A kind of preparation method of metal/ceramic composite porous material

A technology of porous material and ceramic composite, applied in the field of metal matrix composite material preparation, can solve the problem of large difference in process route, achieve the effect of low cost, good electromagnetic shielding performance, and ensure process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

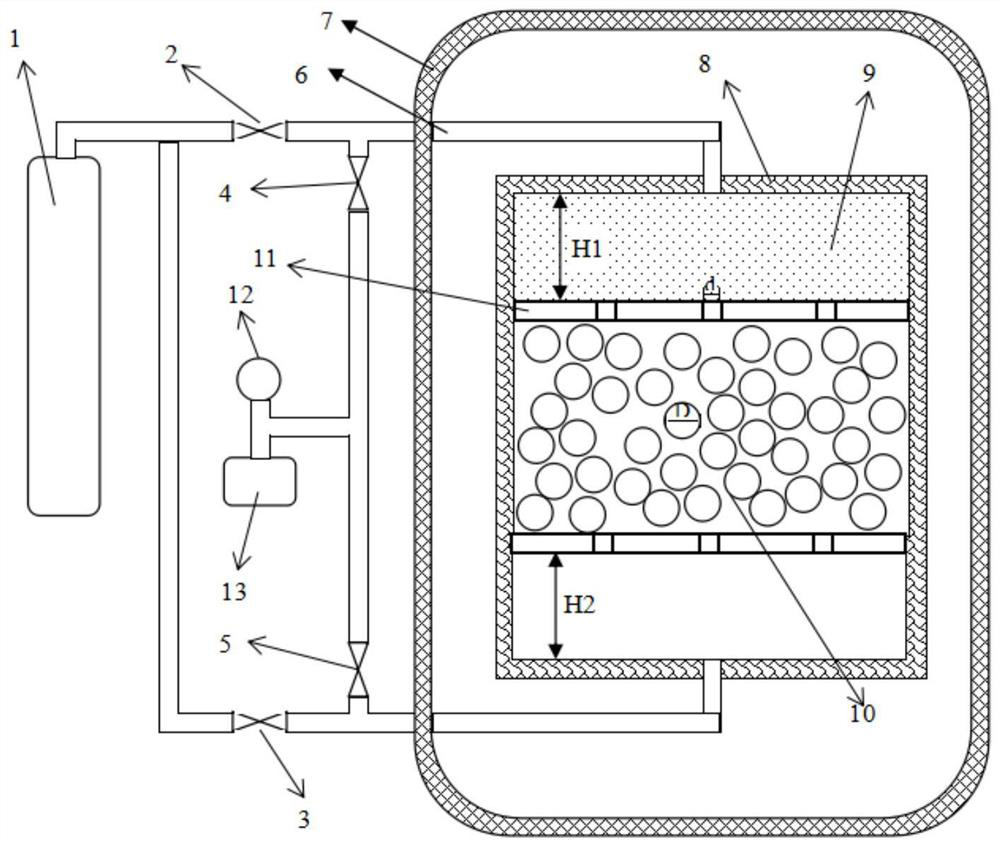

[0036] A method for preparing a metal / ceramic composite porous material, comprising the following steps:

[0037] (1) the first perforated plate, Al 2 o 3 The hollow ball, the second perforated plate, and the LZ91 magnesium-lithium alloy substrate are put into the package in this order, and the first perforated plate, the second perforated plate and the package wall are fixed by argon arc welding, and the package is fixed by argon arc welding. The cover is sealed well, wherein the apertures on the first perforated plate and the second perforated plate are smaller than the diameter of the hollow sphere, and the apertures on the first perforated plate and the second perforated plate are 3.5mm, Al 2 o 3 The diameter of the hollow ball is 4mm. The first perforated plate and the second perforated plate divide the space in the sheath into three areas. The height H1 of the uppermost area is equal to the height H2 of the lowermost area. airway and second airway;

[0038] (2) The s...

Embodiment 2

[0050] A method for preparing a metal / ceramic composite porous material, comprising the following steps:

[0051] (1) Put the first perforated plate, SiC hollow sphere, second perforated plate, and aluminum alloy matrix into the package according to this order. After adding the aluminum alloy matrix, use argon arc welding to weld the first perforated plate and the second perforated plate It is fixed with the sheath wall, and the sheath is sealed by argon arc welding, wherein the apertures on the first perforated plate and the second perforated plate are smaller than the diameter of the hollow sphere, and the apertures on the first perforated plate and the second perforated plate are 1.5mm, the diameter of the SiC hollow ball is 2mm, the first perforated plate and the second perforated plate divide the space inside the sheath into three areas, the height H1 of the uppermost layer is equal to the height H2 of the lowermost area, and the outer part of the sheath connected with a ...

Embodiment 3

[0064] A method for preparing a metal / ceramic composite porous material, comprising the following steps:

[0065] (1) The first perforated plate, the AlN hollow sphere, the second perforated plate, and the aluminum-lithium alloy substrate are packed into the package according to this order, wherein the apertures on the first perforated plate and the second perforated plate are smaller than the diameter of the hollow sphere, The hole diameter of the first perforated plate and the second perforated plate is 4.5 mm, and the diameter of the AlN hollow sphere is 5 mm. The first perforated plate and the second perforated plate divide the space in the envelope into three areas, and the height of the uppermost zone is H1 It is equal to the height H2 of the lowest layer area, and the outer part of the sheath is connected with a first air guide tube and a second air guide tube;

[0066] (2) The sealed bag is connected to the loading gas source and the vacuum unit through the first valve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com