A method for preventing and extinguishing fire and reducing oxygen content in flue gas by injecting flue gas from a power plant downhole

A technology of oxygen content and injection well, which is applied in fire prevention, dust prevention, earth drilling and mining, etc. It can solve the problems of generating other harmful substances and high cost, and achieve the effects of cost reduction, convenient operation and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Specific embodiments of the present invention will be described in detail below.

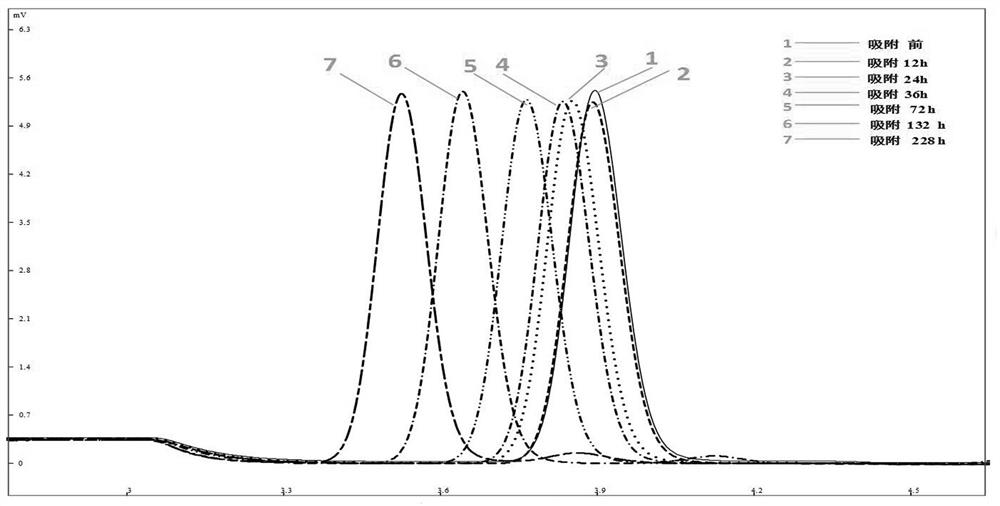

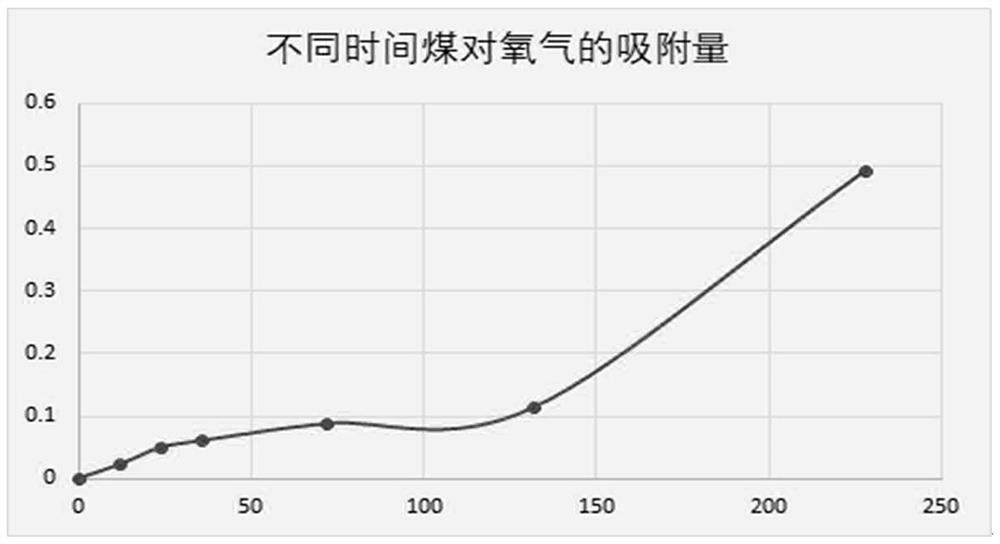

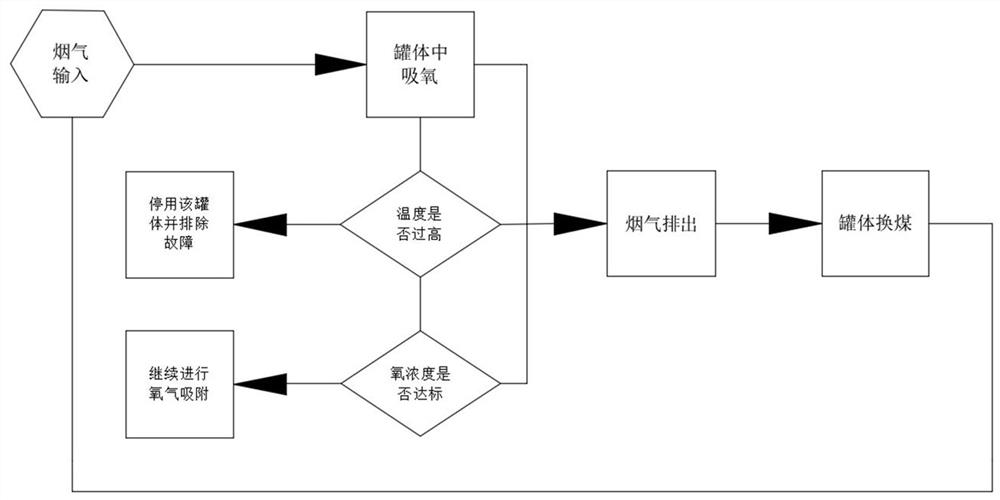

[0056] The oxygen content in the flue gas of the power plant is about 4% to 7%. This volume fraction of oxygen will not cause the coal to spontaneously combust, and it is not enough to generate harmful gases such as CO. The coal absorbs oxygen differently for different periods of time. Coal first physically adsorbs oxygen at low temperature. At this time, the adsorption amount is close to that of nitrogen. The physical adsorption process of coal to oxygen is very fast, and the physical adsorption can reach about 80% of the saturated oxygen absorption within a few seconds. Then it will gradually transform into chemical adsorption, and the chemical adsorption will continue at low normal temperature, and the adsorption amount is still increasing after 228 hours. Coal mines are rich in coal resources. In order to ensure the adsorption efficiency of coal to oxygen and the continuous gas supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com