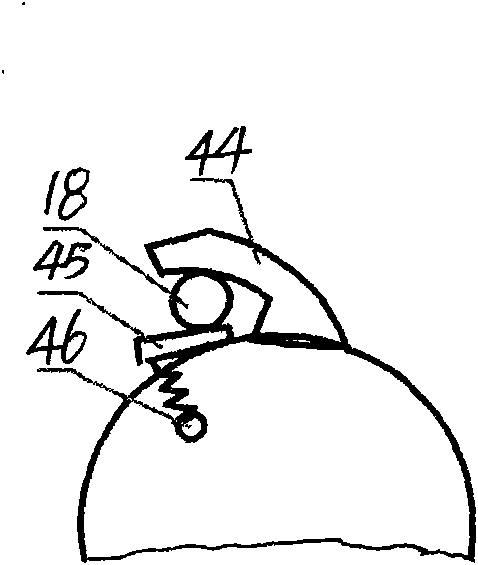

Firecracker manufacturing all-in-one machine

InactiveCN101713622BImprove production and processing efficiencyImprove processing qualityFireworksFirecrackerDistributor

The invention discloses a firecracker manufacturing all-in-one machine comprising a reel mechanism, a fuse inserting mechanism, a firecracker connecting mechanism, a conveying mechanism, a powder charging mechanism and an encapsulating mechanism, wherein the reel mechanism comprises a center wheel (24), and at least four tiles and rollers, wherein the tiles and the rollers are evenly arranged in the middle of the axial direction of the excircle of the center wheel at intervals; the fuse inserting mechanism comprises a fuse inserting wheel (21), and at least four pairs of shuttle needle pipes (65) and shuttle needles (66), wherein the shuttle needle pipes (65) and the shuttle needles (66) are evenly arranged on one end of the fuse inserting wheel at intervals; a transition wheel (23) and aclamping hook (44) are arranged between the fuse inserting wheel and the center wheel; a swing flask conveying device (20) on the conveying mechanism is arranged between the fuse inserting wheel and a delivery wheel (10); the powder charging mechanism comprises a spiral conveyor (17) and distributors (11), wherein the distributors on both ends are respectively connected with an agitating vessel; the distributor in the middle is connected with the spiral conveyor; and the spiral conveyor is connected with the distributors. The invention greatly increases the firecracker producing and processing efficiency, improves the firecracker processing quality, and can ensure the firecracker processing safety, thereby being beneficial to organizing scale production and processing of firecrackers, andlowering the firecracker processing cost.

Owner:黎高明 +4

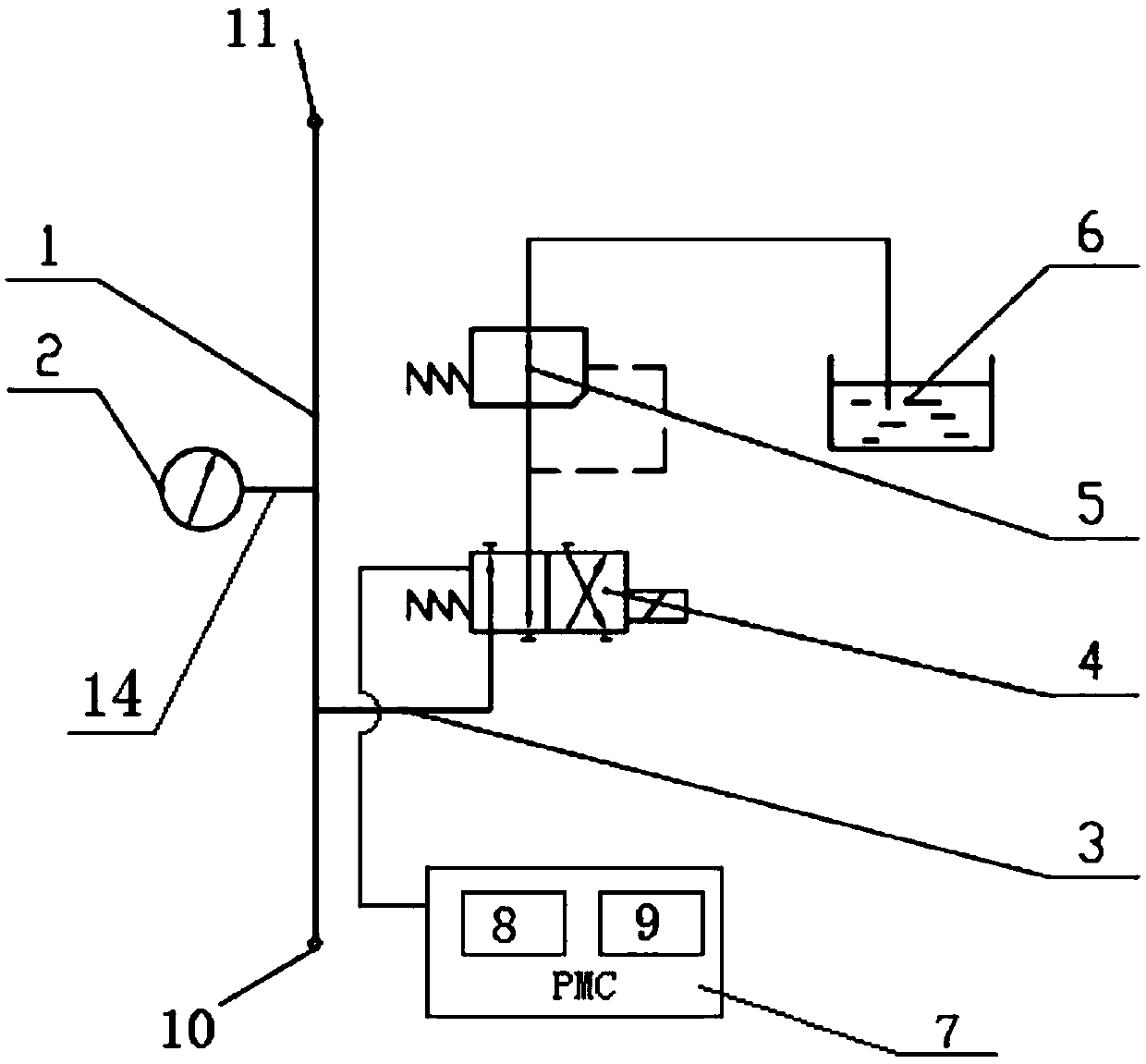

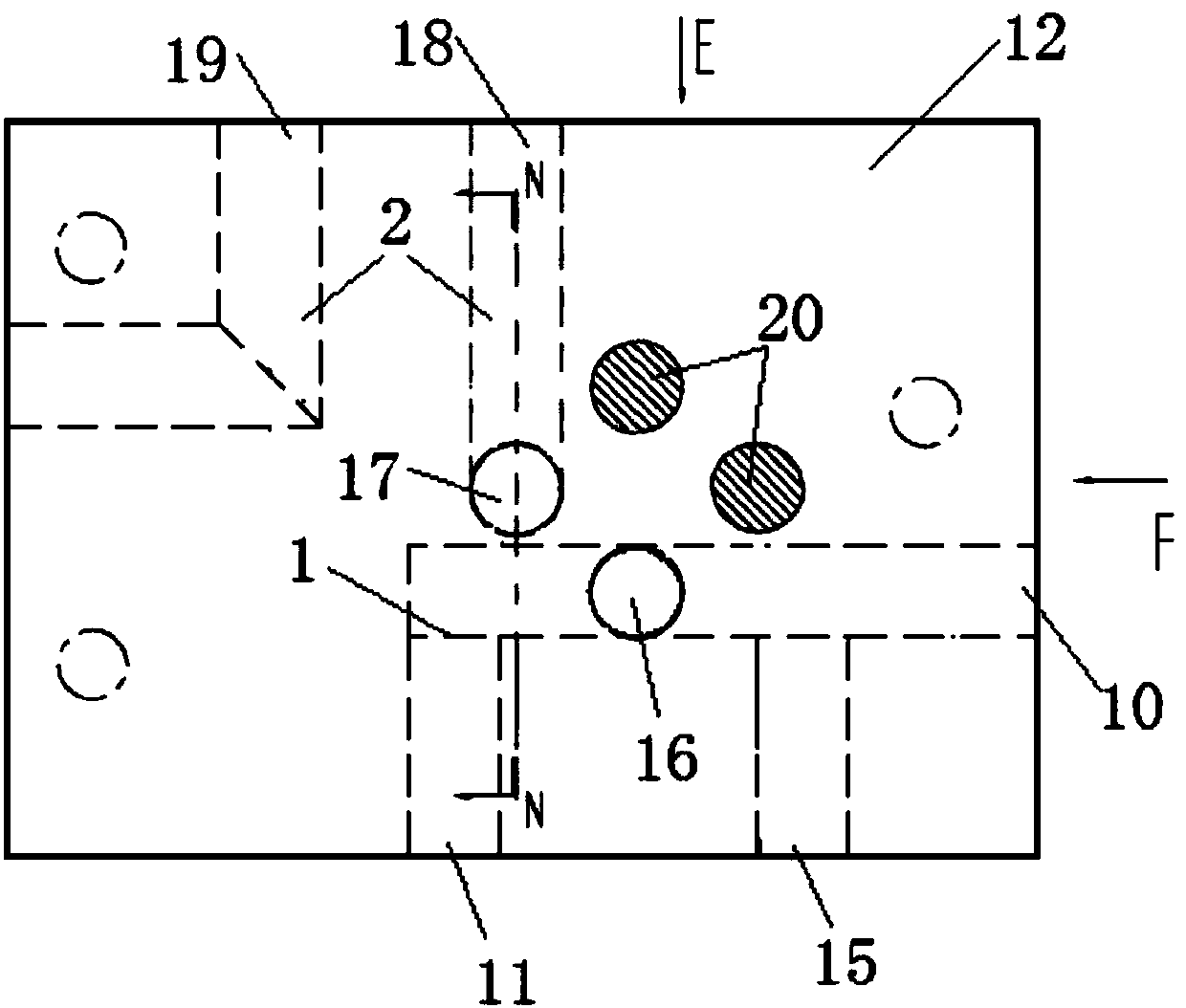

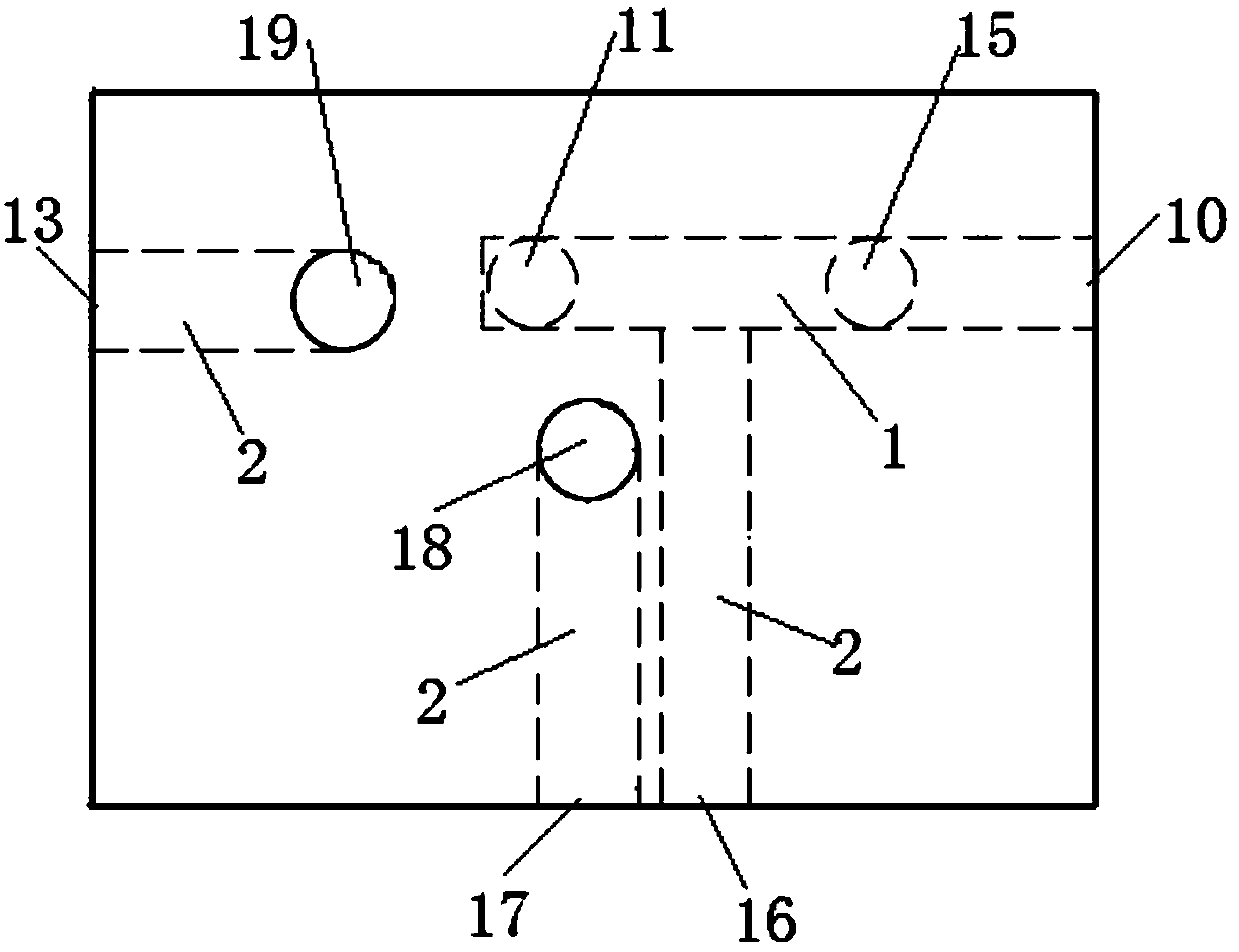

A hydraulic switching device applied to the processing of disk parts

The invention discloses a hydraulic switching device applicable to disc part processing. The hydraulic switching device is mounted in an external machine tool of part processing, and comprises a distributer, an electromagnetic valve and an overflow valve, wherein a first oil way and a second oil way which communicate with each other are arranged in the distributer; the two ends of the first oil way are an oil inlet and an oil outlet; the oil inlet receives hydraulic oil and the hydraulic oil flows into a chuck cylinder; the electromagnetic valve and the overflow valve are mounted on the outer side surface of the distributer, and are sequentially positioned in a hydraulic oil circulation path of the second oil way; an unloading port communicates with a hydraulic station of the external machine tool; the electromagnetic valve is electrically connected with a PMC controller in the external machine tool; a first built-in relay and a second built-in relay are arranged inside the PMC controller for controlling the turn-on and turn-off of the electromagnetic valve; and the PMC controller has a program for automatically controlling the operation of the relays inside. According to the technical scheme, the high and low pressure states of hydraulic oil can be automatically switched, the deformation of disc parts after processing is eliminated, the processing safety is guaranteed, and the production efficiency is improved.

Owner:宁波东力股份有限公司

Automatic cold bending device for building construction embedded steel bars

InactiveCN112845961AImprove cooling effectReduce the impactSound producing devicesConstruction engineeringRebar

The invention relates to the technical field of building construction equipment, and discloses an automatic cold bending device for building construction embedded steel bars. The automatic cold bending device comprises a rack, wherein feeding wheels and a guiding grooved wheel are arranged outside the rack, a cutting blade is movably connected to the interior of the rack, a cooling disc is movably connected to the side, away from the guiding grooved wheel, of the cutting blade, a condensation pipe is arranged in the cooling disc, a circulating pump is arranged in the condensation pipe, and a refrigeration pipe is connected to the exterior of the condensation pipe in a winding mode. Through the cooperative use of the cooling disc, the condensation pipe, the circulating pump and the refrigeration pipe, the effect of cooling the steel bars is effectively achieved, internal high temperature generated by cutting, other machining technologies or other factors in the steel bars is eliminated, the influence of temperature on a steel bar bending technology is reduced, the steel bars can be subjected to the cold bending technology, then the strength and internal pretension stress of the steel bars are effectively guaranteed, the steel bars are prevented from generating cooling shrinkage after pouring, and thus the strength and quality of a building object are guaranteed.

Owner:张明

Clamp for short-axis parts of numerically-controlled machine tools

PendingCN112692601AEasy to holdImprove reliabilityWork clamping meansPositioning apparatusNumerical controlEngineering

The invention discloses a clamp for short-axis parts of numerically-controlled machine tools. The clamp comprises a fixing clamp, clamping jaws, a top ring and an air channel; a cylindrical fixing cavity is formed in the fixing clamp, one end of the fixing cavity is provided with an opening, and the other end is provided with a clamping end in a protruding mode along the axis; the multiple clamping jaws are arranged in the fixing cavity and are arranged in the circumferential direction of the fixing cavity at equal-angle intervals, and the clamping jaws can do translational motion in the radial direction of the fixing cavity; the top ring is coaxially arranged in the fixing cavity and located on the sides, away from the opening, of the clamping jaws, the outer ring wall of the top ring is fixedly connected with the inner wall of the fixing cavity, and the ends of the short-axis parts can abut against and be tightly attached to one side of the top ring; the air channel is formed in the side, away from the opening, of the fixing clamp and enables the fixing cavity to communicate with the outside. According to the clamp for the short-axis parts of the numerically-controlled machine tools, the ends of the short-axis parts can be positioned and clamped, the short-axis parts are pressed on the top ring through external air pressure, the clamping firmness of the short-axis parts is improved, the machining safety is guaranteed, and the structure is simple.

Owner:太仓盘齐精密模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com