A device for slicing silicon wafers

A technology of silicon wafers and driving devices, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of discontinuity and low slicing efficiency, and achieve the effect of small damage and high slicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

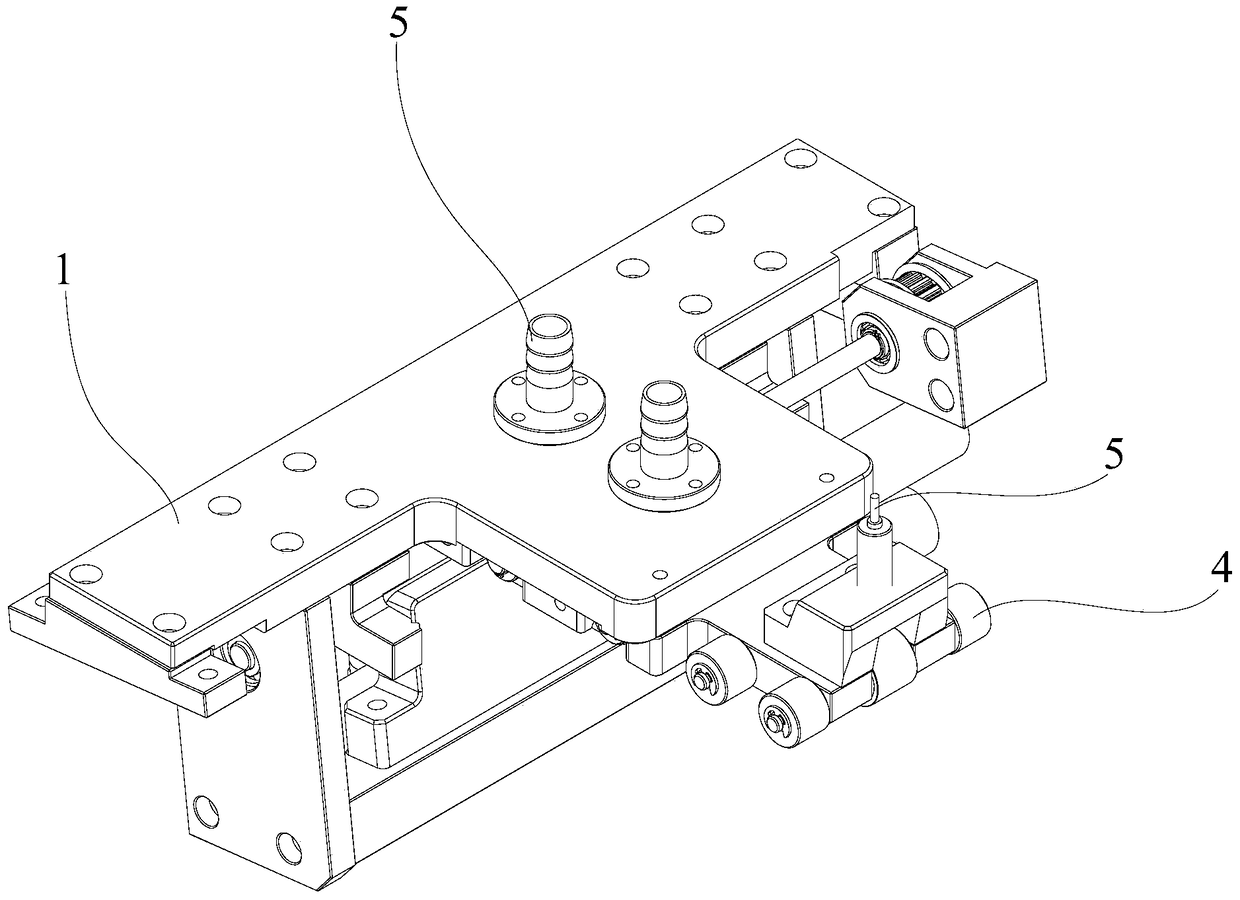

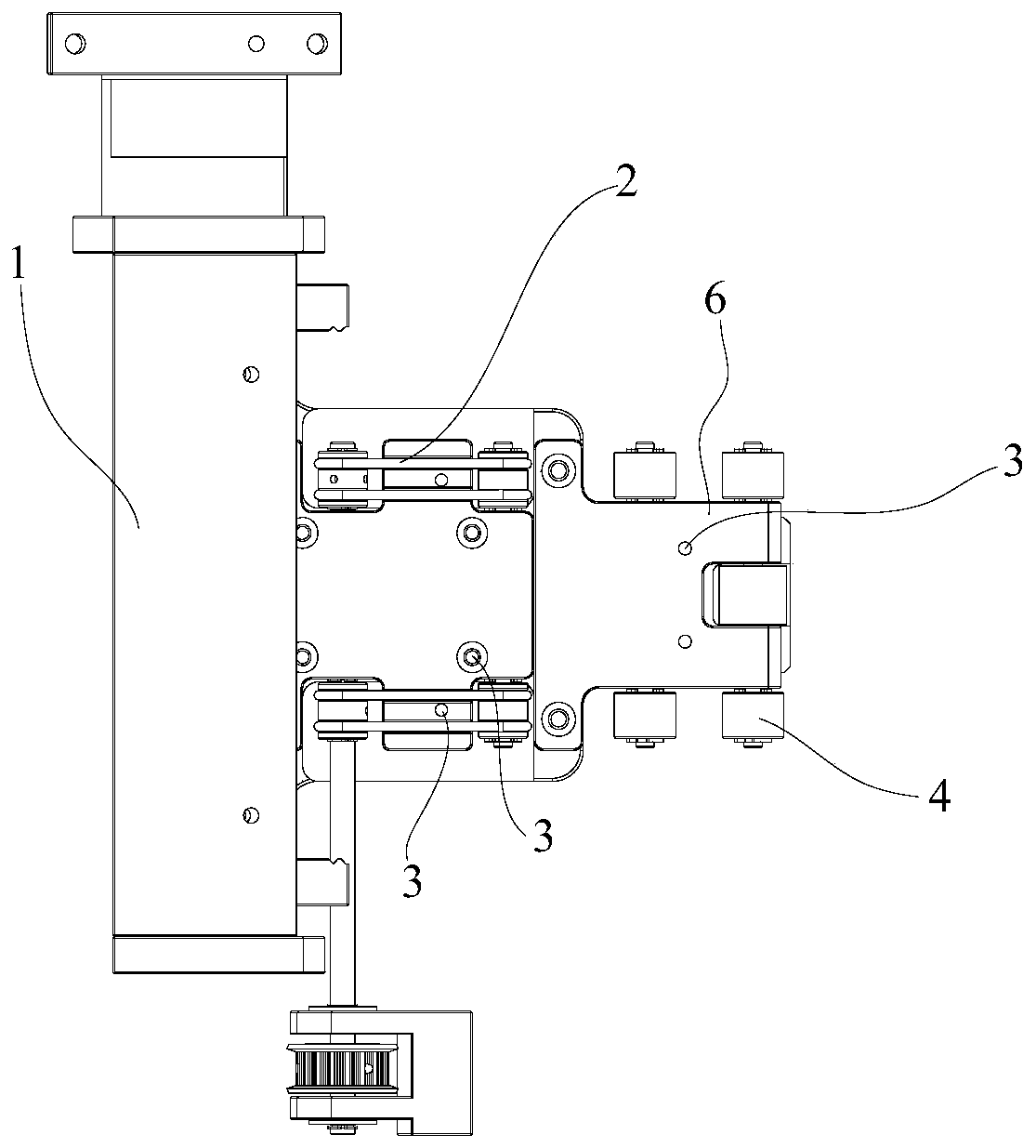

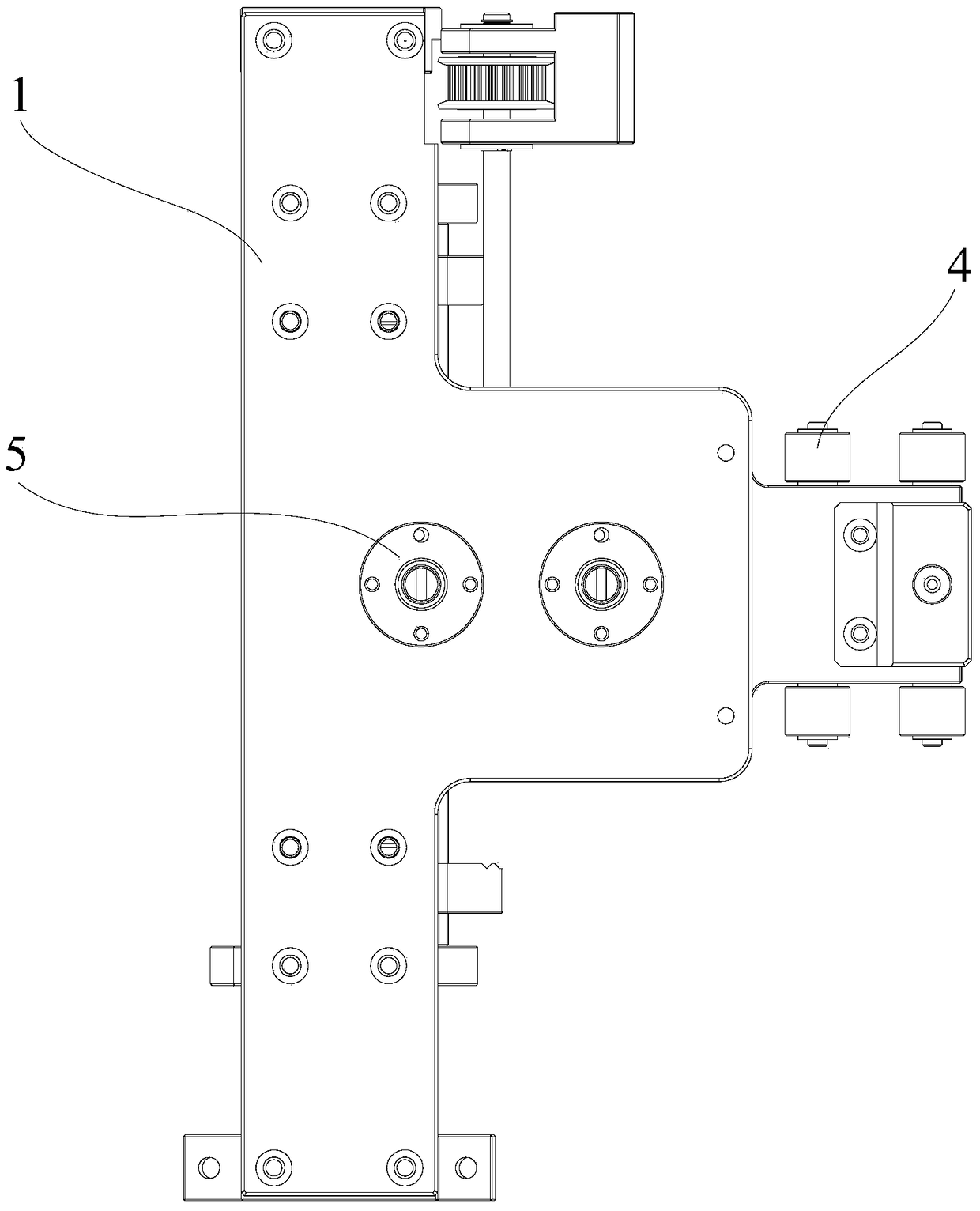

[0026] Embodiment: A kind of silicon wafer slicing device

[0027] See attached Figure 1~6 As shown, the silicon wafer slicing device includes a slicing mechanism 10 and a feed chute.

[0028] Slicing mechanism, including silicon chip slicing mechanism body 1, this silicon chip slicing mechanism body 1 is provided with two parallel and spaced apart slicing conveyer belts 2 downwards, and described silicon chip slicing mechanism body 1 faces the described The fragmented conveyor belt 2 is provided with an air hole 3, and the air hole 3 communicates with an air extraction device (not shown in the figure) through a pipeline;

[0029] A preferred embodiment is: the piece conveyor belt 2 is a synchronous belt.

[0030] A preferred embodiment is: the synchronous belt is sheathed on the driving wheel and the driven wheel, and the driving wheel is in transmission connection with the driving device.

[0031] A preferred embodiment is: the driving device is a driving motor, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com