Method and device for slitting plank

A technology for cutting wood boards and strips, which is applied to sawing equipment, wood processing equipment, circular saws, etc., can solve the problems of slow processing speed, low work efficiency, and high labor intensity of workers, and achieve uniform speed, reduce labor intensity, and cut good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

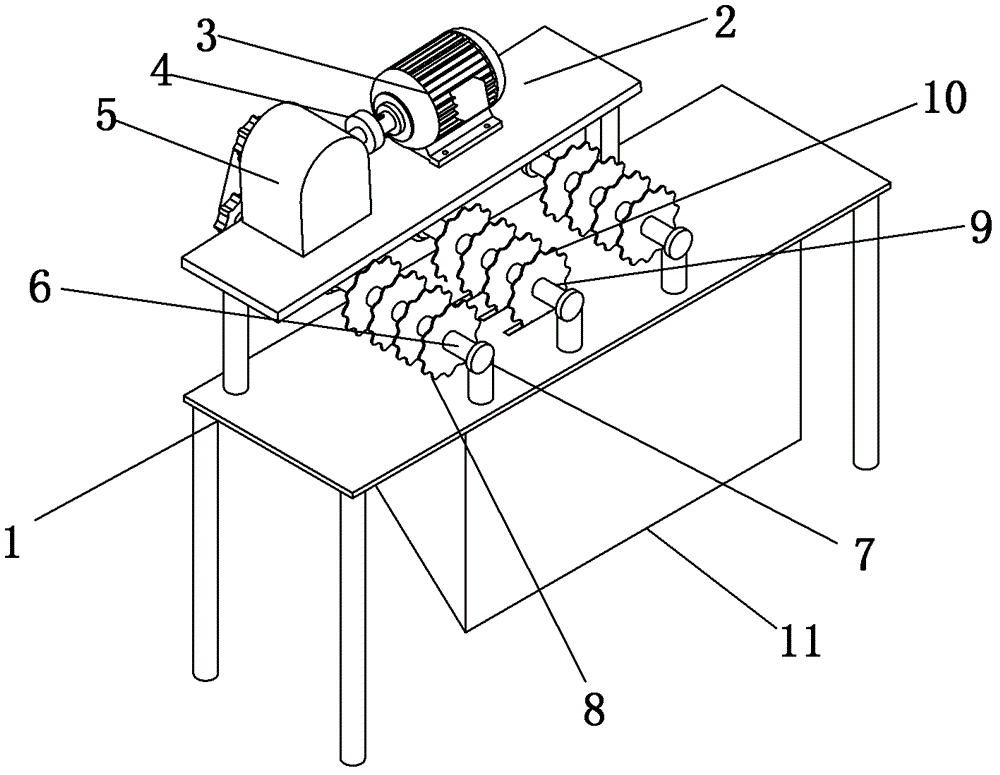

[0016] Example. A method for cutting wood boards, characterized in that the pressure wheel assembly is driven to rotate by a transmission device, and the weight of the transmission device is used to press the wood board through the pressure wheel assembly to drive the wood board, and then the wood board is cut into strips by the cutting blade assembly.

[0017] The method of driving the pressure wheel assembly to rotate through the transmission device is to use the motor to connect the reducer through the shaft coupling, and the reducer is respectively connected to two sets of the pressure wheel assembly through the sprocket drive to make the pressure wheel assembly rotate.

[0018] The plank strip cutting device that aforementioned plank strip cutting method is used, constitutes as figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com