Preparation method of nanoparticle/hollow sphere composite reinforced metal-based composite material

A nanoparticle and composite material technology, which is applied in the field of preparation of nanoparticle/hollow sphere composite reinforced metal matrix composite materials, can solve the problems of complex preparation process, high preparation cost, hollow sphere breakage, etc., and achieve simple process and ensure process Safe, avoid burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a nanoparticle / hollow sphere composite reinforced metal matrix composite material, comprising the following steps:

[0026] (1) The silicon carbide nano-particle reinforced LZ91 magnesium-lithium alloy composite blank is obtained by stirring casting method, and the mass fraction of the silicon carbide nano-particle in the silicon carbide nano-particle reinforced LZ91 magnesium-lithium alloy composite blank is 0.5%;

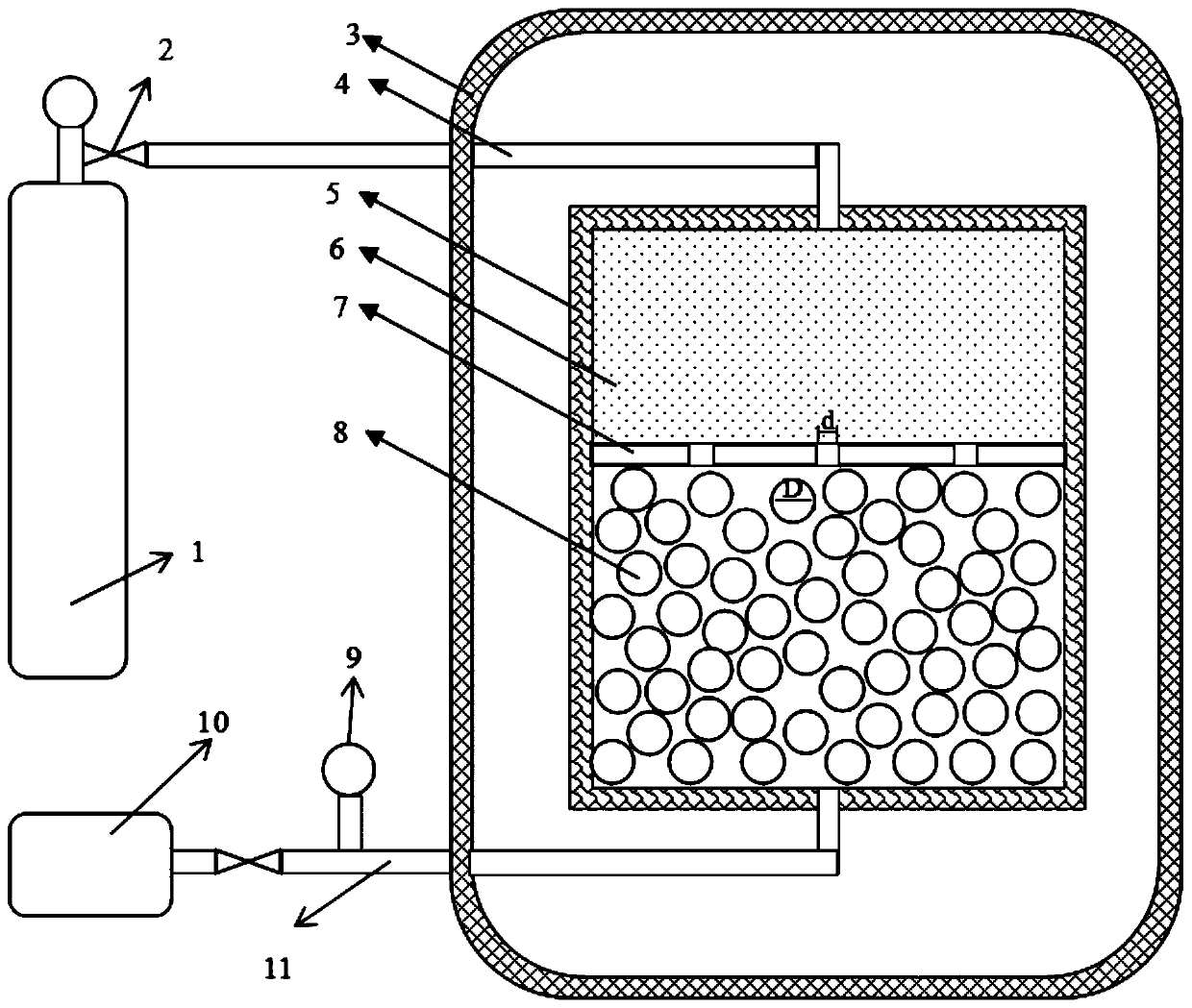

[0027] (2) Al 2 O hollow balls, Q235 steel perforated plates and silicon carbide nanoparticles reinforced LZ91 magnesium-lithium alloy composite blanks are loaded into Q235 steel ladles in sequence and sealed with argon arc welding. The hole diameter d is smaller than the diameter D of the hollow ball. The hole diameter d of the perforated plate is 3.5 mm, and the diameter D of the hollow ball is 4 mm. The Q235 ladle is covered with two air guide tubes. The first air guide tube is connected to the blank end for loading. The two air g...

Embodiment 2

[0031] A method for preparing a nanoparticle / hollow sphere composite reinforced metal matrix composite material, comprising the following steps:

[0032] (1) The carbon nanotube CNTs reinforced aluminum-lithium alloy composite blank is obtained by powder metallurgy, and the mass fraction of the carbon nanotube CNTs in the carbon nanotube CNTs reinforced aluminum-lithium alloy composite blank is 0.1wt%;

[0033] (2) Put SiC hollow spheres, 45# steel perforated plates and carbon nanotube CNTs reinforced aluminum-lithium alloy composite blanks into 45# steel ladles in sequence, and seal them with argon arc welding. 45# steel perforated plates are provided with Through the small hole, the aperture d of the small hole is smaller than the diameter D of the hollow ball. The aperture d of the 45# steel perforated plate is 0.2mm, and the diameter D of the hollow ball is 0.5mm. The 45# steel ladle is covered with two air ducts. The first The air guide tube is connected with the blank en...

Embodiment 3

[0037] A method for preparing a nanoparticle / hollow sphere composite reinforced metal matrix composite material, comprising the following steps:

[0038] (1) A silicon carbide nanoparticle reinforced aluminum alloy composite billet is obtained by stirring casting, and the mass fraction of the silicon carbide nanoparticle in the silicon carbide nanoparticle reinforced aluminum alloy composite billet is 10wt%;

[0039] (2) Al 2 o 3 / SiO 2Hollow balls, 20# steel perforated plates and silicon carbide nano-particle reinforced aluminum alloy composite blanks are sequentially loaded into 20# steel ladles and sealed with argon arc welding. The aperture d of the hole is smaller than the diameter D of the hollow ball. The aperture d of the 45# steel perforated plate is 4.5mm, and the diameter D of the hollow ball is 5mm. The 20# ladle is covered with two air guide tubes, and the first air guide tube is connected to the blank end. For load loading, the second air duct is connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com