Dust-free universal digital display sample preparation equipment for friction materials

A friction material and universal technology, applied in the field of dust-free universal digital display sample preparation equipment for friction materials, can solve problems such as low processing efficiency, damage to the surface of friction materials, and deviation of processing accuracy of friction materials, so as to improve processing efficiency and ensure processing Accuracy, the effect of ensuring cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

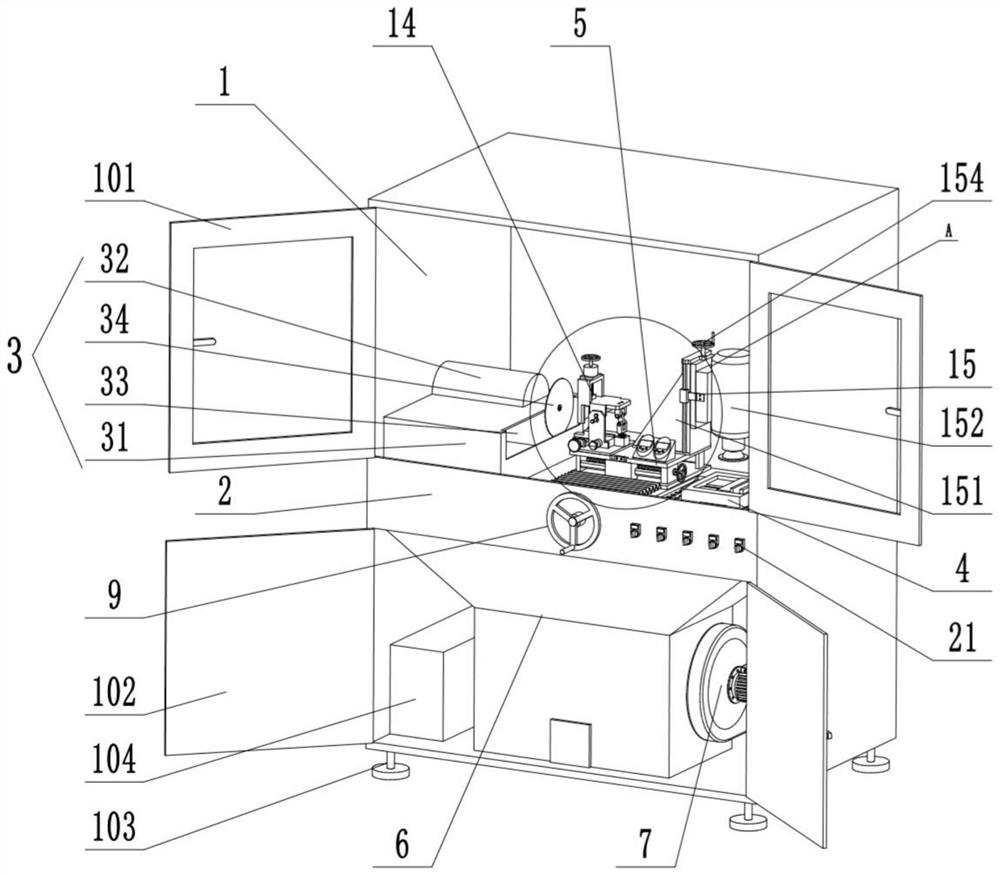

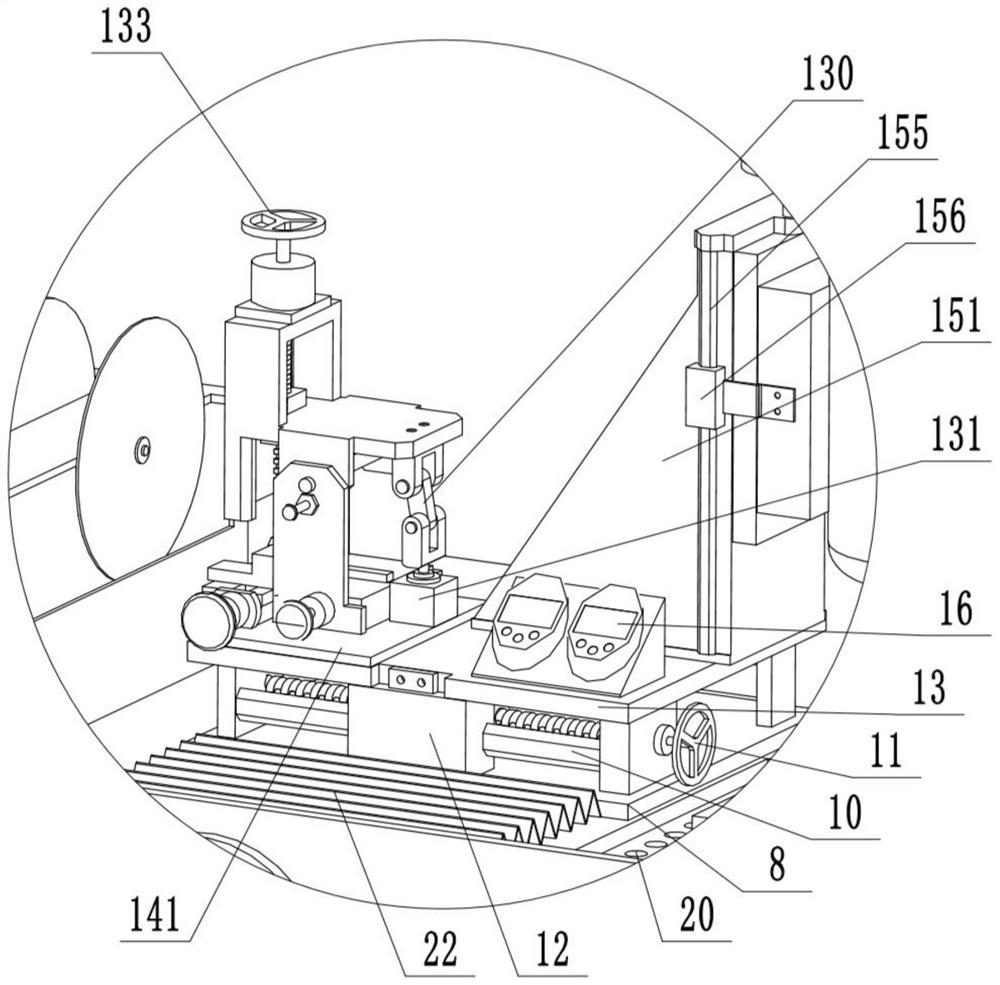

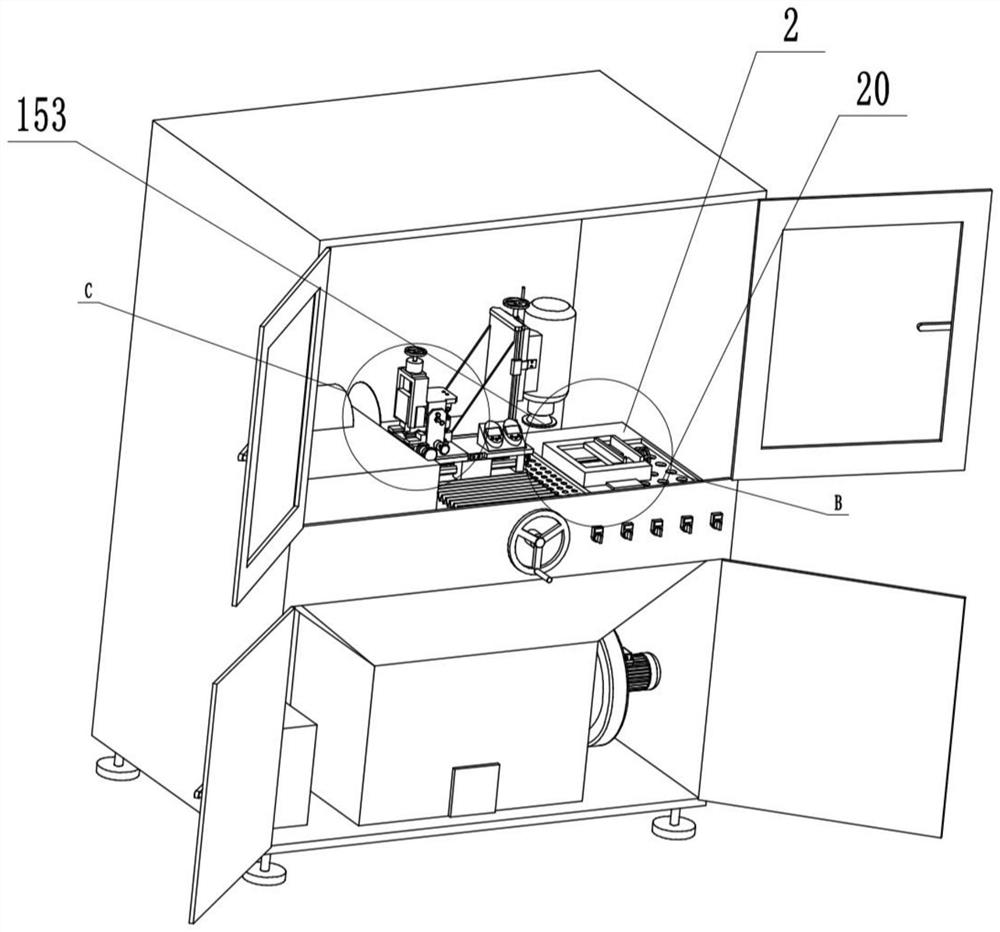

[0028] combined with Figure 1-7 , dust-free universal digital display sample preparation equipment for friction materials, including a box body 1 for installing various components, a workbench 2 is slidably set in the middle of the box body 1, and a cutting device 3 is set on the left side of the workbench 2, so A grinding fixture 4 is set on the right side of the workbench 2, a mobile platform 5 is set in the middle of the workbench 2, a debris recovery box 6 is set at the bottom of the workbench 2, and a dust suction device is set on one side of the debris recovery box 6 7. The mobile platform 5 includes a sliding plate 8, which is slidably connected to the surface of the workbench 2. The bottom of the sliding plate 8 is connected to the feed hand wheel 9 through a threaded cylinder and a threaded rod. A translation slide rail 10 is provided through the fixed block, and the fixed blocks at both ends of the translation slide rail 10 are connected to the translation hand whee...

Embodiment 2

[0036] When the device is in use, open the upper door panel and use the cutting fixture to clamp the friction material to be processed. The clamping method is as follows: when it is necessary to use the inclined pad 145, turn the gasket to adjust the handwheel to adjust the inclined pad to a suitable position; turn the slider to adjust The hand wheel 144 adjusts the two L-shaped support sliders 143 to a suitable position; the jig adjustment handwheel 133 is turned to adjust the height of the jig adjustment slider 132 to a suitable position to initially fix the sliders, and the jig adjustment sliders are pressed against the upper end of the friction material to secure them. Preliminary fixation, pull out the spring positioning pin 148, open the cylinder 131 switch cylinder to generate thrust to push the rocker arm clamp 147 to clamp the friction material stably. Adjust the translation handwheel 11 to move the cutting fixture 14 and the friction material to the left to enter the ...

Embodiment 3

[0039] Each adjustment handwheel of this equipment can also be replaced by a micro motor, and the corresponding button is used to control the micro motor to realize the automatic adjustment of each moving part in the equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com