Silicon wafer separation mechanism

A silicon wafer, body technology, applied in conveyor objects, sustainable manufacturing/processing, electrical components, etc., can solve the problems of low slicing efficiency and discontinuity, and achieve the effect of high slicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

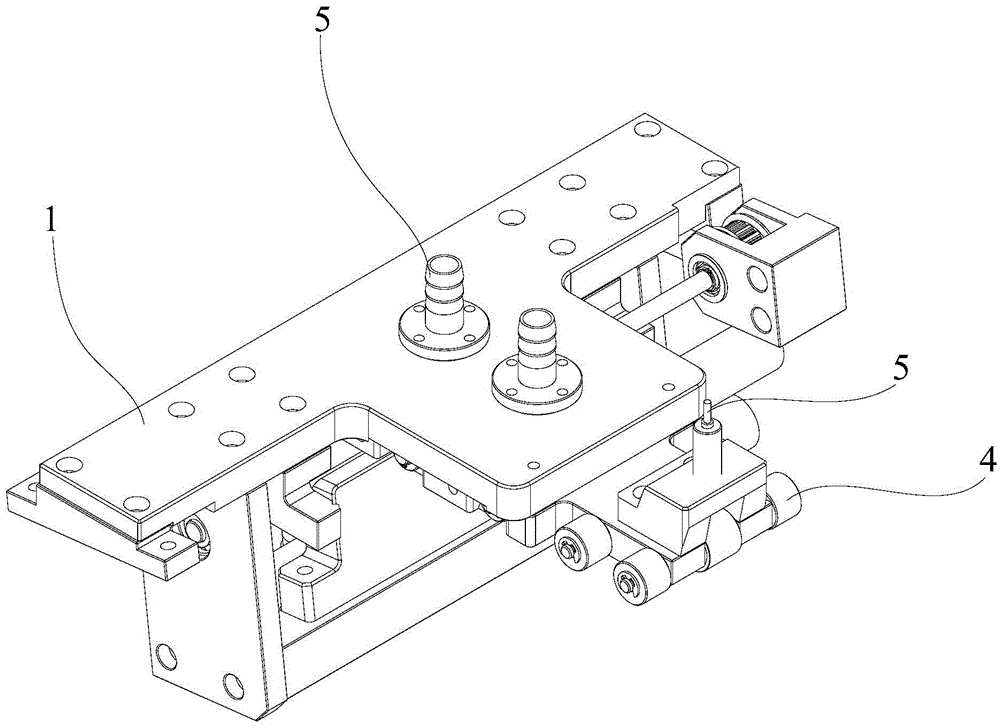

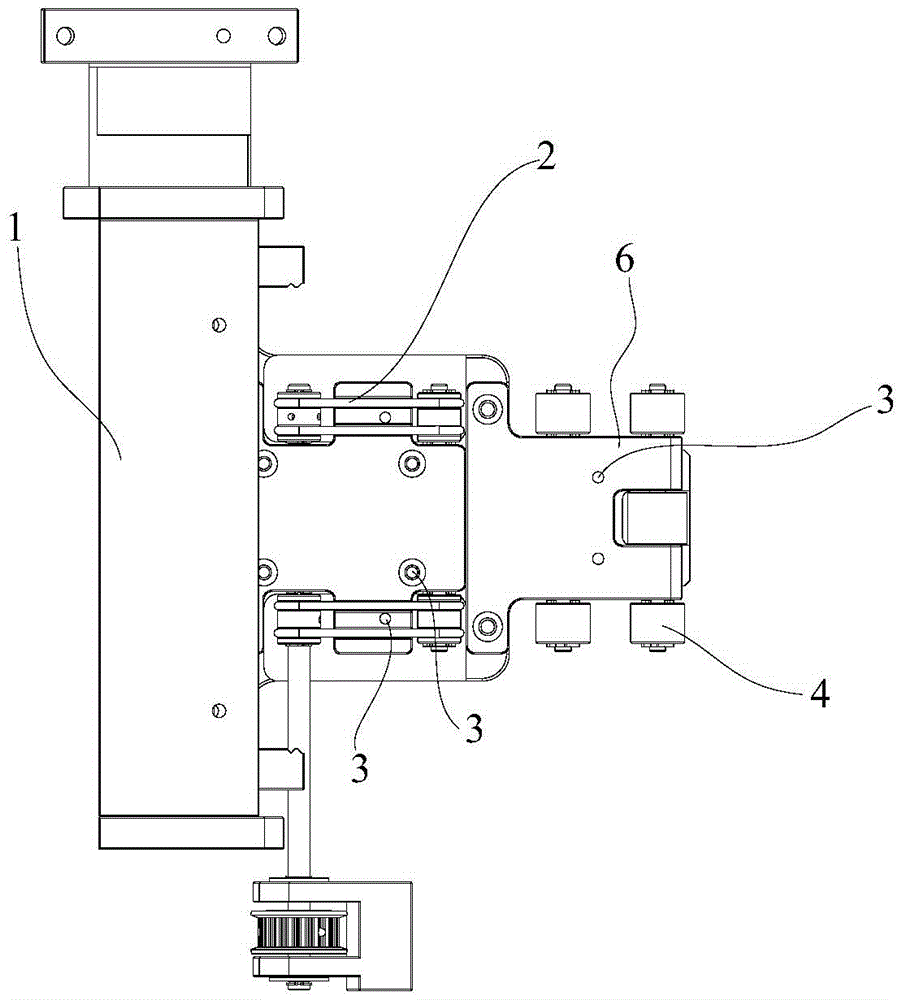

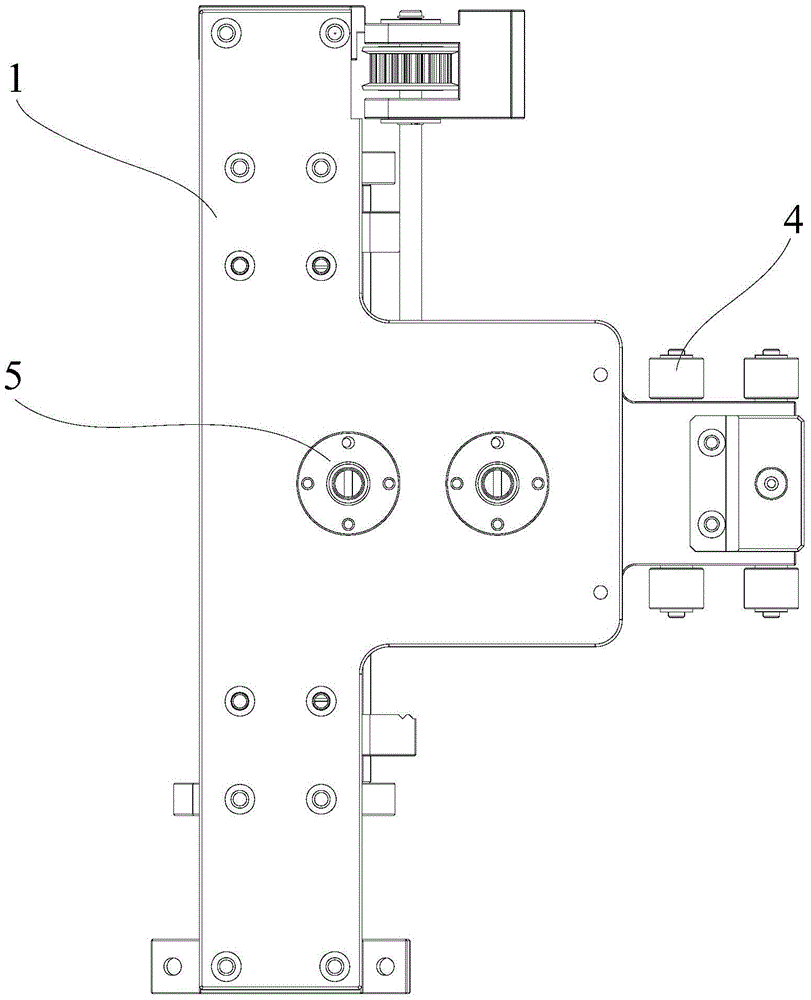

[0023] Embodiment: A kind of silicon wafer slicing mechanism

[0024] See attached Figure 1~5 As shown, a silicon chip slicing mechanism includes a silicon chip slicing mechanism body 1, and the silicon chip slicing mechanism body 1 is provided with two parallel and spaced conveyor belts 2 downwards. The silicon chip slicing mechanism The main body 1 is provided with an air hole 3 facing the conveyor belt 2 , and the air hole 3 communicates with an air extraction device (not shown in the figure) through a pipeline; the front end of the conveyor belt 2 in the conveying direction is provided with a roller 4 .

[0025] A preferred embodiment is: the conveyor belt 2 is a synchronous belt.

[0026] A preferred embodiment is: the synchronous belt is sheathed on the driving wheel and the driven wheel, and the driving wheel is in transmission connection with the driving device.

[0027] A preferred embodiment is: the driving device is a driving motor, and the output shaft of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com