Beam bottom overhaul platform capable of spanning bridge piers and obstacle pillars and use method of beam bottom overhaul platform

A technology for repairing platforms and bridge piers, which is applied in bridge maintenance, bridges, bridge parts, etc., can solve the problems that the hangers under the bridge cannot move continuously along the bridge direction, the fixed platform is not easy to erect, and the use of bridge inspection vehicles is limited, etc. Ability to adapt to engineering boundary conditions, fast and convenient detection and construction, simple construction and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

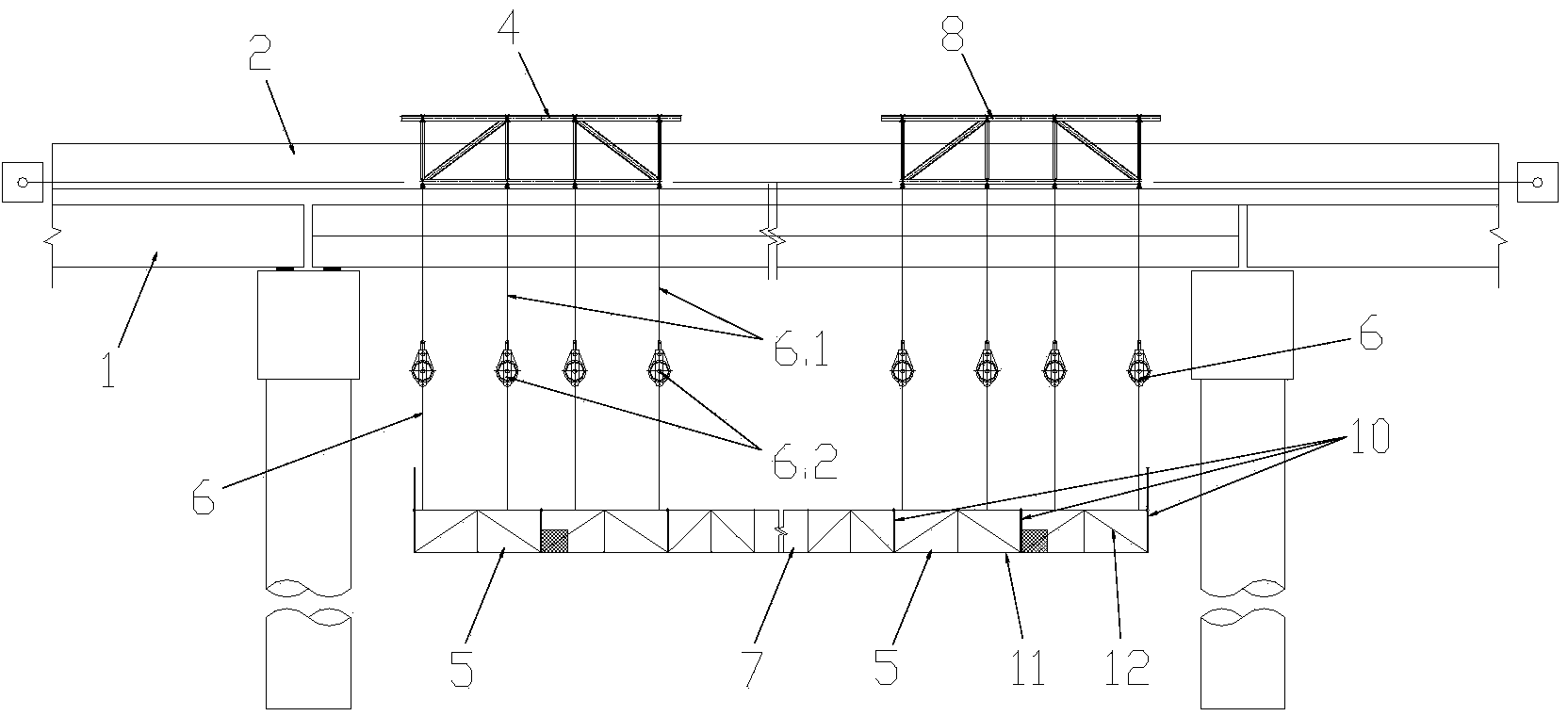

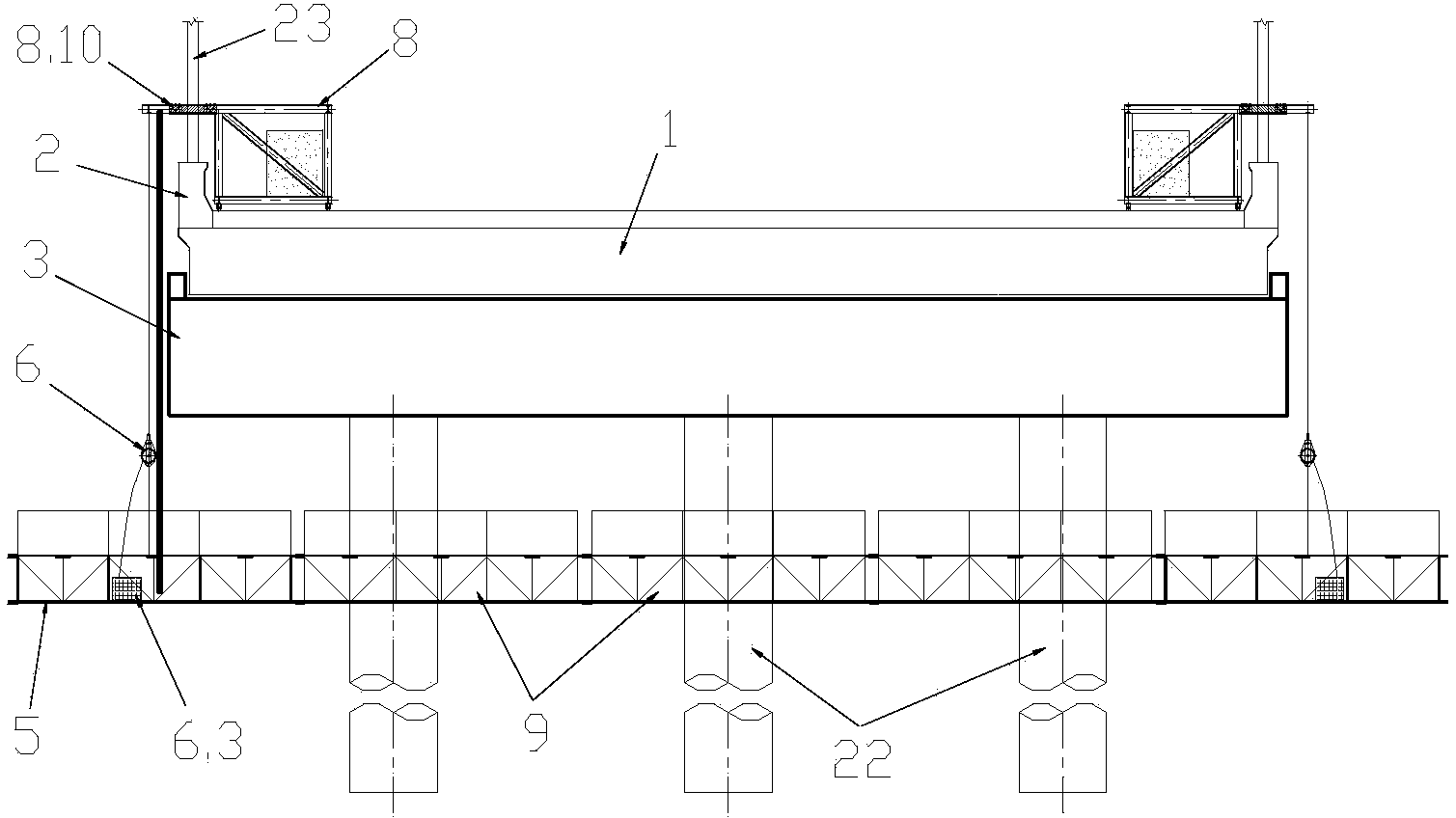

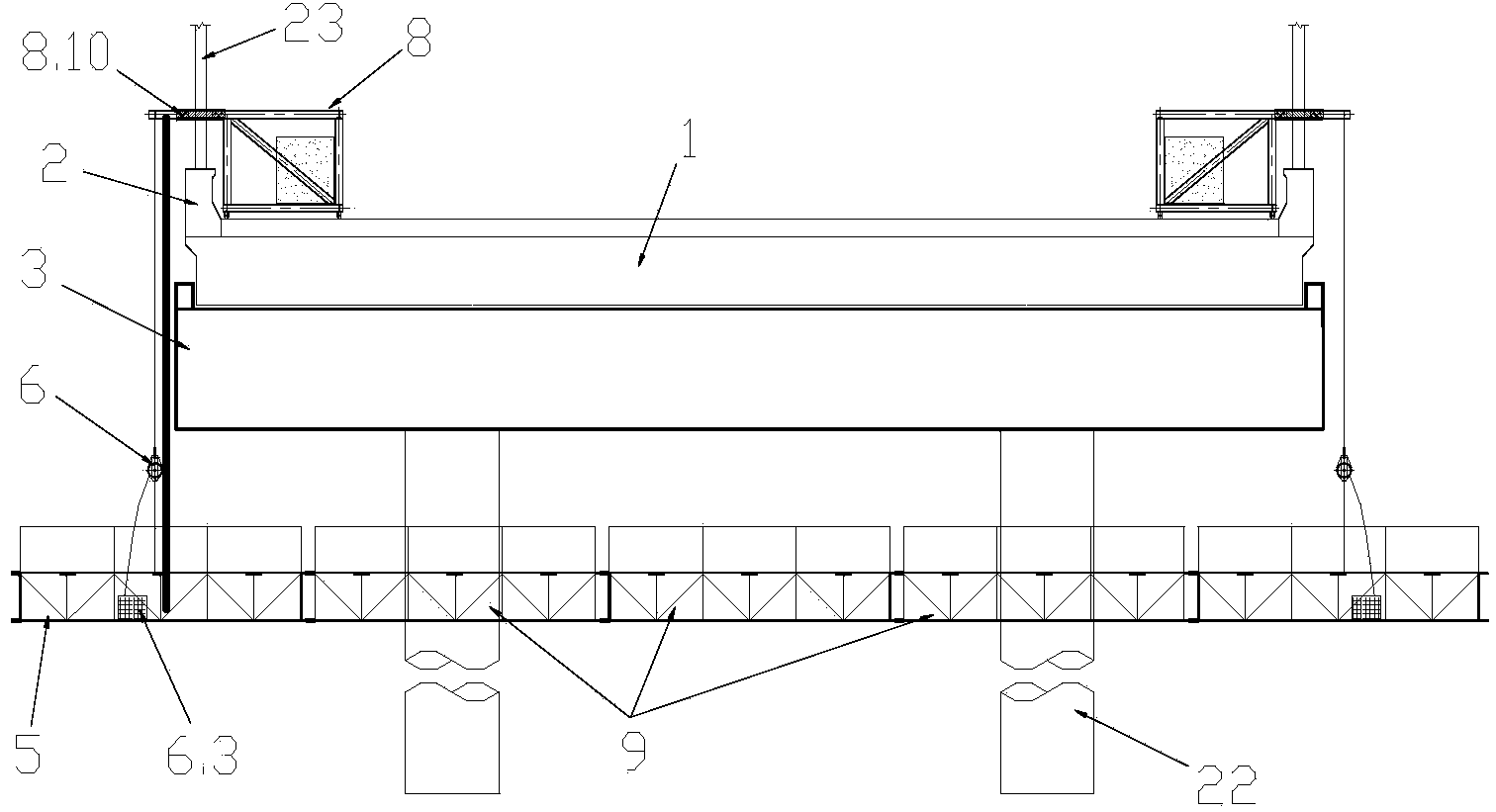

[0043] Such as Figure 1-4 As shown, a beam bottom maintenance platform capable of spanning bridge piers and obstacle columns of the present invention includes a column-span truss vehicle 4, a pier-span column hanger 5, a hoisting system 6 and a connecting unit 7, and the column-span truss vehicle 4 includes two pairs of The truss trucks 8 on the inside of the guardrails 2 on both sides of the bridge 1 can move along the direction of the bridge and are symmetrically arranged. The truss trucks 8 stick to the side of the guardrail and protrude four detachable cantilever rods 8.10. Each pair of truss trucks 8 The cantilever rods on the top are respectively hoisted by the hoisting system 6 to jointly lower the pier-span hangers 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com